Thixotrope for packaging LED (light emitting diode ) chip

A technology of LED chips and thixotropes, applied in the field of thixotropes, can solve the problems of increasing cost, reducing light transmittance, uneven color temperature, etc., and improving the resistance to cold and thermal shock, improving elongation at break, elongation at break, etc. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

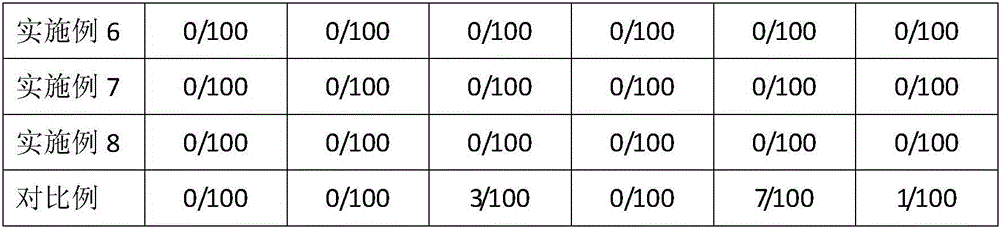

Examples

Embodiment 1

[0023] Component A consists of 60 parts by weight of 5000mPa.s vinyl-terminated silicone oil, 5 parts by weight of polyvinyl silicone oil with a viscosity of 5000mPa.s and a vinyl content of 5wt%, 5 parts by weight of a thixotropic agent, and 0.1 part by weight of a catalyst, and mix Uniform; B component consists of 50 parts by weight of vinyl MQ silicone resin with a vinyl content of 0.9wt% and MQ resin content of 60wt%, 15 parts by weight of a chain extender with a viscosity of 1500mPa.s, and 3 parts by weight of a hydrogen content of 1.5wt%. It is composed of hydrogen-containing silicone oil, 2 parts by weight of KH560, and 0.01 part by weight of inhibitor, and mixed uniformly; A:B components are mixed uniformly according to the ratio of 1:1 by weight, and after vacuum defoaming, the thixotropic compound for LED chip packaging can be obtained. glue. The vulcanization temperature of the thixotropic rubber is 80°C for 5 hours.

Embodiment 2

[0025] Component A consists of 30 parts by weight of vinyl-terminated silicone oil with a viscosity of 300mPa.s, 20 parts by weight of vinyl-terminated silicone oil with a viscosity of 5000mPa.s, 10 parts by weight of vinyl-terminated silicone oil with a viscosity of 100000mPa.s, 2 parts by weight of vinyl-terminated silicone oil with a viscosity of 10000mPa.s and ethylene Polyvinyl silicone oil with a base content of 10wt%, 8 parts by weight of a thixotropic agent, and 0.1 part by weight of a catalyst, and mixed uniformly; component B consists of 30 parts of vinyl-terminated silicone oil with a viscosity of 3500mPa.s, 25 parts by weight of a vinyl group with a content of 0.9 The content of wt% and MQ resin is 60wt% vinyl MQ silicone resin, 12 parts by weight of chain extender with a viscosity of 1000mPa.s, 2.5 parts by weight of hydrogen-containing silicone oil with a hydrogen content of 1.23wt%, 1 part by weight of KH560, agent; A:B components are uniformly mixed according to...

Embodiment 3

[0027] Component A consists of 40 parts by weight of 1000mPa.s vinyl-terminated silicone oil, 20 parts by weight of vinyl-terminated silicone oil of 10000mPa.s, 5 parts by weight of polyvinyl silicone oil with a viscosity of 5000mPa.s and a vinyl content of 5wt%, 5 parts by weight Thixotropic agent, 0.3 parts by weight of catalyst, and mixed uniformly; Component B consists of 30 parts of vinyl-terminated silicone oil with a viscosity of 5000mPa.s, 20 parts by weight of vinyl with a vinyl content of 1.3wt% and MQ resin with a content of 50wt%. MQ silicone resin, 13 parts by weight of a chain extender with a viscosity of 1200mPa.s, 5 parts by weight of hydrogen-containing silicone oil with a hydrogen content of 0.8 wt%, 2 parts by weight of allyl glycidyl ether, and 0.05 parts by weight of an inhibitor, and mix uniformly; A : Component B is uniformly mixed according to the ratio of 1:1 by weight, and after vacuum defoaming, the thixotrope for LED chip packaging is obtained. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tear strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com