Turnover machine for automobile accessory production

A turning machine and auto parts technology, which is applied in the field of auto parts and auto repair, can solve the problems of force deformation at the contact position of the door and the fixture, and affect the appearance of the door, so as to avoid deformation and increase the force bearing area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

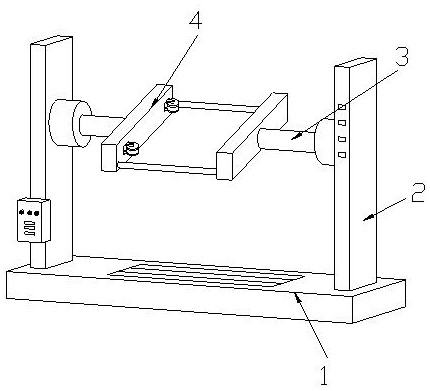

[0026] Example 1: Please refer to Figure 1-Figure 6 , the specific embodiments of the present invention are as follows:

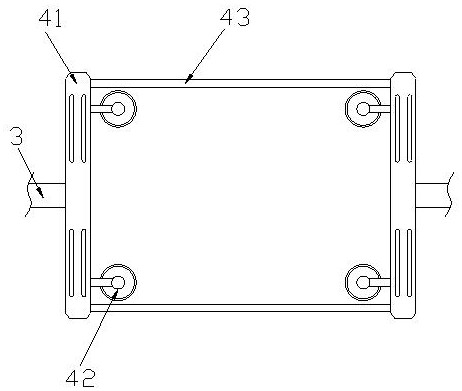

[0027] Its structure includes a base 1, a supporting column 2, an overturning column 3, and a fixture 4. The supporting columns 2 are welded on both sides of the top of the base 1, and there are two overturning columns 3, which are respectively installed on the two supporting columns. 2, both sides of the fixture 4 are welded to the flip column 3, the fixture 4 includes a side plate 41, a clamping device 42, and a connecting rod 43, and the side plate 41 is provided with two, and the clamping There are four devices 42 installed in the two side plates 41 respectively, and two connecting rods 43 are provided and connect the two side plates 41 .

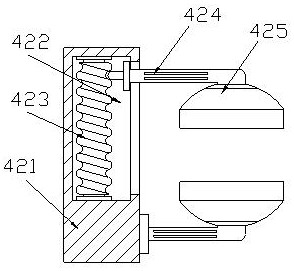

[0028] The clamping device 42 includes a fixed block 421, a groove 422, a threaded block 423, a support rod 424, and a clamping block 425. The inside of the fixed block 421 is provided with a groove 422 in the midd...

Embodiment 2

[0033] Example 2: Please refer to Figure 7-Figure 8 , the specific embodiments of the present invention are as follows:

[0034] The clamping block 425 includes a top cover c1, an elastic rod c2, an engaging block c3, a bottom plate c4, a rotating shaft c5, and a rubber pad c6. The inside of the top cover c1 is hollow, and the elastic rod c2 is embedded in In the middle of the inside of the top cover c1, there are two engaging blocks c3, which are respectively embedded and fixed on both sides of the bottom of the top cover c1, and two bottom plates c4, which are engaged with the engaging blocks c3 , the rotating shaft c5 connects the elastic rod c2 and the two bottom plates c4, the rubber pad c6 is provided with two, and fits on the bottom of the two bottom plates c4, the elastic rod c2 is movably matched with the bottom plate c4, It is beneficial to keep the bottom plate c4 parallel to the door, so as to avoid deformation of the door due to force.

[0035] The rubber pad c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com