Hitching hidden-frame glass curtain wall

A hidden frame glass curtain wall, glass technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of low installation efficiency, opening fan corners, frame fan scraping, etc., to improve flatness, prevent opening fan corners , The effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

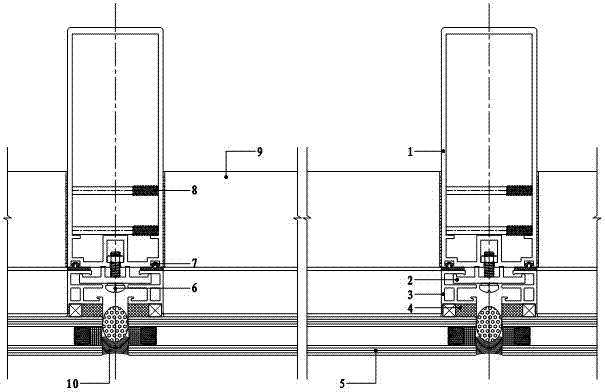

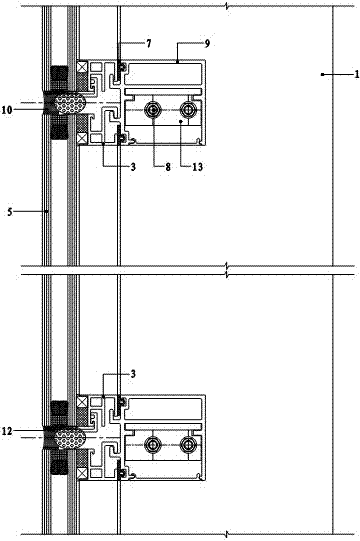

[0024] figure 1 , figure 2 Respectively represent the horizontal and vertical section structures of the fixed fan of the hook-type hidden frame glass curtain wall, mainly showing the cross-sectional structure of the fixed fan. As shown in the figure: the left and right vertical sides of the main frame 1 and the sub-frame 3 are connected by the pressure plate 2, and the upper and lower horizontal sides are connected by hooks. There is a rubber strip 7 between the main frame 1 and the sub-frame 3; The code 13 is fixed on the main frame 1; the sub-frame 3 is hung on the crossbeam 9, the lower end is provided with a support bar 12, and the lower end of the other side of the sub-frame 3 is provided with a small support bar 11; the glass 5 is bonded to the On the sub-frame 3, silicone weather-resistant glue 10 is injected at the seams of the glass 5.

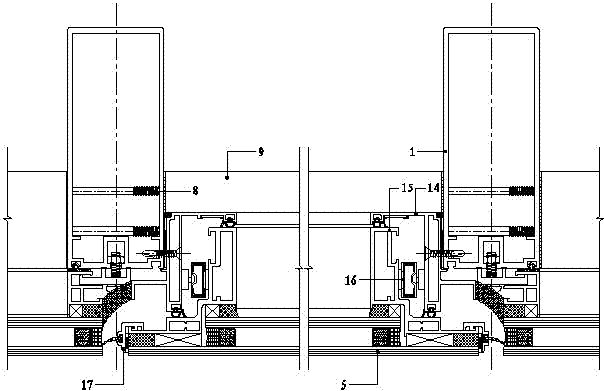

[0025] image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com