Rapid cap cutting device and method for semiconductor laser tube cap

A laser and semiconductor technology, applied in positioning devices, clamping, supports, etc., can solve problems such as difficult control of strength, failure of lasers, laborious cutting, etc., to achieve the effect of improving cutting efficiency, increasing contact area, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

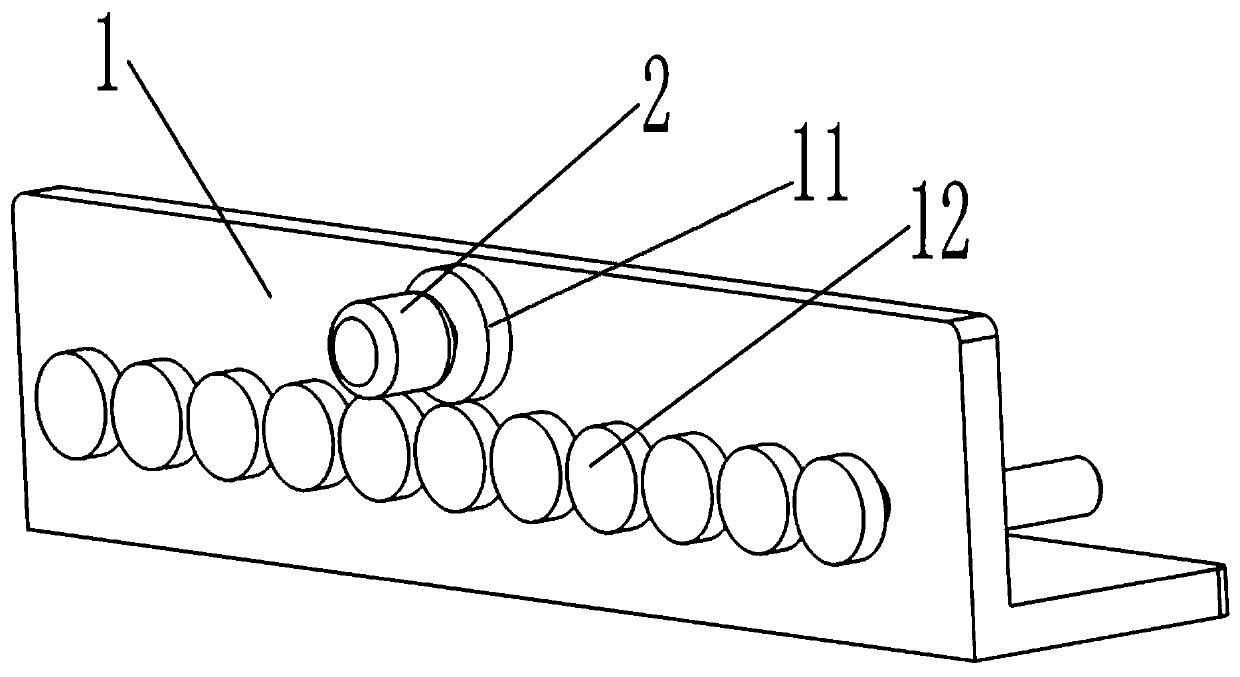

[0042] The drive mechanism of the fixed seat can be the following structure, which includes the motor 2 installed on the base 1, the gear I 11 installed on the output shaft of the motor 2, and the gear II 12 installed on the fixed seat 9, and every two adjacent gears The IIs 12 mesh with each other, and the gear I 11 and a gear II 12 mesh with each other. When the motor 2 rotates, it drives the gear I 11 to rotate, and when the gear I 11 rotates, it drives the gear II 12 meshed with it to rotate. Since each gear II 12 is meshed with each other, the purpose of the motor 2 driving each gear II 12 to rotate synchronously is realized. The rotation of the laser 26 is achieved.

Embodiment 2

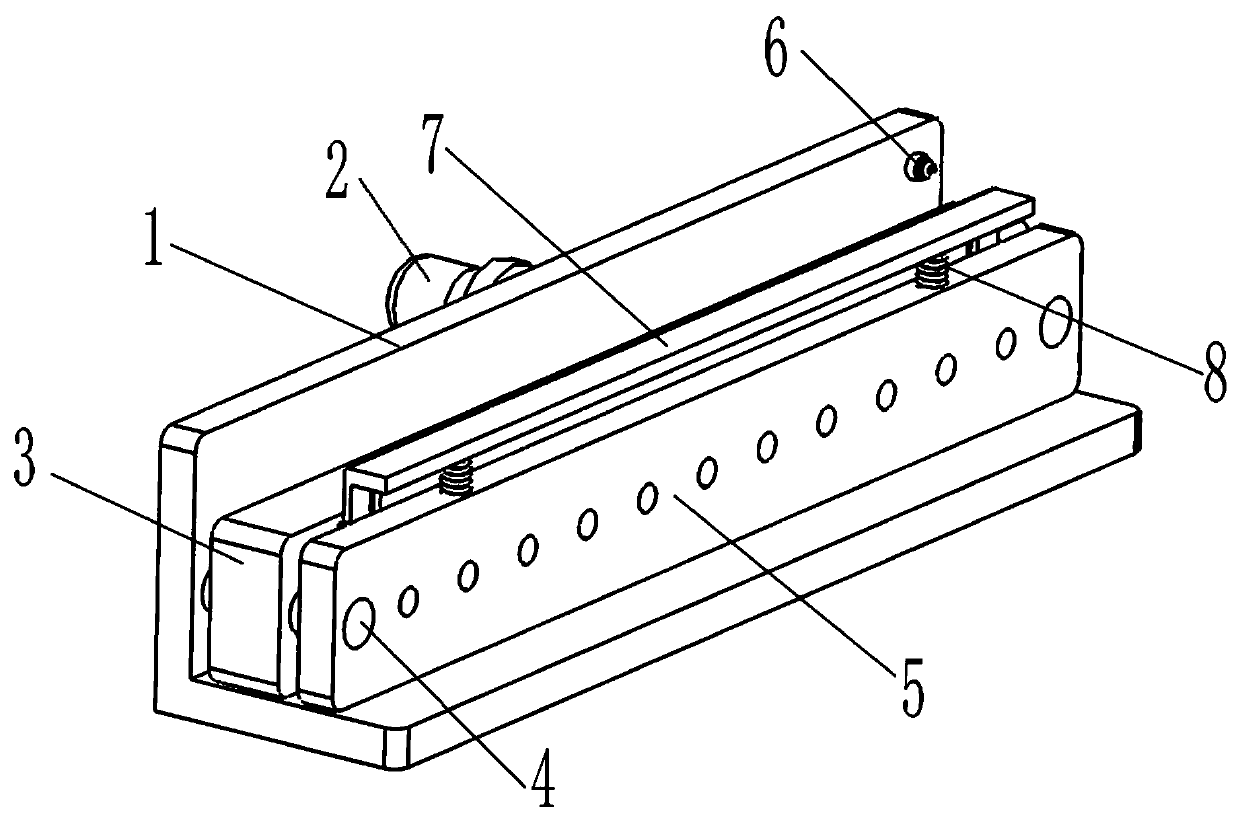

[0044] It also includes a tube cap fixing plate 5, which is arranged at the front end of the laser fixing plate 3, and guide holes II 18 matching with the guide rod 4 are respectively provided at the left and right ends of the tube cap, and the laser fixing plate 3 is inserted into the guide rod 4 through the guide hole II 18 On the cap fixing plate 5, N circular holes II 19 matching the caps 29 are provided at intervals along the horizontal direction, and the head ends of the caps 29 are inserted into the corresponding circular holes II 19. Pass the tube cap fixing plate 5 through the guide hole II 18 and insert it on the guide rod 4, then push it toward the direction of the laser fixing plate 3 so that each tube cap 29 is inserted into the round hole II 19 . Since the tube cap 29 is supported and fixed by the round hole II 19, the tube cap 29 is more stable and firm when the cutting knife 7 presses down to cut the tube cap 29, avoiding the one-sided support of the laser 26 by...

Embodiment 3

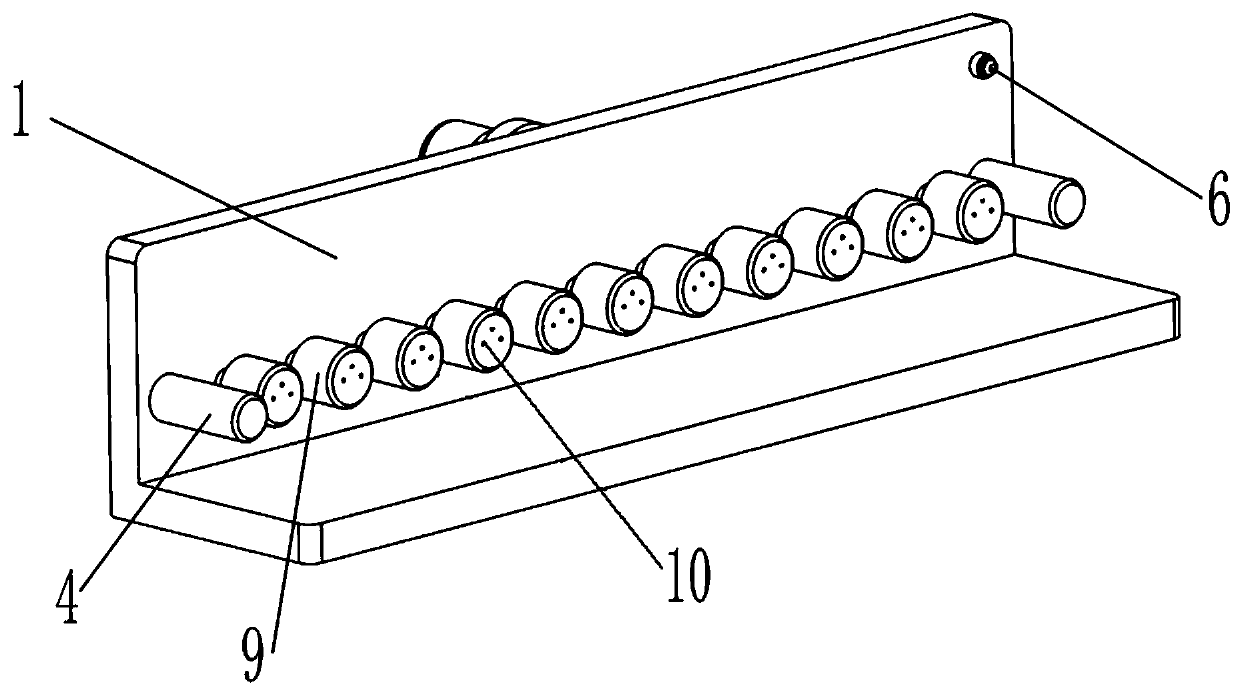

[0046] It also includes a switch 6 installed on the base 1, and the motor 2 is connected to the power supply through the switch 6. The opening and closing of the motor 2 can be conveniently controlled by the switch 6, and the control of the rotation or stop of the fixed seat 9 can be realized conveniently, thereby improving the convenience of operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com