Liquid crystal glass dust-free protective paper

A technology of liquid crystal glass and protective paper, which is applied in the field of papermaking, can solve problems such as scattering, and achieve the effects of reducing water consumption, good heat resistance, and protecting the glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

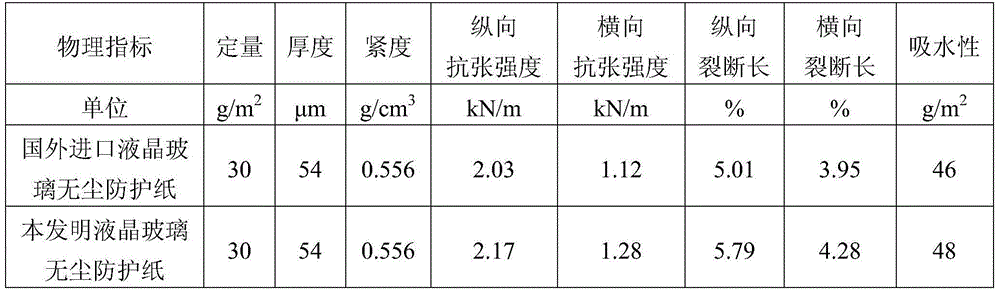

Embodiment 1

[0009] The dust-free protective paper for liquid crystal glass of this embodiment adopts 100% bleached chemical coniferous wood pulp with a freeness of 620c.s.f. as a raw material, which is polished into a single fiber and then sent to each cage of the forming head through a feeding fan, The negative pressure formed by the air supply system and the exhaust system is used to make the fibers fall evenly from the cage and settle disorderly on the forming wire to form a paper web. After upper glue spraying, drying, lower glue spraying and further drying, it is placed in room temperature environment and finally calendered to obtain the dust-free protective paper for liquid crystal glass. In the production process, the temperature that the wet strength agent can resist is 183°C, the drying temperature and re-drying temperature are both 150°C, and the total amount of glue added to the latex is 1g / m 2 .

[0010] Add dry strength agent 0.1kg / t, softener 1kg / t, antistatic agent 5kg / t, ...

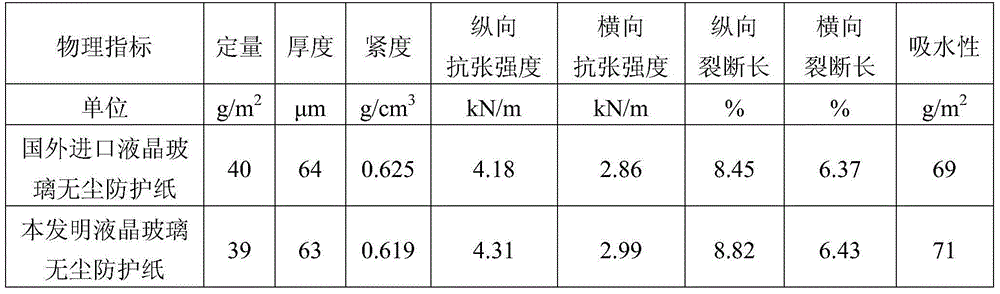

Embodiment 2

[0016] The dust-free protective paper for liquid crystal glass of this embodiment adopts 100% bleached chemical coniferous wood pulp with a freeness of 610c.s.f. as a raw material, which is polished into a single fiber and then sent to each cage of the forming head through a feeding fan, The negative pressure formed by the air supply system and the exhaust system is used to make the fibers fall evenly from the cage and settle disorderly on the forming wire to form a paper web. After upper glue spraying, drying, lower glue spraying and further drying, it is placed in room temperature environment and finally calendered to obtain the dust-free protective paper for liquid crystal glass. During the production process, the temperature that the wet strength agent can resist is 201°C, the drying temperature and re-drying temperature are both 160°C, and the total gluing amount of the latex is 15g / m 2 .

[0017] Add dry strength agent 0.5kg / t, softener 5kg / t, antistatic agent 3kg / t, an...

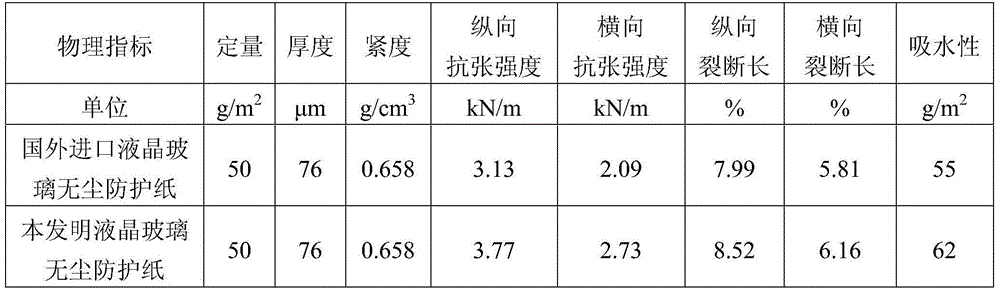

Embodiment 3

[0023] The dust-free protective paper for liquid crystal glass of this embodiment adopts 100% bleached chemical coniferous wood pulp with a freeness of 620c.s.f. as a raw material, which is polished into a single fiber and then sent to each cage of the forming head through a feeding fan, The negative pressure formed by the air supply system and the exhaust system is used to make the fibers fall evenly from the cage and settle disorderly on the forming wire to form a paper web. After upper glue spraying, drying, lower glue spraying and further drying, it is placed in room temperature environment and finally calendered to obtain the dust-free protective paper for liquid crystal glass. In the production process, the temperature that the wet strength agent can resist is 203°C, the drying temperature is 153°C, and the re-drying temperature is 152°C, and the total glue amount of latex is 10g / m 2 .

[0024] Add dry strength agent 1kg / t, softener 10kg / t, antistatic agent 3kg / t, antic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com