Release film applied to glass cover plate

A technology of glass cover plate and release film, which is applied in the direction of film/sheet release liner, film/sheet adhesive, adhesive, etc., which can solve the problem that the release film does not have high temperature resistance and antistatic properties effect, affect the service life and other issues, to achieve the effect of increasing anti-static effect, good high temperature resistance effect, and increasing wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

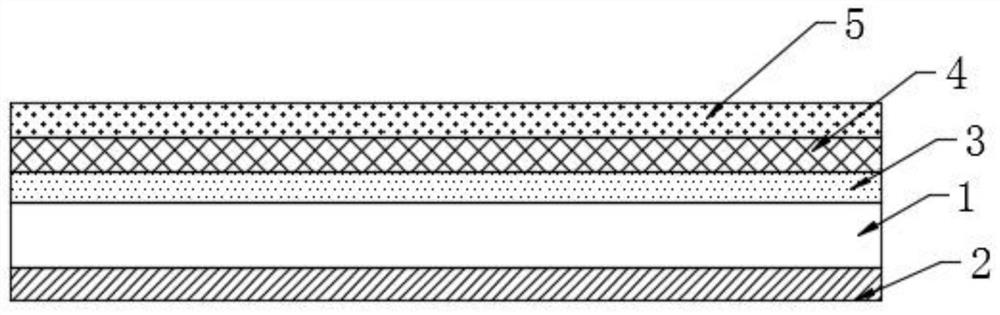

[0023] like figure 1 As shown, the present invention provides a technical solution: a release film applied to a glass cover plate, comprising a base film layer 1, an adhesive layer 2 is provided on the lower surface of the base film layer 1, and the base film layer 1 The upper surface is provided with an antistatic layer 3, and the antistatic layer 3 is fixedly adhered to the surface of the base film layer 1. Fixed adhesion, the surface of the high temperature resistant layer 4 is provided with a wear-resistant surface layer 5, and the wear-resistant surface layer 5 is fixedly adhered to the surface of the high temperature resistant layer 4.

[0024] Further, the thickness of the base film layer 1 is 150-200 microns.

[0025] Further, the antistatic layer 3 adopts an antistatic film, and the thickness of the antistatic layer 3 is 40-50 nanometers.

[0026] Further, the wear-resistant surface layer 5 adopts BOPP scratch-resistant film, the wear-resistant surface layer 5 is pr...

Embodiment 2

[0031] A release film applied to a glass cover, comprising a base film layer 1, the lower surface of the base film layer 1 is provided with an adhesive layer 2, and the upper surface of the base film layer 1 is provided with an antistatic layer 3, and the base film layer 1 is provided with an antistatic layer 3. The antistatic layer 3 is fixedly adhered to the surface of the base film layer 1, and the surface of the antistatic layer 3 is provided with a high temperature resistant layer 4, and the surface of the described high temperature resistant layer 4 is fixedly adhered to the surface of the antistatic layer 3, and the surface of the described high temperature resistant layer 4 is provided with There is a wear-resistant surface layer 5, and the wear-resistant surface layer 5 is fixedly adhered to the surface of the high-temperature resistant layer 4.

[0032] Further, the thickness of the base film layer 1 is 150-200 microns.

[0033] Further, the antistatic layer 3 adopts...

Embodiment 3

[0039] A release film applied to a glass cover, comprising a base film layer 1, the lower surface of the base film layer 1 is provided with an adhesive layer 2, and the upper surface of the base film layer 1 is provided with an antistatic layer 3, and the base film layer 1 is provided with an antistatic layer 3. The antistatic layer 3 is fixedly adhered to the surface of the base film layer 1, and the surface of the antistatic layer 3 is provided with a high temperature resistant layer 4, and the surface of the described high temperature resistant layer 4 is fixedly adhered to the surface of the antistatic layer 3, and the surface of the described high temperature resistant layer 4 is provided with There is a wear-resistant surface layer 5, and the wear-resistant surface layer 5 is fixedly adhered to the surface of the high-temperature resistant layer 4.

[0040] Further, the thickness of the base film layer 1 is 150-200 microns.

[0041] Further, the antistatic layer 3 adopts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com