Quick drainage tubular pile

A technology for drainage pipe piles and drainage pipes, which is applied to sheet pile walls, buildings, infrastructure projects, etc., can solve the problems of complex jumping pile construction technology, high construction costs, and complicated construction operations, so as to reduce the effect of soil squeeze and ensure The effect of normal use and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Below in conjunction with accompanying drawing, the present invention is described in further detail;

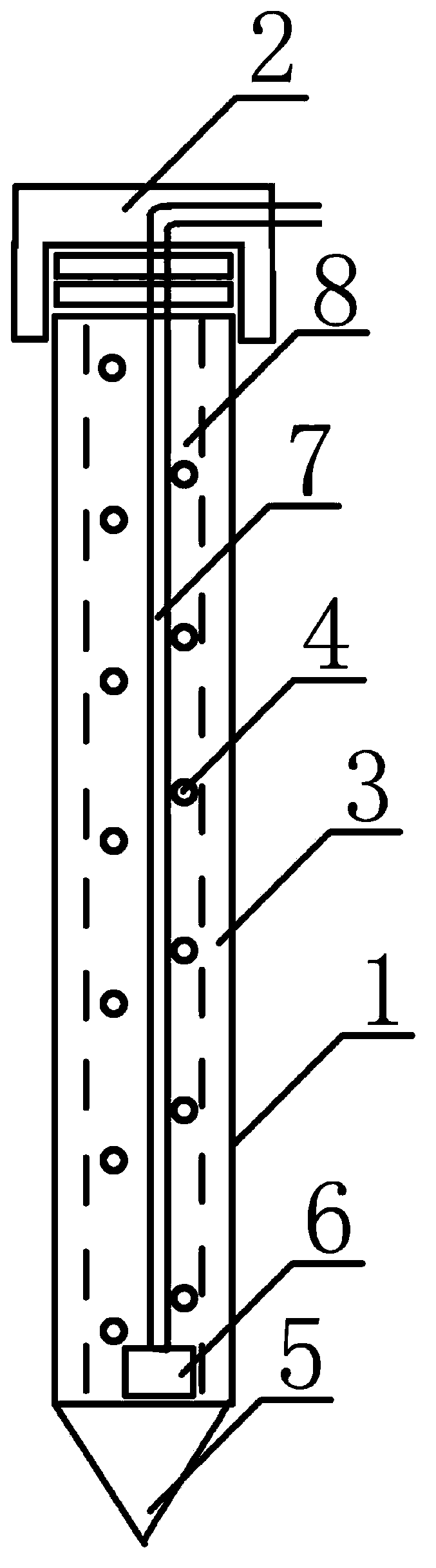

[0008] like figure 1 As shown, a certain number of small holes 4 penetrating through the pipe wall 3 are opened on the pipe wall 3 of the pipe pile main body 1, a pipe pile driving part 2 is arranged on the upper part of the pipe pile main body 1, and a tapered pile is arranged on the lower part of the pipe pile main body 1. Boot 5, in the pile hole 8 of pipe pile main body 1, be placed with water pump 6, a drainage pipe 7 is installed on the water pump 6, and water pipe 7 other end passes pipe pile and replaces part 2, stretches to the outer end.

[0009] Before piling, first pass one end of the drainage pipe 7 through the pipe pile replacement part 2, put the water pump 6 at the other end of the drainage pipe 7 into the pile hole 8 of the pipe pile main body 1, and place the pipe pile replacement part 2 On the pipe pile main body 1, the piling can be started, and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com