Foundation pit supporting construction technology combining equal-thickness cement-soil diaphragm wall and tubular piles

A construction technology and foundation pit support technology, which is applied in basic structure engineering, sheet pile walls, excavation, etc., can solve the problems of large site occupation, high construction cost, and high cost, and achieves space saving, high pile strength, The effect of cost economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

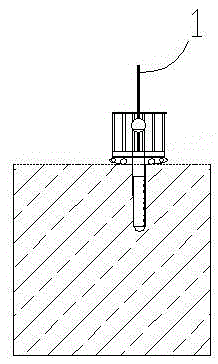

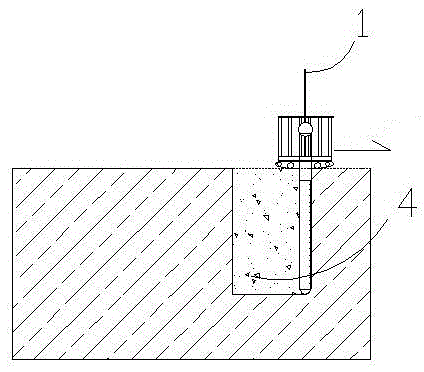

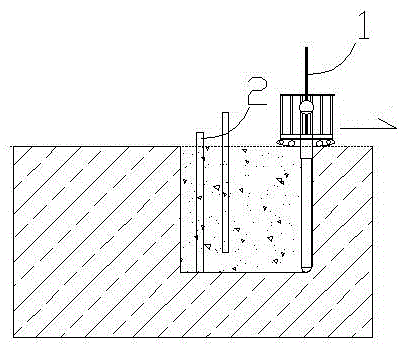

[0026] Please refer to Figure 1 to Figure 5 , the embodiment of the present invention combines the foundation pit support construction technology of the continuous wall and the pipe pile under the cement soil with equal thickness. Form a whole that surrounds the foundation pit, where the specific construction process of each support structure is:

[0027] Step a: After the pile position is measured and placed, the continuous wall pile machine 1 is installed and moved to the position according to the design depth, and then cut downwards and sprayed, and sprayed and stirred at the same time until the construction reaches the predetermined depth;

[0028] Step b: After cutting down to a predetermined depth, the continuous wall pile machine 1 starts to cut the soil layer forward along the sideline of the foundation pit, and at the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com