Revolving cutting mechanism for one-die two-yield precise sleeve member

A technology of one mold, two outs, and sleeve parts, applied in the field of mold manufacturing, can solve the problems of deformation, the punch cannot be supported by the sleeve parts, and it does not have the ability to produce two precision sleeve parts at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

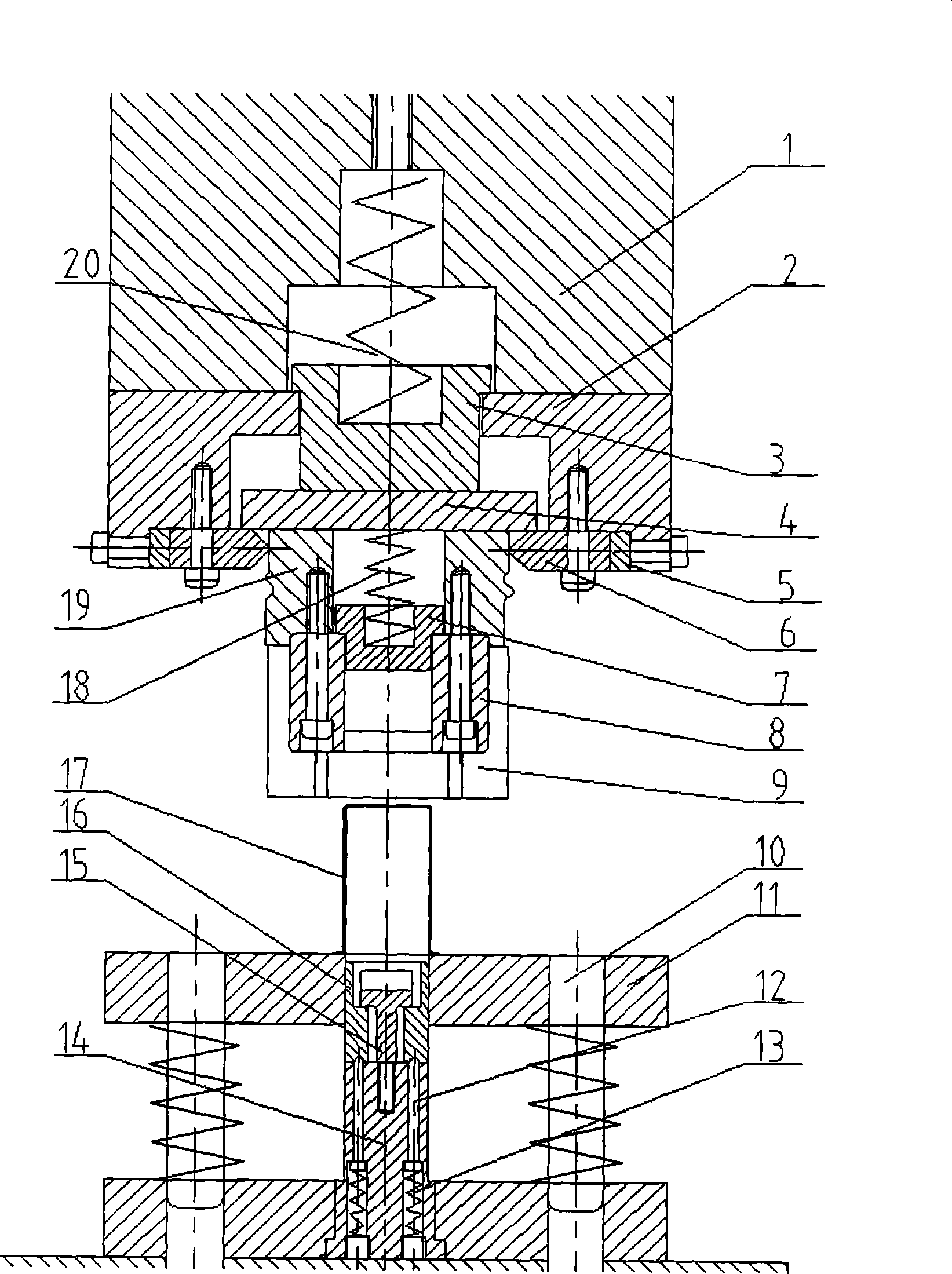

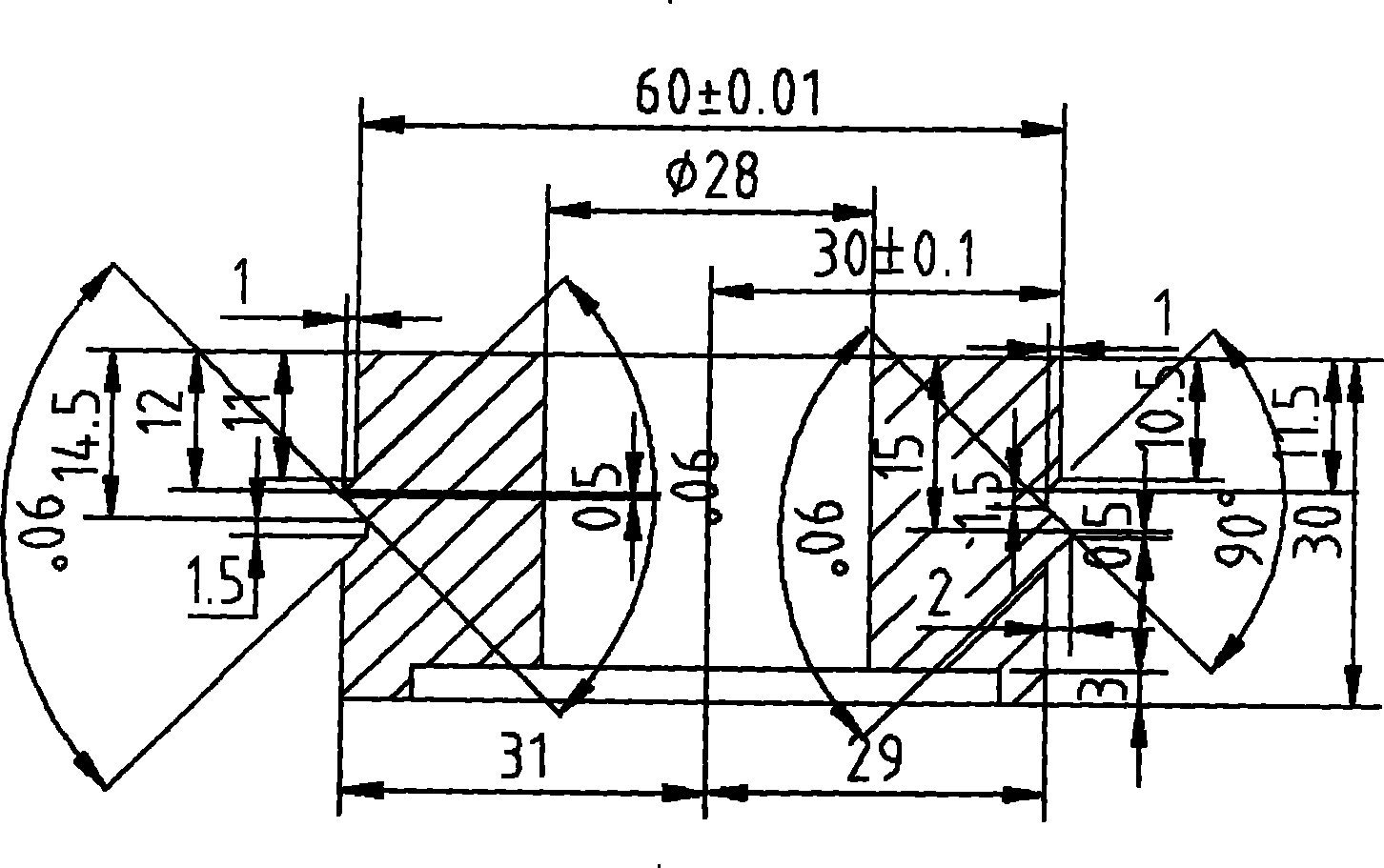

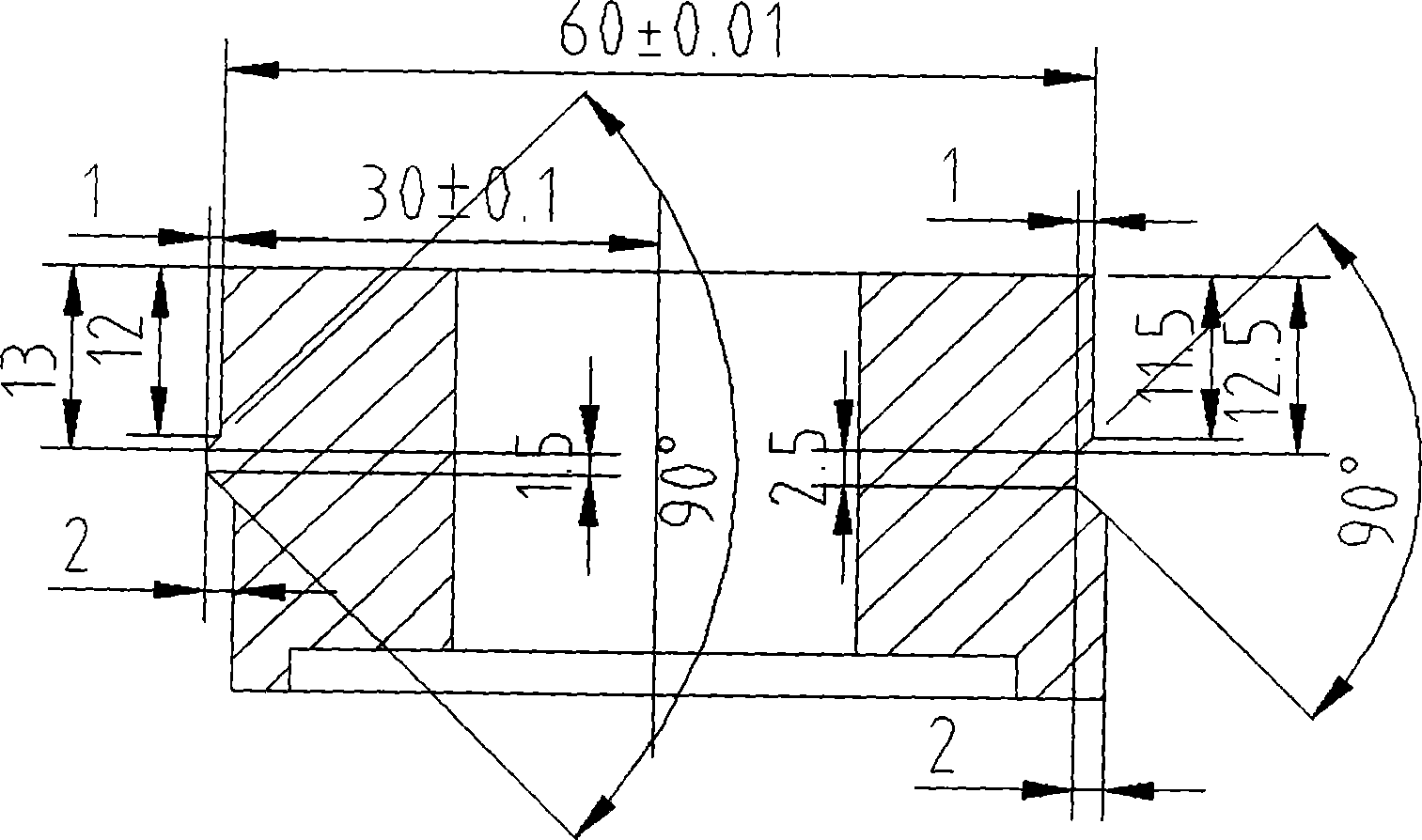

[0019] figure 1 It is a sectional view of an assembly of an embodiment of the present invention; figure 2 It is a front sectional view of a swing block according to an embodiment of the present invention; image 3 It is a left sectional view of the swing block according to the embodiment of the present invention; Figure 4 It is a perspective view of a swing block according to an embodiment of the present invention; Figure 5 It is a movement path diagram of the central axis of the ring-cut once ring-cut die according to the embodiment of the present invention.

[0020] like figure 1 As shown, the circumcision mechanism of one mold with two precision sleeve parts includes an upper mold part and a lower mold part, wherein:

[0021] The upper mold part includes a large empty pad 1, a small empty pad 2, and a swing block 19 in order from top to bottom. The space formed by the connection of the large empty pad 1 and the small empty pad 2 is provided with a large spring 20, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com