A kind of automatic packing equipment

A technology of automatic boxing and equipment, applied in the direction of packaging, transportation and packaging, single objects, etc., can solve the problems of low boxing efficiency, inappropriateness, troublesome boxing efficiency, etc., and achieve the effect of improving boxing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

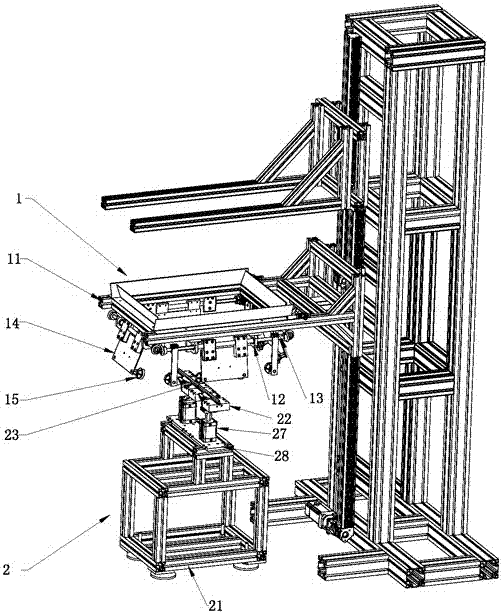

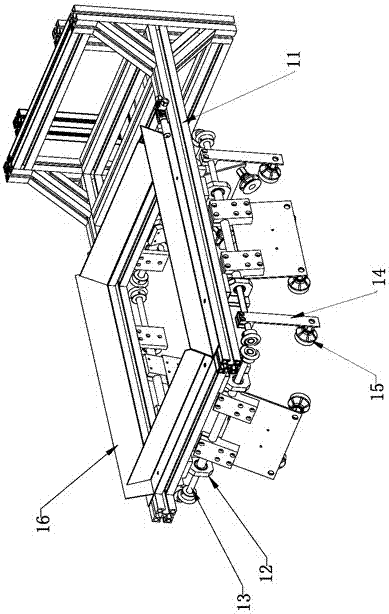

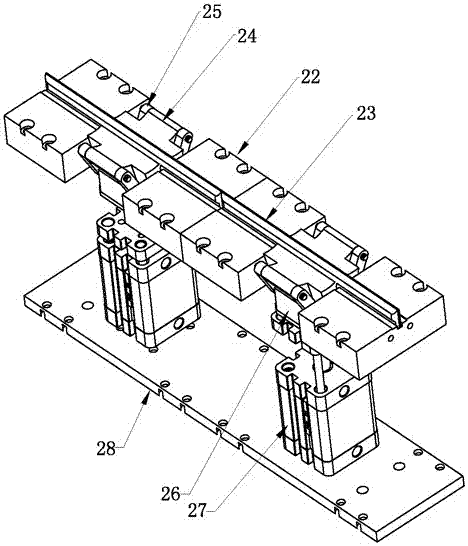

[0032] The present invention is further described in conjunction with the following examples.

[0033] The invention creates a specific embodiment of automatic box sealing equipment, which includes: a stacking part, a box forming part, a box fitting part and a box sealing part. In this embodiment, the stacks that need to be packed are as follows: Figure 7 As shown, it is formed by stacking a plurality of boxes at the stacking part, and the lower edge of each box has a bottom flange 4, and the box used for packaging box stacking in this embodiment is as follows Figure 8 As shown, it includes a square box body 51, the upper and lower ends of the box body 51 are open, and the periphery of each opening is provided with two oppositely arranged pre-sealing plates 52 and two oppositely arranged full-sealing plates 53 . Two pre-sealing plates 52 are arranged oppositely. The pre-sealing plate 52 does not completely seal the opening when sealing, but misses the supporting assembly 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com