Perforated pipe method super-deep, fast, and super-large diameter high pressure chemical churning pile construction method

A technology of high-pressure rotary grouting piles and super large diameters, which is applied in the direction of drill pipes, casings, sheet pile walls, etc., can solve the problems of low pile-forming efficiency, large soil-squeezing effect, and small pile-forming diameters, so as to save engineering cost, The effect of increasing the pile forming efficiency and enlarging the pile diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

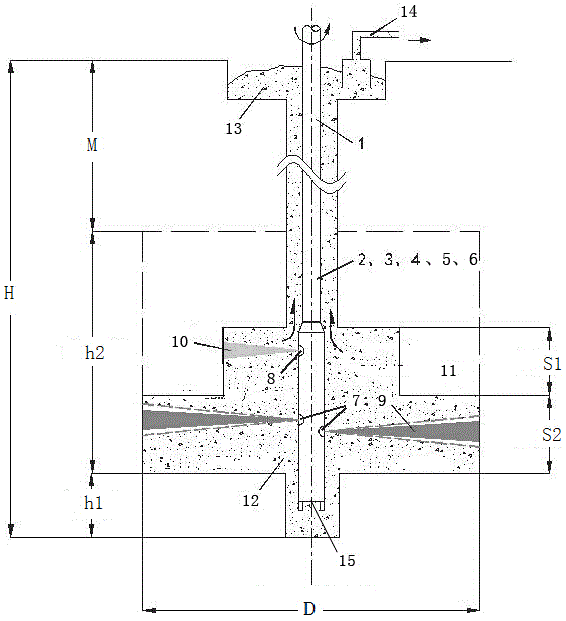

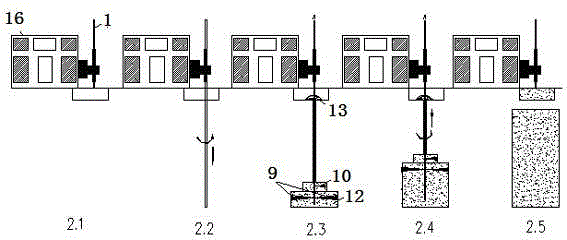

[0019] The invention provides an ultra-deep, fast and ultra-large diameter high-pressure rotary jetting pile construction method (D-RJP construction method) by a porous tube method. Layout and optimization, in the process of lifting the drill pipe to form a pile, the upper end high-pressure water flow and compressed air jet and the lower end ultra-high pressure curing liquid jet and compressed air jet are used for joint relay cutting, so that the diameter of the high-pressure rotary jet pile reaches 3.0 ~3.5m, the piling efficiency is greatly improved. In conjunction with the accompanying drawings, the specific description is as follows:

[0020] like figure 1 As shown in the figure: H is the drilling depth, D is the diameter of the designed pile, h1 is the over-drilling section, h2 is the pile-forming section, S1 is the advance cutting section, S2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com