Patents

Literature

82results about How to "There will be no deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

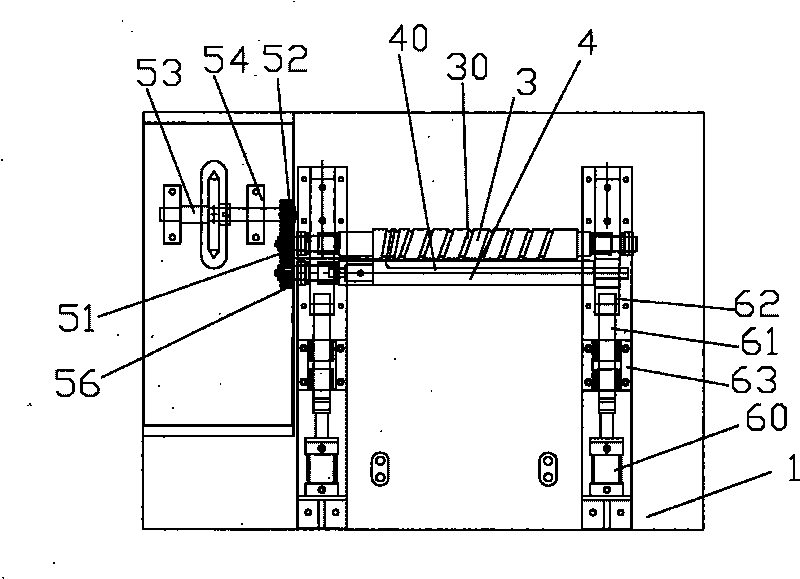

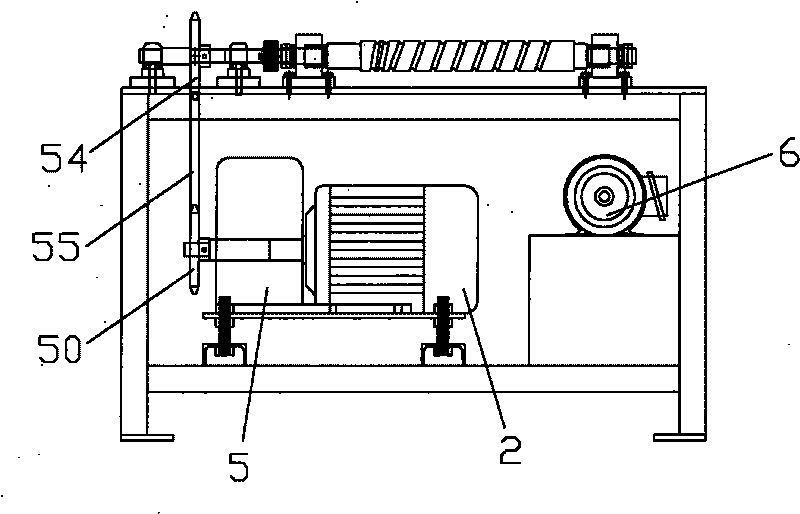

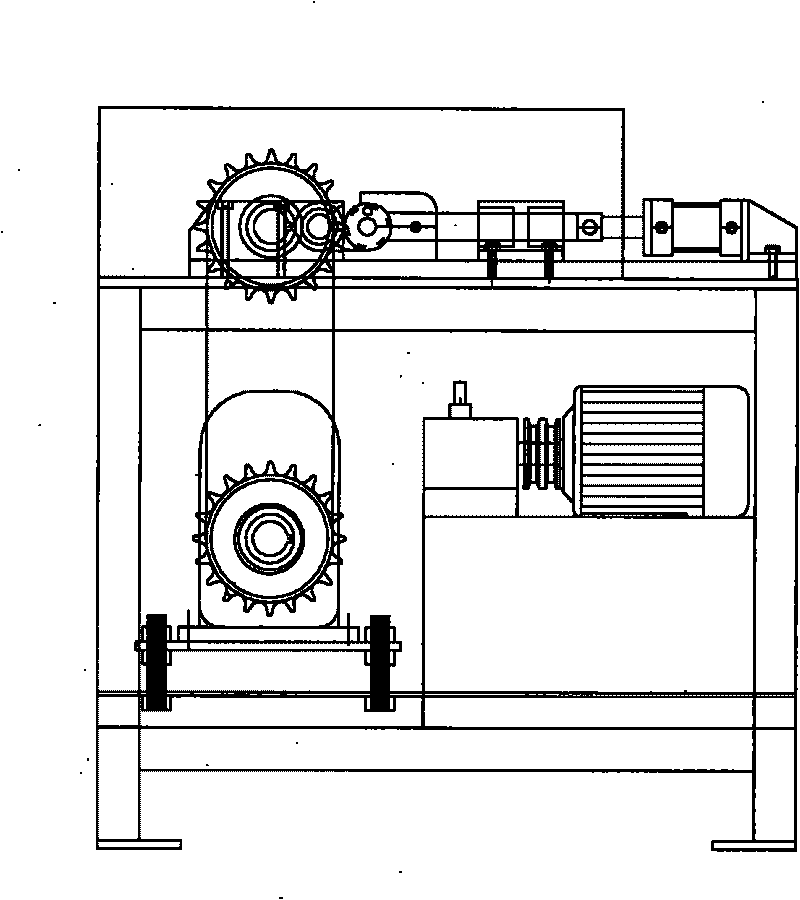

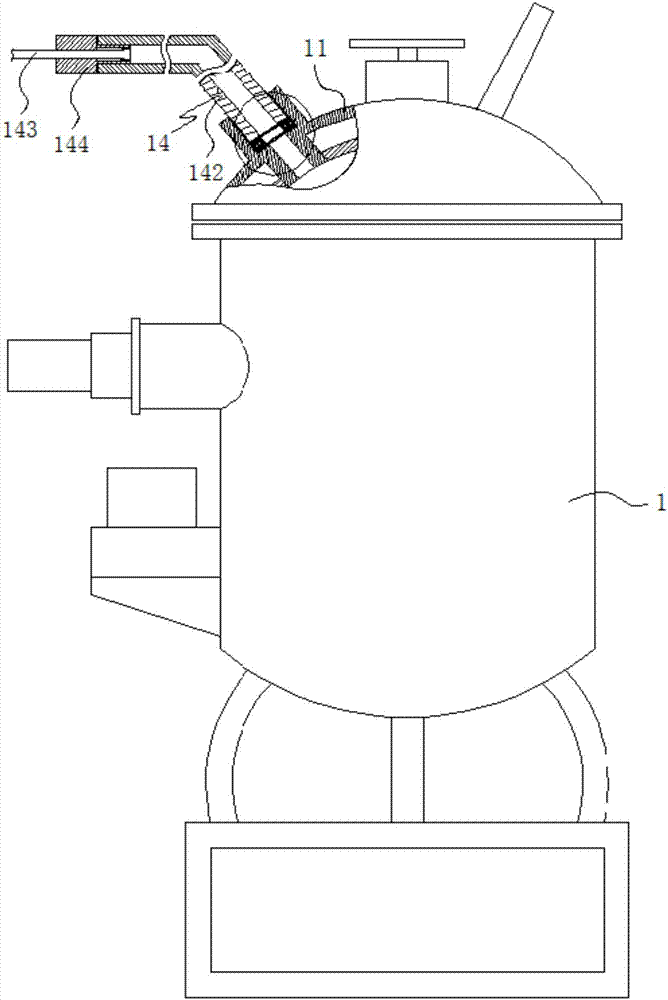

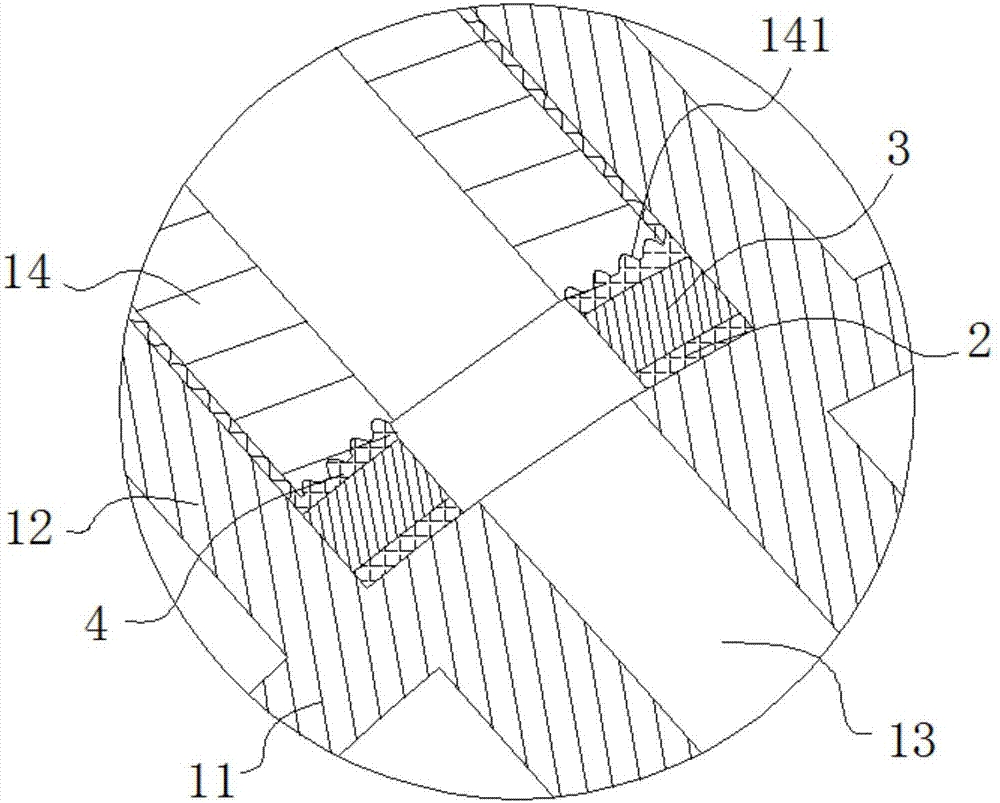

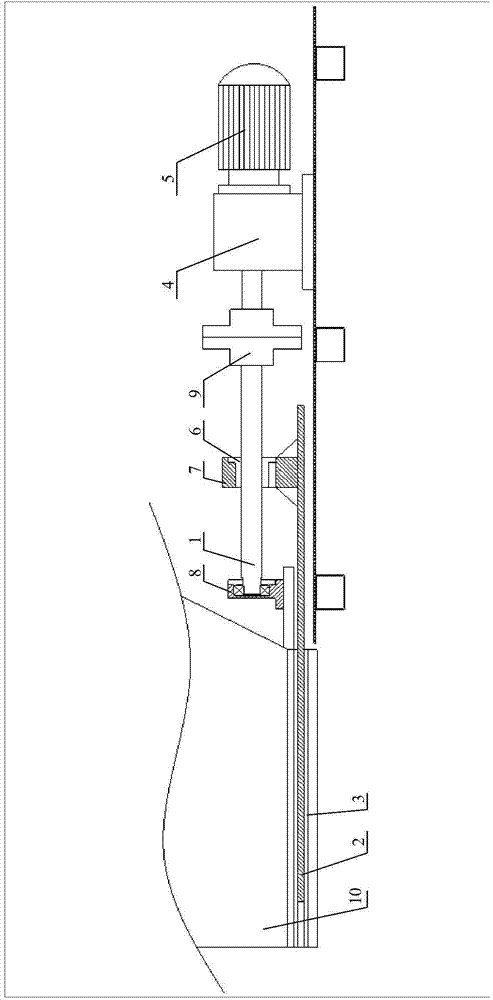

Processing process of screw pipe bending machine

The invention relates to a processing process of a screw pipe bending machine, which is used for bending hollow steel pipes. The processing process comprises the following steps of: (1) filling a real object into a hollow steel pipe, sealing both ends of the steel pipe and bending the steel pipe; (2) receding a counter shaft through a driving and reversing mechanism, mounting one end of the steel pipe in a mounting groove of the counter shaft, aligning a bending part to the end part of the counter shaft, and buckling the other end of the steel pipe into a first tooth of a thread groove; (3) forwards impelling the counter shaft through the driving and reversing mechanism until the counter shaft is engaged with a spindle; (4) starting a motor to drive the spindle to rotate and bending and molding the steel pipe along the thread groove of the spindle; (5) receding the counter shaft, taking out the counter shaft through manpower, taking out a processed and molded product and pouring out the real object in the steel pipe; and (6) mounting the counter shaft on an engine base to renewedly produce a next workpiece. The processing process does not need too much manpower so as to reduce the production cost, improve the efficiency and have stable quality.

Owner:王吉光

Thixotrope for packaging LED (light emitting diode ) chip

ActiveCN105950105AHigh elongation at breakIncrease crosslink densityNon-macromolecular adhesive additivesSemiconductor devicesSilicone resinTransmittance

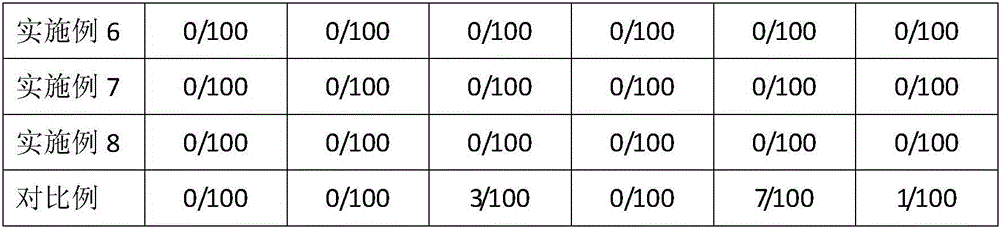

The invention discloses thixotrope for packaging an LED (light emitting diode ) chip. The thixotrope is prepared from a component A and a component B, wherein the component A is prepared from 60 parts by weight of vinyl-terminated silicone oil, 2-7 parts by weight of polyvinyl silicone oil, 3-8 parts by weight of a thixotropic agent and 0.1-0.3 part by weight of a catalyst, and is obtained by evenly mixing the raw materials; the component B is prepared from 0-30 parts by weight of the vinyl-terminated silicone oil, 20-50 parts by weight of MQ-type vinyl silicone resin, 10-20 parts by weight of a chain extender, 2-5 parts by weight of hydrogen-containing silicone oil, 1-2 parts by weight of a thickening agent and 0.01-0.05 part by weight of an inhibitor; the thixotrope is prepared by evenly mixing the component A and the component according to the weight ratio of 1: 1, and defoaming under the vacuum condition. The thixotrope provided by the invention is high in thixotropic index, can be adjusted and controlled, is high in elasticity, tensile strength and tear strength after vulcanization, and is good in light transmittance. The thixotrope is applicable to a dispensing packaging technology of the chip of an LED lamp filament, and has good shape preserving capacity after dispensing and during curing.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

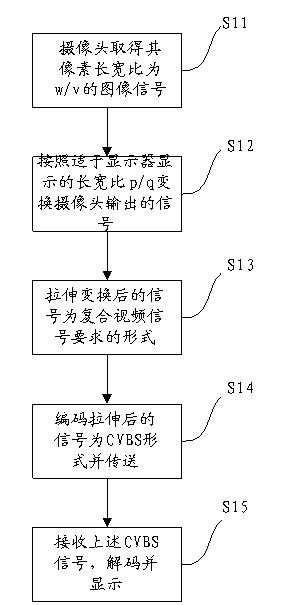

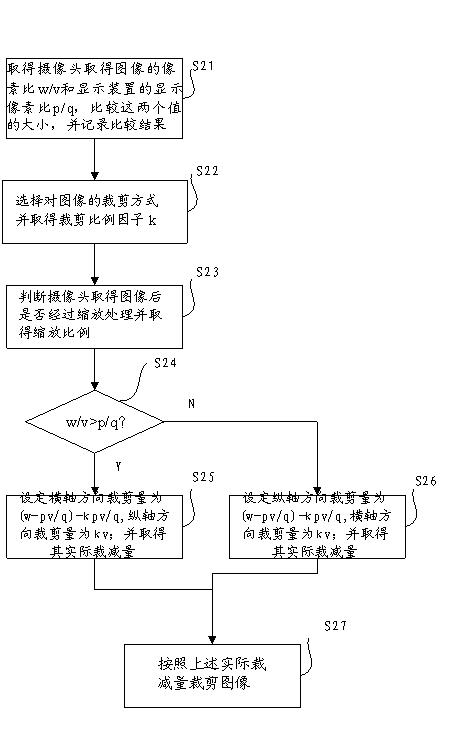

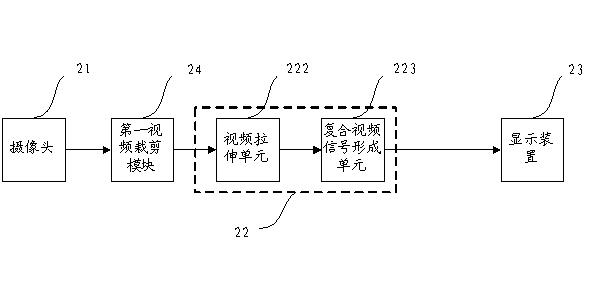

Method and device for changing image length-width ratio in video signals of security system

InactiveCN102447887AThere will be no image distortionThere will be no deformationClosed circuit television systemsComputer graphics (images)Display device

The invention relates to a method for changing the image length-width ratio in video signals of a security system. A security device comprises a camera and a display device. The method comprises the following step of: before or after converting video signals into complex video signals, converting the video signals with the length-width ratio being w / v into the video signals with the length-width ratio p / q through cutting, wherein p refers to the length of an image represented by the cut video signals, and q refers to the width of the image represented by the cut video signals. The invention further relates to a device for changing the image length-width ratio in the video signals of the security system. After the method and the device for changing the image length-width ratio in the video signals of the security system in the invention are implemented, the beneficial effect that the image signals cannot undergo display deformation in the traditional security system can be achieved.

Owner:SHENZHEN ADVANCE RIVER SYST TECH CO LTD

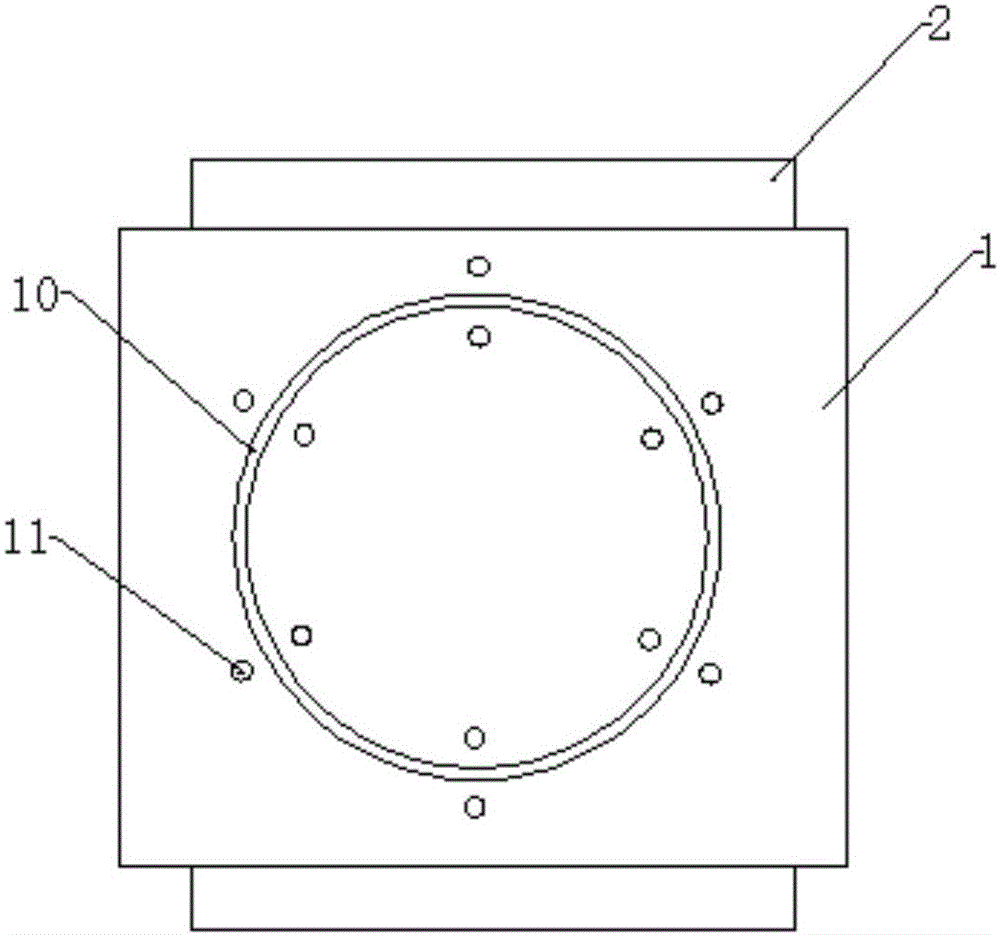

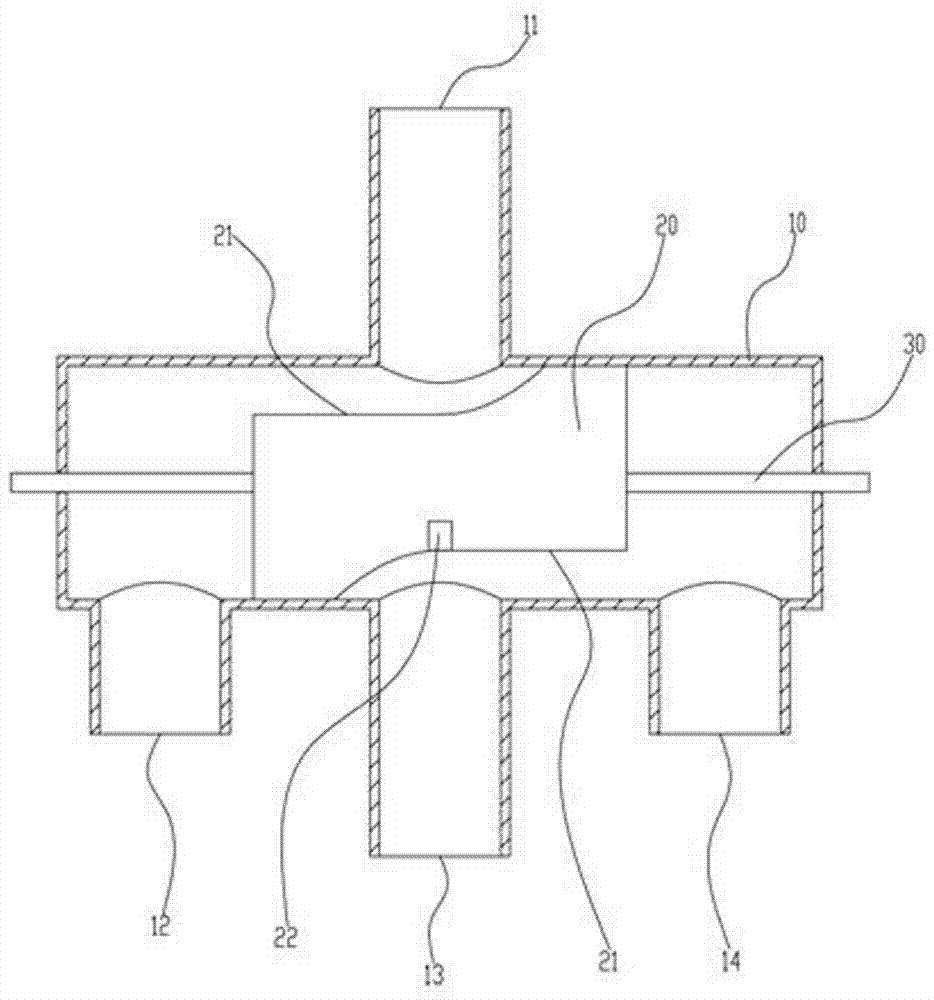

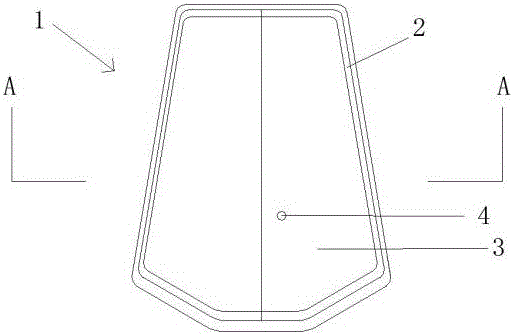

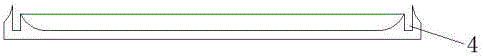

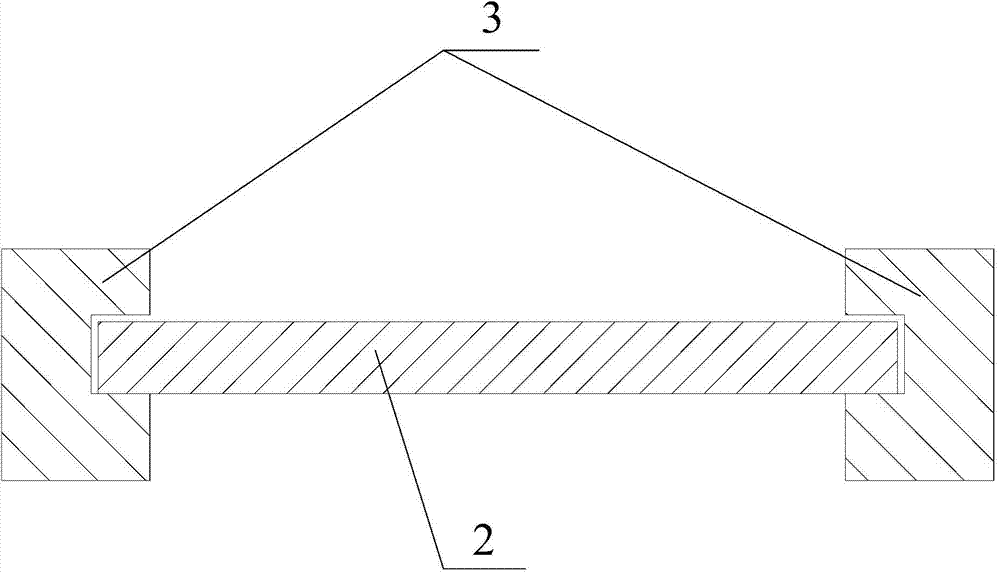

Die for cutting thin sheet and method for cutting thin sheet

InactiveCN106002039ANo sinkingThere will be no deformationWelding/cutting auxillary devicesAuxillary welding devicesLaser cuttingThin sheet

The invention provides a mold for thin plate cutting, which includes a tire board, cutting grooves are provided on the upper surface of the tire board, and the shape of the cutting grooves corresponds to the shape of workpieces to be processed. Magnets are arranged on the upper surface of the tire plate. When cutting, the thin plate is placed on the upper surface of the tire plate, and the cutting path of the laser follows the cutting groove on the tire plate. When the pressure gas acts on the thin plate, the entire thin plate can be supported by the tire plate, and there will be no sinking and deformation of the thin plate. The thin plate is firmly fixed on the tire plate through the magnet, which solves the problem of displacement of the thin plate during the cutting process and improves the machining accuracy of the cutting workpiece. The invention also provides a thin plate cutting method, which includes making cutting grooves of the mold, fixing the thin plate on the tire plate through magnets, and cutting along the cutting grooves with laser light.

Owner:四川新远宏机械设备有限公司

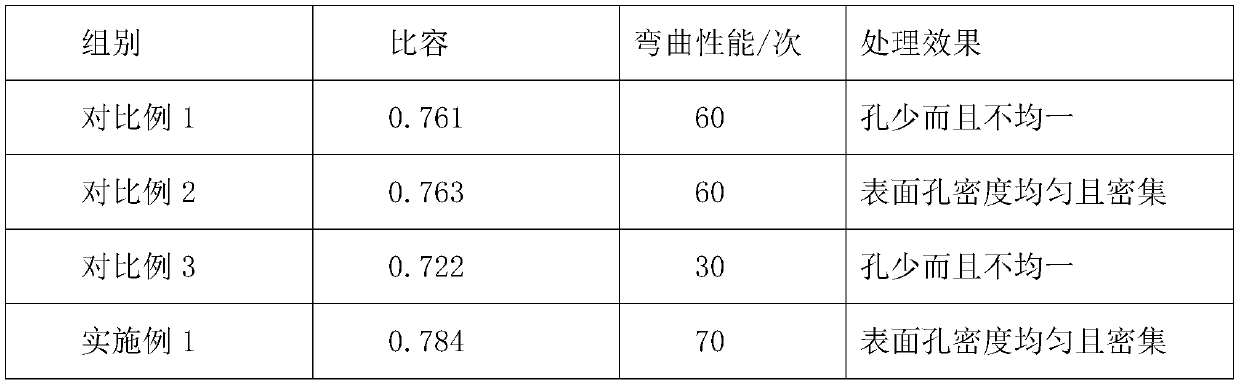

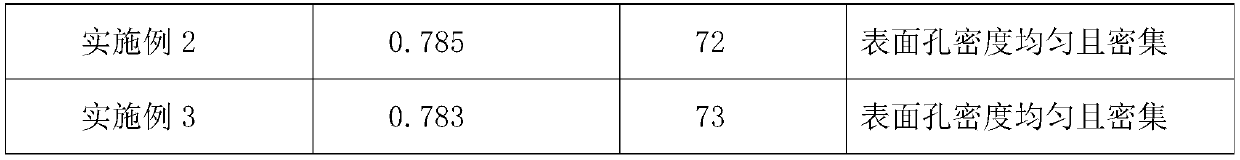

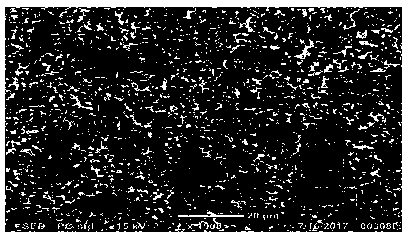

Manufacturing process for middle-high-voltage etched foil

InactiveCN109750346AStrong activation surfaceImprove bending performanceCapacitor manufactureAluminium electrolysisAluminum foil

The invention discloses a manufacturing process for middle-high-voltage etched foil, and relates to the technical field of production of etched foil. In order to solve the problem that etched foil isprone to deforming in the prior art, the manufacturing process comprises the steps of pretreatment, primary foaming corrosion, secondary foaming corrosion, third hole expansion corrosion and aftertreatment for high-purity aluminum foil; in the pretreatment, the aluminum plain foil is put into pretreatment liquid to be soaked for 40-50 seconds; then the aluminum plain foil is washed and then put into primary corrosion mixing liquid with the temperature of 80-90 DEG C, the foil is washed with pure water to be put into 2% of nitric acid liquid with the temperature of 70-80 DEG C, and direct current with the current density of 0.15 A / cm2 is applied for electrolytic corrosion for 500-600 seconds; and the aftertreatment adopts two-stage annealing heat treatment of different temperatures. The pretreatment process is simple, operation is convenient, deformation is avoided, the annealing process is improved in the aftertreatment, the two-stage annealing heat treatment of different temperaturesis adopted, and the bending performance of the etched foil for an aluminum electrolytic capacitor is greatly improved.

Owner:CENT SOUTH UNIV

Novel aluminum corrosive foil pre-treatment process

The invention relates to a novel aluminum corrosive foil pre-treatment process which comprises the following steps of: (1) putting an aluminum plain foil in a pre-treatment liquid to be soaked for 45s; (2) then cleaning the foil thoroughly, putting the foil in a primary corrosive mixed liquid at 70 DEG C, and applying a direct current, the current density of which is 0.70A / cm<2> for electrolytic corrosion for 60s; (3) cleaning the foil thoroughly with pure water, putting the foil in a tank liquid containing 2% of nitric acid at 70 DEG C, and applying a direct current, the current density of which is 0.15A / cm<2> for electrolytic corrosion for 600s; and (4) finally, cleaning the foil thoroughly with pure water, and then putting the foil in an oven at 220 DEG C to be dried. The process provided by the invention overcomes related defects that the corrosive foil which is pre-treated is likely to deform, the surface of the foil is of chromatic aberration after treatment, trace elements beneficial for generating holes will be removed through treatment, follow-up operations are not facilitated and the like.

Owner:江苏国瑞科技有限公司

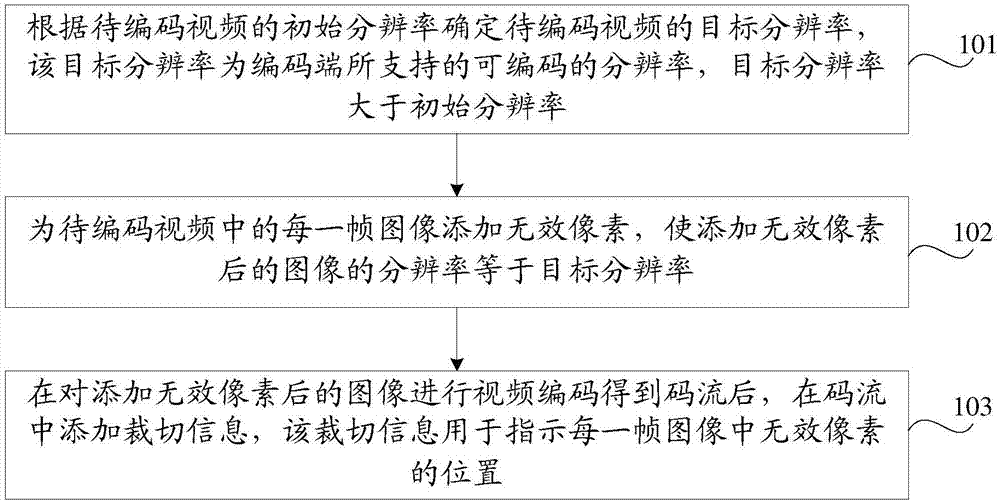

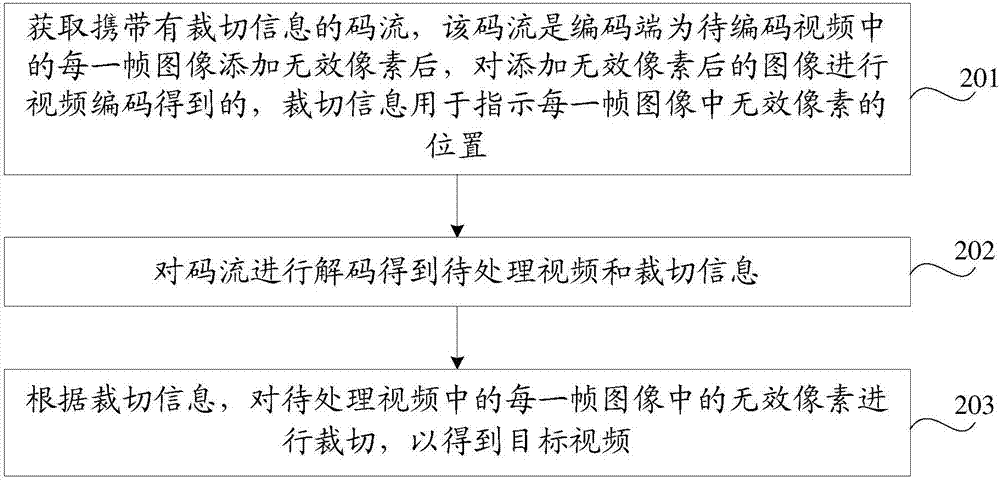

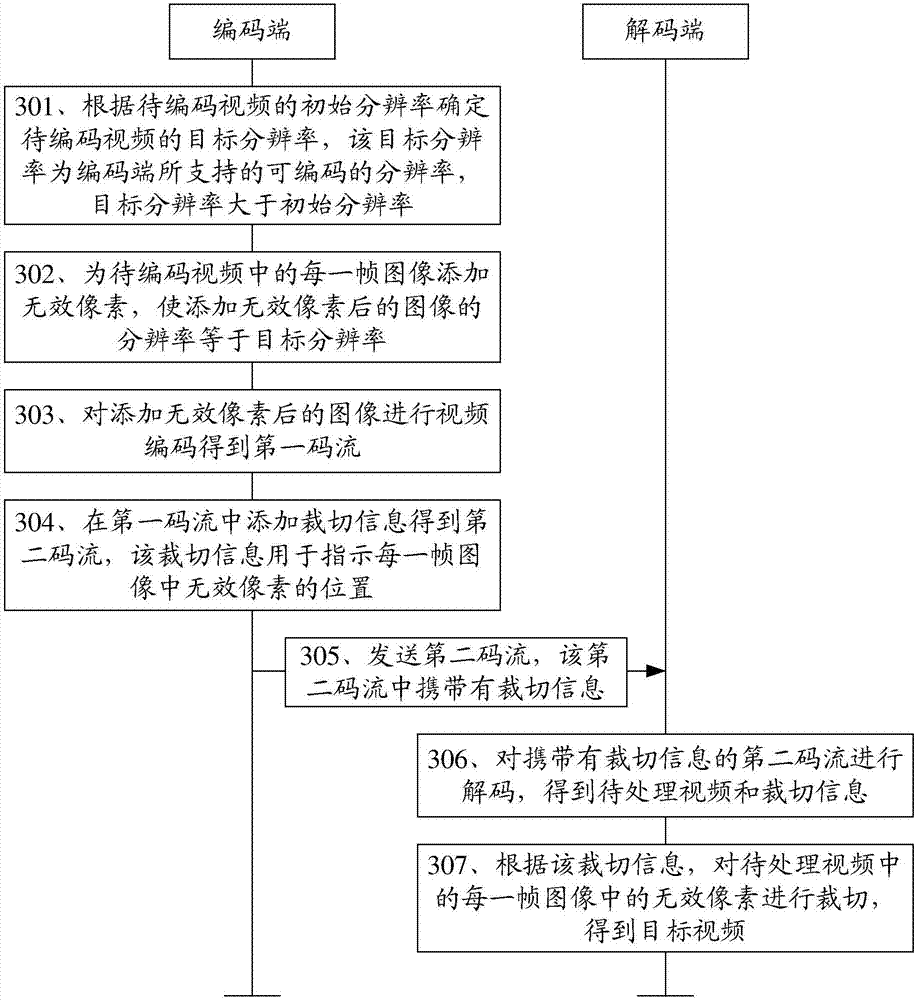

Video coding method and apparatus, and storage medium

InactiveCN107197329AThere will be no deformationGuaranteed display effectSelective content distributionImage resolutionImage deformation

The invention discloses a video coding method and apparatus, and a storage medium, and belongs to the technical field of video processing. The method comprises the following steps: determining a target resolution of a to-be-coded video according to the initial resolution of the to-be-coded video, wherein the target resolution is a codable resolution supported by a coding terminal, and the target resolution is greater than the initial resolution; adding invalid pixels to each frame of image in the to-be-coded video, so that the resolution of the image with the added invalid pixels is equal to the target resolution; and performing video coding on the image with the added invalid pixels to obtain a code stream, adding cutting information to the code stream, wherein the cutting information is used for indicating the positions of the invalid pixels in each frame of image. By adoption of the video coding method and apparatus disclosed by the invention, the following problem in related art is solved: in order to ensure the breadth length ratio, the size of each frame of image in the decoded video needs to be compressed, thereby being liable to cause an image deformation phenomenon, resulting in poor display effect of the image on the terminal. The video coding method and apparatus disclosed by the invention is applied to video coding.

Owner:GUANGZHOU BAIGUOYUAN INFORMATION TECH CO LTD

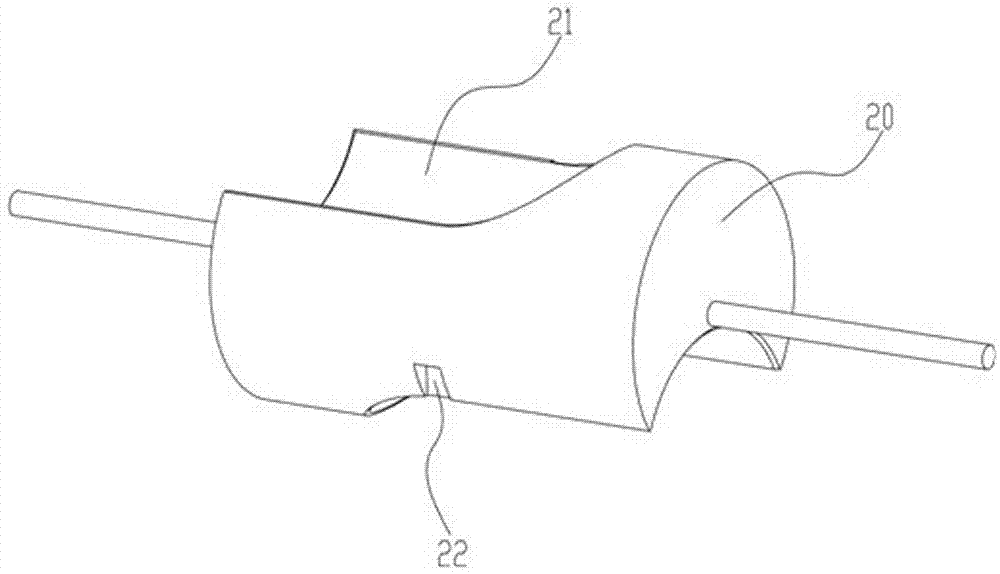

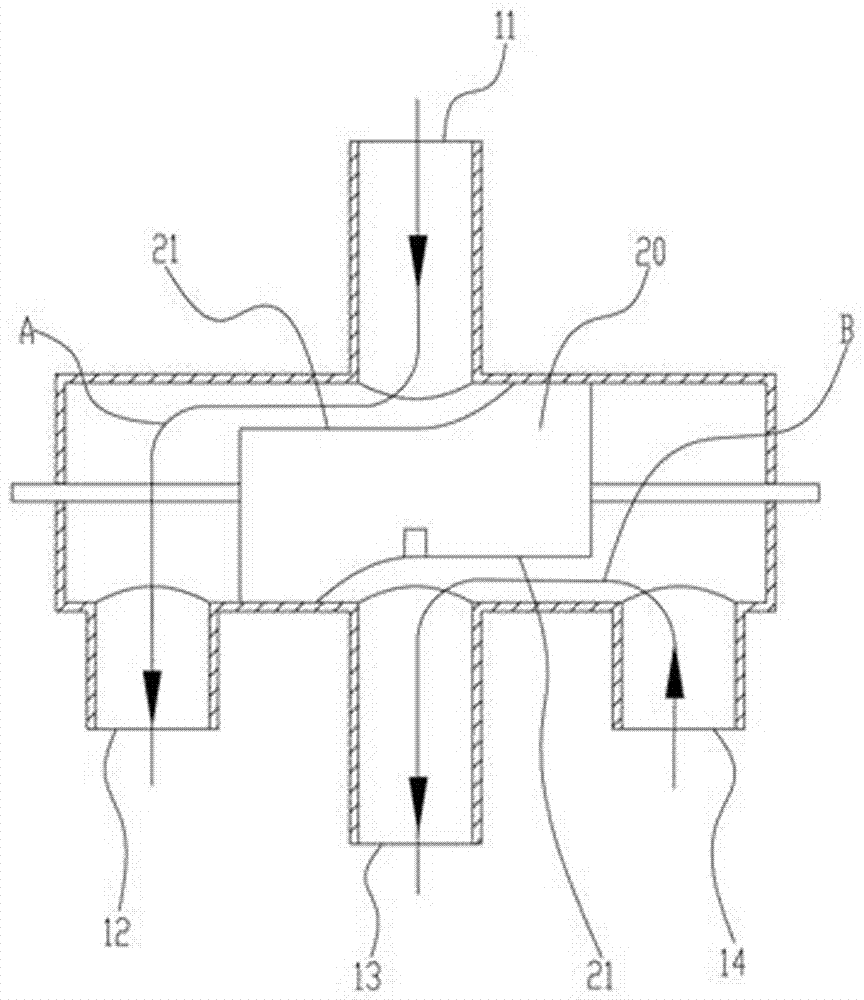

Rotary type four-way reversing valve and air conditioner

PendingCN107883019AThere will be no deformationGuaranteed normal commutationPlug valvesMultiple way valvesMechanical engineeringPhysics

The invention discloses a rotary type four-way reversing valve and an air conditioner. The rotary type four-way reversing valve comprises a valve body and a valve element, a fluid inlet, a fluid outlet, a first interface and a second interface are formed in the valve body, the valve element is in a cylindrical shape, the valve element is rotatably arranged in the valve body, the valve element andthe valve body are coaxial with each other, and the excircle surface of the valve element is in seal fit with the inner circle surface of the valve body; and two centrosymmetric flow guiding parts arearranged on the valve element, the fluid inlet communicates with the first interface and the second interface in a switched mode through the two flow guiding parts, and correspondingly the fluid outlet communicates with the second interface and the first interface in a switched mode. According to the rotary type four-way reversing valve and the air conditioner, reversing is conducted through rotation of the valve element in the valve body, the situation of valve element deformation cannot occur, therefore normal reversing of the four-way reversing valve can be ensured, and the service life ofthe four-way reversing valve is prolonged.

Owner:GREE ELECTRIC APPLIANCES INC

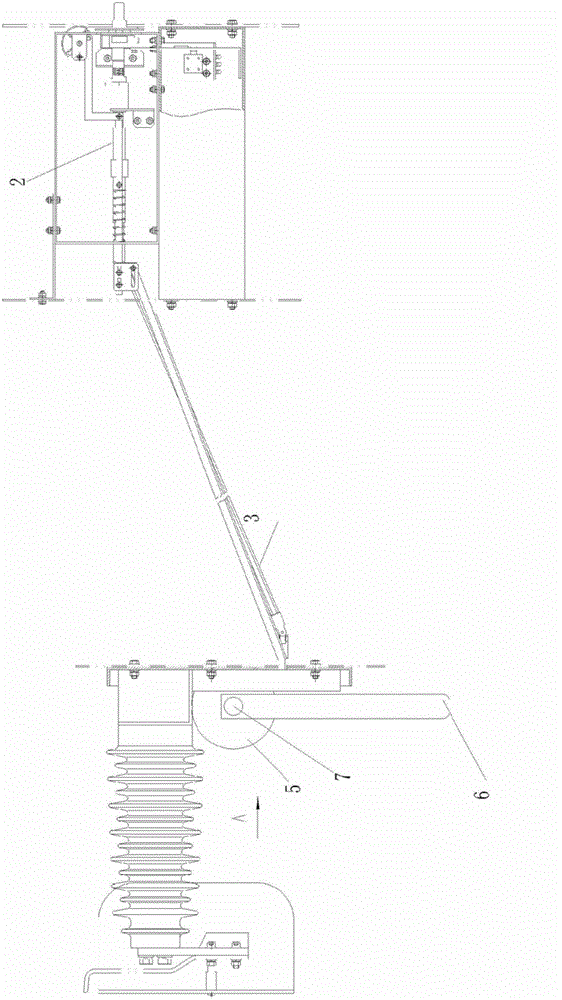

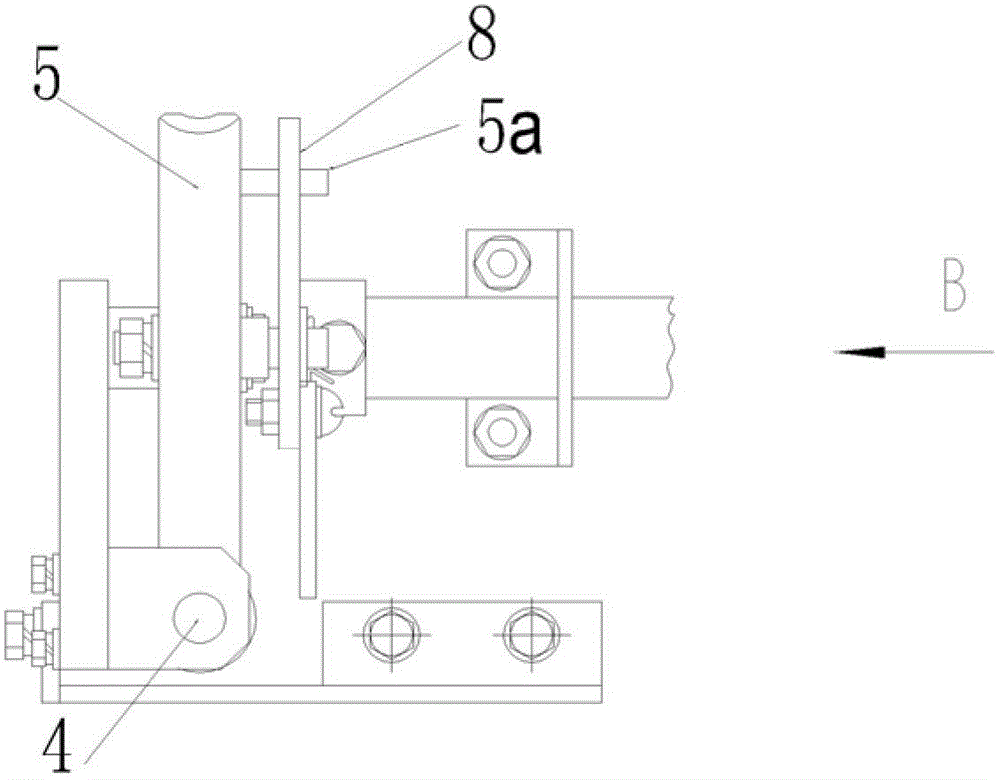

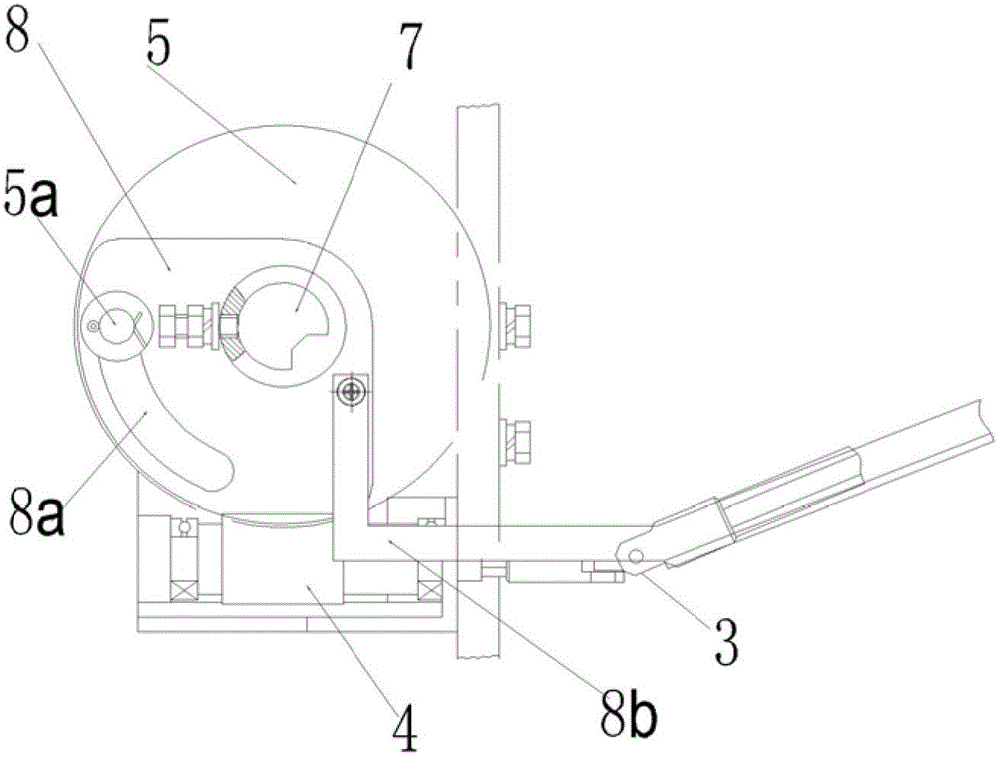

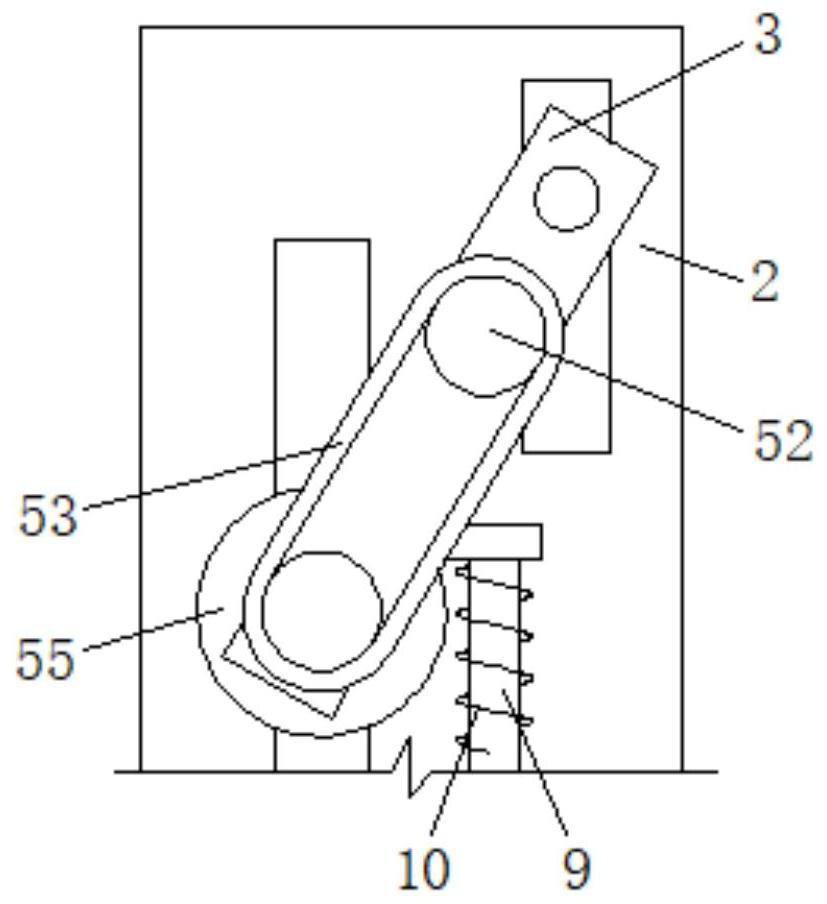

Driving device for switch operation interlocking mechanism

InactiveCN102723223AThere will be no deformationEasy to operateAir-break switch detailsUniversal jointGear wheel

The invention belongs to the field of switch equipment, in particular to a switch operation interlocking mechanism. A driving device for the switch operation interlocking mechanism comprises a rotating mechanism arranged inside a mechanism box, a worm gear, a worm and a travel plate, wherein the travel plate is fixed on a spindle of a grounding switch; the rotating mechanism is connected with the worm by a universal joint; the worm is worked with the worm gear; a push rod is fixed on an end of the worm gear; and the travel plate is provided with a travel space, in which the push rod is inserted. The driving device for the switch operation interlocking mechanism has the advantages that the original bevel gear driving is replaced with the cooperated driving of the worm gear and worm, the operation of the rotating mechanism and the switching spindle of a flashboard can be performed at different positions, so that the operation is convenient; meanwhile, the phenomenon of gear sliding or mechanism deformation can be avoided, and the stability of the equipment is improved.

Owner:江苏华冠电器集团有限公司

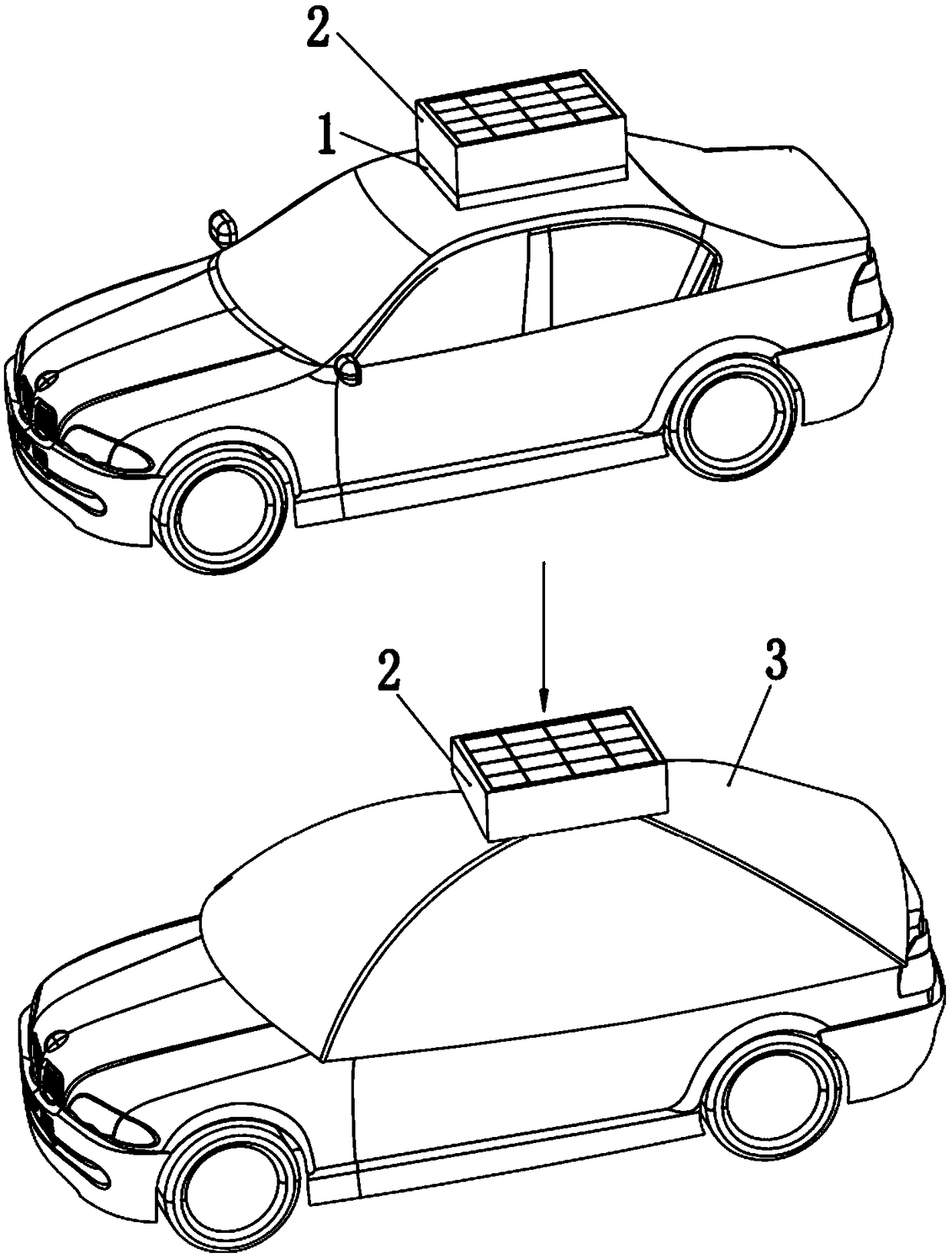

Automobile sunscreen device

InactiveCN109177706AWon't touchWill not polluteRemovable external protective coveringsEngineeringMechanical engineering

The invention relates to an automobile sunscreen device, comprising a lower main body, an upper main body, a sunscreen and a first driving mechanism. An accommodating space for accommodating sunscreenclothes is arranged between the upper main body and the lower main body; the first driving mechanism is arranged on the upper main body for driving the periphery of the sunscreen into and out of theaccommodating space through the first gap when an annular access first gap is formed between the upper main body and the lower main body; a sunscreen device of an automobile further comprise a liftingdrive assembly, wherein the lifting drive assembly moves up and down with respect to the lower body by drive the upper body, and the first drive mechanism is mounted on the upper body by a mounting mechanism, wherein the mounting mechanism comprises a mounting plate and a plurality of elastic connectors; the first drive mechanism is mounted on the mounting plate, and each elastic connector connects the upper body and the mounting plate. The lifting drive assembly for controlling movement of the upper body up and down and a first drive mechanism for automatically retracting and releasing the sunscreen garment can achieve the purpose the other component in the sunscreen device of the automobile are not exposed when the sunscreen garment is unfolded.

Owner:XIAMEN UNIV OF TECH

Making process of Mongol stringed instrument box

ActiveCN106328100AShorten the timeImprove bending performanceStringed musical instrumentsFiberTrimethylsilyl chloride

The invention discloses a making process of a Mongol stringed instrument box. First, a bottom board and a surface board are made; then, side boards are made; and finally, box preprocessing and box assembly are performed. The making process of a Mongol stringed instrument box overturns the traditional making process, and saves the time of making. The water content of wood at local gaps is raised or reduced to 40%, the water content at the moment is equal to the water content when wood fibers are saturate, and the water content is most suitable for bending a long wooden board; and then, heating is performed to reduce the water content. Sodium hydroxide can decompose hemicelluloses in wood and reduce hydroxyl in wood. Paraffin used can go into the capillary pores in the surface and middle layers of wood at high temperature, and fill the capillary pores after cooled and solidified. Thus, outside moisture is prevented from going into wood again, and deformation of wood is prevented effectively. Then, the surface of wood is uniformly and fully coated with trimethyl chlorosilane, which can modify wood. After modification, the water absorption rate is reduced, and the hydrophobic property of the surface of wood is enhanced.

Owner:都安瑶族自治县计量检定测试所

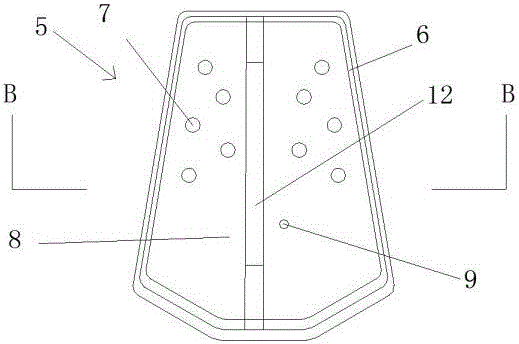

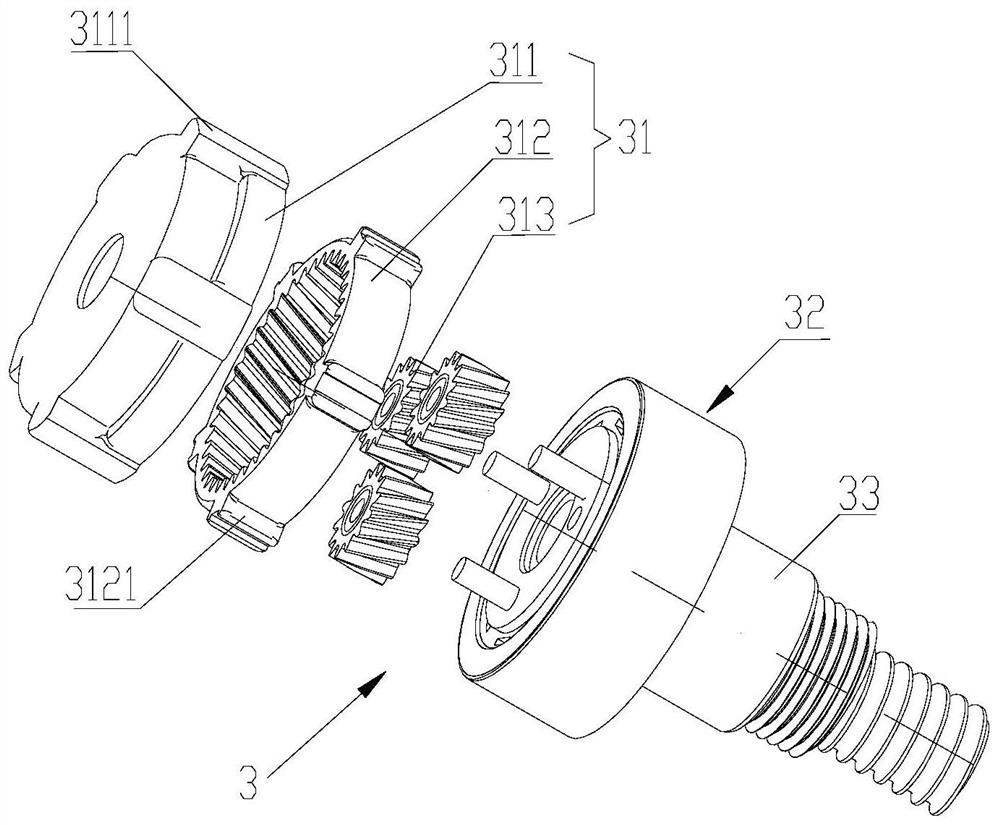

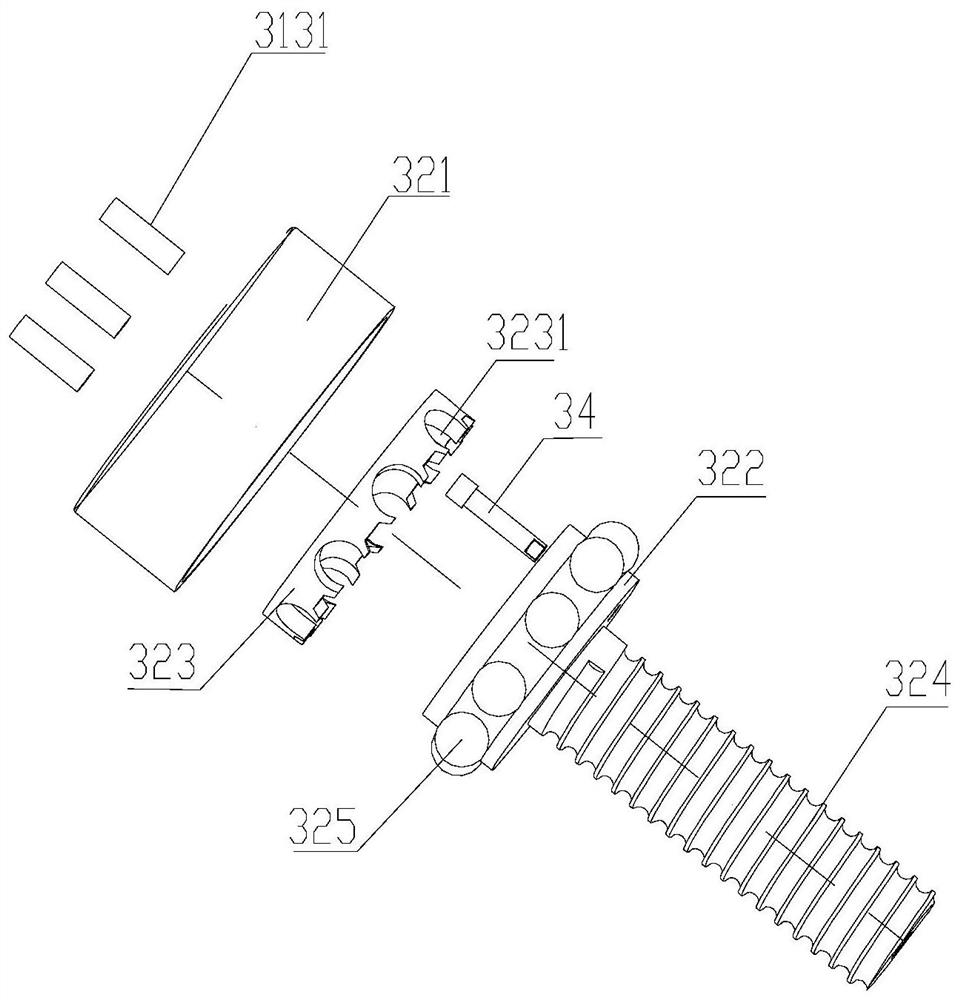

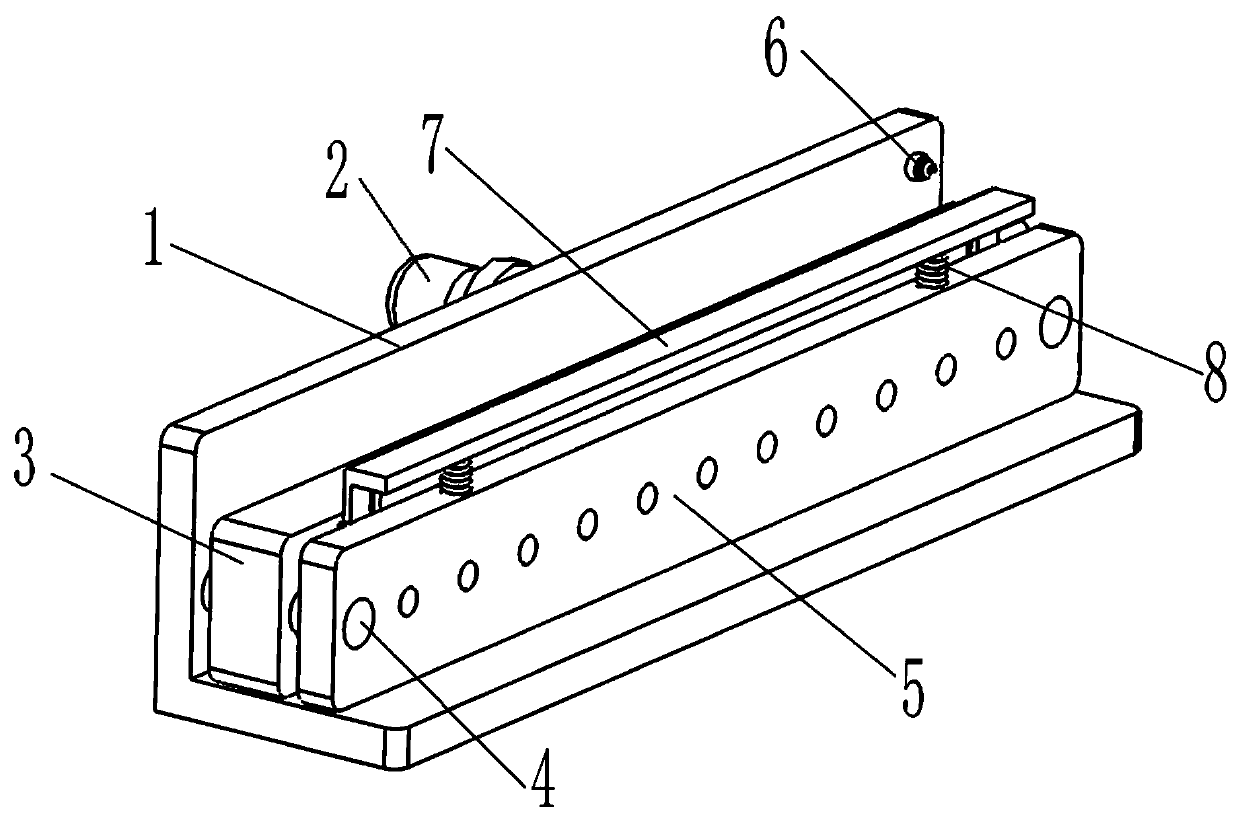

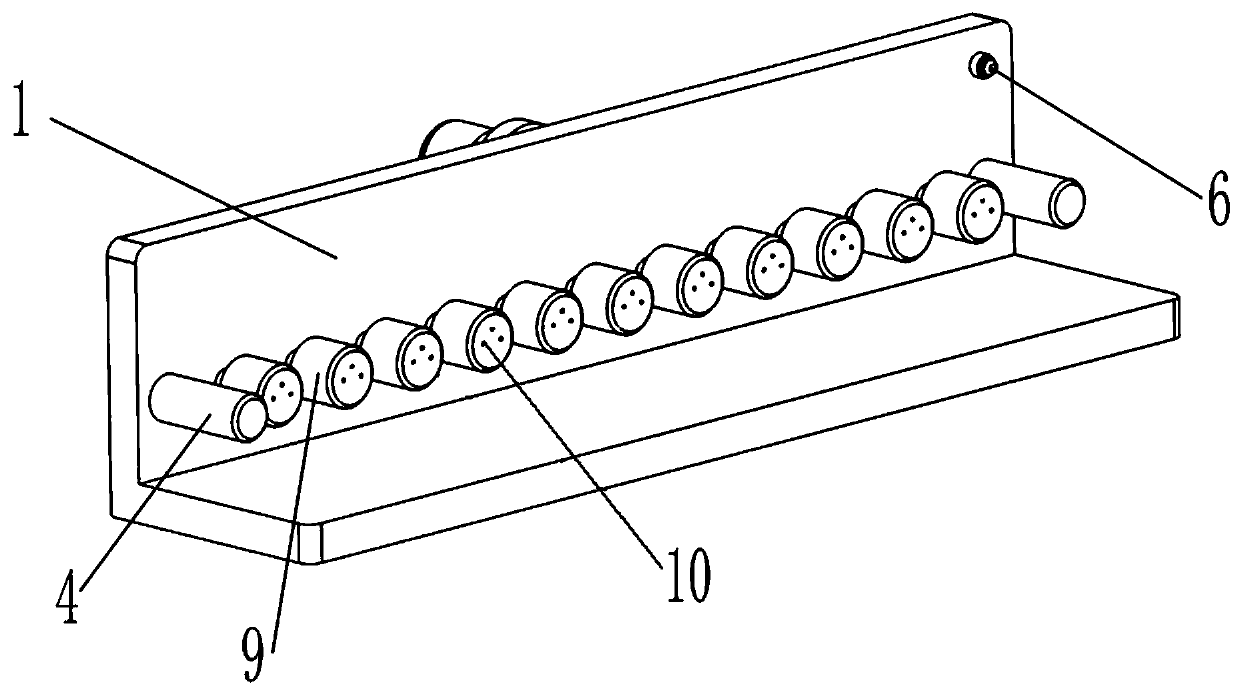

Piston pump set for brake system and control method thereof

ActiveCN112664440AEnough pressureAvoid collision interferencePositive displacement pump componentsFluid braking transmissionGear wheelBraking system

The invention is applicable to the technical field of hydraulic braking, and discloses a piston pump set for a brake system. The piston pump set comprises a piston, a pump body with a working cavity and a transmission mechanism for driving the piston to move in the working cavity, wherein the transmission mechanism comprises a lead screw transmission assembly, a driven part and a planetary gear assembly for transmitting power to the lead screw transmission assembly; the driven part is fixedly connected with the piston; the lead screw transmission assembly is used for driving the driven part to move relative to the working cavity; and a limiting component used for limiting movement of the driven part is arranged between the lead screw transmission assembly and the driven part. The invention further provides a control method for controlling the piston pump set for the brake system. According to the piston pump set for the brake system and the control method provided by the invention, the effect of pumping out high-pressure liquid can be better achieved, stable brake pressure is provided for the brake system, and the working stability is high.

Owner:BYD CO LTD

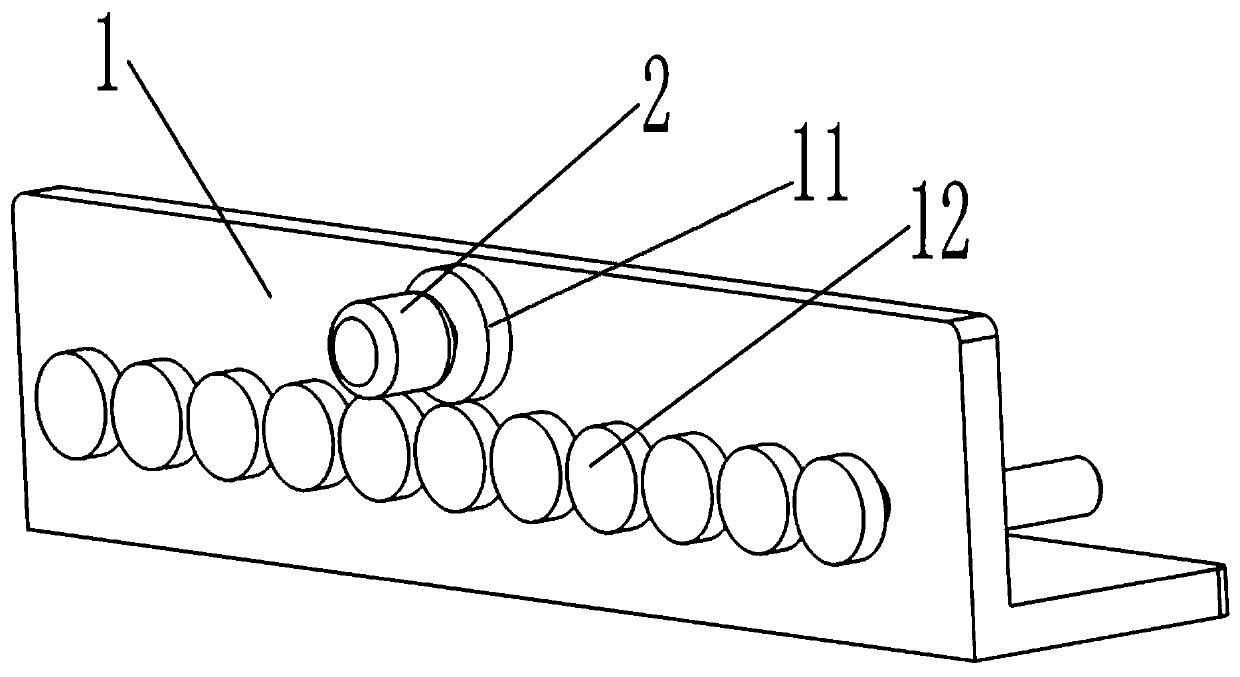

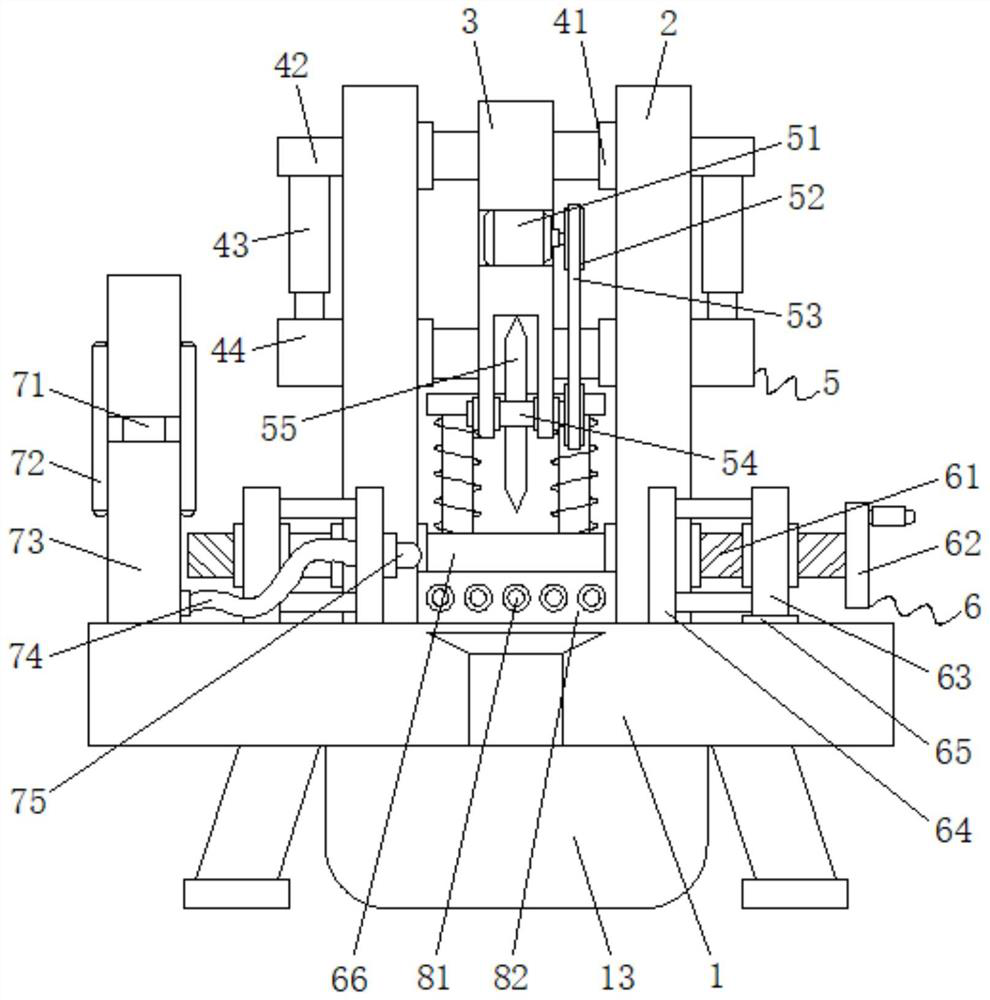

Rapid cap cutting device and method for semiconductor laser tube cap

ActiveCN111195750AEffective protectionWill not cause bending and closing phenomenonPositioning apparatusMetal-working holdersEngineeringErbium lasers

A rapid cap cutting device for a semiconductor laser tube cap comprises a base, N fixing seats, a fixing seat driving mechanism, a laser fixing plate and a cutting knife. The laser fixing plate can beinstalled in place after being inserted on a guide rod through a guide hole I, tube legs of lasers are inserted into corresponding insertion holes in the fixing seats, the fixing seat driving mechanism drives each fixing seat to rotate, rotation of each laser is achieved, the cutting knife is pressed downwards, a cutting edge below the cutting knife is in contact with the corresponding tube cap,and the rotating tube cap is cut off by the cutting edge. The tube legs are inserted into the insertion holes, so that the tube legs can be effectively protected, and the tube legs cannot be bent andfolded. When the tube cap is cut, the cutting force on the tube cap is uniform, the end face of the cut tube cap is tidy, deformation of the tube cap during cutting can not occur, damage to the insides of the lasers can not occur, and the product quality of cap cutting is improved.

Owner:潍坊华光光电子有限公司

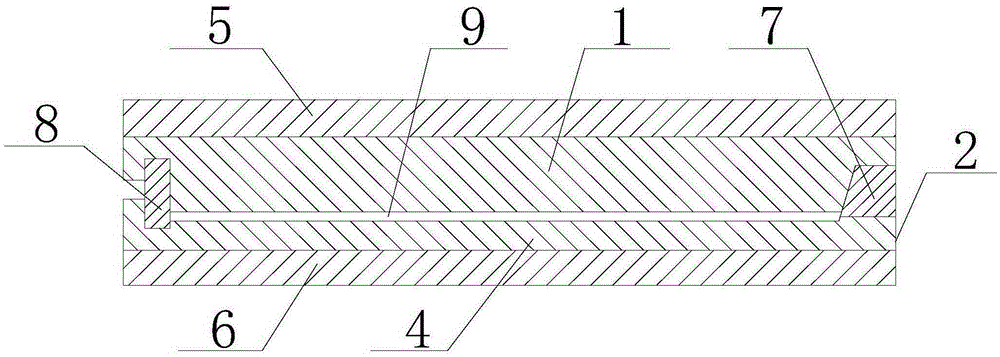

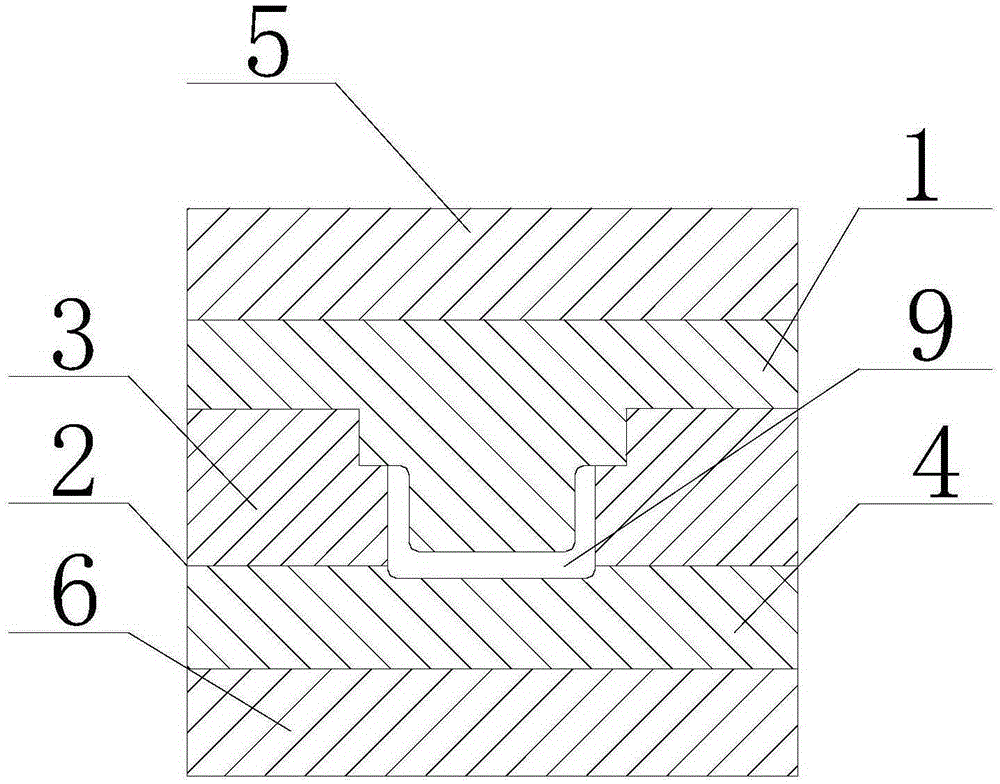

Hot pressing die without ejection rod traces on surfaces of products

InactiveCN105313312AOvercome demoulding resistanceGuarantee the appearance qualityEngineeringMechanical engineering

The invention discloses a hot pressing die without ejection rod traces on surfaces of products. The hot pressing die comprises a convex die and a concave die and is characterized in that the convex die and the concave die are spliced up and down together through clearance fit; a sealed die cavity is formed between the convex die and the concave die; the concave die adopts a combined structure and comprises side die plate and a bottom die plate; the side die plates are arranged on two sides of the top surface of the bottom die plate and are combined to form a groove; the bottom of the convex die is inserted into the groove to form a sealed die cavity; the convex die is mounted on an upper fixing plate; the bottom die plate is mounted on a lower fixing plate. The hot pressing die without ejection rod traces on surfaces of products adopts a combined die; the die can be removed without an ejection mechanism; the high size accuracy of products can be ensured; the die structure is simplified; the manufacturing difficulty and the manufacturing cost of the die are reduced; the surfaces of the products are free of ejection traces; the later treatment workload is effectively reduced; the attractive appearance and the market competitiveness of the products can be ensured.

Owner:SICHUAN D&F ELECTRICAL TECH

Method for machining plywood

InactiveCN109648676AThere will be no deformationQuality improvementWood veneer joiningEngineeringPoor quality

The invention discloses a method for machining plywood. The method for machining the plywood comprises seventeen steps including selecting raw materials, sawing wood, debarking round wood, conductingrotary cutting, a first laminating procedure, arranging slab, a first pre-pressing procedure, a first hot pressing procedure, surface finishing, surface sanding, a second laminating procedure, cladding, a second pre-pressing procedure, a second hot pressing working procedure, edge-sawing, detecting and packaging. According to the method for machining the plywood, in the pre-pressing procedures andthe hot pressing procedures, parameters and time are strictly controlled so as to improve the quality of plywood and to avoid the situations that gluing between the plywood is poor and the plywood has foams; manual pressure relief is carried out, so that the phenomenon that the plywood has the foams due to direct pressure relief is avoided, and the defective rate of the plywood is reduced; strictquality control is carried out before the plywood leaves the factory, so that the plywood with poor quality is prevented from entering a market, and the quality of the released products is guaranteed; and each step is completely implemented, so that the plywood with excellent quality is obtained.

Owner:太和县金鑫木业有限公司

Preparation technology of glass fiber F9 grade air filtering material

InactiveCN110090493AImprove efficiencyImprove moisture resistanceMembrane filtersFiltration separationGlass fiberAir filter

The invention discloses a preparation technology of a glass fiber F9 grade air filtering material. The preparation technology comprises the following steps: taking raw materials comprising 30 wt% of 10-12 [mu]m glass fibers, 55 wt% of 5-8 [mu]m glass fibers and 15 wt% of glass wool, adding water with a pH value of 2.6, having a weight 20 times the weight of the raw materials, performing mixing, stirring the obtained mixture to form a slurry, and ensuring that the pH value of the slurry is 2.5; carrying out an existing wet papermaking process on the slurry to prepare a filtering material; allowing the filtering material to sequentially pass through three drying cylinders at a paper feeding speed of 35 m / min to dry the filtering material; and coating two sides of the dried filtering materialwith an acrylic resin solution, and allowing the coated filtering material to sequentially pass through two drying cylinders at a paper feeding speed of 35 m / min to make the water content of the dried filtering material less than 5% in order to obtain the glass filter F9 grade air filtering material. The F9 grade air filtering material product prepared by the method has high efficiency, high moisture resistance, non-deformability and long service life.

Owner:HUNAN ZHENGJIA SPECIAL MATERIAL

Coating material replacing hard chromium plating and method for carrying out laser cladding by using coating material

InactiveCN107267978ABarrier contactAvoid Pore CracksMetallic material coating processesImpurityMetal

The invention relates to a coating material replacing hard chromium plating and a method for carrying out laser cladding by using the coating material, and belongs to the technical field of restoration. The coating material comprises C, Cr, Ni, impurities and Fe. The method comprises the steps that elemental metal is atomized to obtain the coating material for replacing the hard chromium plating, and a final finished workpiece is obtained through cleaning, laser outputting, cladding and post-treatment. According to the coating material and the method, the laser cladding technology is adopted, a uniform and dense metal coating is formed on the surface of a substrate, and therefore the generation of pore cracks is completely avoided, and the contact between water and the substrate is completely obstructed.

Owner:WUXI ZHOUXIANG LASER MACHINERY

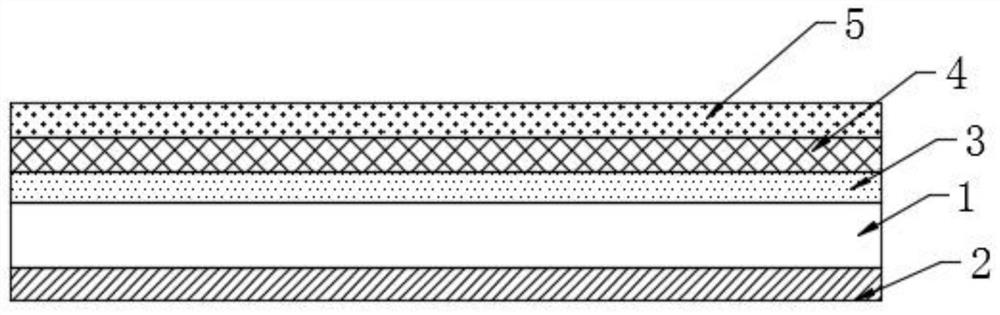

Release film applied to glass cover plate

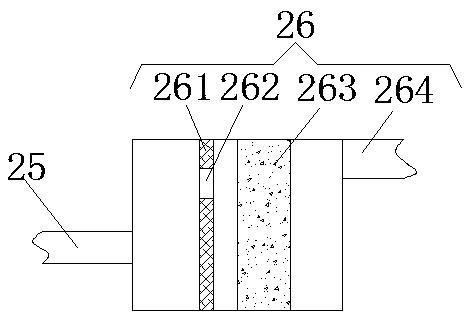

PendingCN112831293AImprove anti-static performanceImprove wear resistanceFilm/foil adhesive release linersGlass coverMaterials science

The invention discloses a release film applied to a glass cover plate. The release film comprises a base film layer, wherein an adhesive layer is arranged on the lower surface of the base film layer, an anti-static layer is arranged on the upper surface of the base film layer, the anti-static layer is fixedly adhered to the surface of the base film layer, a high-temperature-resistant layer is arranged on the surface of the anti-static layer, the high-temperature-resistant layer is fixedly adhered to the surface of the anti-static layer, a wear-resistant surface layer is arranged on the surface of the high-temperature-resistant layer and is fixedly adhered to the surface of the high-temperature-resistant layer. The anti-static effect of the release film can be improved by arranging the anti-static film layer; the release film cannot deform under the high-temperature condition by arranging the high-temperature-resistant film layer, the overall high-temperature-resistant effect of the release film is good; the overall wear-resistant effect of the release film can be improved by arranging the wear-resistant surface layer, the phenomenon that the use is affected by damage caused by friction is avoided, and the service lifetime is effectively prolonged.

Owner:东莞市金恒晟新材料科技有限公司

Fire retardant for plastic artware and preparation method of fire retardant

InactiveCN107652877AThere will be no deformationGood heat insulationFireproof paintsPolyamide coatingsWater basedEpoxy

The invention discloses a fire retardant for plastic artware. The fire retardant for the plastic artware is characterized by comprising 70 parts of water-soluble polyamide resin, 14 parts of mica powder, 7 parts of talcum powder, 12 parts of calcium carbonate, 9 parts of wollastonite, 27 parts of water-based epoxy emulsion, 6 parts of silicon dioxide aerogel particles, 11 parts of nano hollow ceramic microspheres, 2 parts of dispersing agents, 3 parts of thickening agents, 0.9 part of coalescing agent, 0.6 part of flatting agent and 13 parts of water, namely deionized water. The plastic artware has high heat-insulating property after being coated with the fire retardant, and the surface of the plastic artware does not deform at a high temperature.

Owner:惠州市海来福实业有限公司

Stainless steel pipe machining method

InactiveCN107881326AThere will be no deformationGuaranteed tight fitRare-earth elementHigh intensity

The invention discloses a stainless steel pipe machining method. The stainless steel pipe machining method comprises the following steps that (1) liquid steel is smelted, specifically, a, sintering isconducted, b, smelting is conducted, and c, nitrogen is introduced; (2) continuous casting is conducted, specifically, a raw material treated through the step (1) is subjected to continuous steel casting through a continuous casting machine, and a round pipe blank is obtained; and (3) fixed cutting and acid pickling are conducted, specifically, the pipe plank is cut into blanks being 4-6 m long through a cutting machine, then the blanks are subjected to acid pickling and passivating through stainless steel acid pickling and passivating solution, and heating is conducted. The nitrogen contentof the stainless steel is up to 3.5-5 wt%, and the effect that a stainless steel pipe has good corrosion resistant, tensile strength and high strength is ensured; meanwhile, rare earth elements and copper elements are added for synergistic effect, killed bacterial microbial species in stainless steel is effectively increased, time is greatly shortened, the efficiency is improved, and the corrosionresistance of stainless steel is improved.

Owner:吴文君

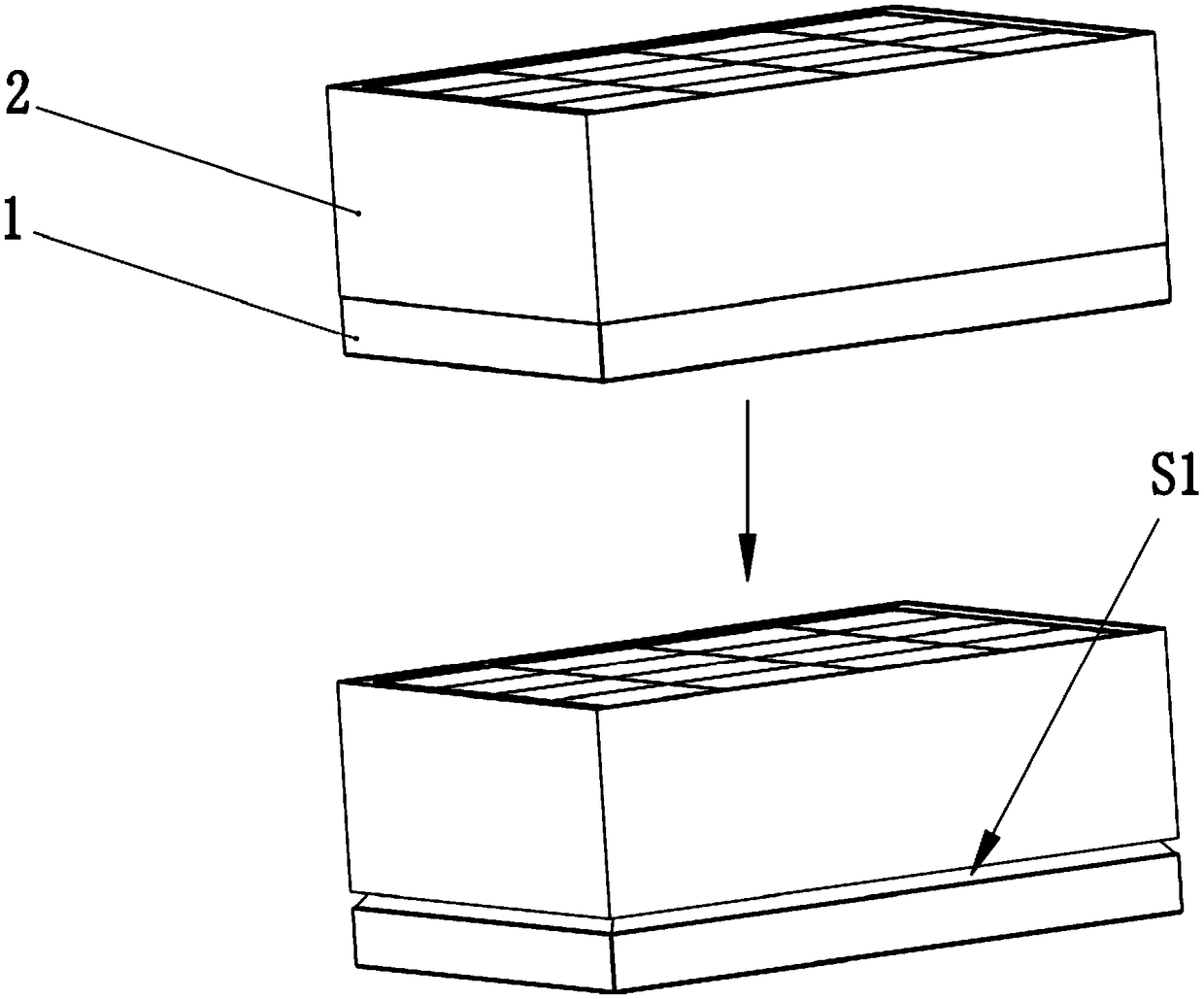

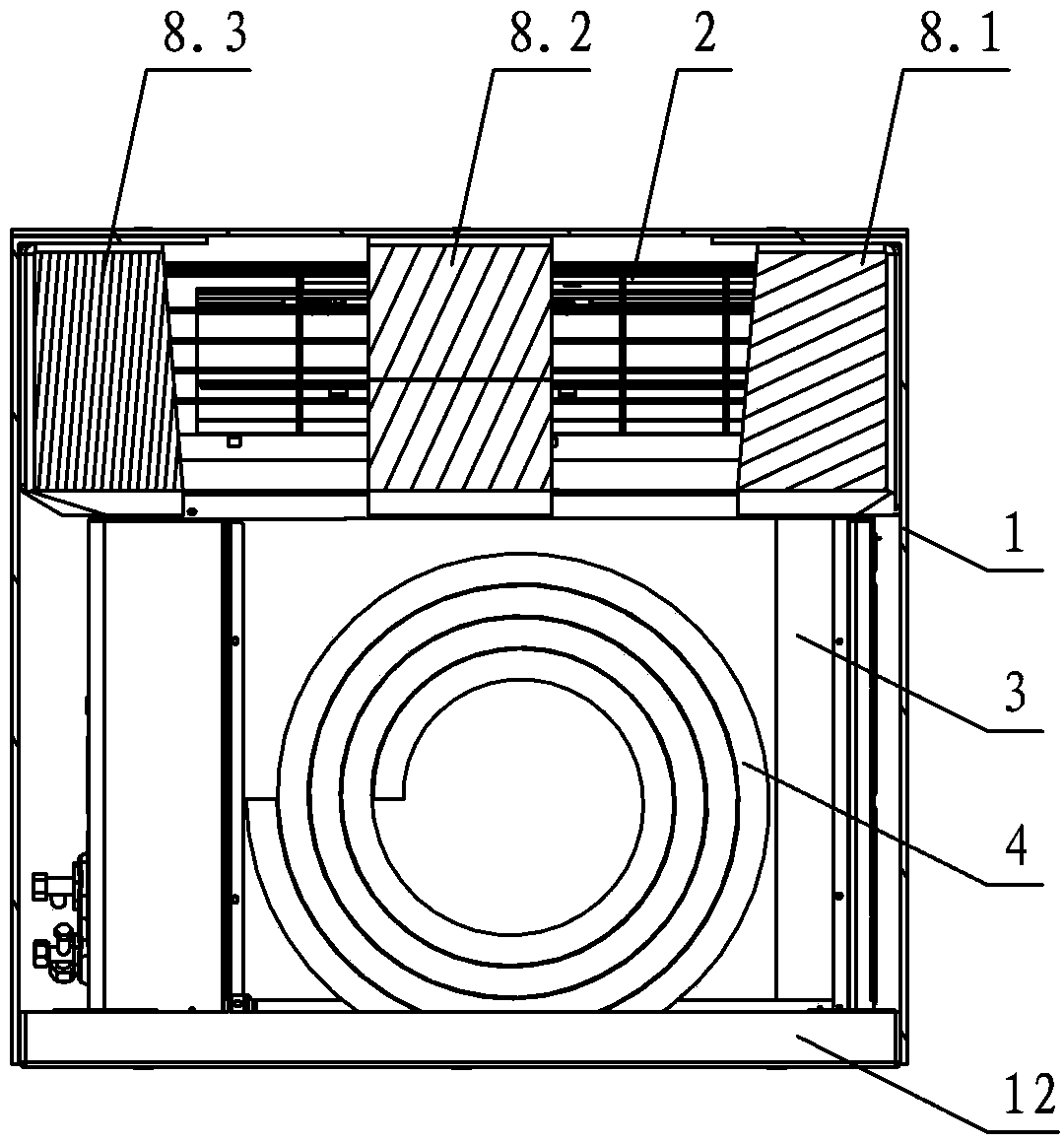

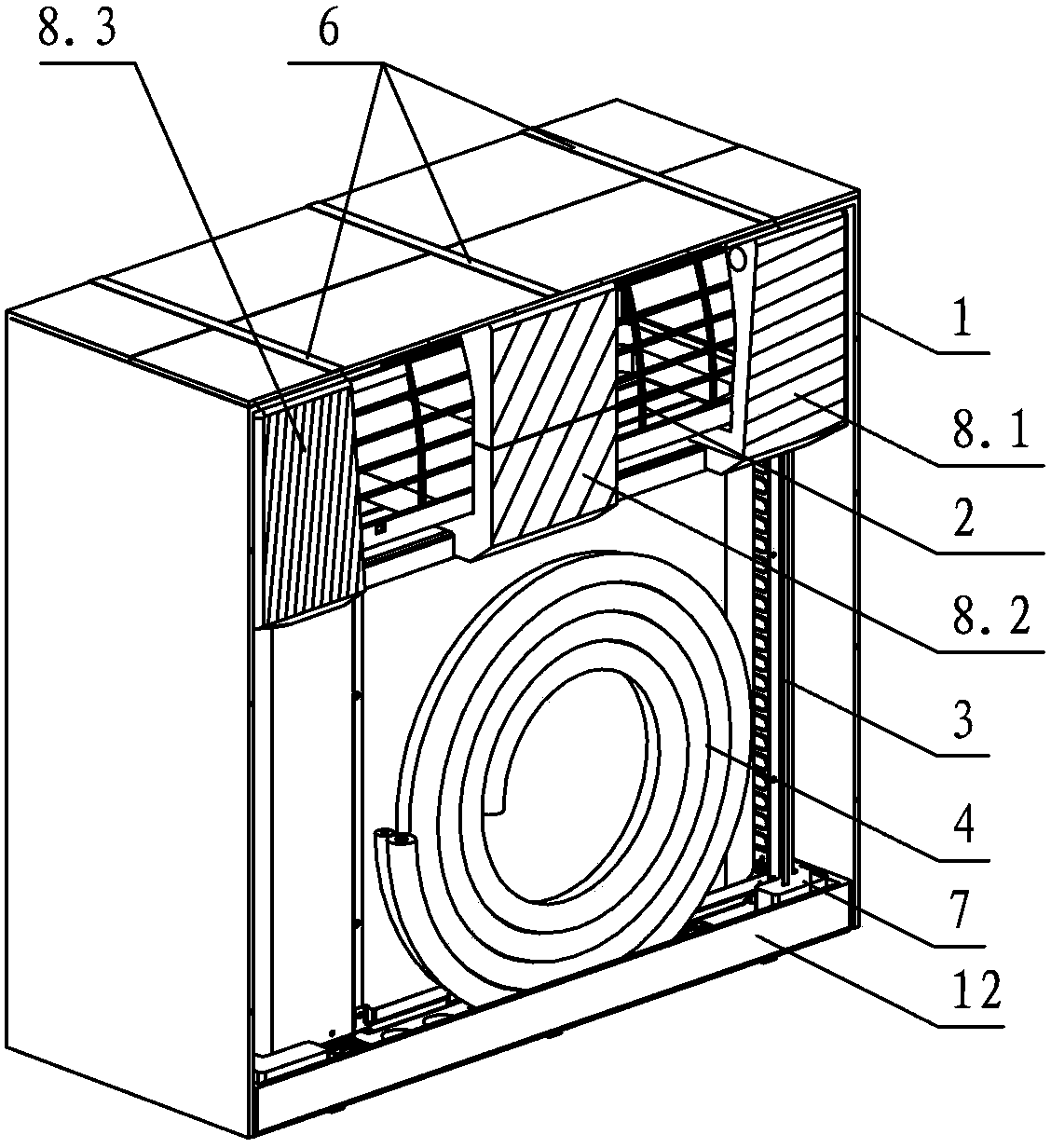

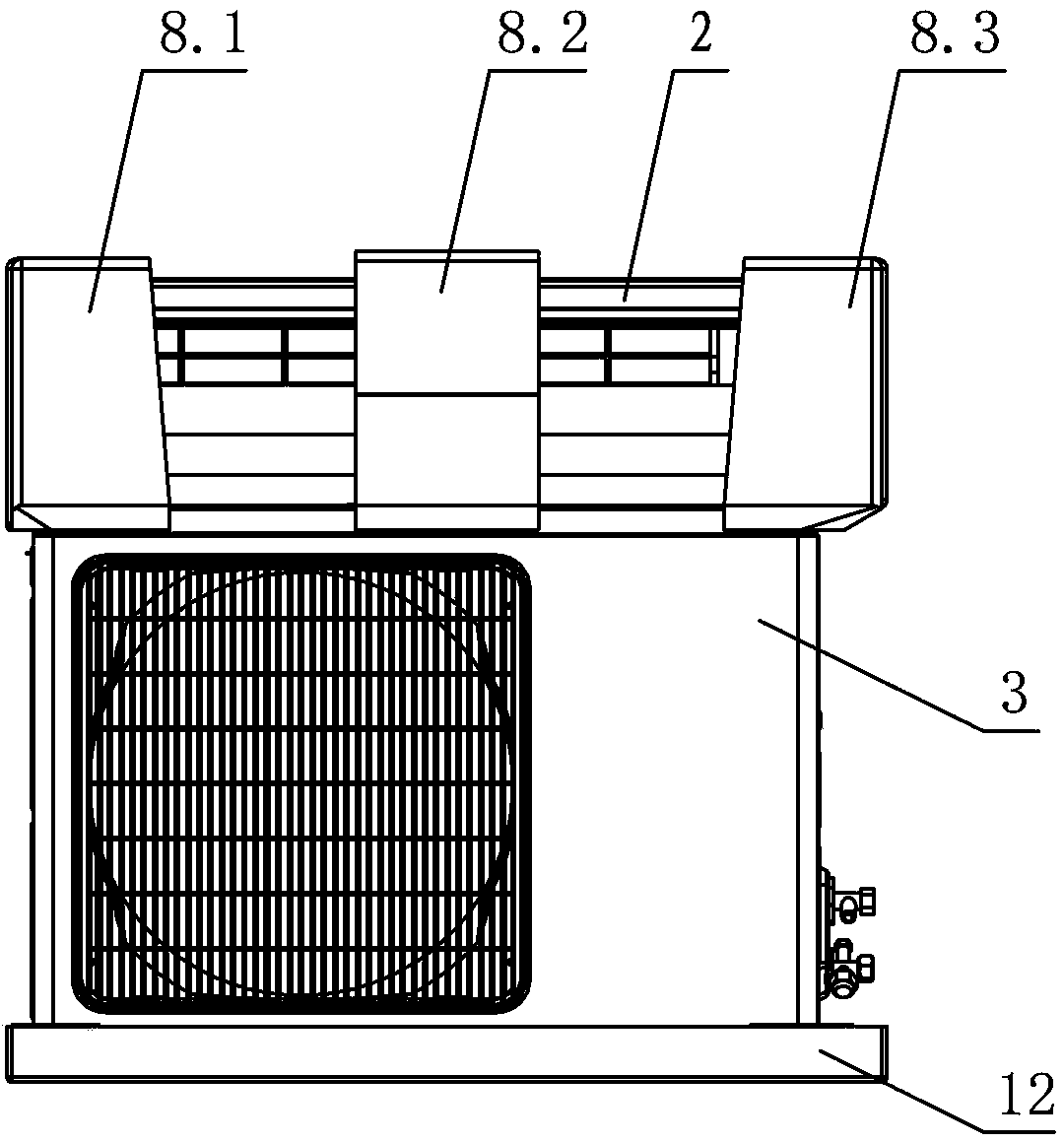

Packing device of split air conditioner and method for packing split air conditioner by using packing device

ActiveCN103350832AHigh strengthThere will be no deformationPackaging vehiclesContainers for machinesCartonCopper

The invention discloses a packing device of a split air conditioner and a method for packing the split air conditioner by using the packing device. The split air conditioner comprises an indoor unit, an outdoor unit and an installing attachment, wherein the installing attachment comprises a connecting copper pipe and a connecting cable, and the indoor unit, the outdoor unit and the installing attachment are arranged in one packing paper box together; the packing paper box is of an upper-down separating structure, and the packing paper box is fixedly bundled through more than two packing belts; the indoor unit is arranged on the upper part and the side surface of the outdoor unit, the front side, the rear side or the right side of the outdoor unit and a packing liner of the outdoor unit and the inner wall of the packing paper box can form a gap together, and the installing attachment is arranged in the gap; and the left and right end surfaces and the middle part of the indoor unit are all provided with upper packing liners matched with the shapes of the left and right end surfaces and the middle part of the indoor unit in the length direction. The packing device and the packing method disclosed by the invention have the characteristics that the structure is simple and reasonable, the volume of the complete machine is small, the rigidity is good, the strength is high, the operation is flexible, the fabricating cost is low, and the packing device is easy to pack.

Owner:GUANGDONG GALANZ GRP CO LTD +1

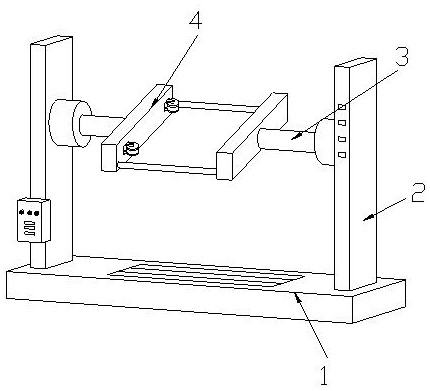

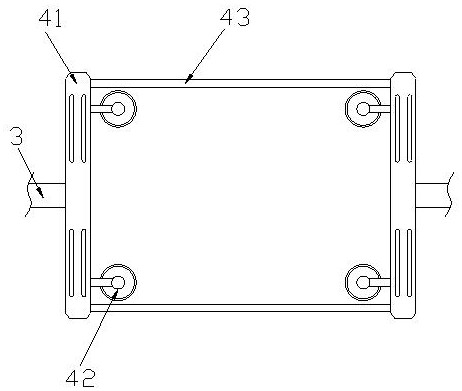

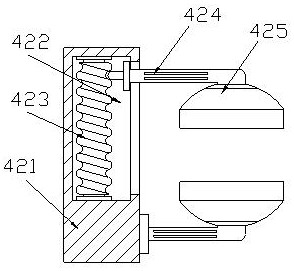

Turnover machine for automobile accessory production

InactiveCN111702730APrevent looseningThere will be no deformationWork holdersWork benchesElastic rodsCar door

The invention discloses a turnover machine for automobile accessory production. The turnover machine structurally comprises a base, two supporting columns, two turnover columns and a clamp, the supporting columns are welded to the two sides of the top end of the base, the two turnover columns are installed on the inner sides of the two supporting columns, the two sides of the clamp are connected with the turnover columns in a welded mode, the clamp comprises a side plate, a clamping device and a connecting rod, the clamping device comprises a fixing block, a groove, a threaded block, a supporting rod and a clamping block, the clamping block comprises a top cover, an elastic rod, a clamping block, a bottom plate, a rotating shaft and a rubber pad, and the rubber pad comprises a rubber body,a mounting groove and an anti-skid groove. According to the turnover machine, an elastic rod is in movable fit with two bottom plates through rotating shafts, when thrust is borne by a vehicle door,the bottom plates can be finely adjusted along with the stress direction of the vehicle door, the thrust borne by the vehicle door is shared to the bottoms of the bottom plate, the stress area of thebottom plates to the vehicle door is increased, and deformation of the vehicle door due to through bearing is avoided.

Owner:广州优讯环保科技有限公司

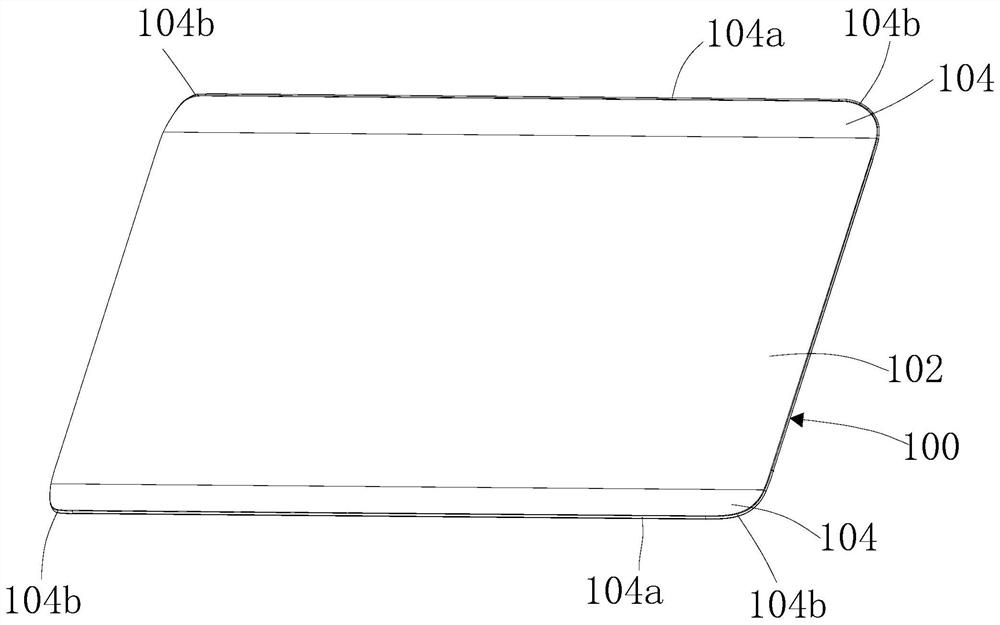

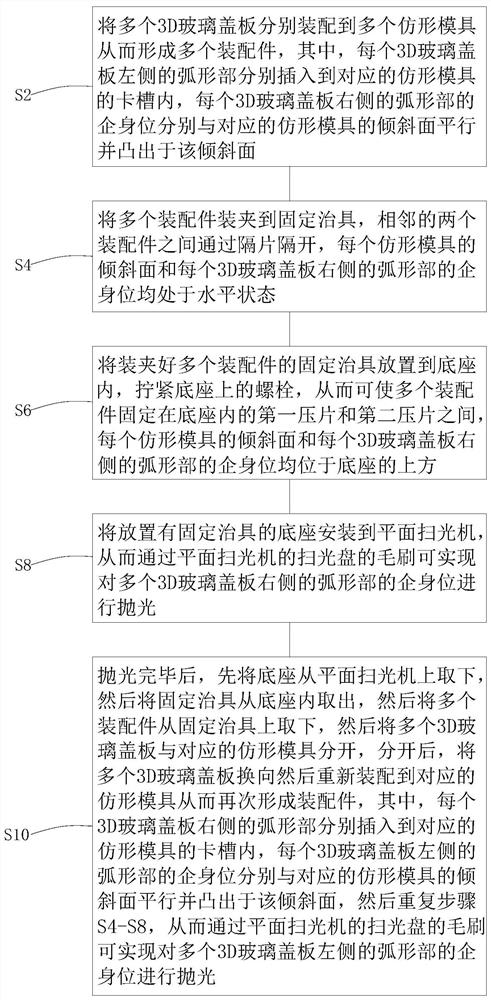

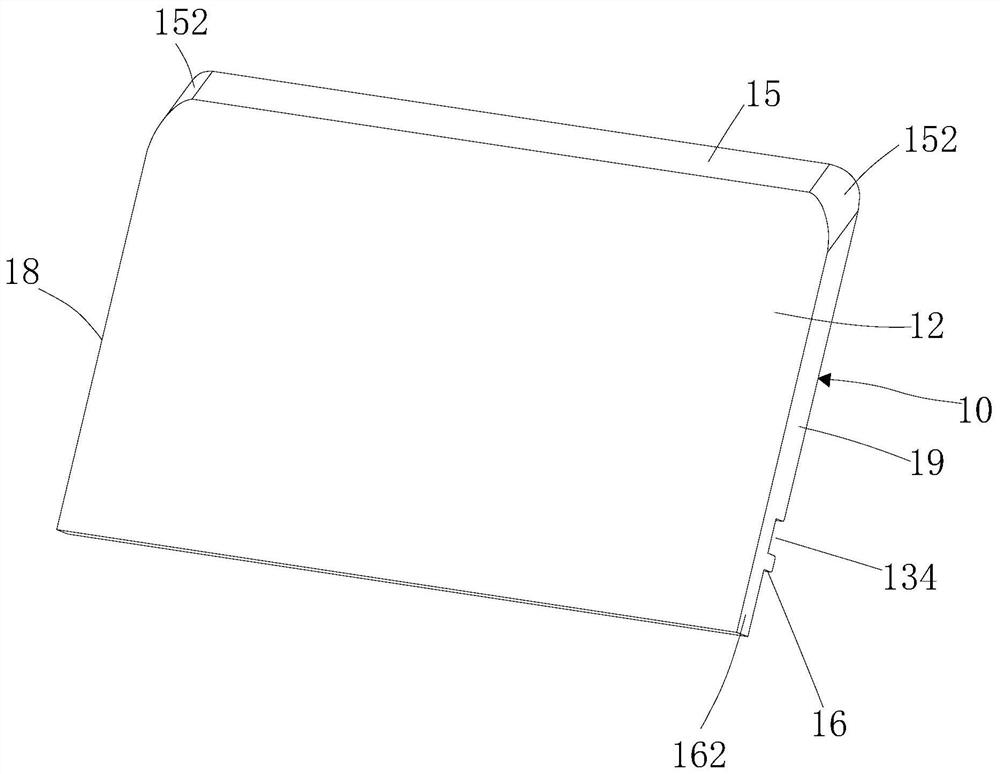

3D glass cover plate rabbet position polishing method

ActiveCN114083354AAvoid contactThere will be no deformationPolishing machinesGlass coverStructural engineering

The invention discloses a 3D glass cover plate rabbet position polishing method, which comprises the following steps that: S2, a plurality of 3D glass cover plates are assembled to a plurality of profiling molds correspondingly, so that a plurality of assembly parts are formed; S4, theplurality of assembly parts are clamped to a fixing jig, the inclined surface of each profiling mold and the rabbet position of the arc-shaped part on the right side of each 3D glass cover plate are in a horizontal state; S6, the fixing jig where the multiple assembly parts are clamped is placed at the bottom in a base, and the inclined face of each profiling mold and the rabbet position of the arc-shaped part on the right side of each 3D glass cover plate are both located above the base; and S8, the base where the fixing jig is placed is installed on a plane sweeping machine, therefore the rabbet positions of the arc-shaped parts on the right sides of the multiple 3D glass cover plates can be polished through a brush of a sweeping disc of the plane sweeping machine. Deformation of the rabbet position of the 3D glass cover plate cannot be caused, the production efficiency is high, and the production cost is low.

Owner:深圳市信濠光电科技股份有限公司

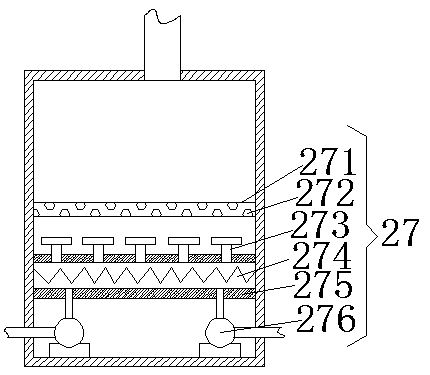

Drying device for electroplating accessories

InactiveCN108870943AIncrease the areaImprove drying effectDrying gas arrangementsDrying machines with progressive movementsPulp and paper industryDrying time

The invention provides a drying device for electroplating accessories, and relates to the field of electroplating processing equipment. The drying device comprises a base, a drying chamber is arrangedon the upper side of the base, an upper supporting block is fixedly arranged at the bottom of the drying chamber, supporting legs are fixedly arranged at the bottom of the upper supporting block, ananti-skid seats are fixedly arranged at the bottoms of the supporting legs, the bottoms of the anti-skid seats are fixedly installed with the top of the base, and a drying box is fixedly arranged inside the drying chamber. According to the drying device for the electroplating accessories, through a heating device, a circulating fan is driven to blow hot air to the electroplating accessories on a conveying belt, so that the drying area is greatly improved, the drying effect is enhanced, and the drying time is saved; through the conveying belt, the electroplating accessories can be automaticallyconveyed into a recovery device, and then the electroplating accessories are dried, so that the drying effect is improved, and the labor force is reduced; and air distribution pipes are arranged so that air can be uniformly conveyed into the electroplating accessories on a placing plate, then the electroplating accessories are heated more uniformly, and the drying effect is greatly improved.

Owner:杨煜海

Anti-deformation cutting device of plastic cosmetic bottle

ActiveCN112248058AEffectively fixedThere will be no deformationHollow article cleaningDirt cleaningBiomedical engineeringComposite material

The invention discloses an anti-deformation cutting device for a plastic cosmetic bottle, and belongs to the technical field of cosmetic bottles. The anti-deformation cutting device comprises a bottomplate and side plates, the side plates are fixedly connected to the left side and the right side of the upper surface of the bottom plate correspondingly, adjusting mechanisms are arranged on the opposite surfaces of the two side plates, a fixing plate is fixedly arranged between the two adjusting mechanisms, a cutting mechanism is arranged on the fixing plate, and a supporting plate is arrangedon the rear side of the cutting mechanism and fixedly connected to the back face of the fixing plate. According to the cutting device, a clamping mechanism is arranged, the cosmetic bottle can be clamped when two clamping plates get close to each other, the cosmetic bottle can be inflated when an inflation mechanism works so that the interior of the cosmetic bottle can be in an expanded state, andtherefore when the cosmetic bottle is cut by a cutting wheel to be extruded, the pressure cannot greatly influence the internally expanded cosmetic bottle, so that the cosmetic bottle does not deformwhen cut, the rejection rate of the cosmetic bottle is greatly reduced, and the processing efficiency of the cosmetic bottle is further improved.

Owner:徐州鸿源玻璃科技有限公司

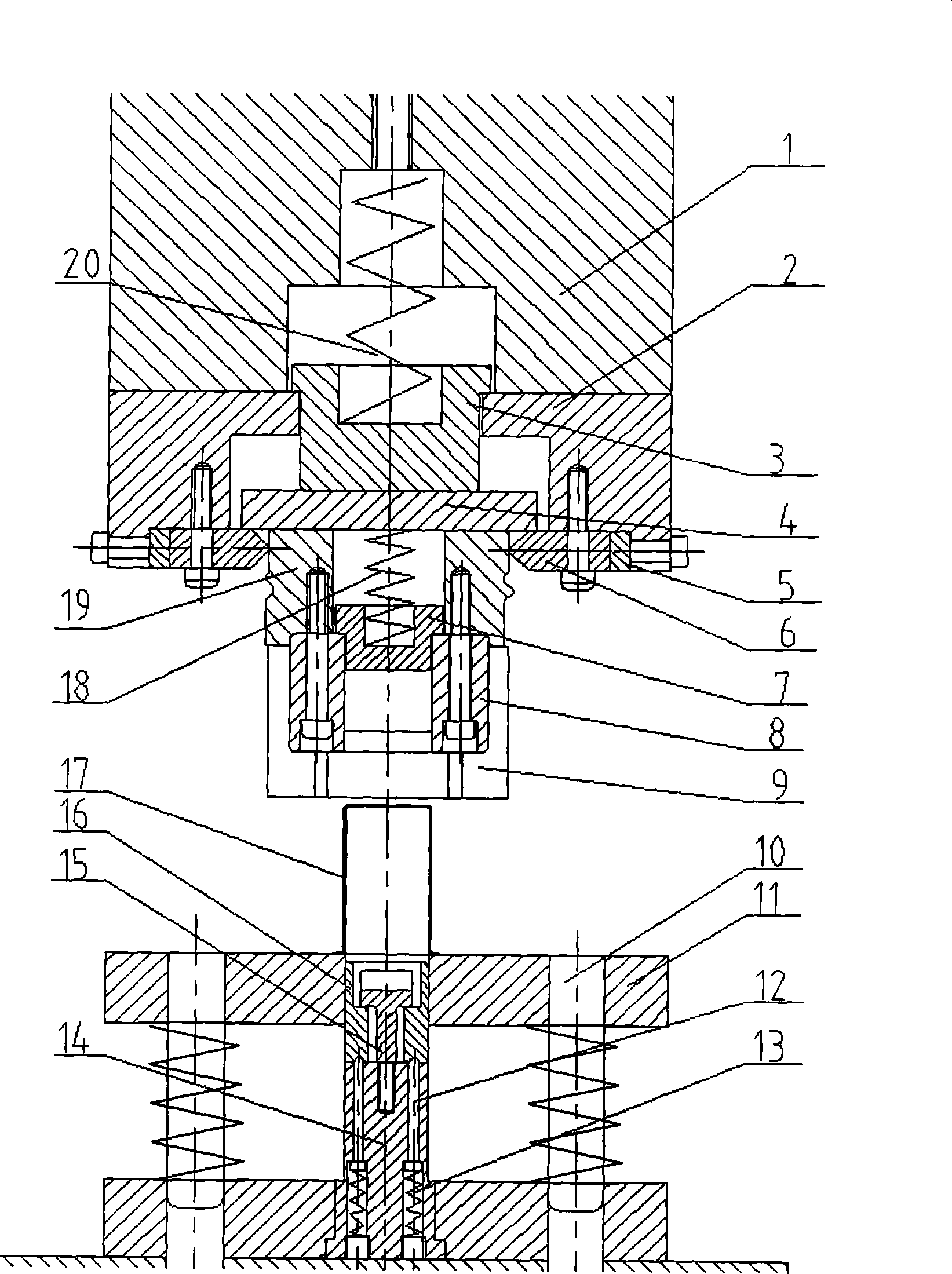

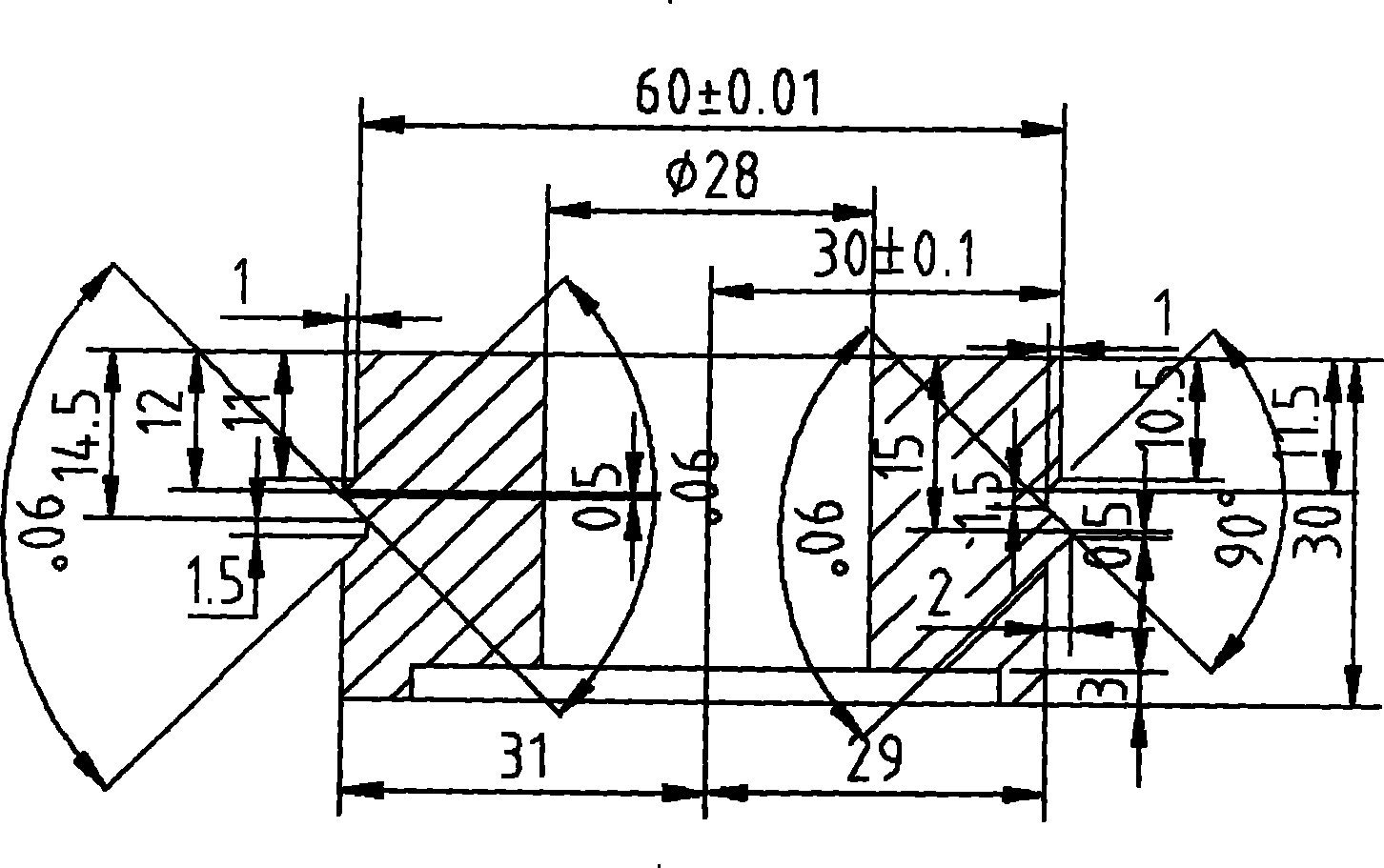

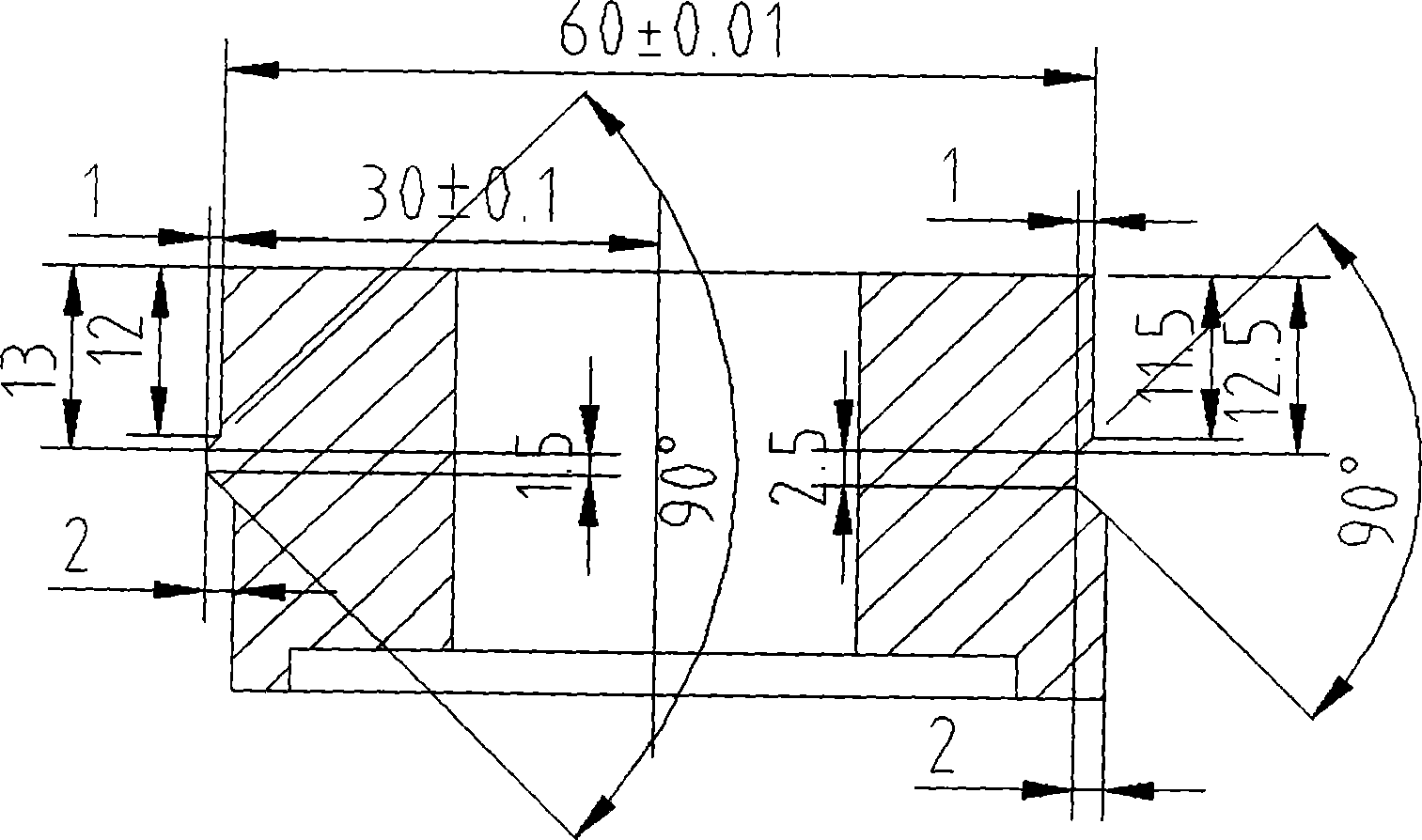

Revolving cutting mechanism for one-die two-yield precise sleeve member

The invention discloses a revolving cutting mechanism for a one-die two-yield precise sleeve member. The revolving cutting mechanism comprises an upper die part and a lower die part. The upper die part comprises a large empty pad, a small empty pad and a swinging block; a large spring, a spring pad and a hanging plate are arranged in the large and the small empty pads; an adjusting block and power-assisted blocks are arranged on the small empty pad; the hanging plat is arranged on an upper part of the swinging block; a revolving cutting concave die and a limiting block are arranged on the lower part of the swinging block; and a middle spring and a top core are arranged in the swinging block. The lower die part comprises a discharging plate and a revolving cutting convex die; the revolving cutting convex die is arranged on a pedestal and corresponds to the revolving cutting concave die of the upper die part; a guide post is arranged on the discharging plate; a movable block and a limit pin are arranged on the revolving cutting convex die; and a pilot pin and a small spring are arranged in the revolving cutting convex die. The power-assisted blocks are respectively fixed at the front side, the back side, the left side and the right side of the lower empty pad of the upper die part; the inner sides of the power-assisted blocks are matched with the outer side of the swinging block; the end spherical surface of the pilot pin on the revolving cutting convex die is matched with the bottom of the movable block; and the movable block is tightly pressed by the small spring. According to the invention, two precise sleeve members required by a high cylinder degree can be simultaneously and efficiently cut, so that the cost is saved.

Owner:JINHUA VOCATIONAL TECH COLLEGE

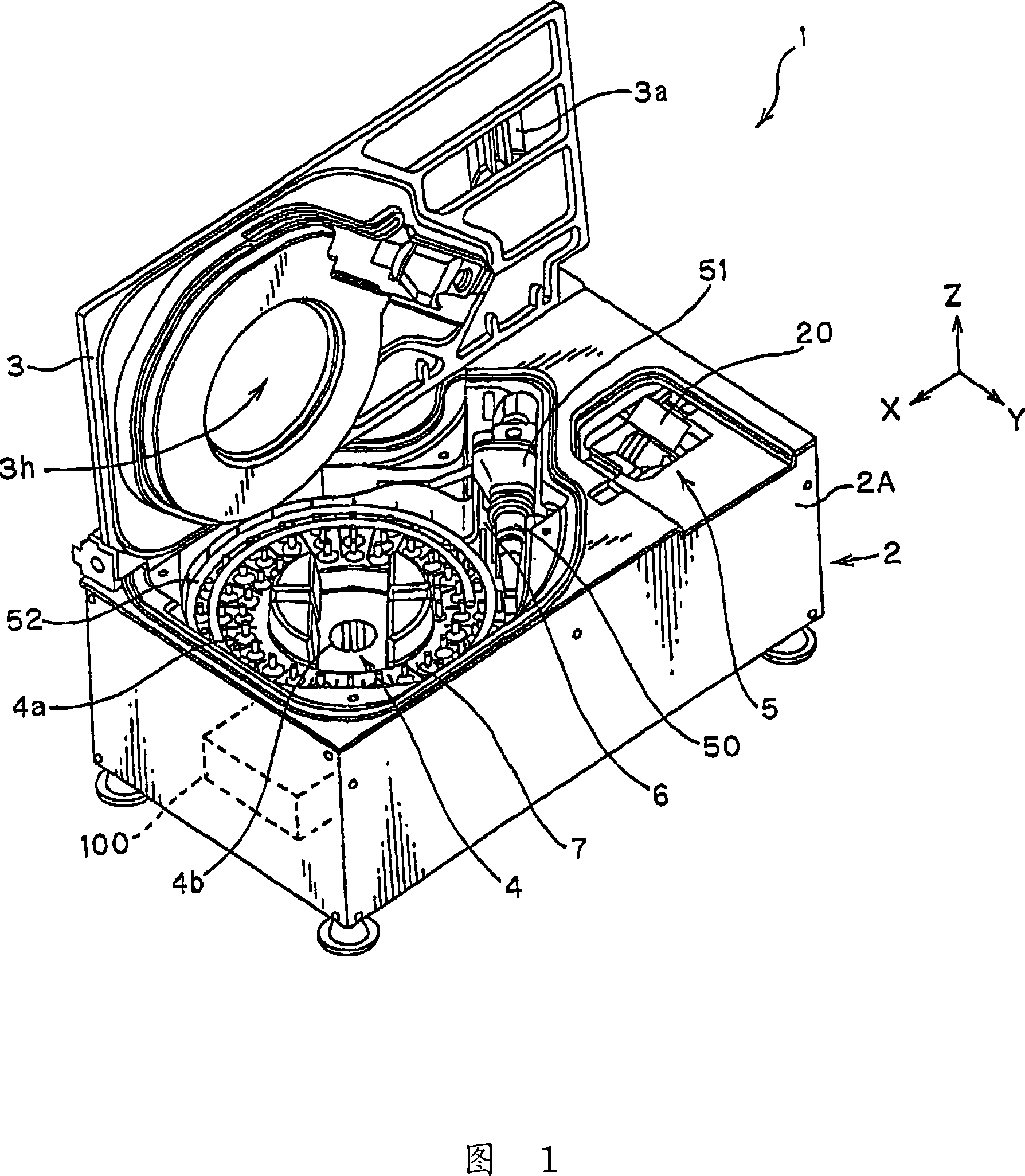

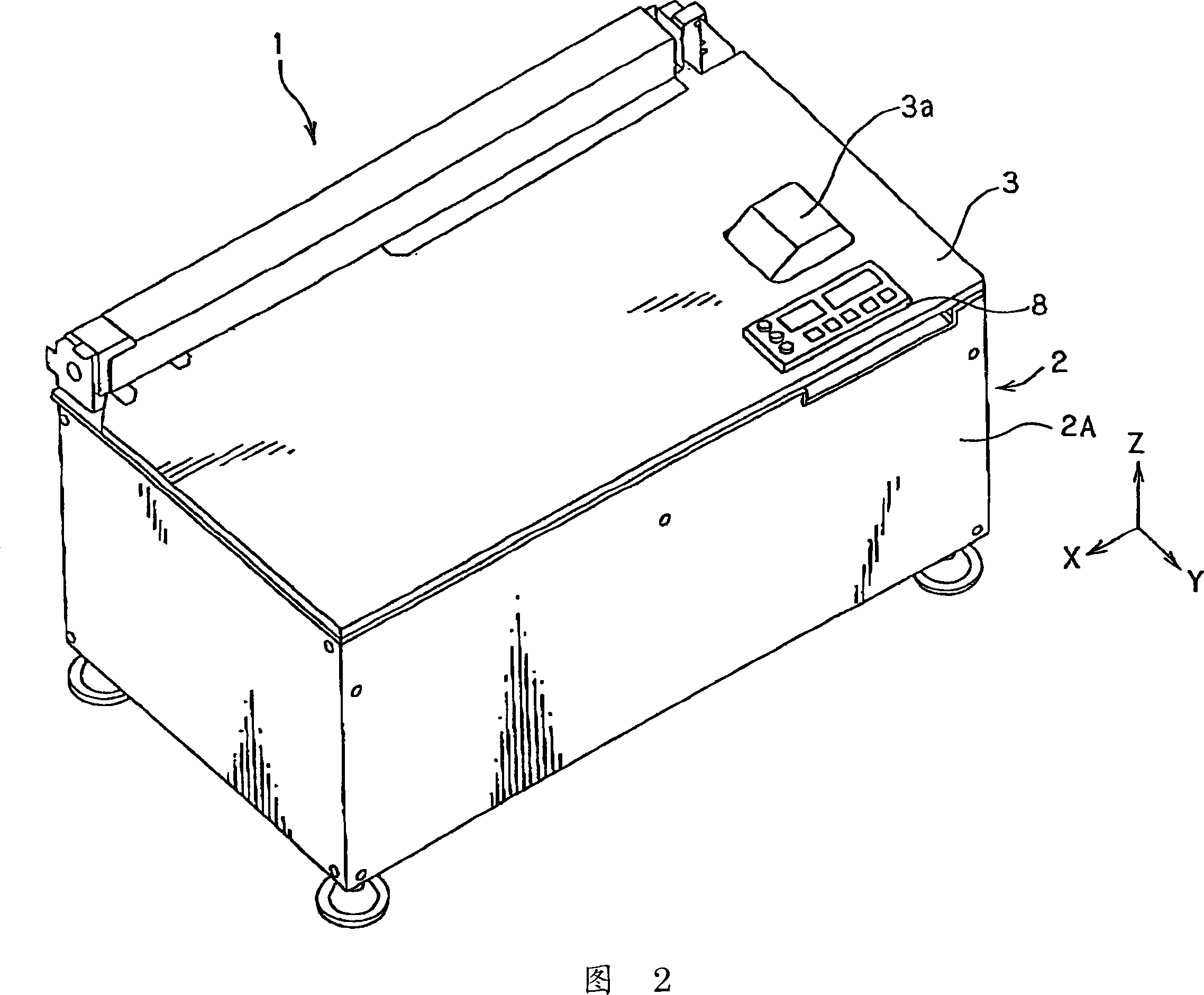

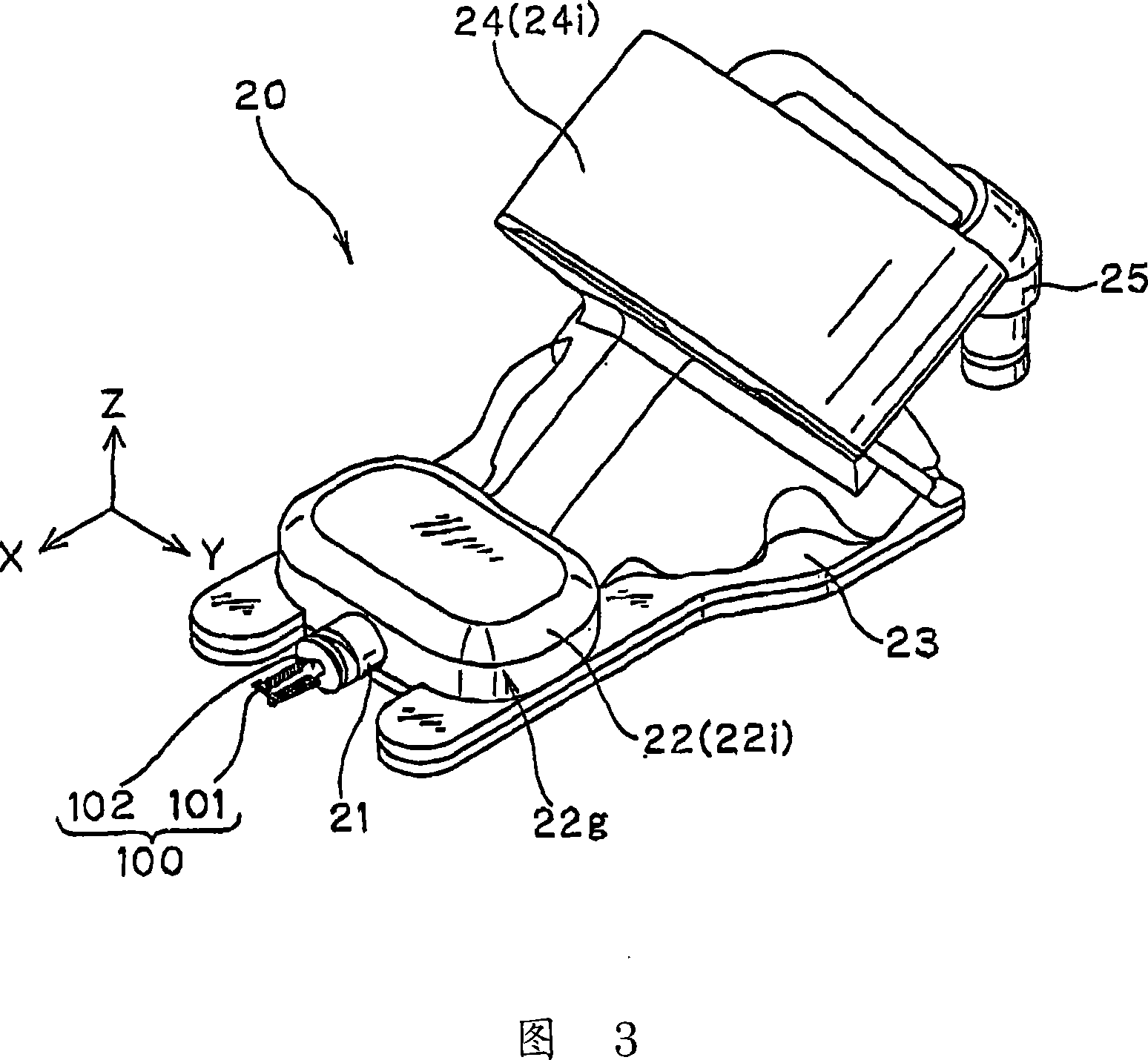

Apparatus for washing and disinfecting endoscope and brush cassette detachably attached thereto

InactiveCN101061944AThere will be no deformationEasy to cleanBrush bodiesSurgeryEndoscopic washingEndoscope

An endoscope washer-disinfector and a brush cassette are disclosed. The apparatus has a slot disposed on the casing, and the endoscope is cleaned and disinfected in the slot. A brush unit is detachably loaded to a loading part of the washer-disinfector. Inside the brush unit, first and second members are formed to hold the handle thread therebetween for making the handle thread advance and retreat to and from the duct of the endoscope. A brush is disposed at the front of the shaft tight for cleaning. When the brush unit is not mounted to the fixed part, a releasing lock device separates the second member from the first member to a set first position, and lock the separating state. When the brush unit is mounted to the fixed part, the releasing lock device opeates responsively to an mounting operation and releases the lock by the applied force and allows the second member to be moved to a second position where the first and second members hold the handle thread. When the brush unit is mounted to the fixed part, the lock is released because the force is applied to the lock part.

Owner:OLYMPUS MEDICAL SYST CORP

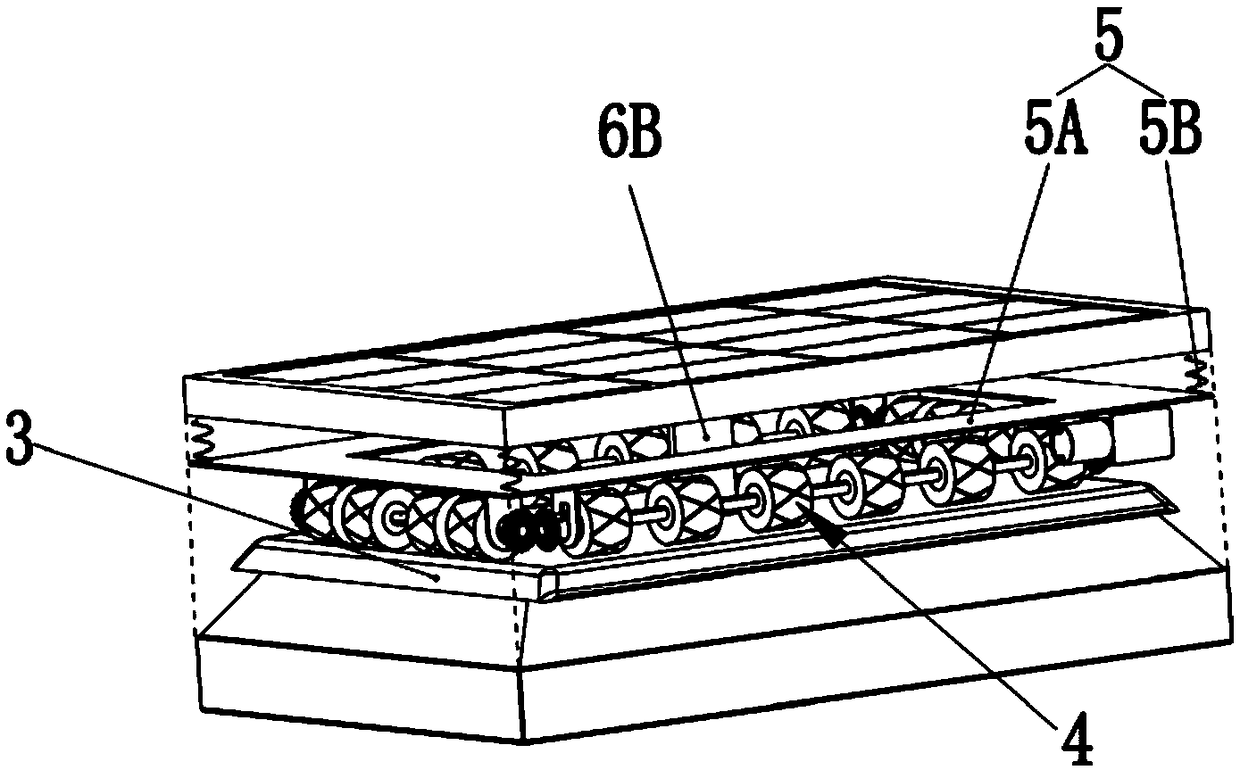

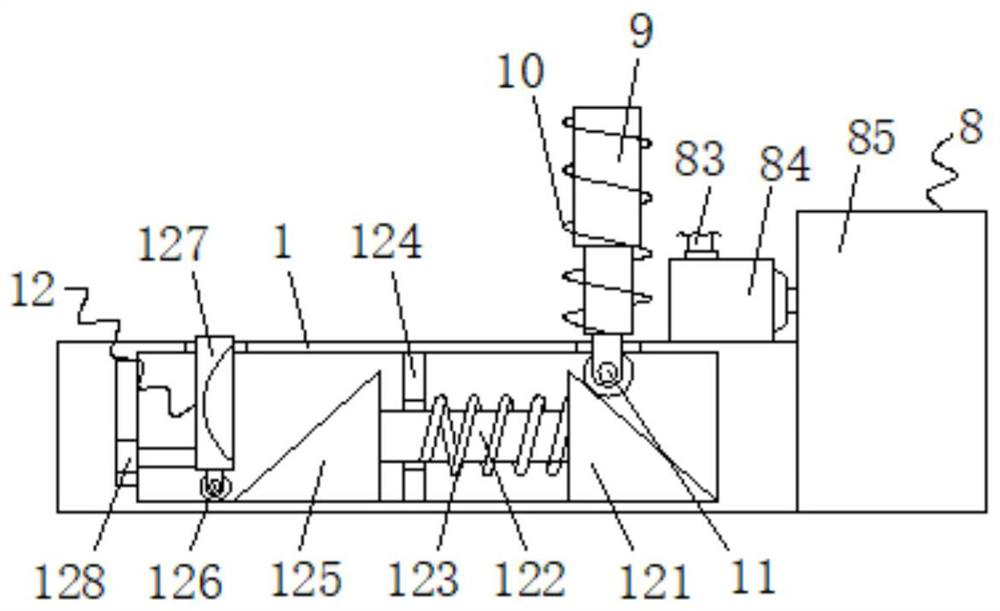

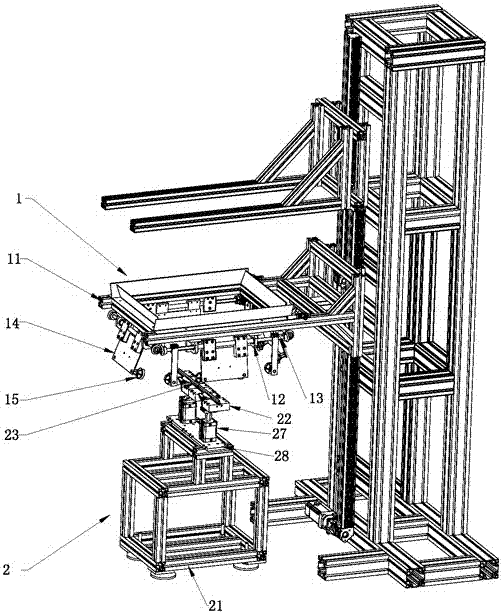

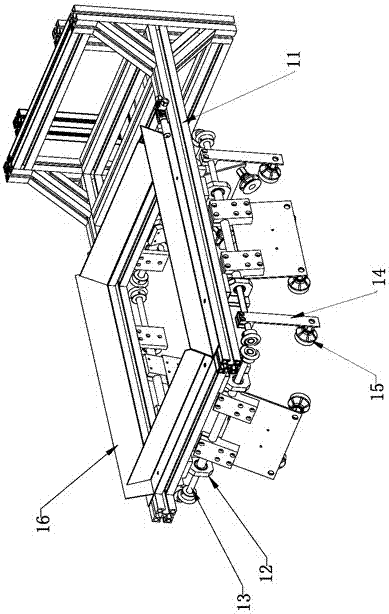

A kind of automatic packing equipment

ActiveCN105197270BThere will be no deformationImprove packaging efficiencyIndividual articlesEngineeringMechanical engineering

The invention provides automatic packing equipment. A bearing assembly for the equipment bears a stack from the position where packing is to be carried out, then a box sleeves the stack from top to bottom, after sleeving is finished, the lower portion is sealed, and in this way, the whole stack can be loaded into the box by means of one action; moreover, as an opening is downward, the situation of deformation of the opening is avoided, and the packing efficiency is greatly improved.

Owner:QKM TECH (DONG GUAN) CO LTD

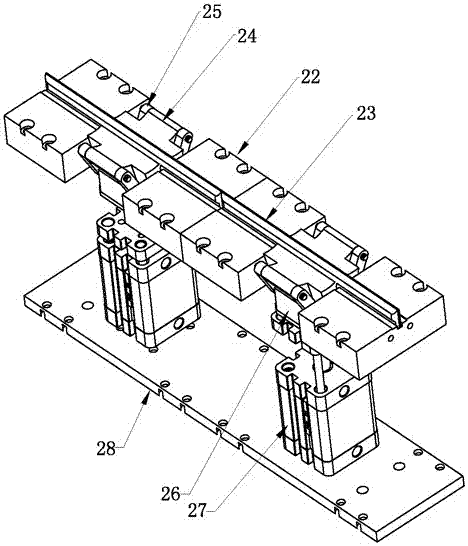

Moving device for insertion plate of material bin

The invention discloses a moving device for an insertion plate of a material bin. The moving device comprises the insertion plate, a guide plate, a lead screw, a threaded sleeve, a lead screw fixing device and a driving device. The guide plate is fixed to a discharging port of the material bin, a guide groove is formed in the guide plate, the top end of the insertion plate is movably arranged in the guide groove, the threaded sleeve is fixed to the tail end of the insertion plate, the lead screw is sleeved with the threaded sleeve, one end of the lead screw is arranged on the lead screw fixing device in a rotatable mode, and the other end of the lead screw is fixedly connected with a driving shaft of the driving device. In the use process, the driving device is started and drives the lead screw to rotate, and the lead screw rotates to drive the threaded sleeve to move forwards or backwards, so that the insertion plate is driven to move forwards or backwards in the guide groove, and the discharging port of the material bin is opened and closed. By the adoption of lead screw driving, thrust is very stable and continuously exerted, so that the insertion plate does not deform, meanwhile, the amount of labor is reduced, and working efficiency is improved.

Owner:花垣县太丰冶炼有限责任公司

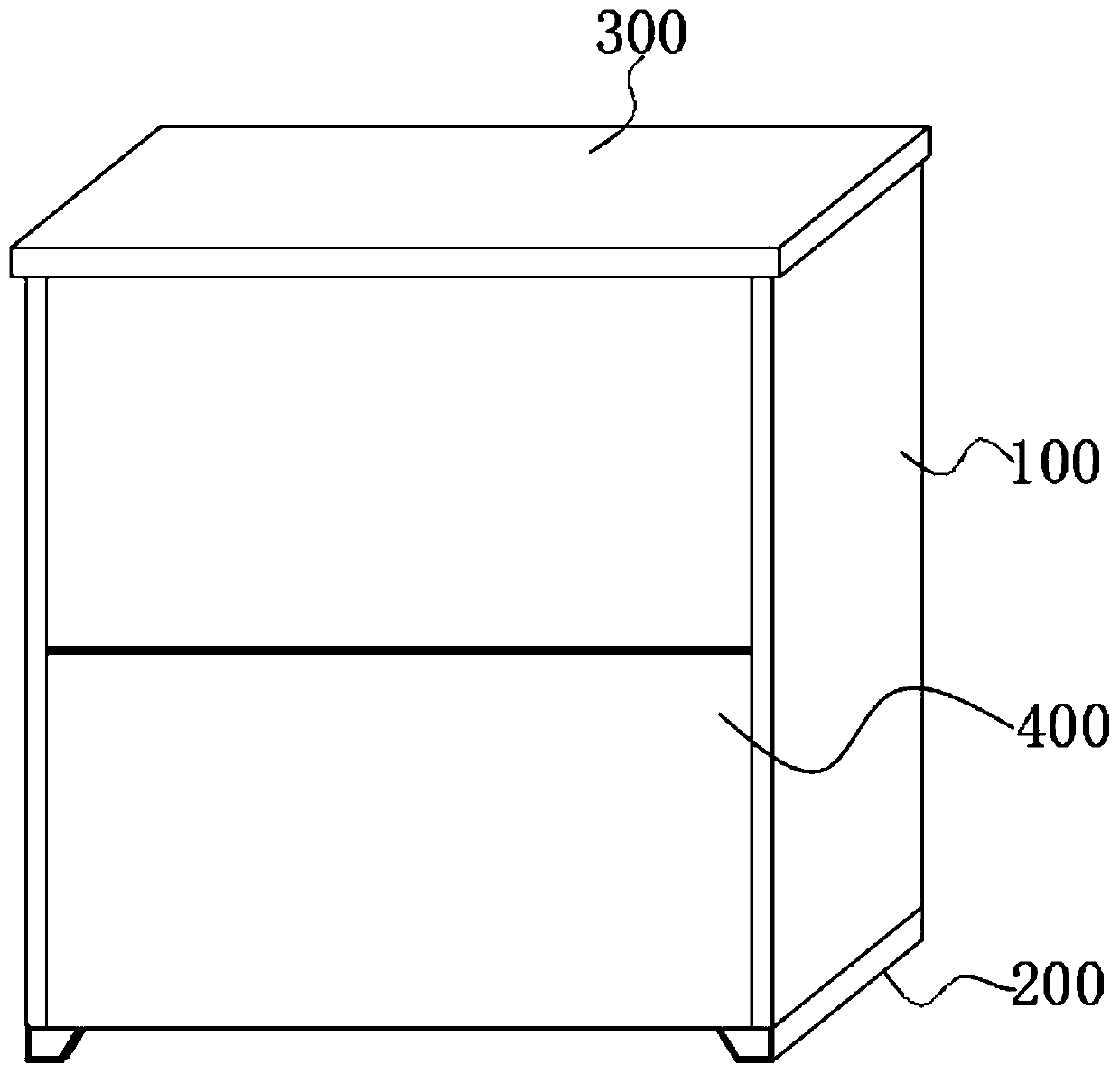

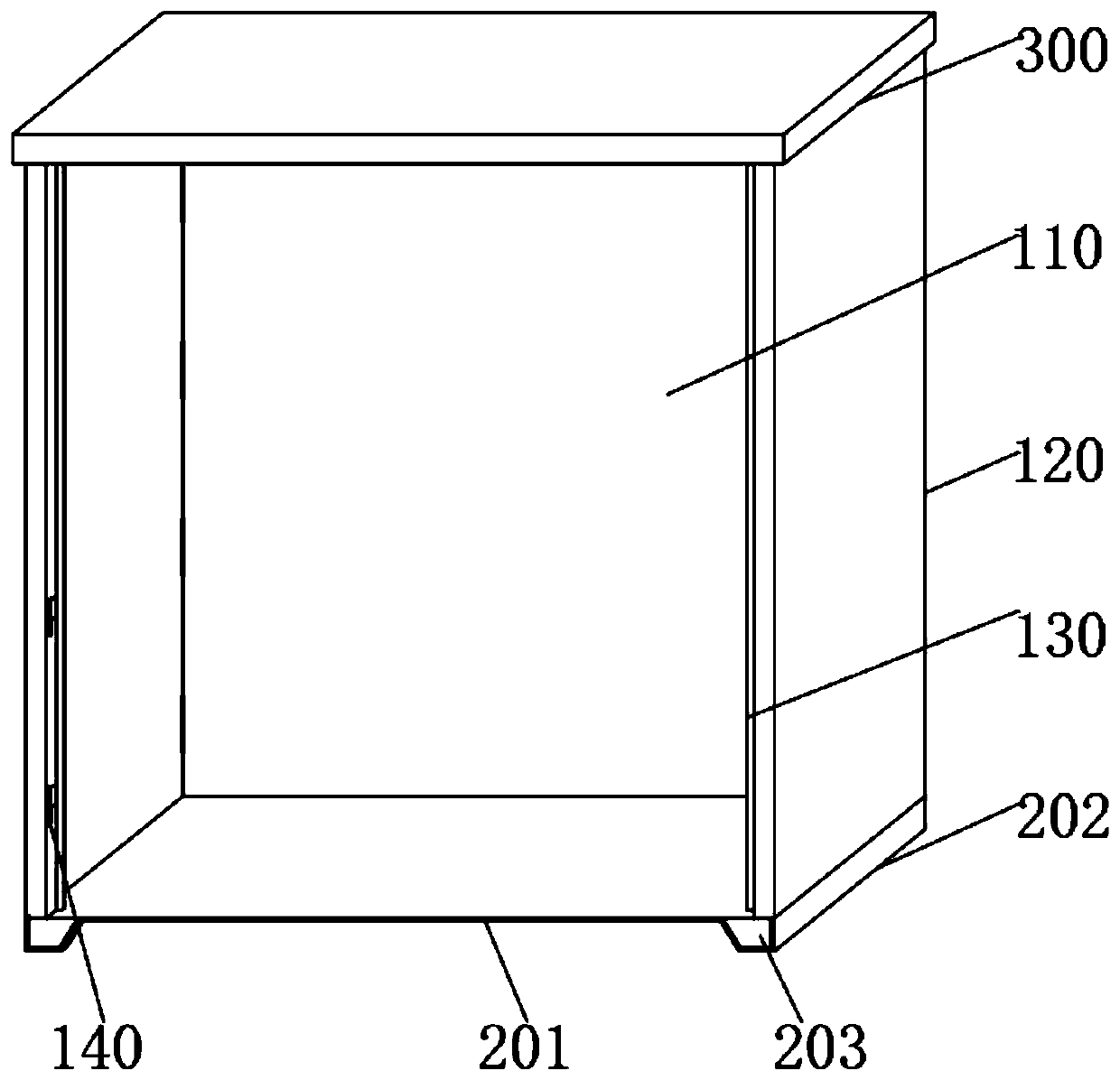

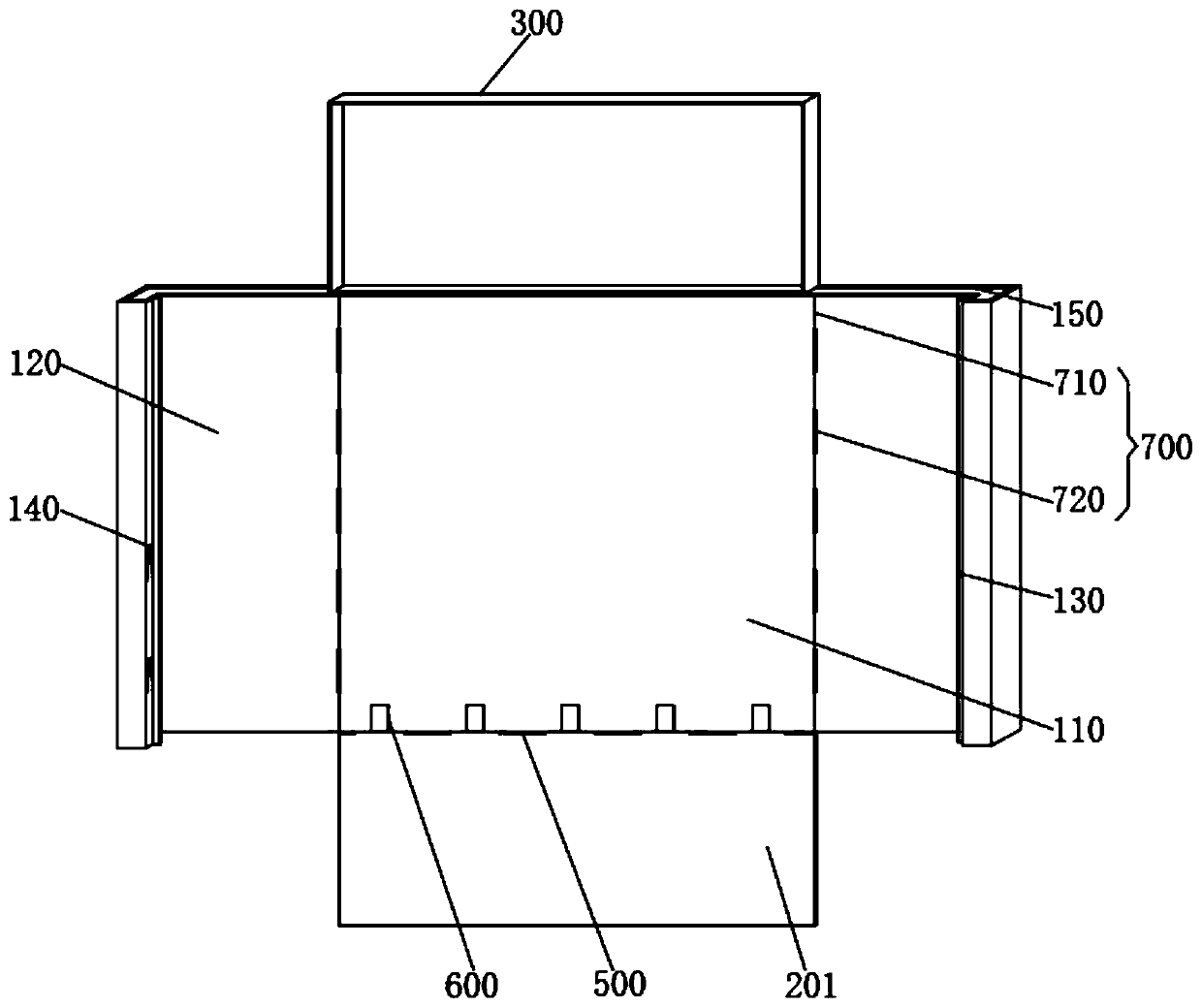

Folding-type fire extinguisher box

PendingCN110694203AThere will be no deformationSmall footprintFire rescueEngineeringStructural engineering

The invention relates to a folding-type fire extinguisher box which includes a box body, a base fixedly connected to the bottom of the box body, a top cover sleeving the top of the box body and a boxdoor sleeving the box body. The box body includes a back plate. An entire plate is cut by means of laser cutting and bending, and the fire extinguisher box is formed by bending treatment, so that thesteps of cutting plates according to size of different part and welding the plate into a whole during machining of an existing product are reduced. The folding-type fire extinguisher box has the advantages that during transportation, the fire extinguisher box can be unfolded into an integral plate, the area occupied by the box body during transportation is reduced, the transportation volume is increased, the integral plate is not deformed when being pressed, even if the deformation occurs, the plate can still be spliced into the box body through treatment, the reject rate and damage rate are reduced, carrying is convenient, the convenience of online sales and delivery is realized, and the subsequent assembly is very convenient.

Owner:安徽向阳消防安全科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com