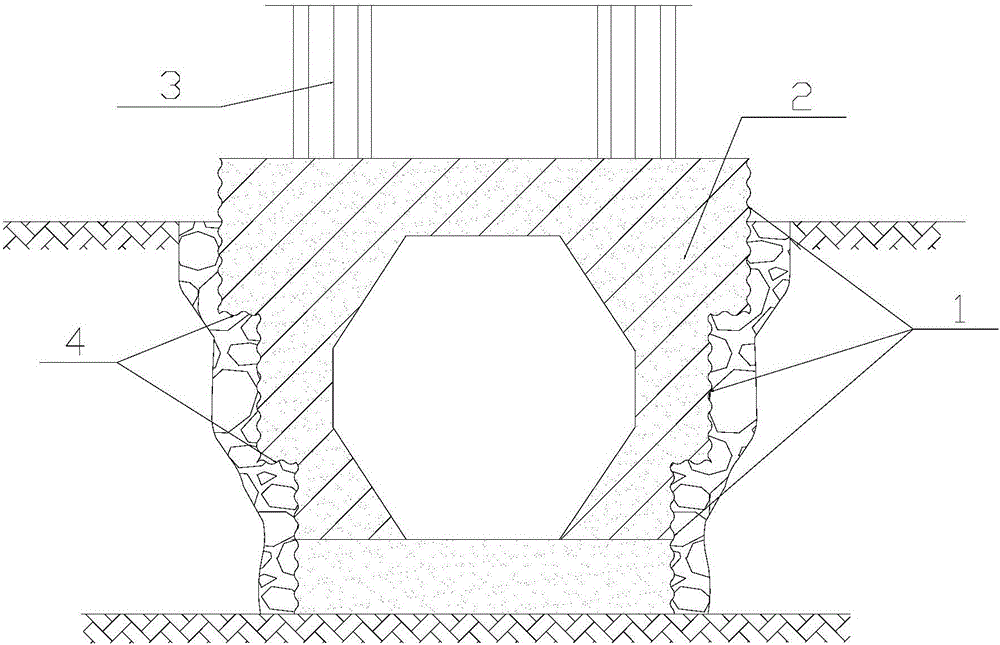

Corrugated steel cofferdam hollow digging pile and manufacturing technique thereof

A technology of corrugated steel and hollow piles, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as difficulty in ensuring the stability of hole walls and construction safety, high cost of forming holes and piles, and difficulties in engineering construction, so as to achieve saving The effect of labor and raw materials, large pile diameter, and simplified construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0030] The excavated hollow pile of a bridge,

[0031] External load: P=40547(kN);

[0032] Weight: G 桩 =31490(kN);

[0033] The sum of the vertical load (dead load) at the bottom of the pile:

[0034] ΣG 0 =P+G 桩 =40547+31490=72037 (kN).

[0035] 1. Calculate the pile bottom stress according to the soil diffusion angle:

[0036] 1. Diffusion angle of soil slope:

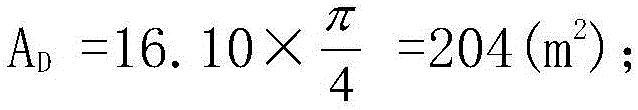

[0037] The diameter of the bottom surface of the diffusion pyramid with a pile length of 16m is as follows:

[0038] D=d+h·tanθ=11+(16×0.0655)×2;

[0039] =11+(1.05×2=2.10)=16.10(m);

[0040] A D = 16.10 × π 4 = 204 ( m 2 ) ;

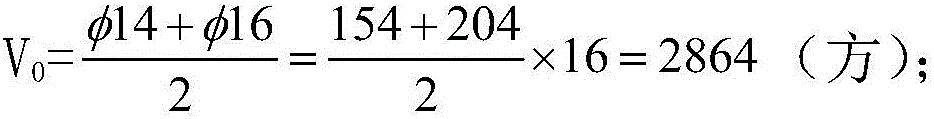

[0041] 2. External volume:

[0042] ΣV g =1957 (square);

[0043] 3. Cone volume in pile length h=16m:

[0044]

[0045] Volume of soil: V 土 =V 0 -V g =2864...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com