Cast-in-place large-diameter pipe pile casing pipe and construction method

A large-diameter pipe and pile casing technology is applied in the field of cast-in-place large-diameter pipe pile casing and construction, which can solve the problems of easy cracking of the pile head and easy occurrence of wall collapse, so as to reduce the soil extrusion effect and reduce the pipe pile. The effect of improving the bearing capacity and overall stiffness and avoiding pile breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] Glossary:

[0030] Three connections and one leveling refer to the preconditions for the start of capital construction projects, specifically: water connection, electricity connection, road connection and site leveling. Shuitong: specifically refers to water supply; Electricity: refers to the construction conditions when the construction electricity is connected to the construction site; Road: refers to the off-site roads that have been paved to the entrances around the construction site to meet the conditions for vehicles to enter and exit; Leveling of the site: refers to the proposed building Objects and conditions The site is basically flat, without mechanical leveling, and can enter the construction state with simple manual leveling, referred to as three links and one leveling.

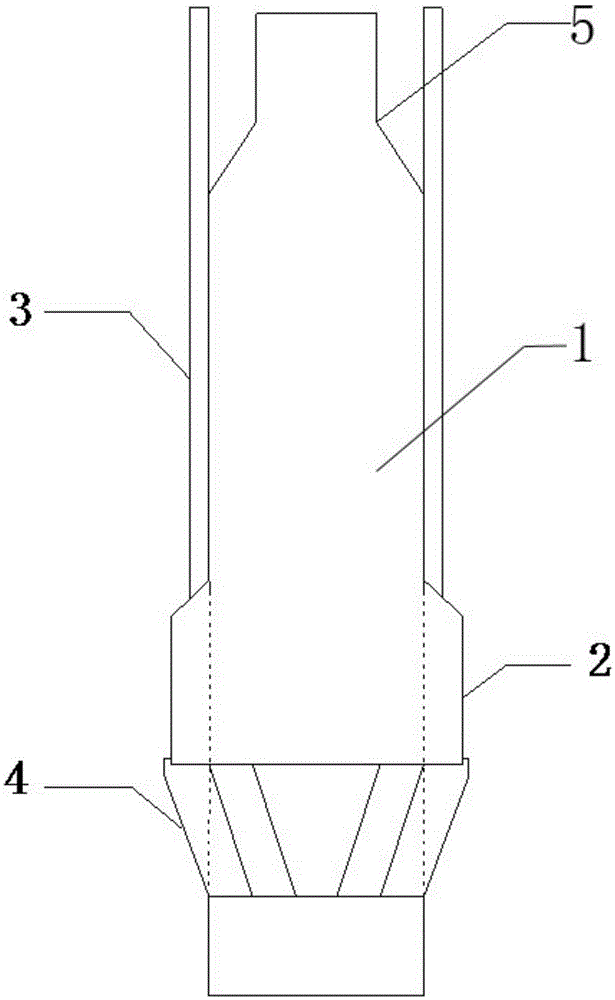

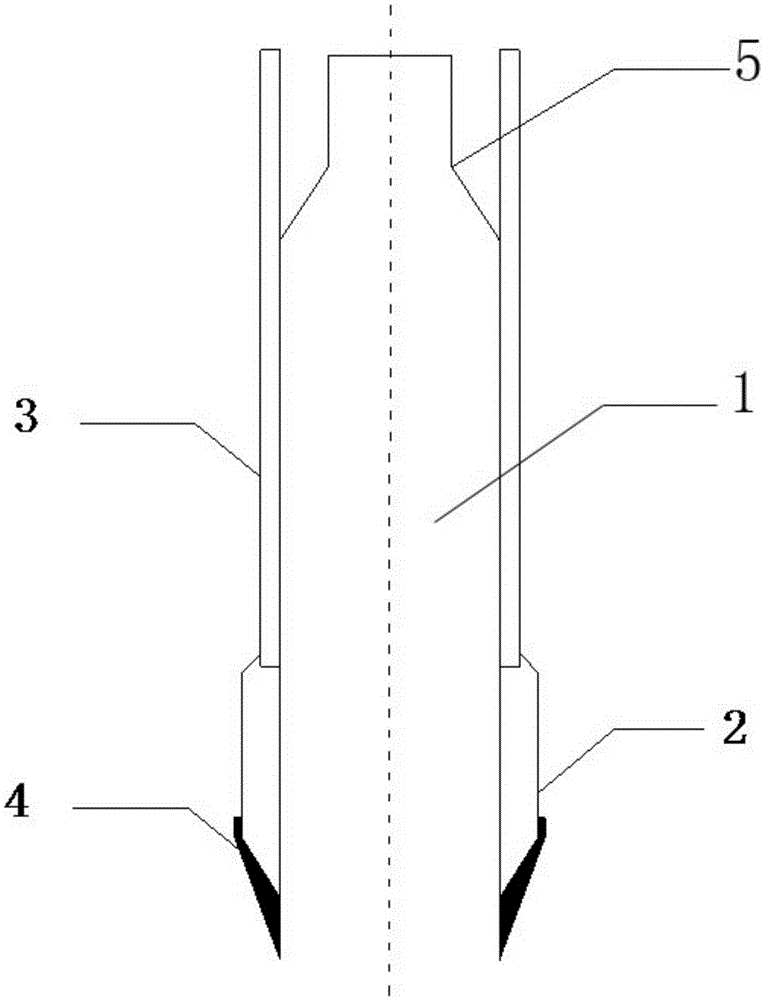

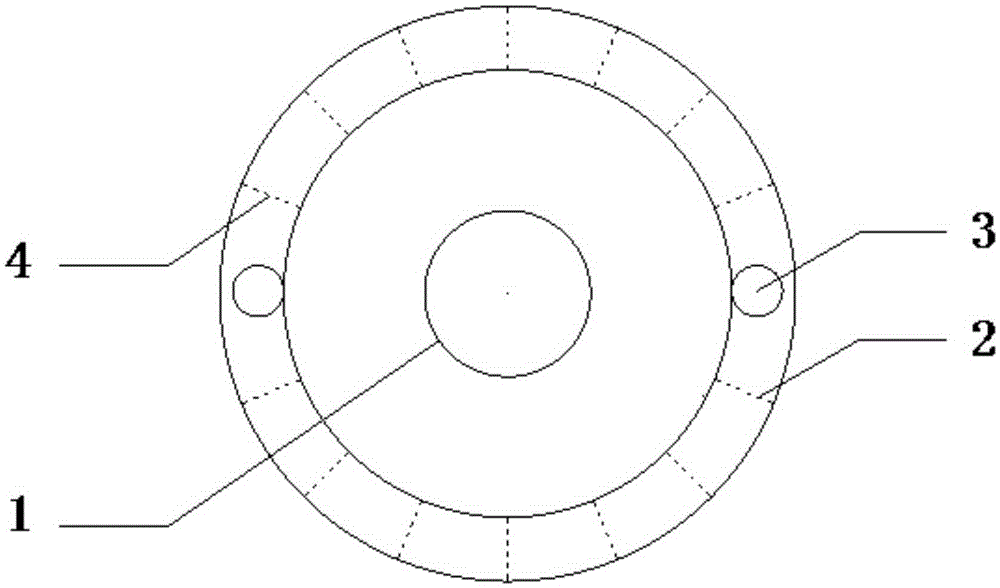

[0031] Such as Figure 1-3 As shown, a cast-in-place large-diameter pipe pile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com