Rotary type four-way reversing valve and air conditioner

A four-way reversing valve, rotary type technology, applied to multi-way valves, valve devices, cocks including cut-off devices, etc., can solve problems such as slider deformation, liquid hammer damage, and affecting the reliability of four-way reversing valves , to avoid liquid hammer damage and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

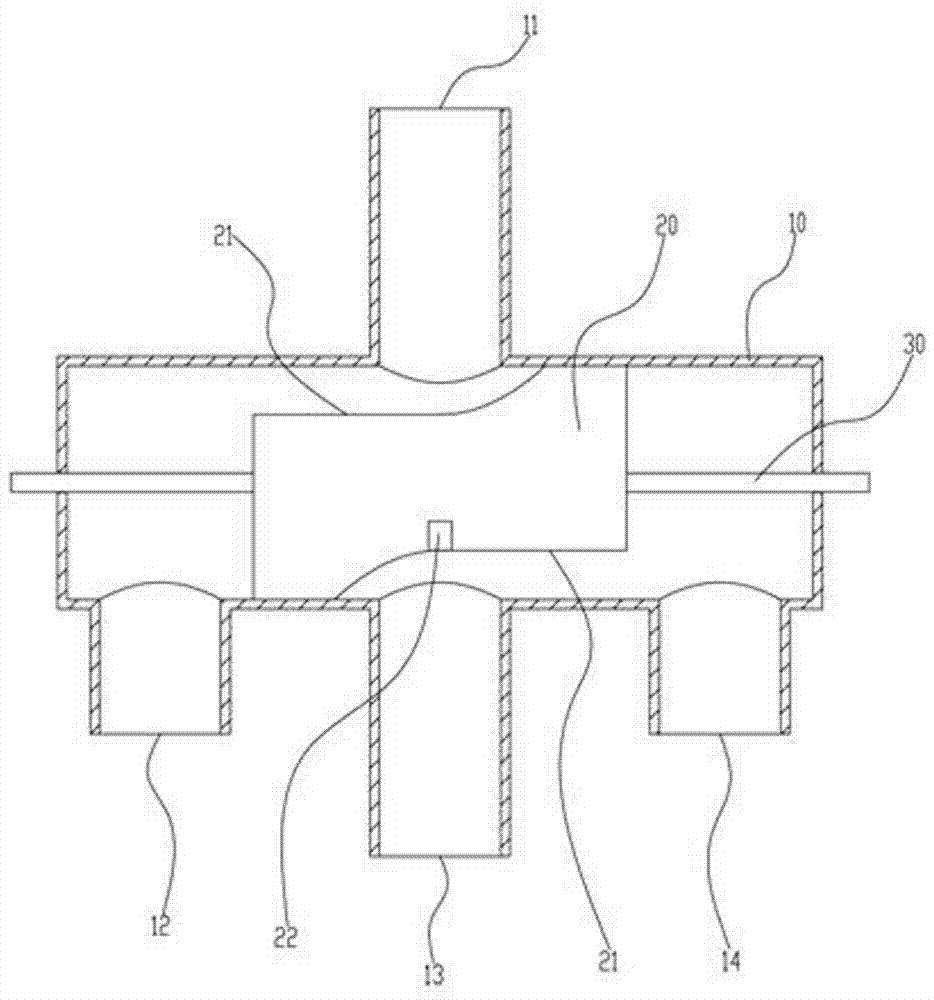

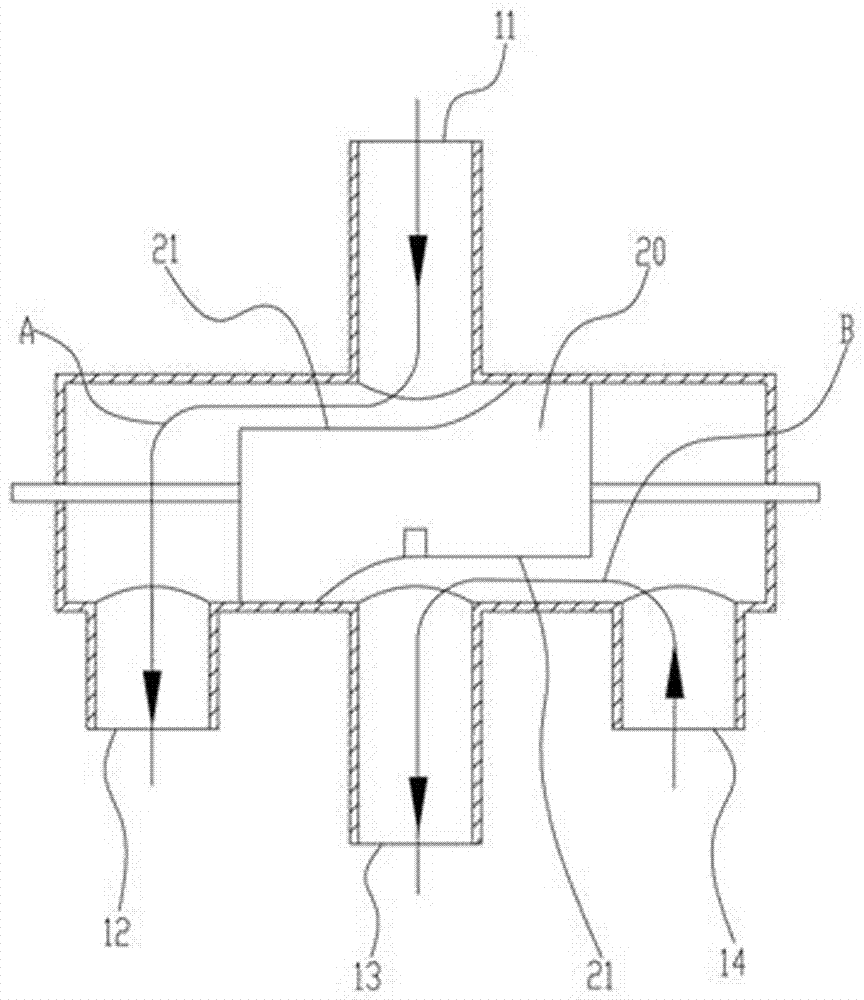

[0036] Such as figure 1 with figure 2 , the rotary four-way reversing valve proposed in the first embodiment of the present invention, the four-way reversing valve can be applied in air conditioners, the four-way reversing valve includes a valve body 10 and a valve core 20, the valve body 20 A fluid inlet 11, a fluid outlet 13, a first interface 12 and a second interface 14 are arranged on the upper body. In this embodiment, the fluid inlet 11 is arranged on one side of the valve body 10, and the first interface 12, the fluid outlet 13 and the second interface 14 are arranged side by side on the opposite side of the valve body 10.

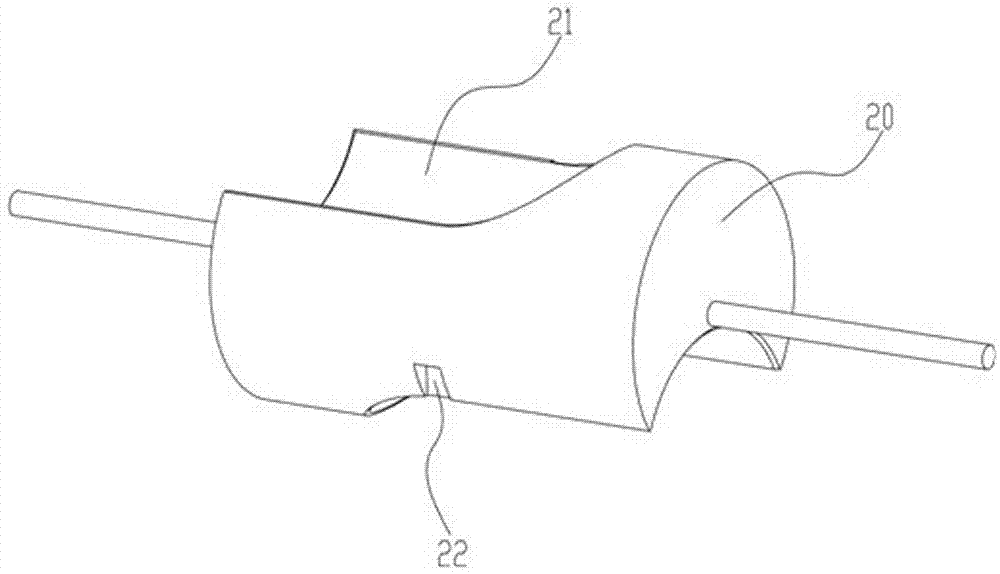

[0037] The valve core 20 is cylindrical. The valve core 20 is rotatably arranged in the valve body 10 and is coaxial with the valve body 10 . The valve core 20 is provided with two centrally symmetrical flow guides 21, through which the fluid inlet 11 is switched to communicate with the first port 12 and the second port 14, and the fluid outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com