Patents

Literature

60results about How to "Avoid collision interference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

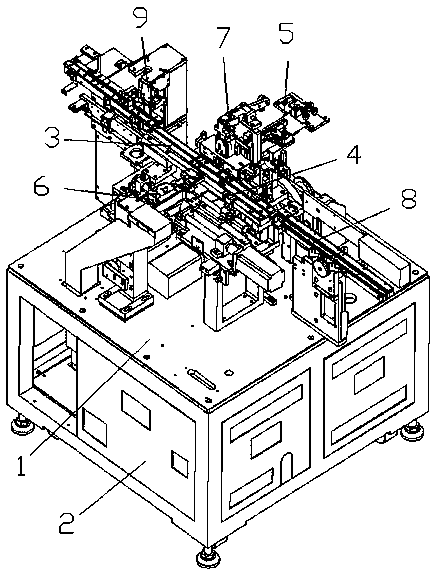

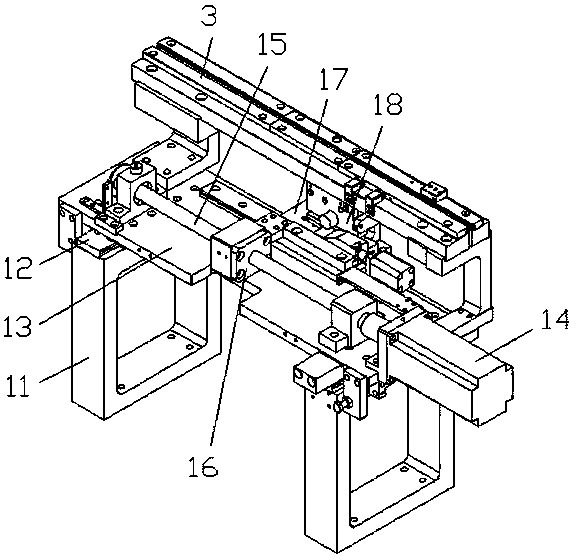

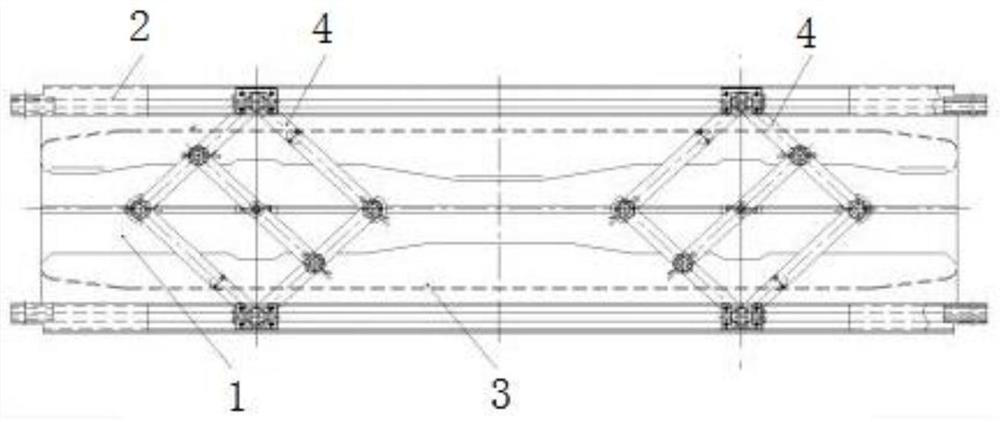

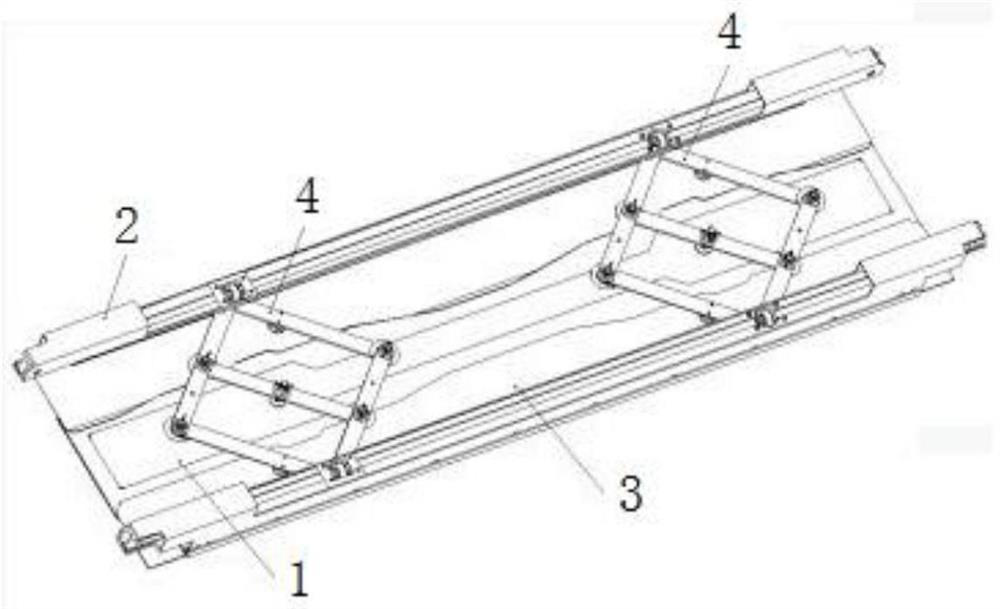

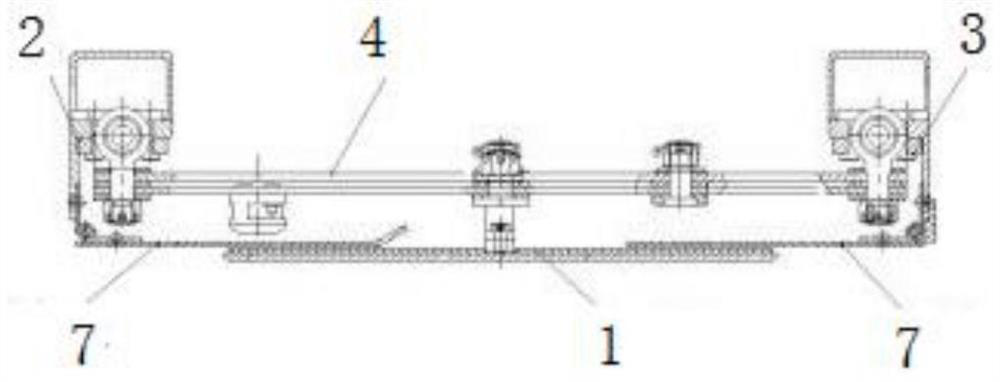

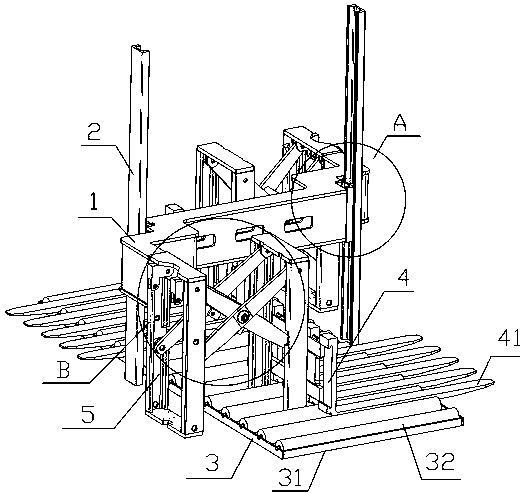

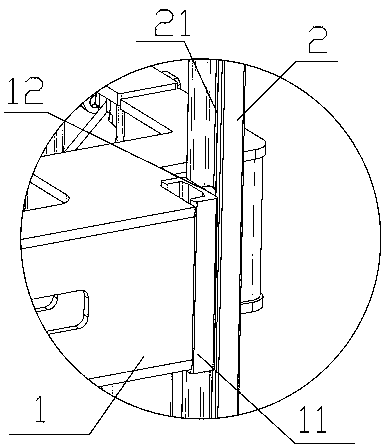

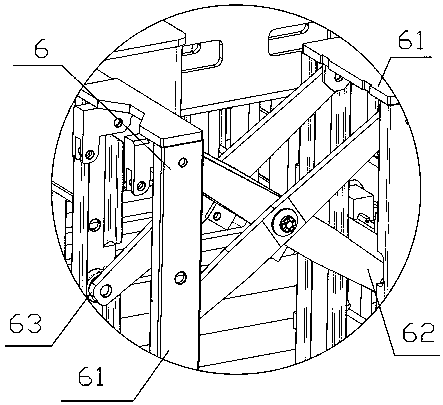

Automatic warehousing system containing conveying line and stacking machines

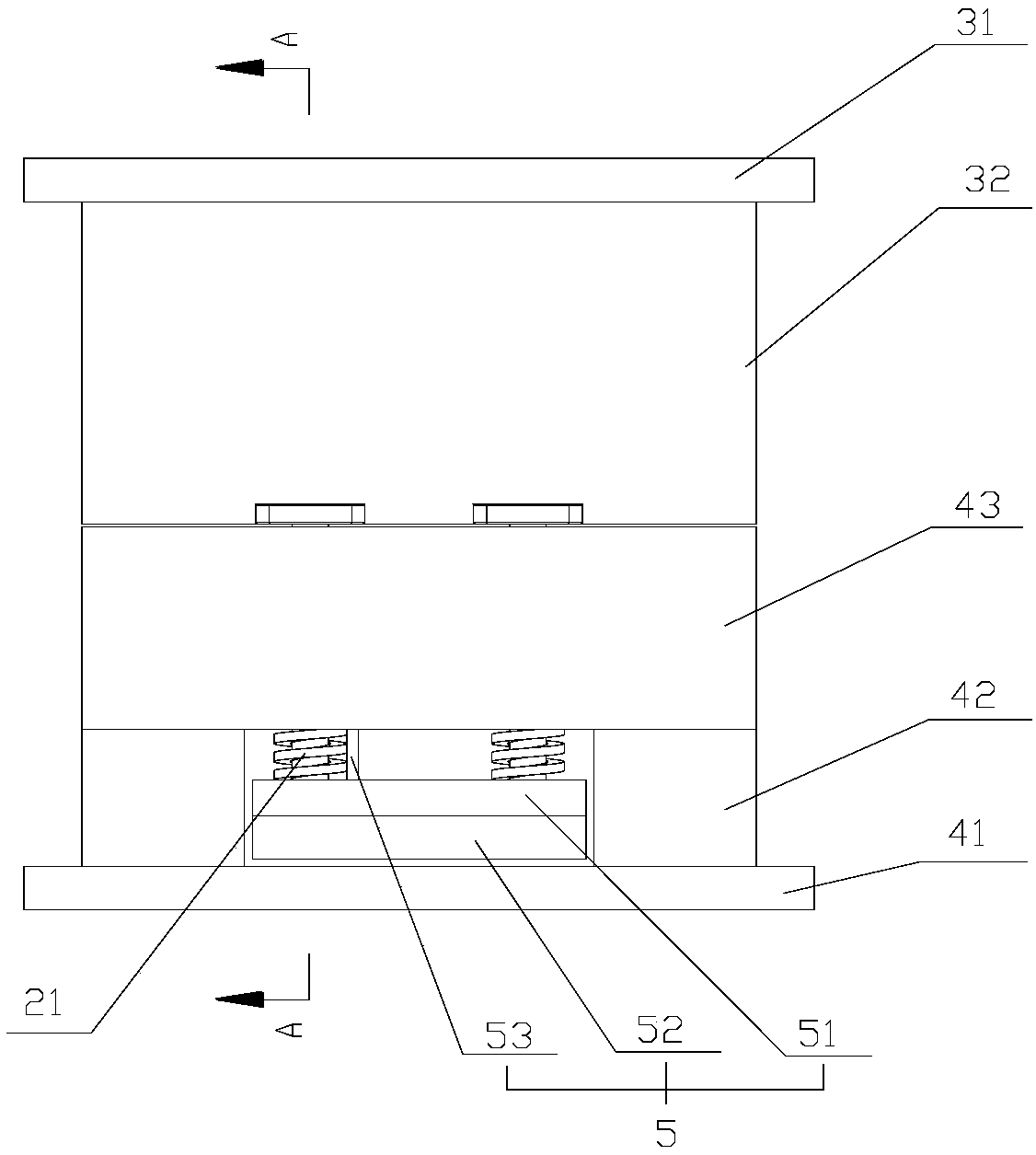

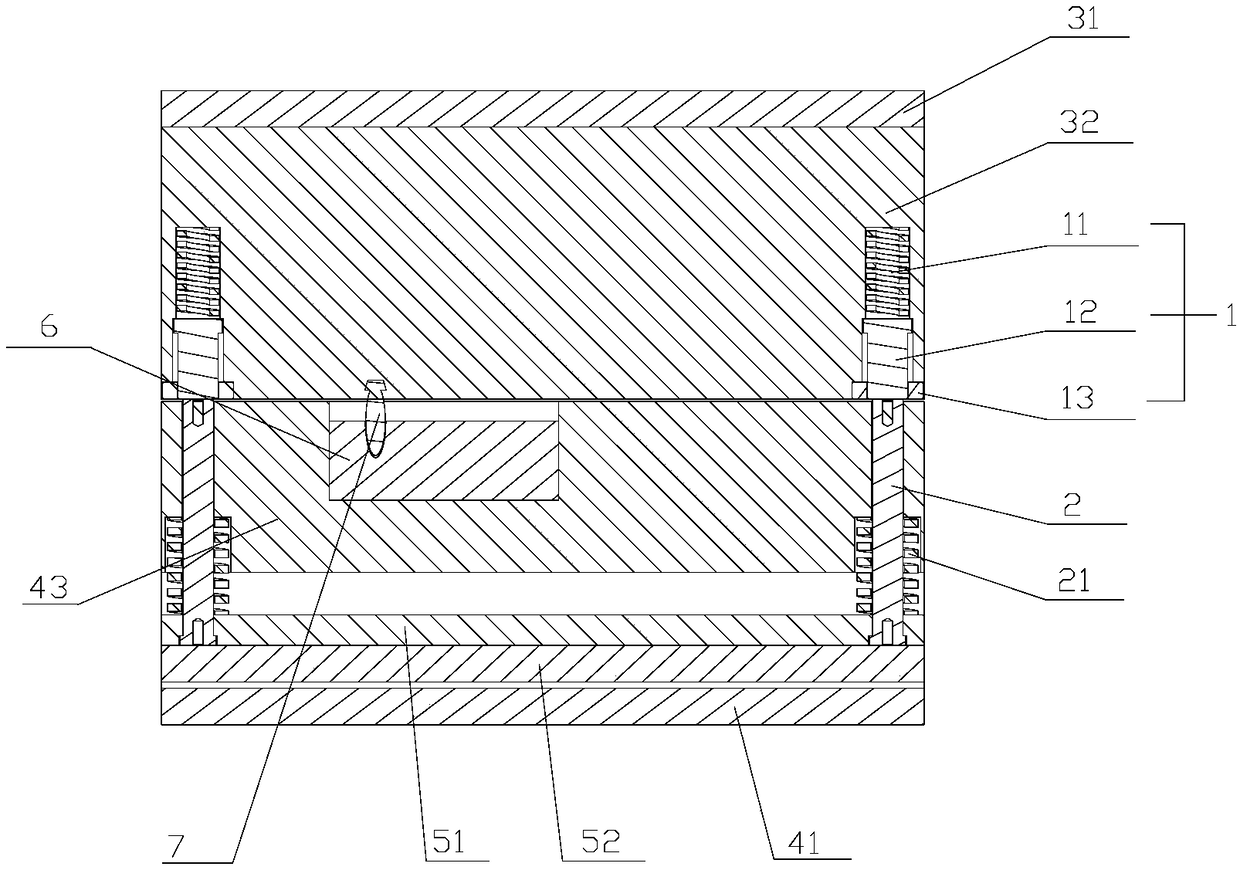

The invention relates to the field of automatic mechanical equipment, in particular to an automatic warehousing system comprising a conveying line and stacking machines. According to the technical scheme, the automatic warehousing system comprises the stacking machines and fork assemblies, the conveying line and guide rails are laid in the lane, the guide rails are arranged on the two sides of the conveying line, and the stacking machines move along the guide rails. The purpose of the present invention is to provide the automatic warehousing system, a cargo fork of the stacking machine is used for directly placing the goods on the conveying line in the lane through the transverse moving and lifting actions, and efficient and automatic conveying of goods is achieved, and the multiple stacking machines can be arranged on one conveying line to work at the same time and the efficiency is improved, the back and forth distance of the stacking machines is shortened, pallets can be accessed, and the pallet-free goods can also be accessed.

Owner:NOBLEELEVATOR INTELLIGENT EQUIP CO LTD

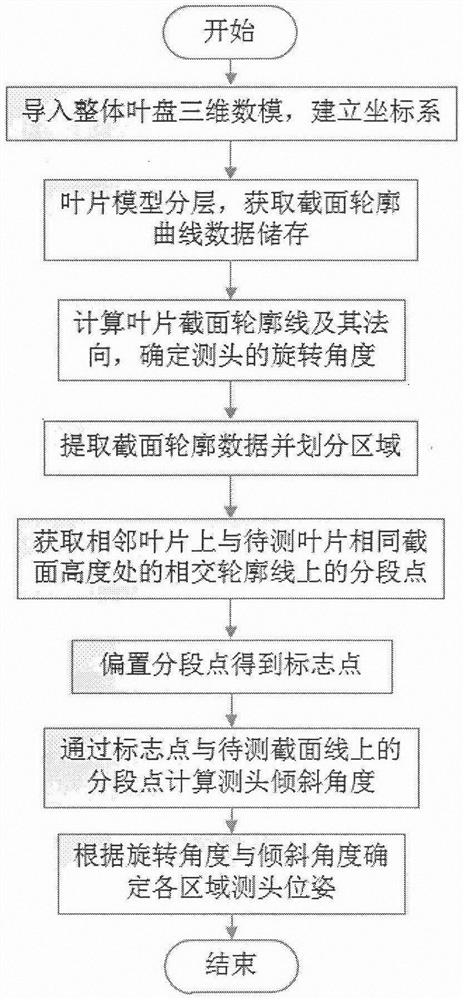

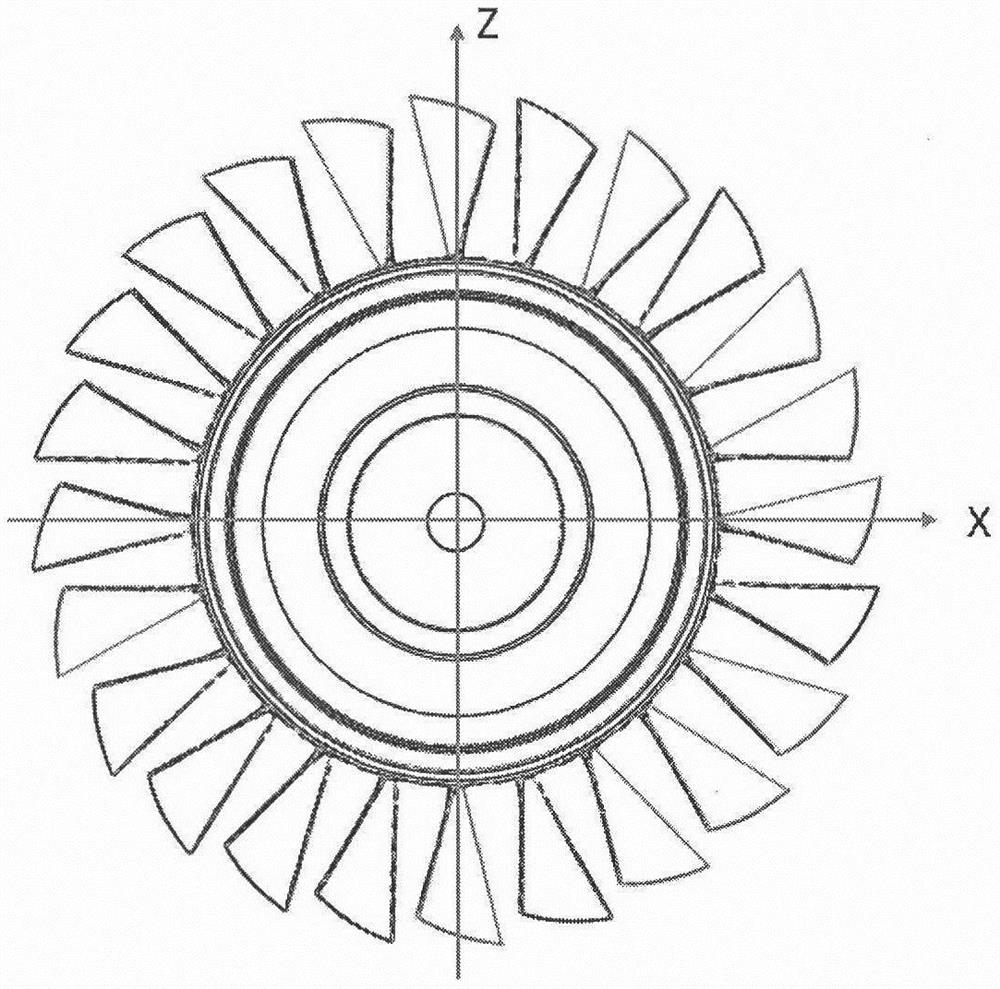

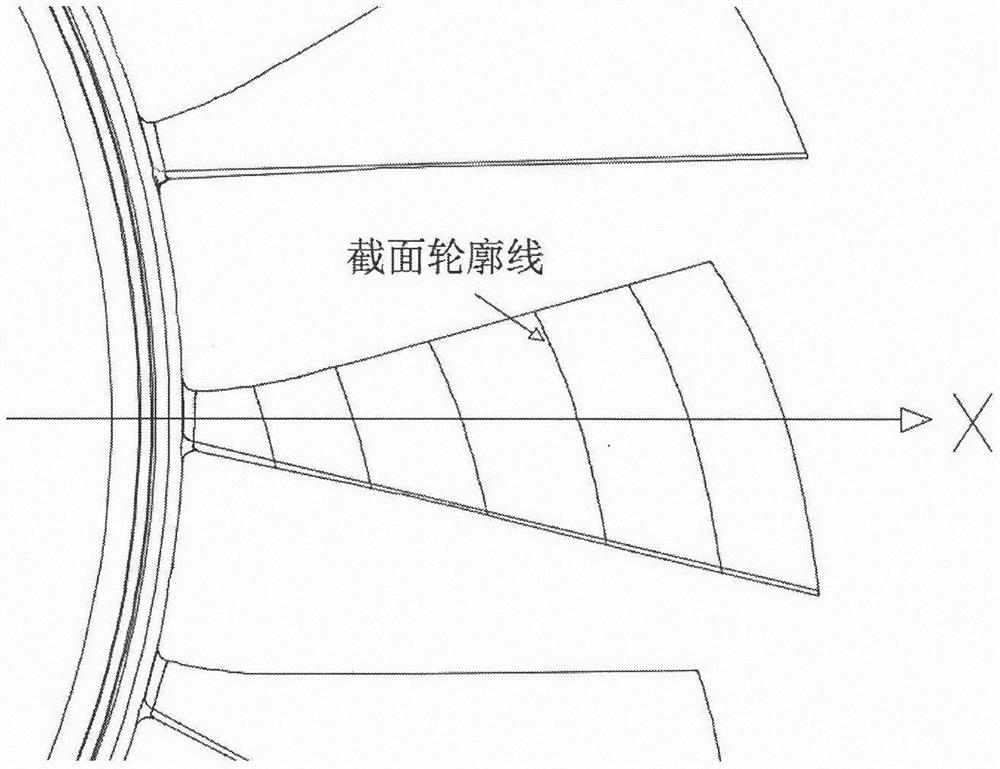

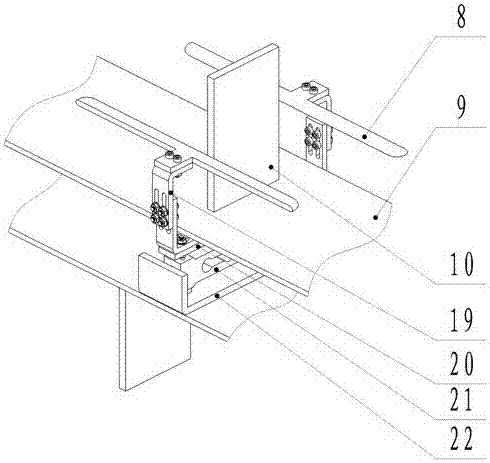

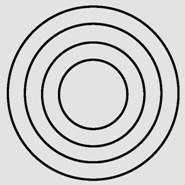

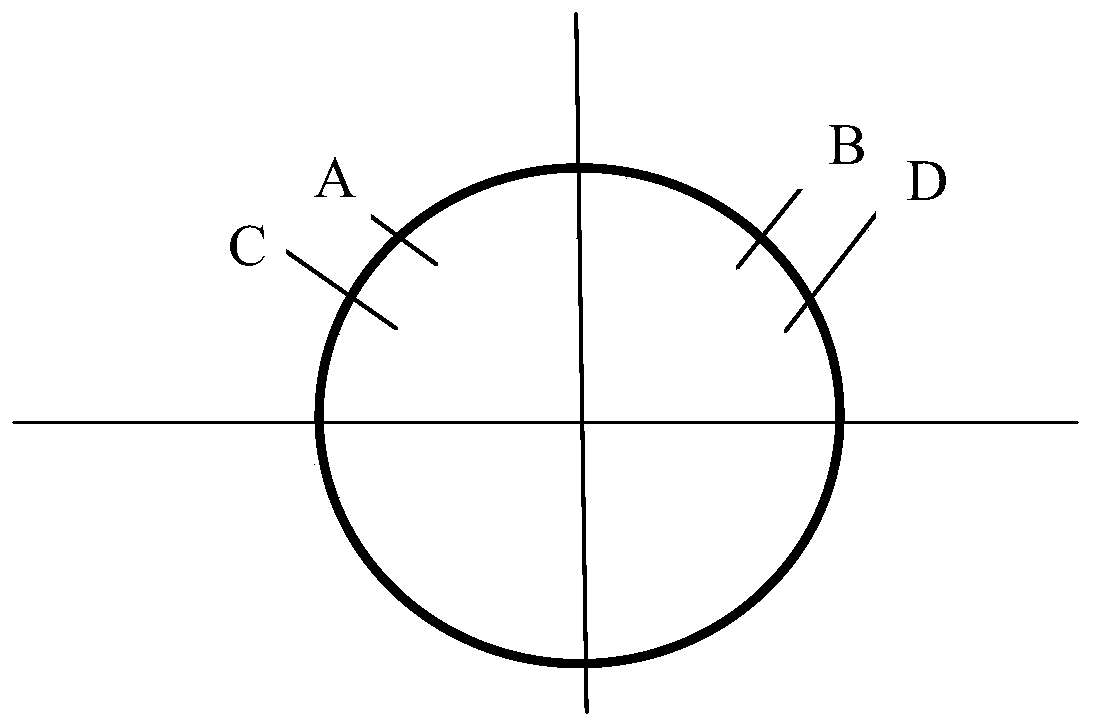

Measuring head pose planning method for blisk three-coordinate measuring machine

ActiveCN112446123AAvoid collision interferenceCalculation method is simpleGeometric CADMeasurement devicesComputer graphics (images)Engineering

The invention discloses a measuring head pose planning method of a blisk three-coordinate measuring machine, which is used for solving the problems of complex calculation method and low calculation efficiency in the measuring head pose determination process during the existing blisk three-coordinate measurement. The method comprises the following steps: firstly, obtaining a measuring section contour line and a normal of a plane where the contour line is located, and calculating a rotation angle of a measuring head; and then dividing the section contour line into regions by using the segmentation points, obtaining mark point information at the same section height on the adjacent blades, and determining the inclination angle of the measuring head according to the mark points and the segmentation points on the section curve. According to the method, the complexity of measuring head pose calculation in the three-coordinate measuring process of the blisk is simplified, the measuring head pose calculation efficiency of non-interference measurement is improved, and scientific and reasonable planning of the measuring head pose of the blisk non-interference measurement is effectively achieved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

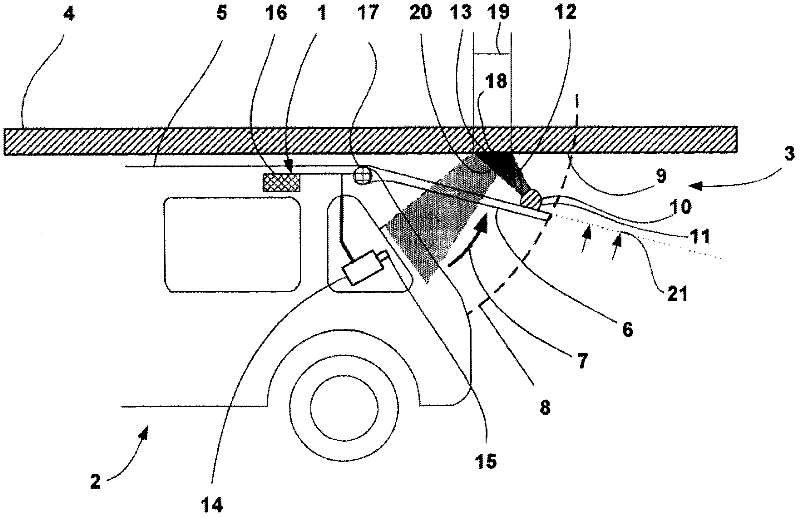

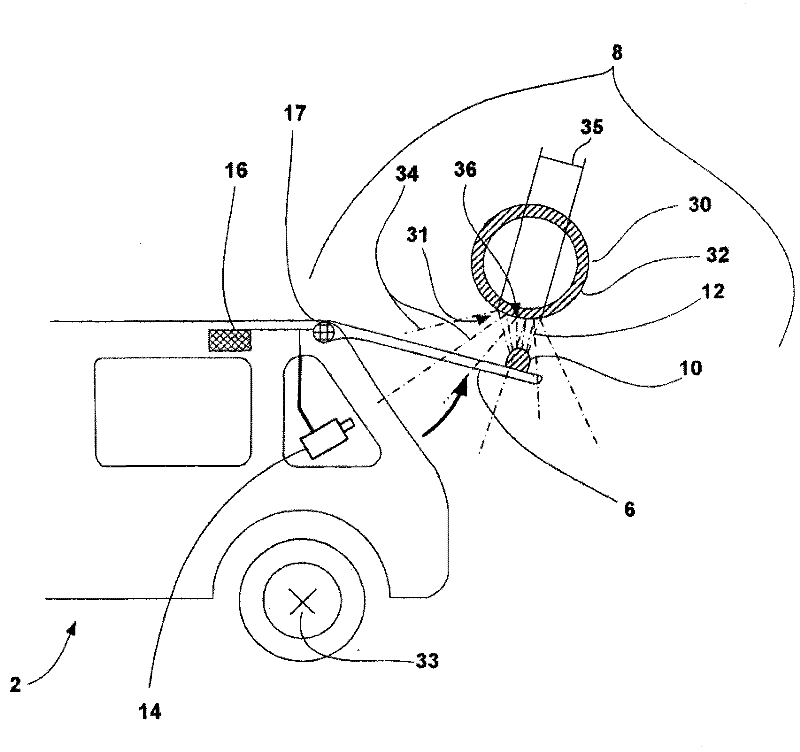

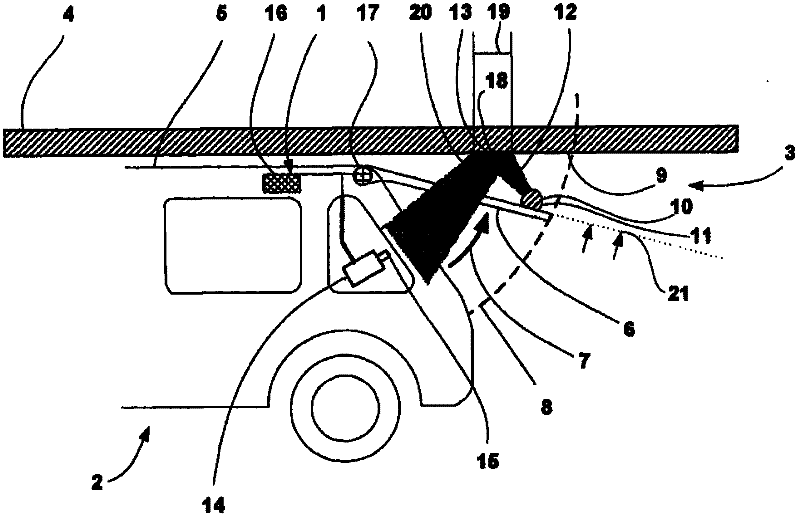

Device for preventing a collision of a pivoting element of a vehicle

InactiveCN102303647AEasy to measureCollision avoidance controlPower-operated mechanismSuperstructure subunitsEngineeringControl unit

A device is provided for preventing a collision between a pivoting element of a vehicle, with an obstacle located in its pivoting area, with a control unit which controls the pivoting movement of the vehicle pivoting element and with a lighting device which is coupled to the pivoting movement and emits light into the pivoting area. Depending on the reflection of the emitted light on the obstacle the control units intervenes in the pivoting movement.

Owner:GM GLOBAL TECH OPERATIONS LLC

Double-action multistage hydraulic oil cylinder with solid piston rod

InactiveCN102852896AAvoid troubleAvoid resistanceFluid-pressure actuatorsReciprocating motionHydraulic ram

The invention relate to a double-action multistage hydraulic oil cylinder with a solid piston rod. The hydraulic oil cylinder comprises a first-stage cylinder sleeve, pistons, the piston rod and a plurality of stages of inner cylinder sleeves including a tail-stage cylinder sleeve. The piston rod is arranged in the tail-stage cylinder sleeve and is a solid rod. An oil feeding hole is arranged at the bottom end of the first-stage cylinder sleeve, and an oil discharging hole is arranged at the other end. A piston is fixed outside one end of each stage of inner cylinder sleeve close to the oil feeding hole, each stage of inner cylinder sleeve is provided with an oil guide hole which is a through hole communicating the inside and the outside of the inner cylinder sleeve, two outlets are located on the same side of the pistons and arranged , the outlet on the outer wall is close to the pistons, and the outlet arranged on the inner wall is arranged at the end far away from the piston. An oil pipe of the oil cylinder is not stretched, shortened or bended with reciprocating movement of the tail-stage piston rod, so that the oil cylinder prevents the oil pipe from being collided and interfered with the tail-stage piston rod in reciprocating movement and being abraded. The piston rod is of a solid structure, and is better in rigidity, low in processing cost and compact in radial size.

Owner:沈姝君

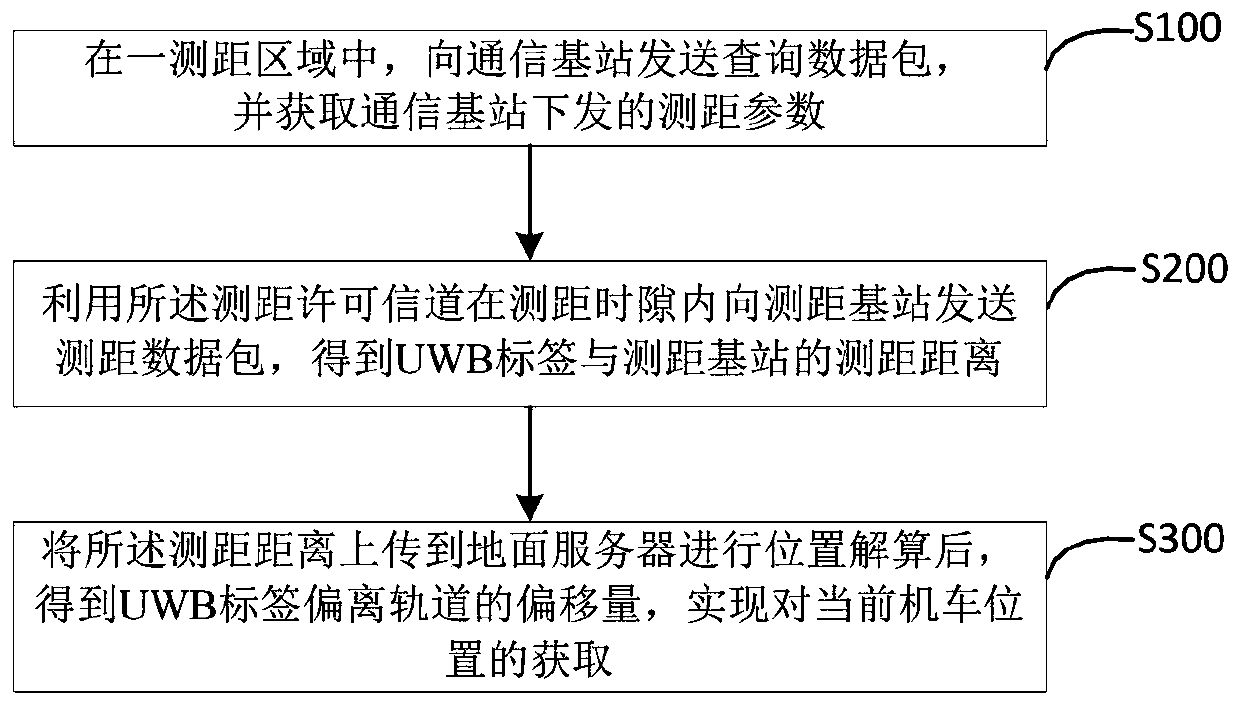

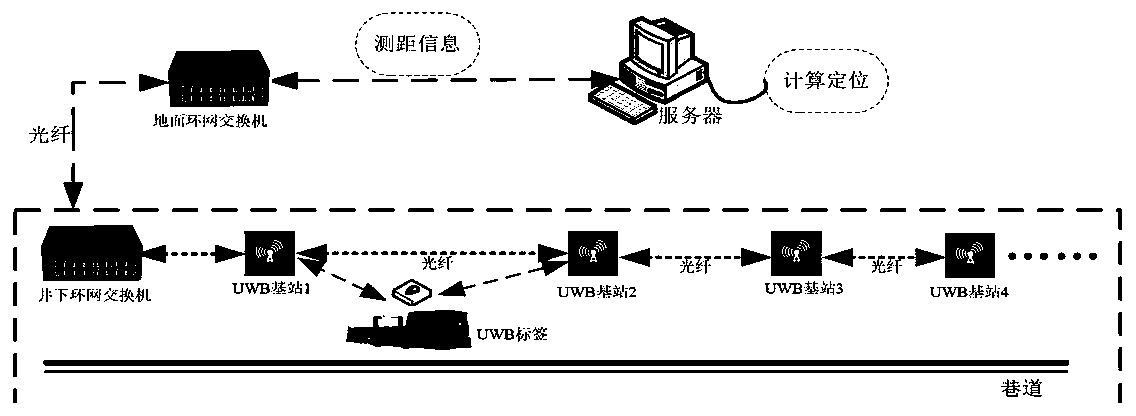

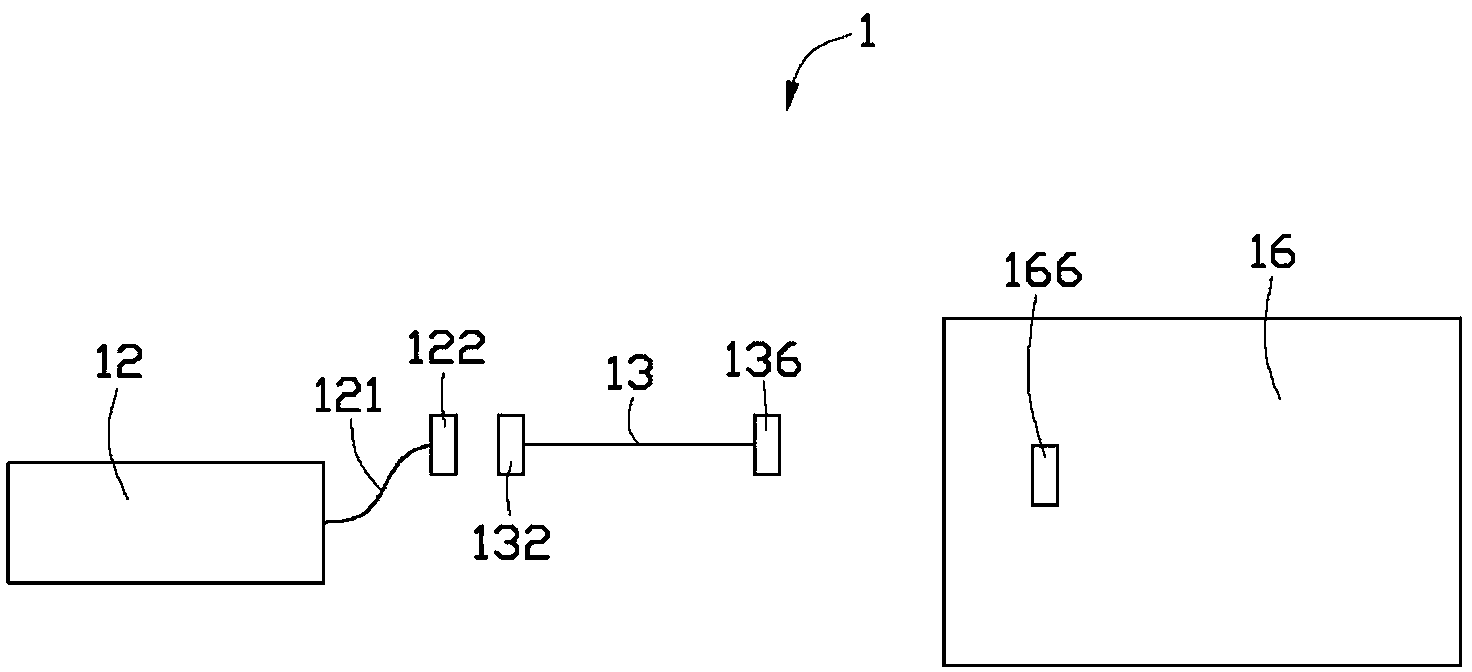

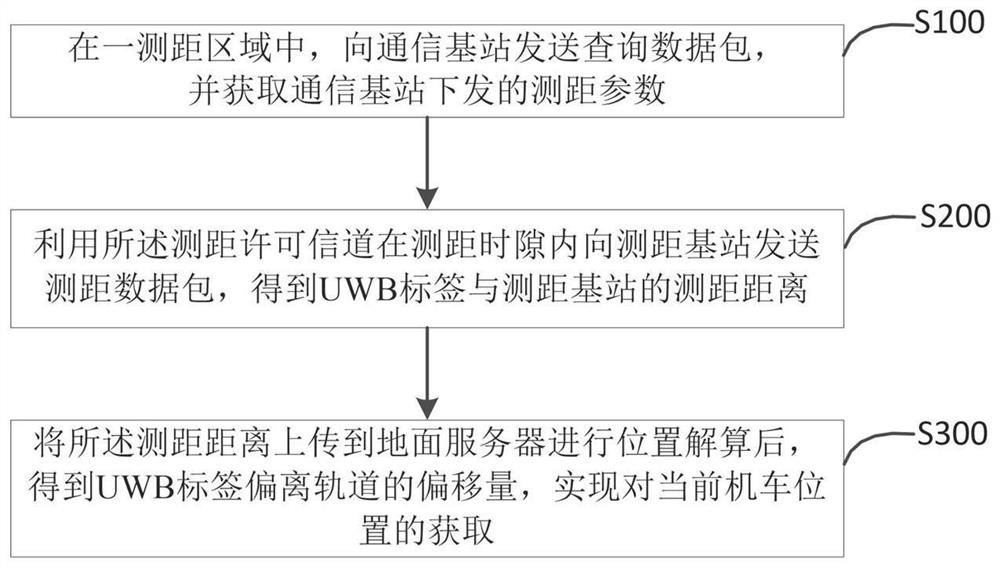

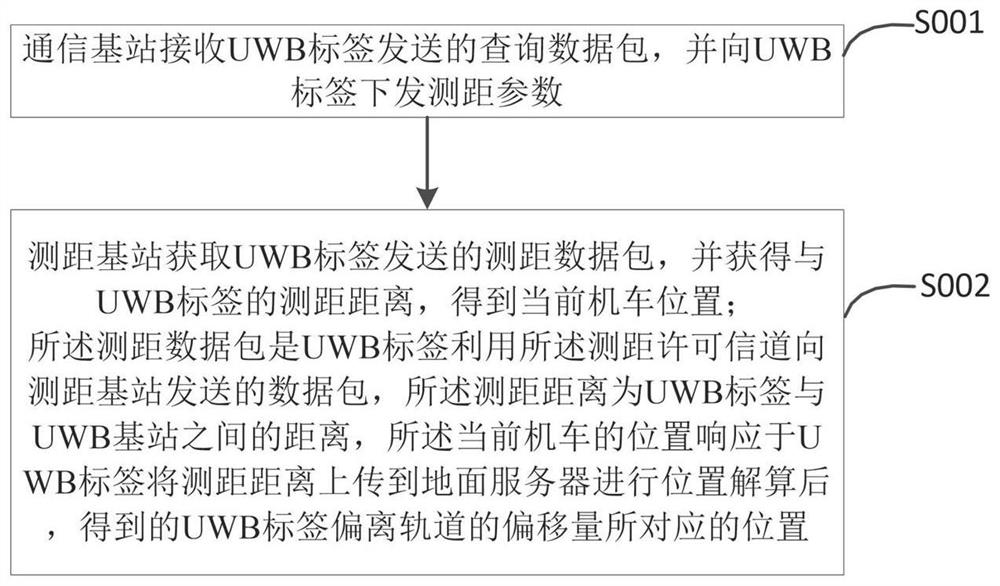

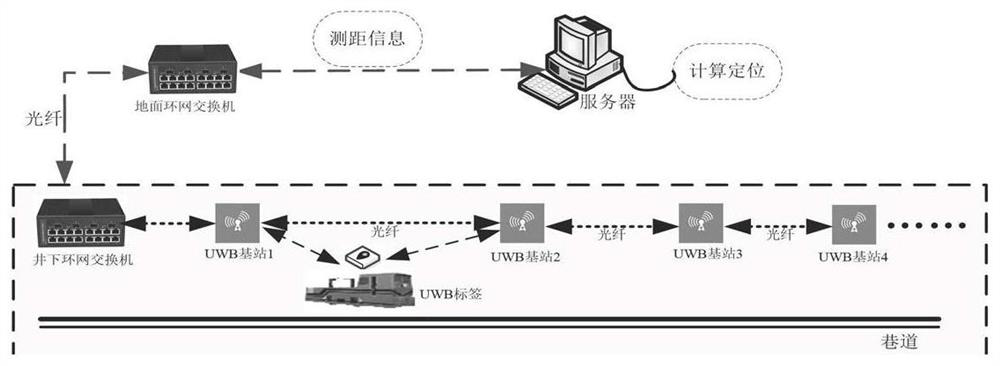

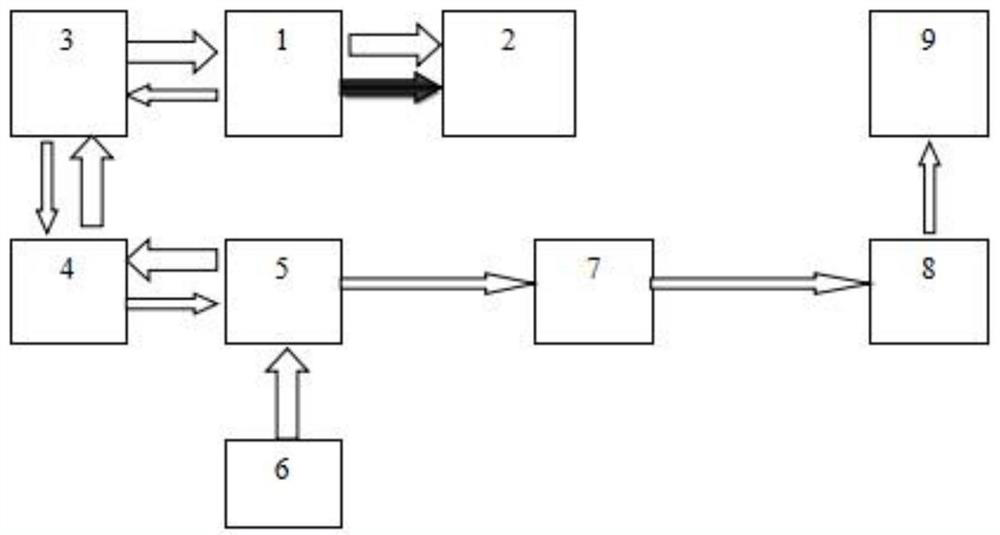

Underground locomotive ranging and positioning method and system based on UWB ultra-wideband wireless communication

ActiveCN111163431AImprove real-time performanceImprove accuracyParticular environment based servicesUltra-widebandData pack

The invention discloses an underground locomotive ranging and positioning method and system based on UWB ultra-wideband wireless communication, and the method comprises the steps: transmitting a querydata packet to a communication base station in a ranging region, and obtaining ranging parameters issued by the communication base station, wherein the ranging parameters comprise a ranging permission channel, a ranging time slot, a ranging waiting time delay, and a ranging base station ID; sending a ranging data packet to a ranging base station in a ranging time slot by using the ranging permission channel to obtain a ranging distance between the UWB label and the ranging base station; and uploading the distance measurement distance to a ground server for position calculation to obtain the offset of the UWB label deviating from the track so as to obtain the current locomotive position. According to the underground locomotive ranging and positioning method, conflicts in the UWB label distance measurement process are avoided, so that positioning calculation is more real-time and more accurate.

Owner:HEFEI UNIV OF TECH +1

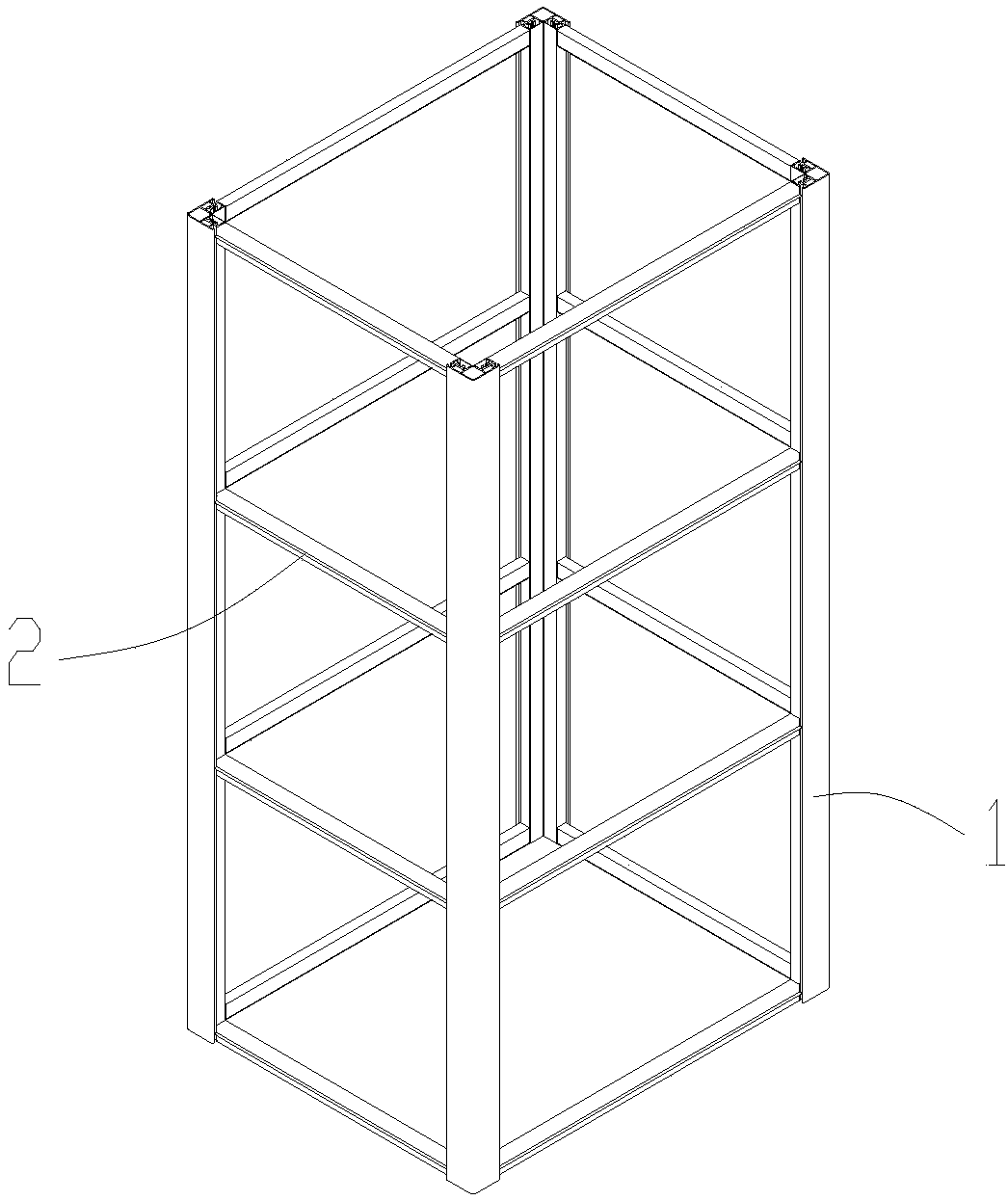

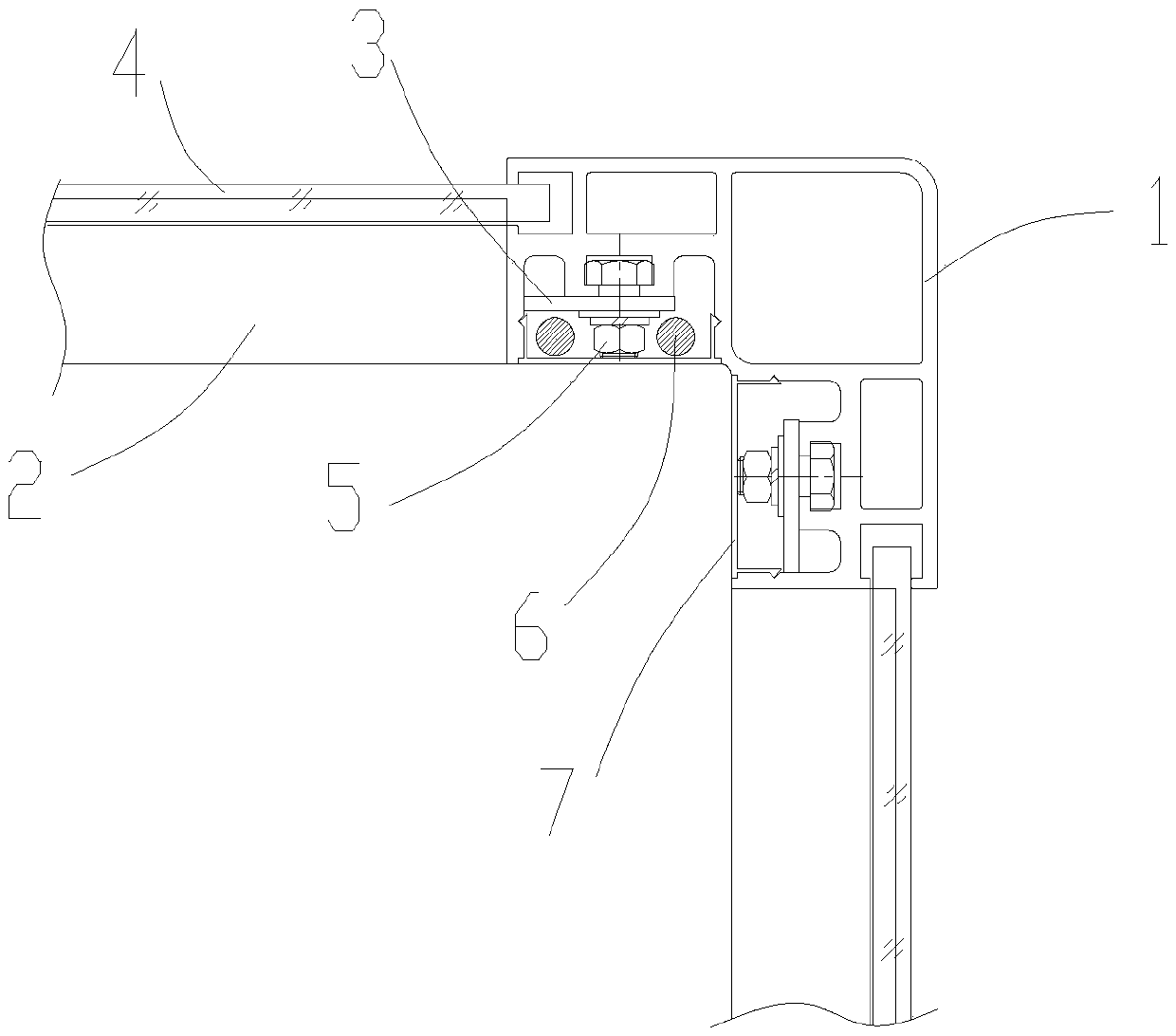

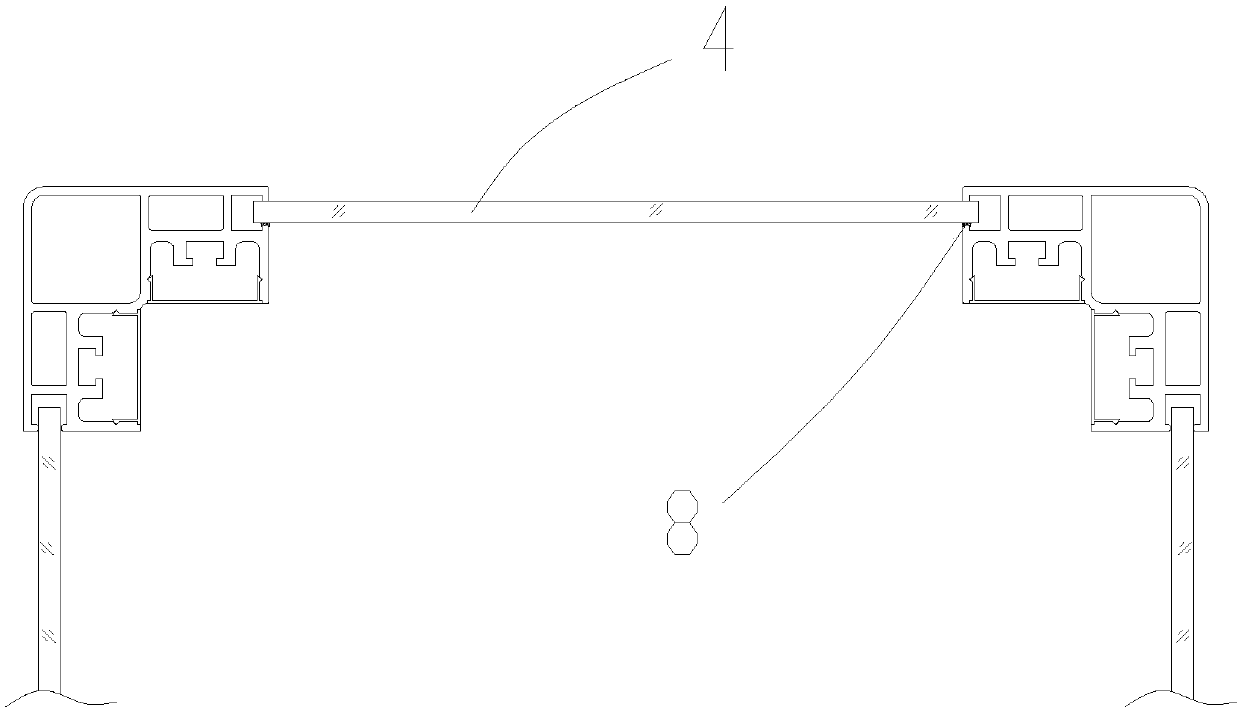

Shaft frame of aluminum alloy sightseeing elevator

PendingCN109098394APrevent random disassembly and movementAvoid Collision InterferenceVertical ductsEngineeringPerpendicular direction

The invention discloses a shaft frame of an aluminum alloy sightseeing elevator. The shaft frame comprises vertical posts positioned at the rectangular corners and crosspieces connected between the corresponding vertical posts. The shaft frame is characterized in that every vertical post comprises a hollow main pipe, mounting wings are arranged in two mutually perpendicular directions by taking the hollow main pipe as a benchmark, every crosspiece are connected on one side of the corresponding mounting wing, a glass bezel is formed in every mounting wing on the outer side of the correspondingcrosspiece, a T-shaped slide groove is formed in the inner side of every mounting wing and is positioned in a cable holding space consisting of one side edge of the mounting wing and a vertical edge of the corresponding hollow main pipe, a cover plate is arranged on an opening of the cable holding space, the crosspieces are connected with the connecting plates arranged in the cable holding spaces,shaft cables are arranged in the cable holding spaces, and exterior decorating glass is assembled through the glass bezels. The shaft frame of the aluminum alloy sightseeing elevator has the advantages that mounting can be carried out inside and outside the shaft frame, all fixing parts and the cables are hidden in the holding spaces, and the exterior decorating glass is safe to assemble and elegant in appearance.

Owner:浙江安家快速电梯有限公司

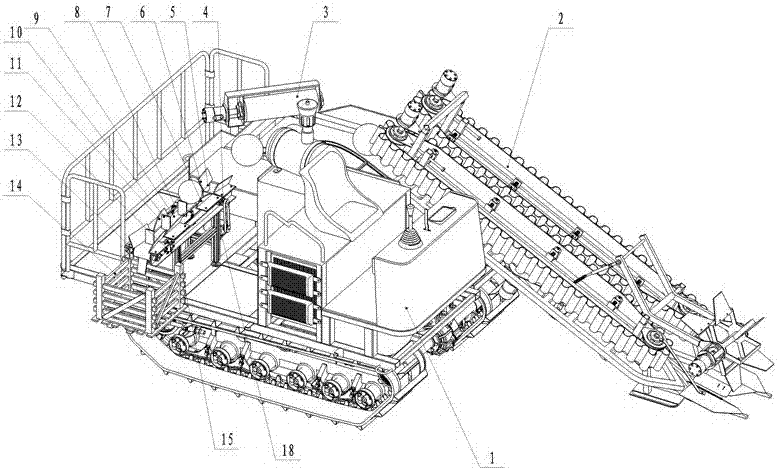

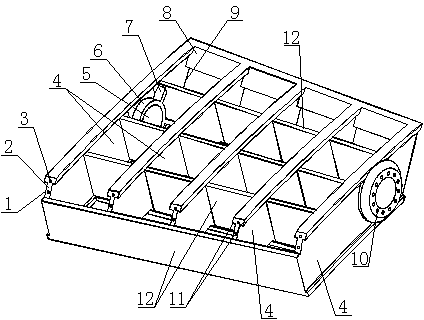

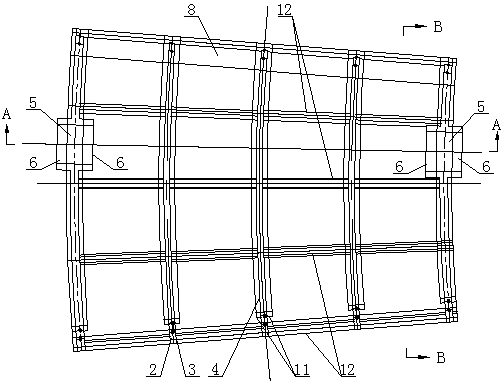

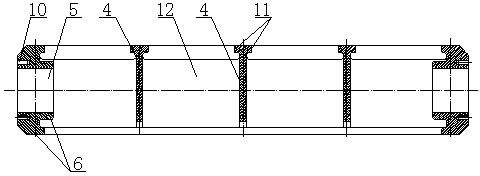

Cabbage weighing device used for cabbage harvester

ActiveCN107396691AAvoid collision interferenceGuaranteed independenceHarvestersWeighing apparatus for materials with special property/formLoad bearingChassis

The invention discloses a cabbage weighing device used for a cabbage harvester. The weighing device is installed at the tail part of a power chassis of the cabbage harvester and located at the behind of a leaf peeling device, and the weighing device comprises a system table frame, a conveying assembly, a weighing platform, a weighing module and the like. The system table frame is located at an outlet of the leaf peeling device, and the system table frame is a physical support of the weighing device; the conveying assembly is a conveyer belt-type structure with push boards, and the conveying assembly conveys cabbages to enter and leave the weighing platform one by one; the weighing platform is located between the system table frame and the conveying assembly, and the weighing platform is a load bearing supporting platform of the cabbages in the weighing zone; and the weighing module is installed on the system table frame, and the weighing module collects cabbage mass data in real time. According to the invention, the conveyer belt-type guiding mechanism and the combined-type weighing platform are adopted, the mechanical structure is simple and the design is ingenious, one-by-one conveying, weighing and collecting of the cabbages can be completed, and cabbage weighing on the cabbage harvester is realized.

Owner:ZHEJIANG UNIV

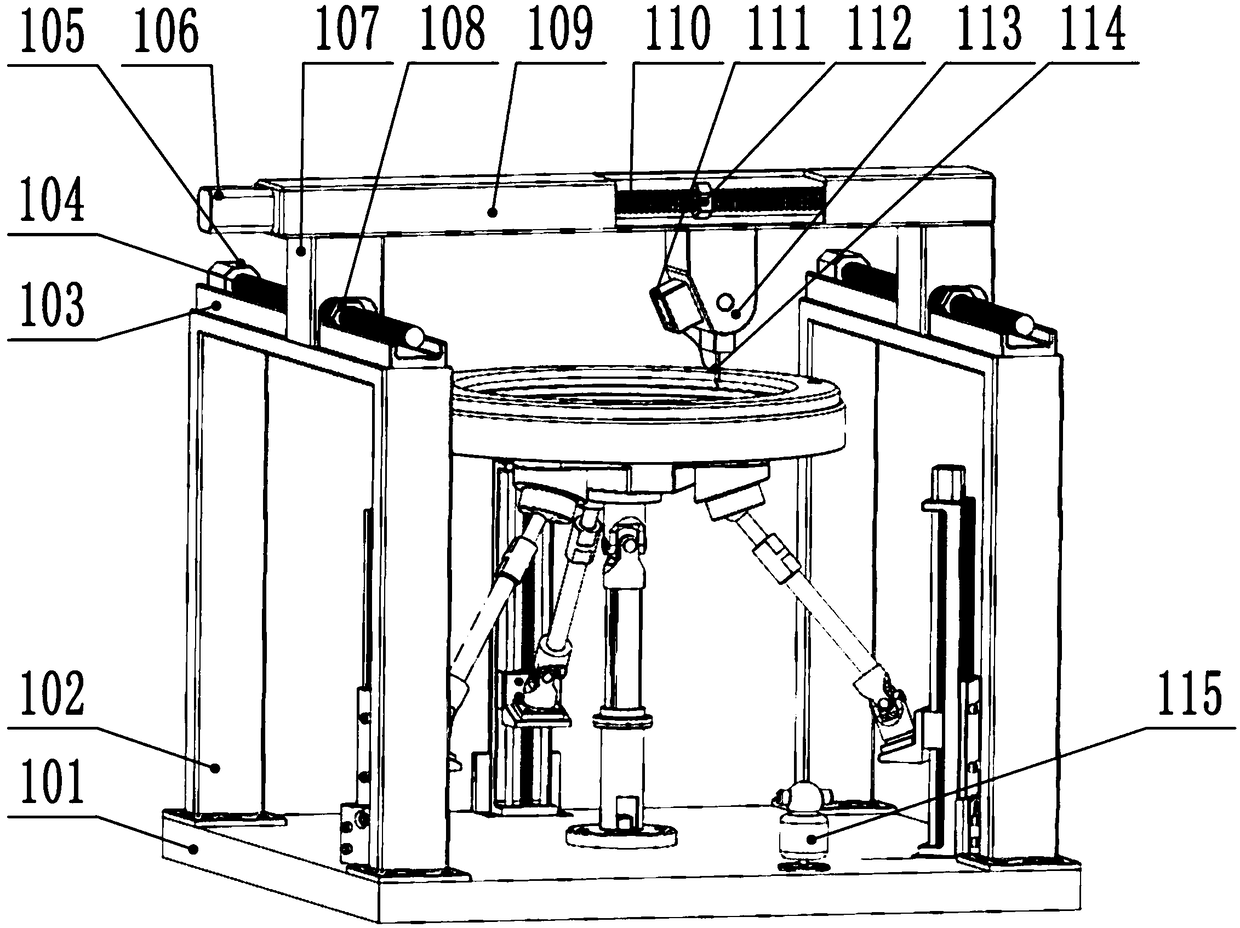

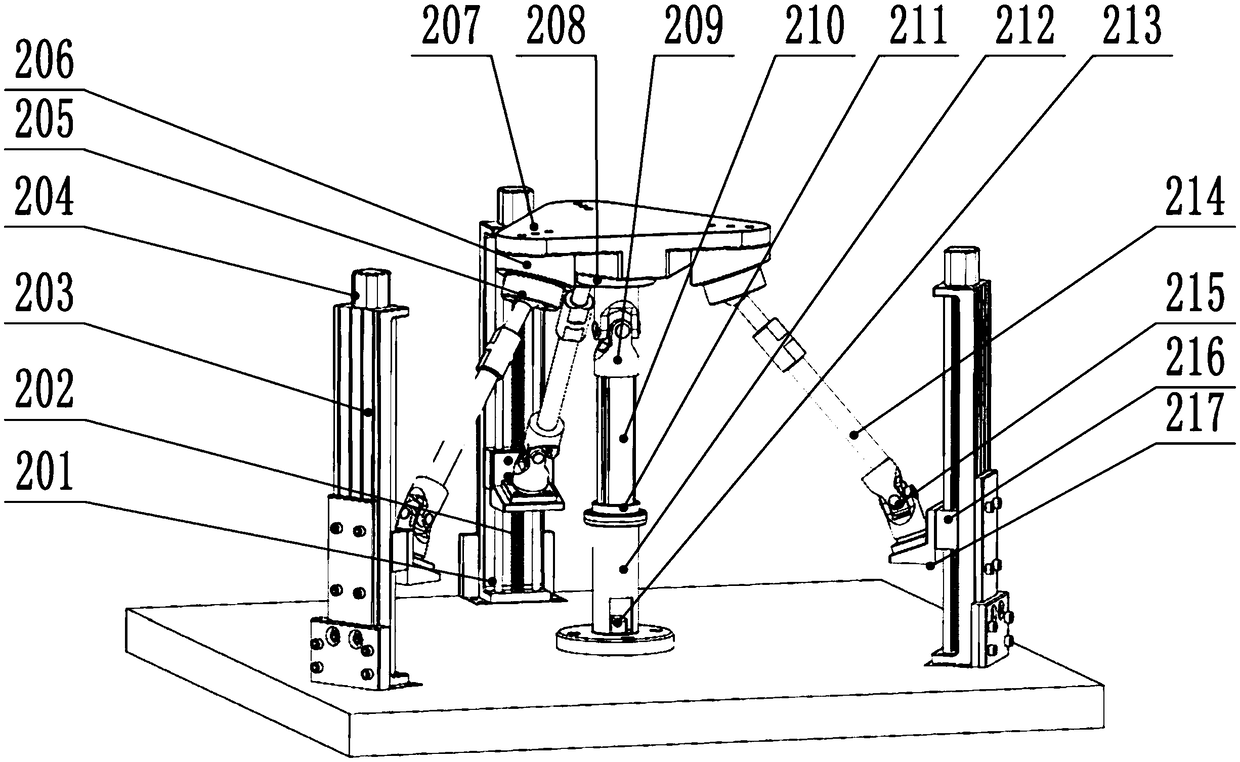

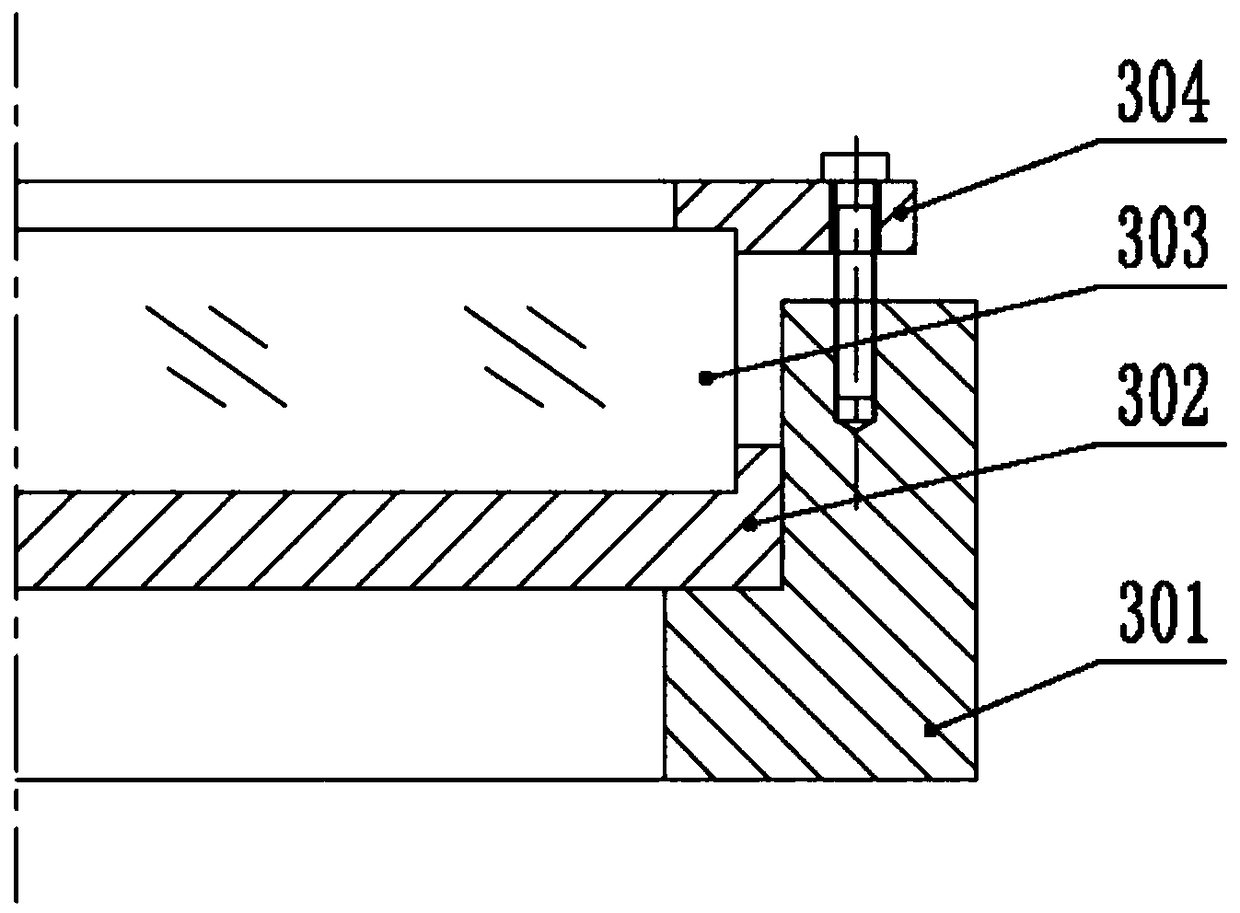

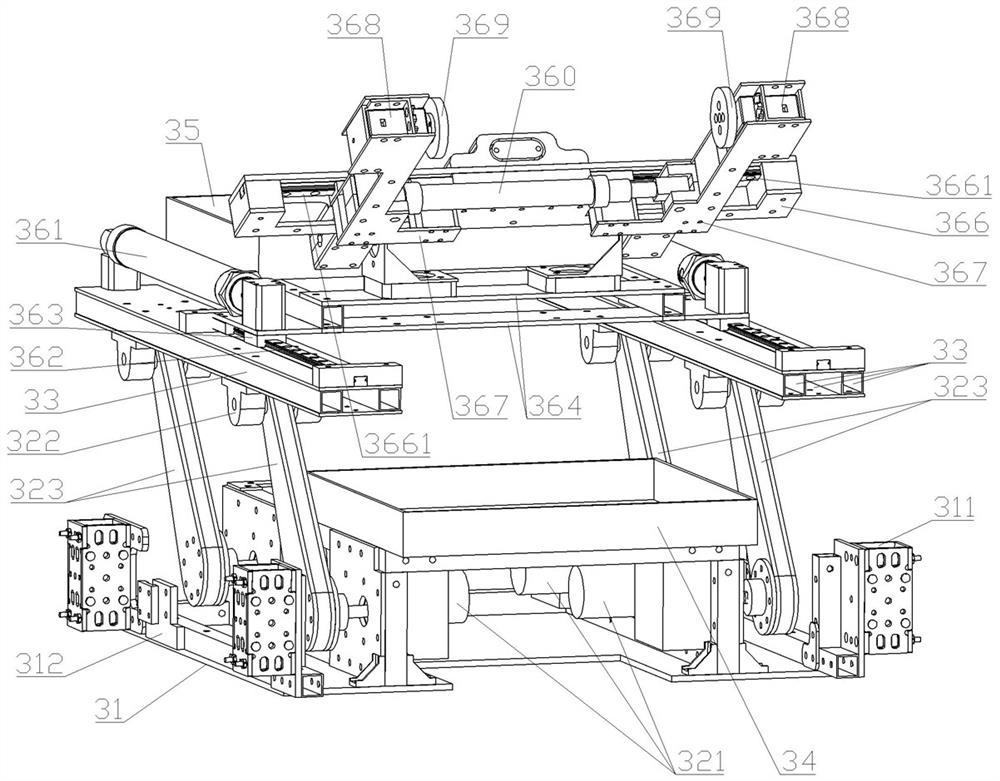

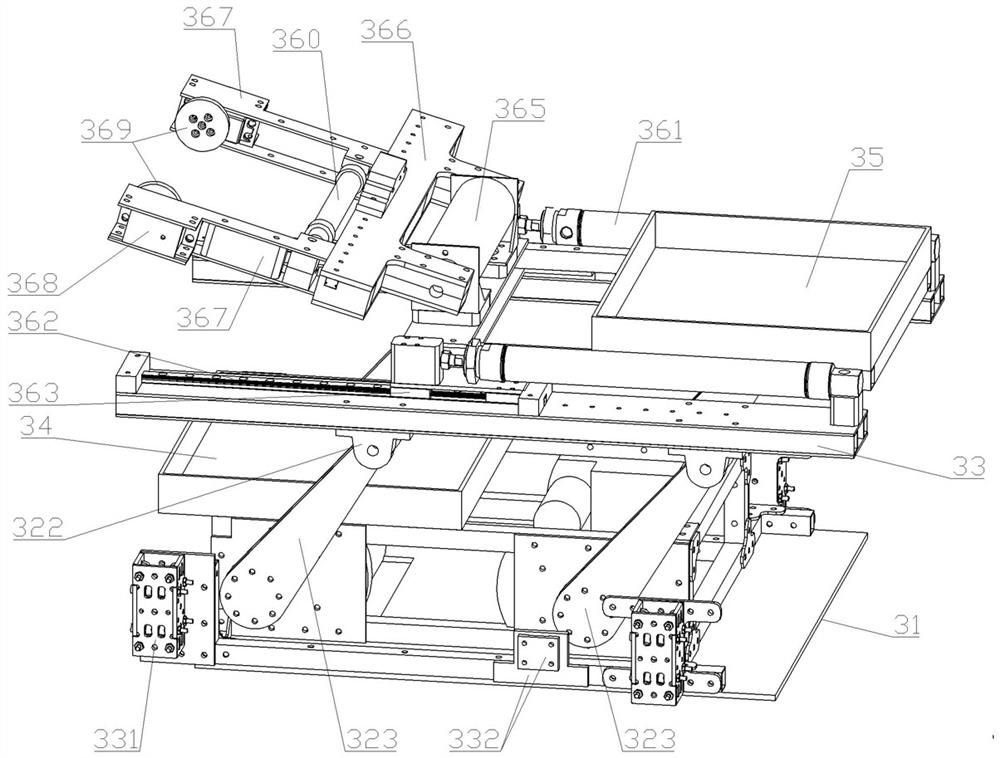

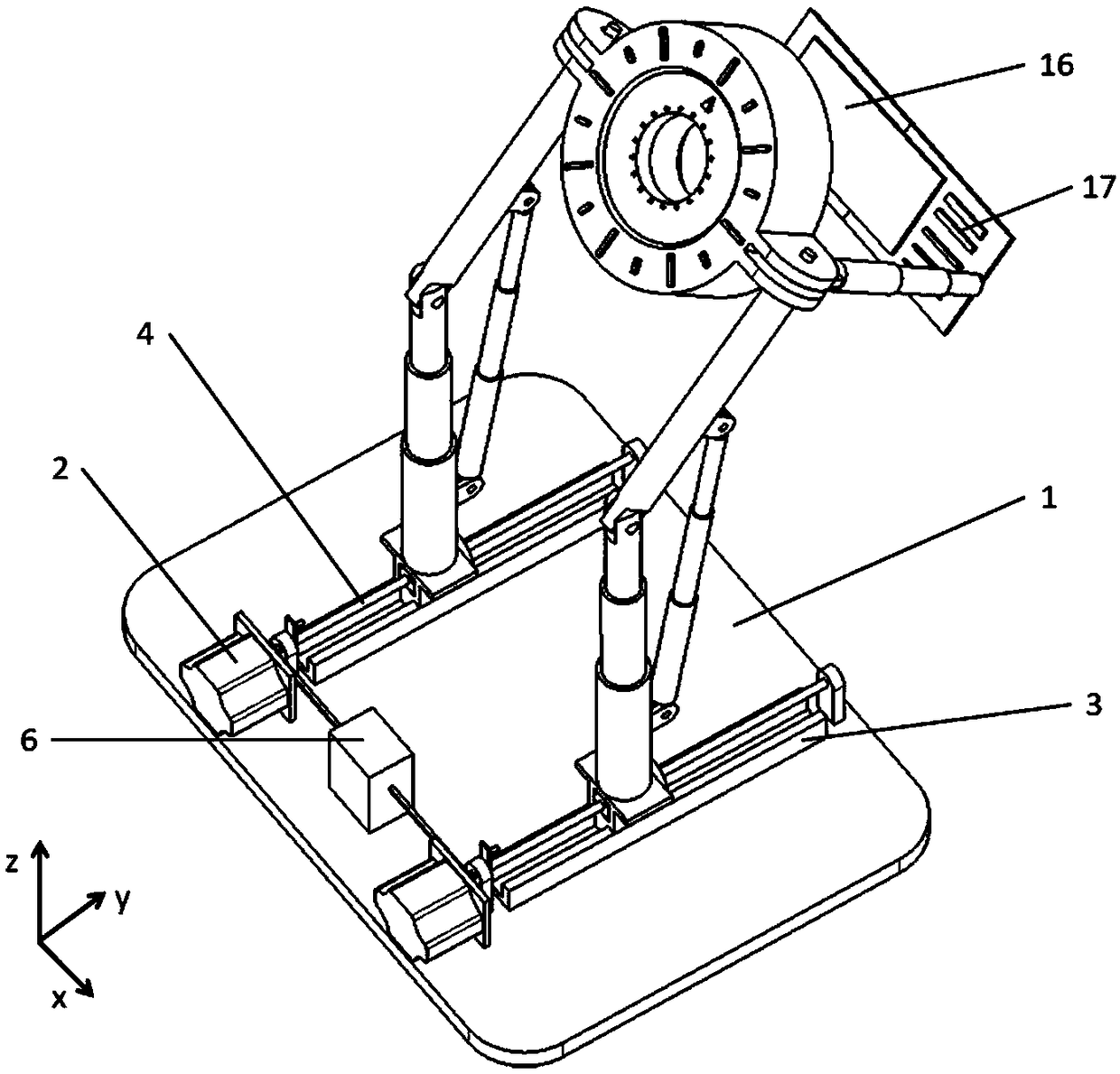

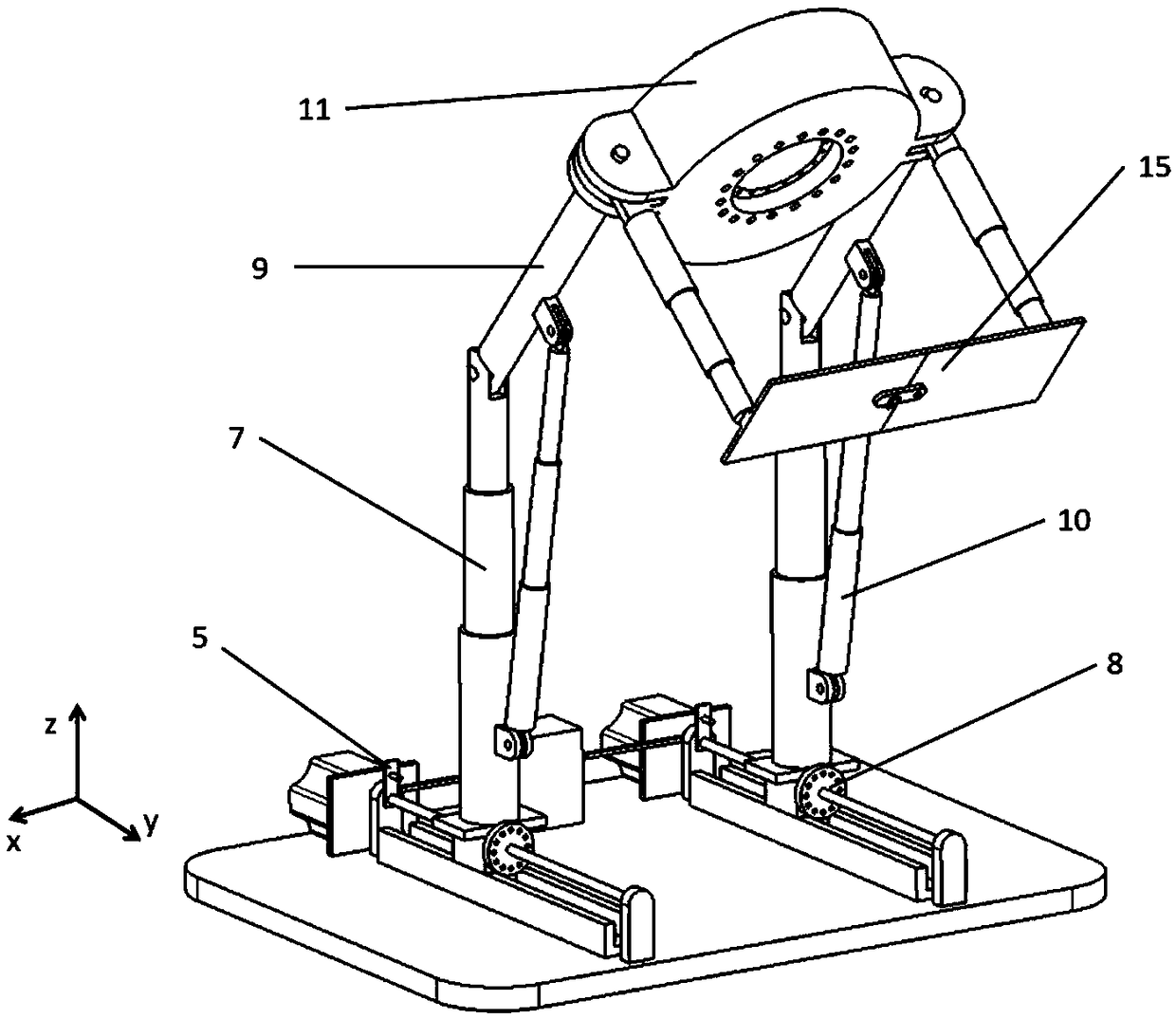

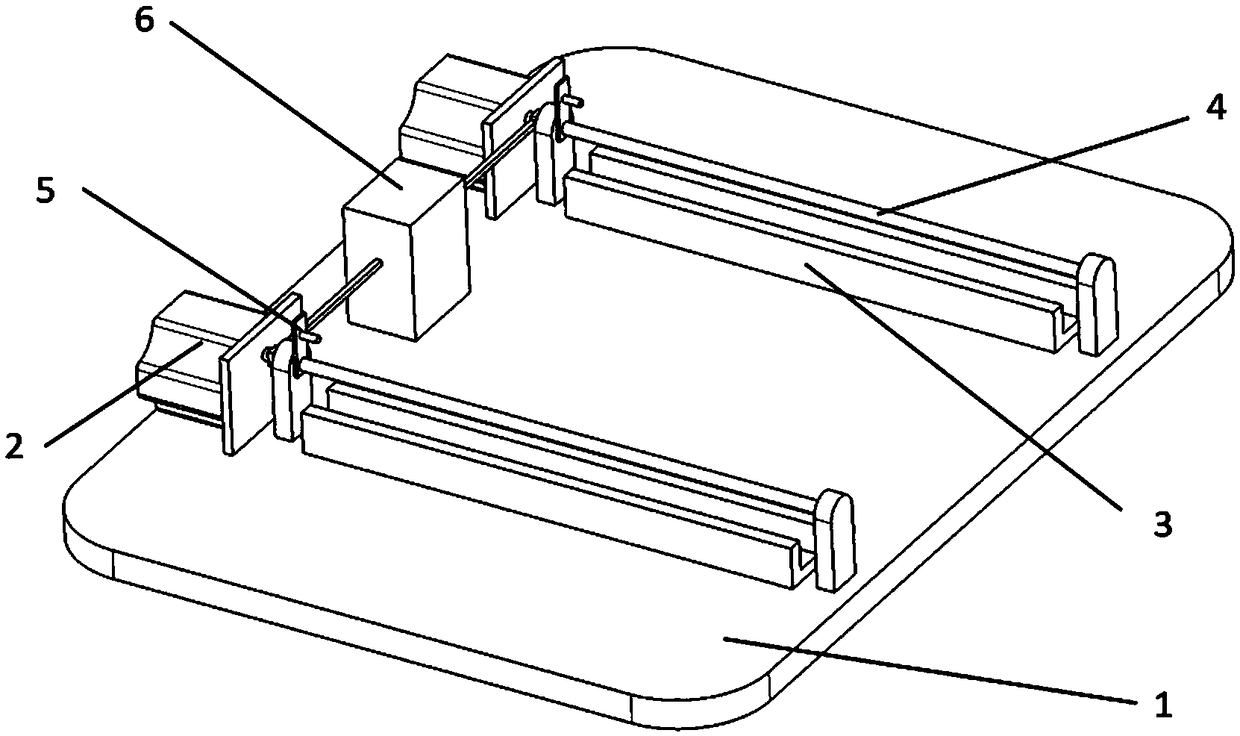

Machining device for large-caliber optic free curved surface

InactiveCN109352459AIncrease the machinable angleProcess controllableOptical surface grinding machinesAutomatic grinding controlFreeform surface machiningCaliber

The invention discloses a machining device for the large-caliber optic free curved surface. The machining device comprises a machining unit, an optic free curved surface supporting unit and an optic free curved surface clamping unit. The machining unit comprises a machining cutter and a drive mechanism for providing a machining path for the machining cutter. The drive mechanism comprises an X-direction drive mechanism and a Y-direction drive mechanism. The optic free curved surface supporting unit comprises a 3HUS+PU parallel mechanism, a moving platform connected to the upper end of the 3HUS+PU parallel mechanism and three sets of linear modules. The parallel mechanism drives the moving platform to move in the vertical direction to machine the curved surface, then the parallel mechanism rotates around the X-axis direction and the Y-axis direction, and then the posture of the free curved surface to be machined can be further adjusted. While the machining precision is ensured, the machining angle of the free curved surface can be increased. The machining device is high in overall equipment rigidity, small in accumulative error, high in machining precision and large in machining range, the optic free curved surface with the high complex degree can be machined, control is easy, and the machining efficiency is improved effectively.

Owner:SHANDONG ZHONGHENG OPTOELECTRONIC TECH CO LTD

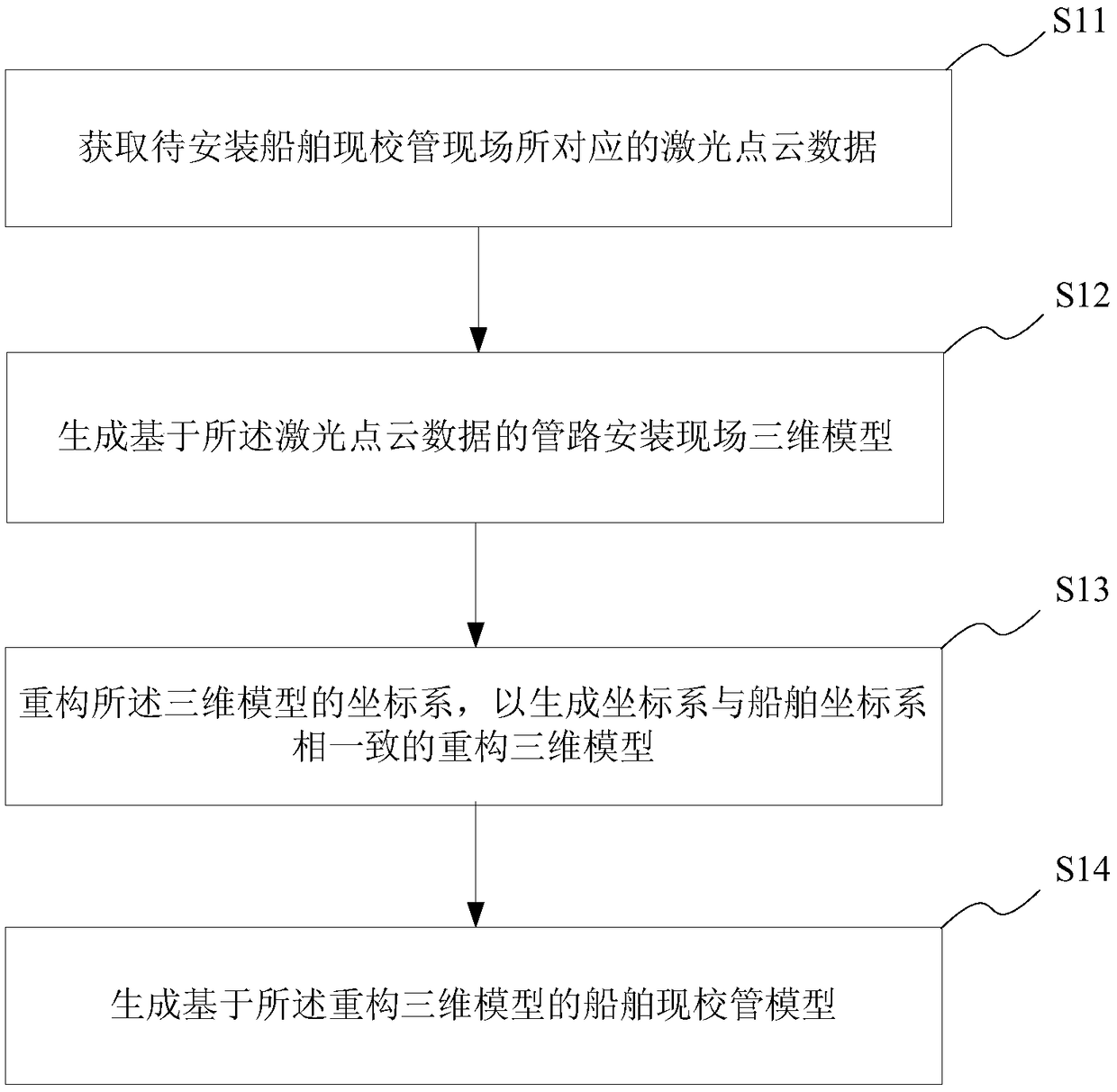

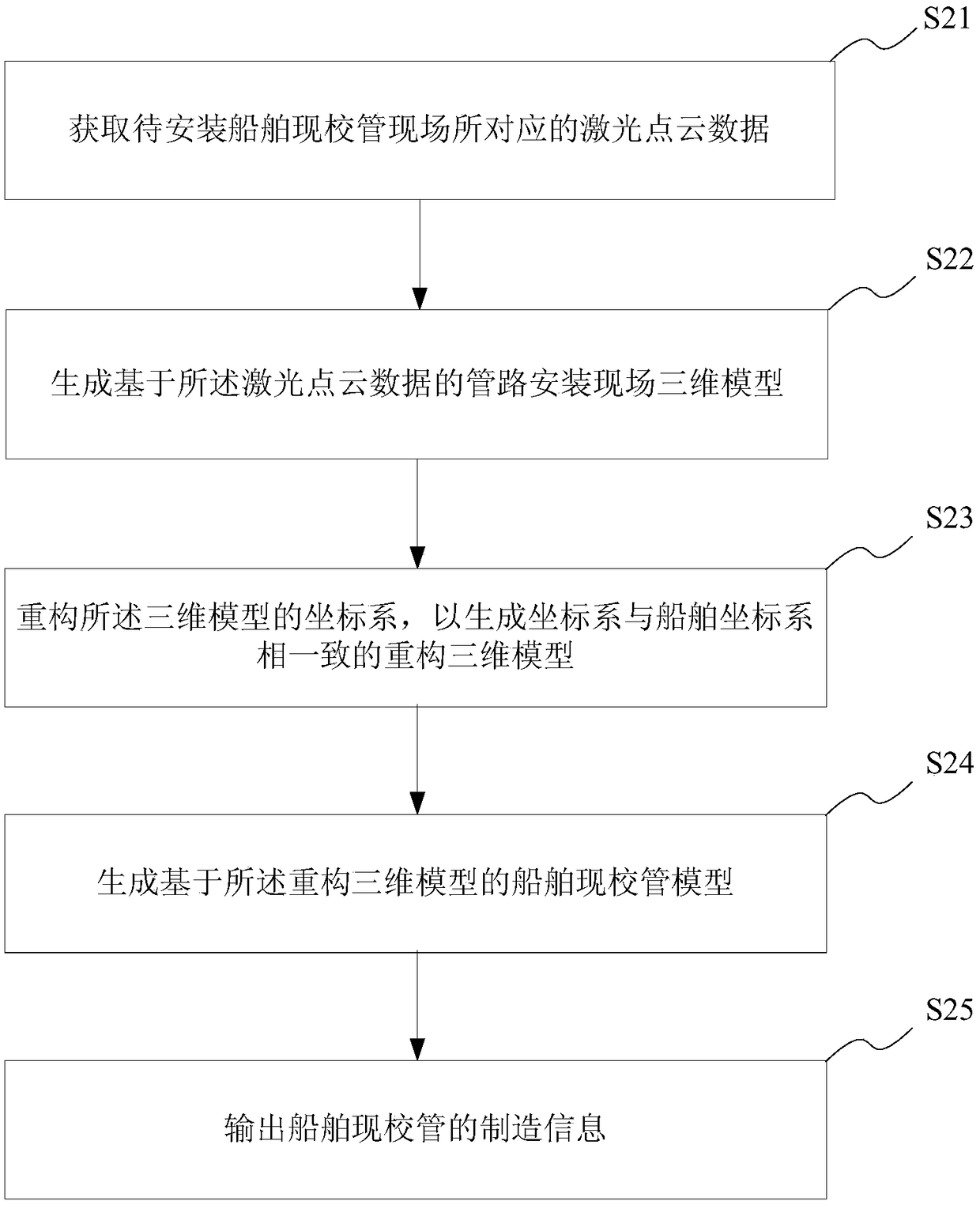

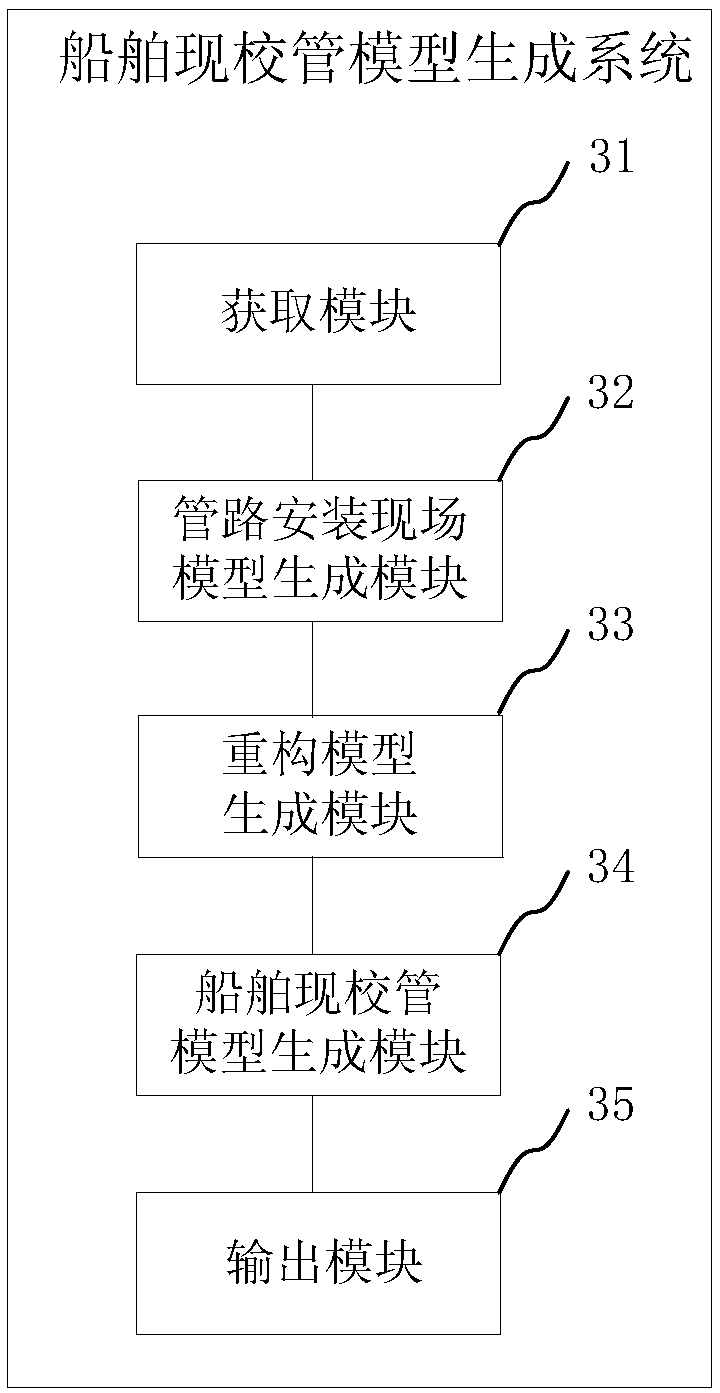

Method, system, terminal and medium for generating ship calibration pipe model based on laser scanning

PendingCN109377559AImprove one-shot molding rateClearly design the production processGeometric CADDesign optimisation/simulationLaser scanningPhysical model

The invention provides a method, a system, a terminal and a medium for generating a ship calibration pipe model based on laser scanning. The invention utilizes laser scanning to measure accurately andimproves measurement accuracy and efficiency. The present calibration tube is created based on the on-site physical model, and the primary forming rate of the present calibration tube is high, and the waste reflection rate is reduced; the connectors at the end of the pipe section are clear, the flange angle can be defined accurately by the current calibration pipe, and the pipe section can be installed directly on the berth after the design and processing is completed, which greatly simplifies the design and production process of the current calibration pipe and shortens the construction period. One measurement can create multiple calibration tube, greatly improve the efficiency of the design of the current calibration tube; the present calibration tube is modeled with reference to the real object background model, avoiding collision interference, improving the design accuracy and ensuring the manufacturability of the model; Incorporating the current school management into the designdata management system to manage it.

Owner:JIANGNAN SHIPYARD GRP CO LTD

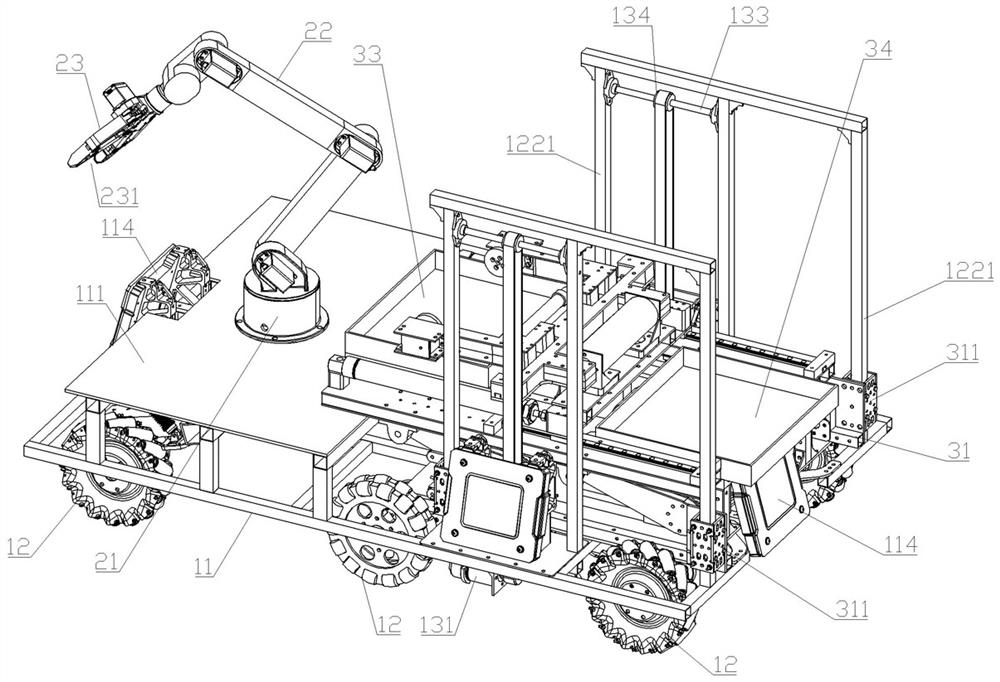

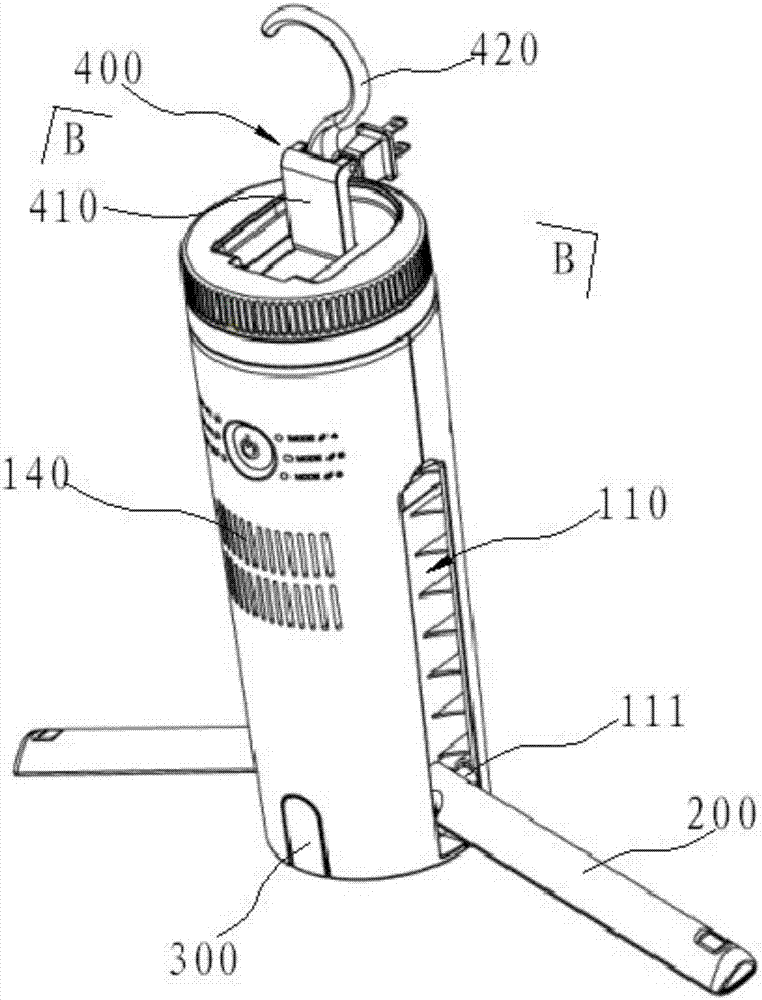

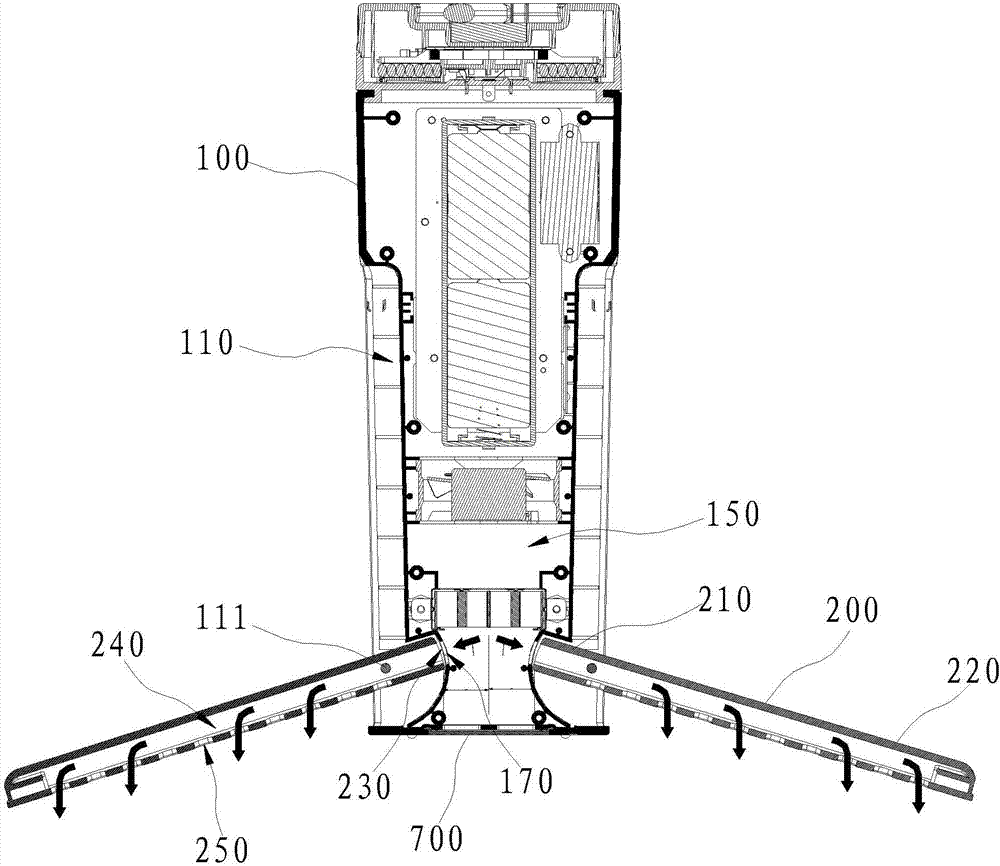

Garbage container transfer robot and method

PendingCN114800425AGood reliabilityHigh degree of automationProgramme-controlled manipulatorGripping headsElectric machineryVehicle frame

The invention discloses a garbage container transfer robot and method and relates to the technical field of automatic transfer equipment. A garbage container transfer robot comprises a movable rack, a mechanical gripper assembly and a carrying assembly. The movable rack comprises a main body frame, electric rollers and a lifting driving assembly; the mechanical gripper assembly comprises a holder motor, a multi-degree-of-freedom mechanical arm and a mechanical gripper; the carrying assembly comprises a base, a reciprocating pushing assembly, an upper base, a low-position tray, a high-position tray and a clamping jaw mechanism. The carrying assembly is installed on the guide rods of the two vertical supports in a sliding mode through guide sleeves on the two sides of the base and located in the carrying interval. The garbage container transfer method is based on the garbage container transfer robot. The garbage can is applied to residential quarters, can replace manual garbage dumping to a designated place, and solves the problem that special crowds in the residential quarters are inconvenient to dump garbage. In the garbage container transferring process, full-process automatic operation including picking, transferring and unloading is achieved.

Owner:NANHUA UNIV

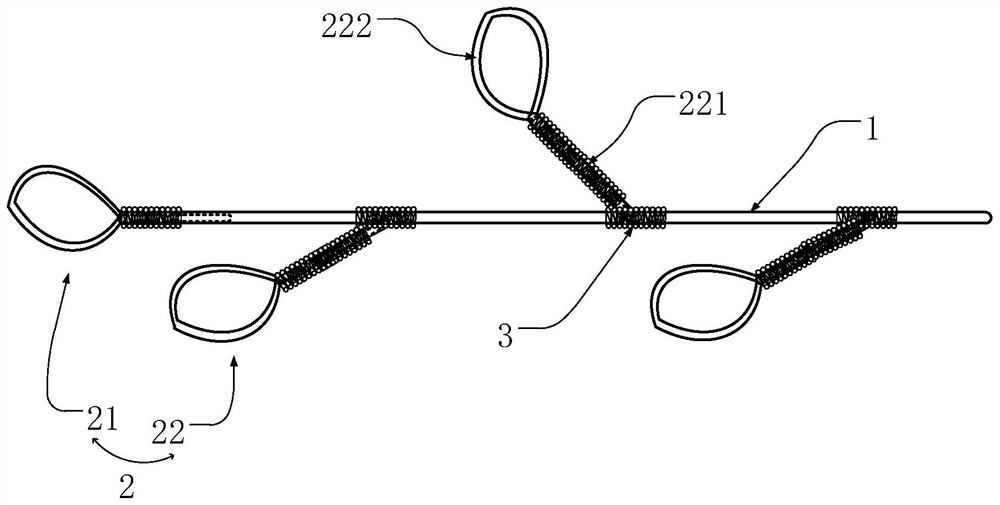

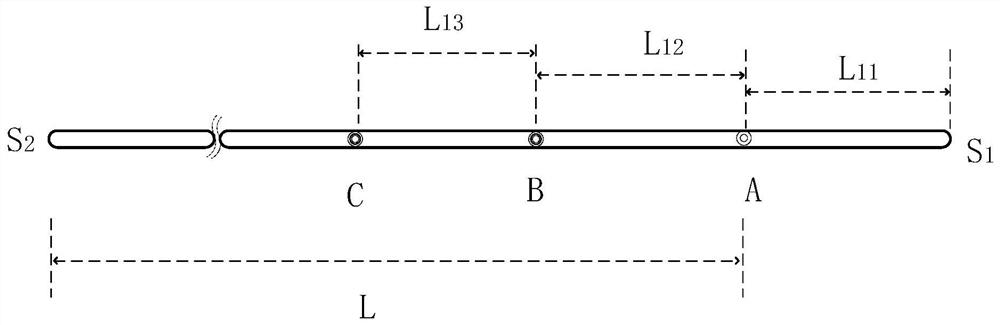

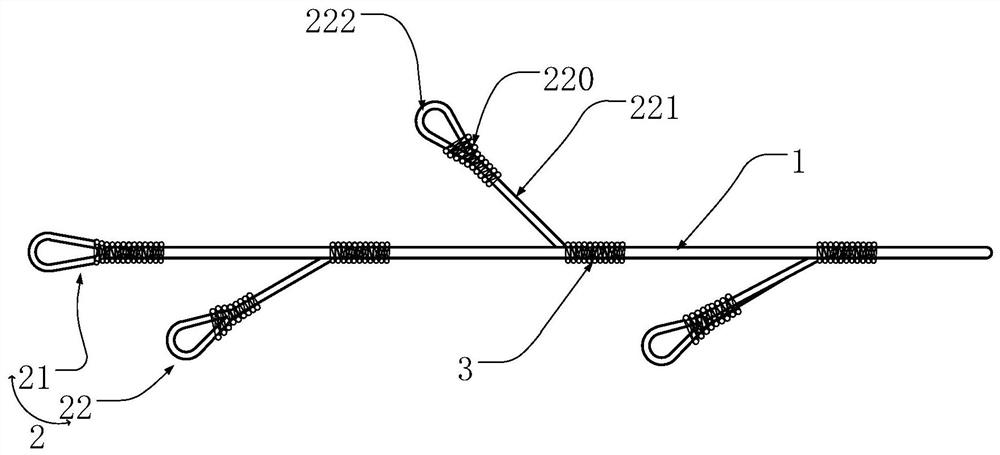

Braided rope provided with multiple hole rings

PendingCN112047228ASimple structureEasy to produceRopes and cables for vehicles/pulleyBraidEngineeringMechanical engineering

A braided rope provided with multiple hole rings comprises a rope body and hole ring parts, wherein each hole ring part comprises a hole ring and a hole ring rope connected therewith, and a hole ringfastening layer is arranged on each hole ring rope; the multiple hole ring parts are arranged at intervals, the hole ring ropes are fixedly connected with the rope body, and a rope fastening layer isarranged on each fixed connection part; and each hole ring part comprises a first hole ring portion arranged at the tail end of the rope body and a second hole ring portion arranged in the middle section of the rope body, and every two directly adjacent second hole ring portions are arranged on different side faces of the rope body. According to the braided rope, the multiple hole ring parts are arranged at intervals on the rope body, so that a plurality of devices can be conveniently pulled or hoisted at the same time, and the operation efficiency is effectively improved; and since reasonablespacing distances are arranged between the hole ring parts, mutual collision interference between the devices can be effectively prevented, the hole ring parts are arranged at intervals on differentside faces of the rope body around the circumference thereof, mutual interference between the devices can further be effectively prevented, and the braided rope has good and wide application prospectsin the related fields of pulling, hoisting and the like.

Owner:SHANDONG ROPE TECH CO LTD

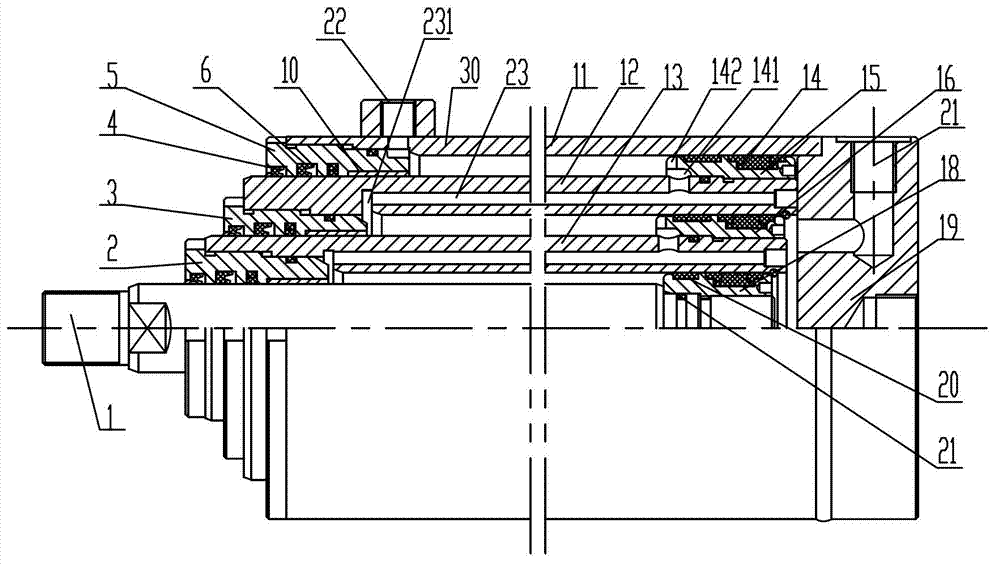

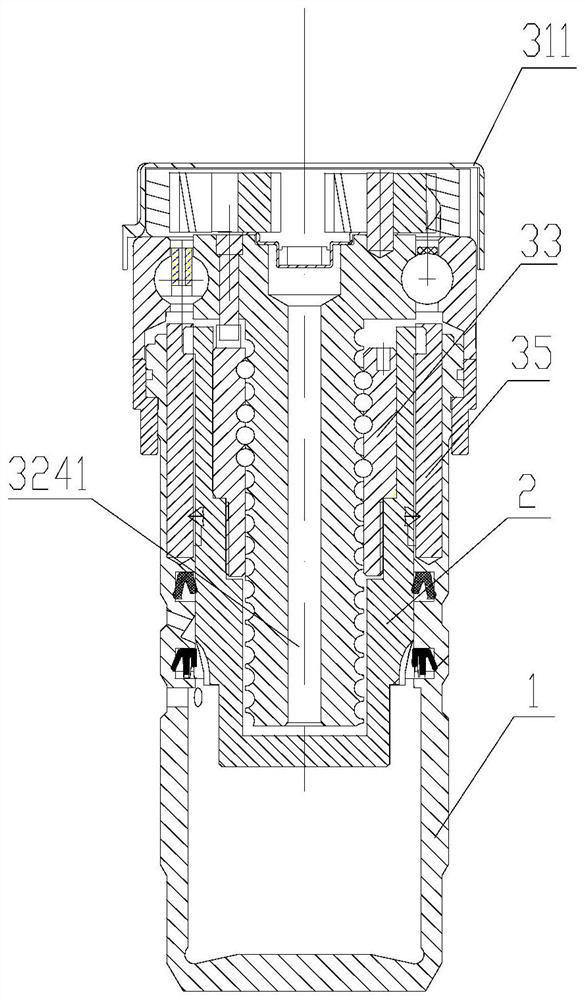

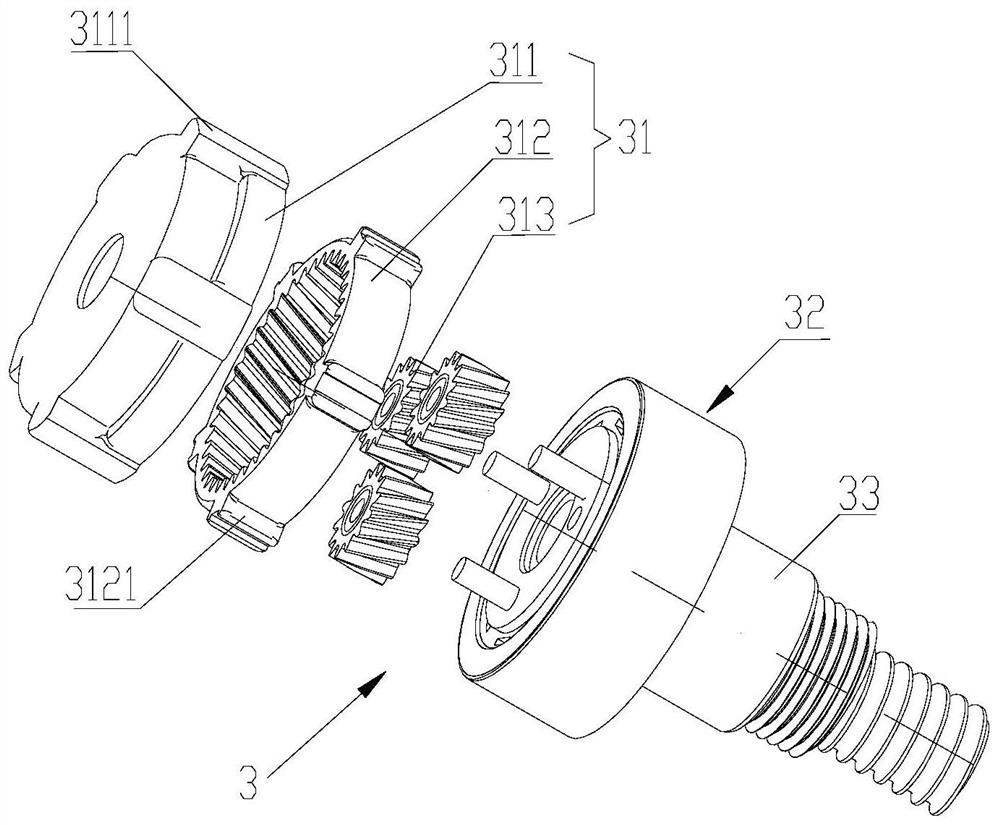

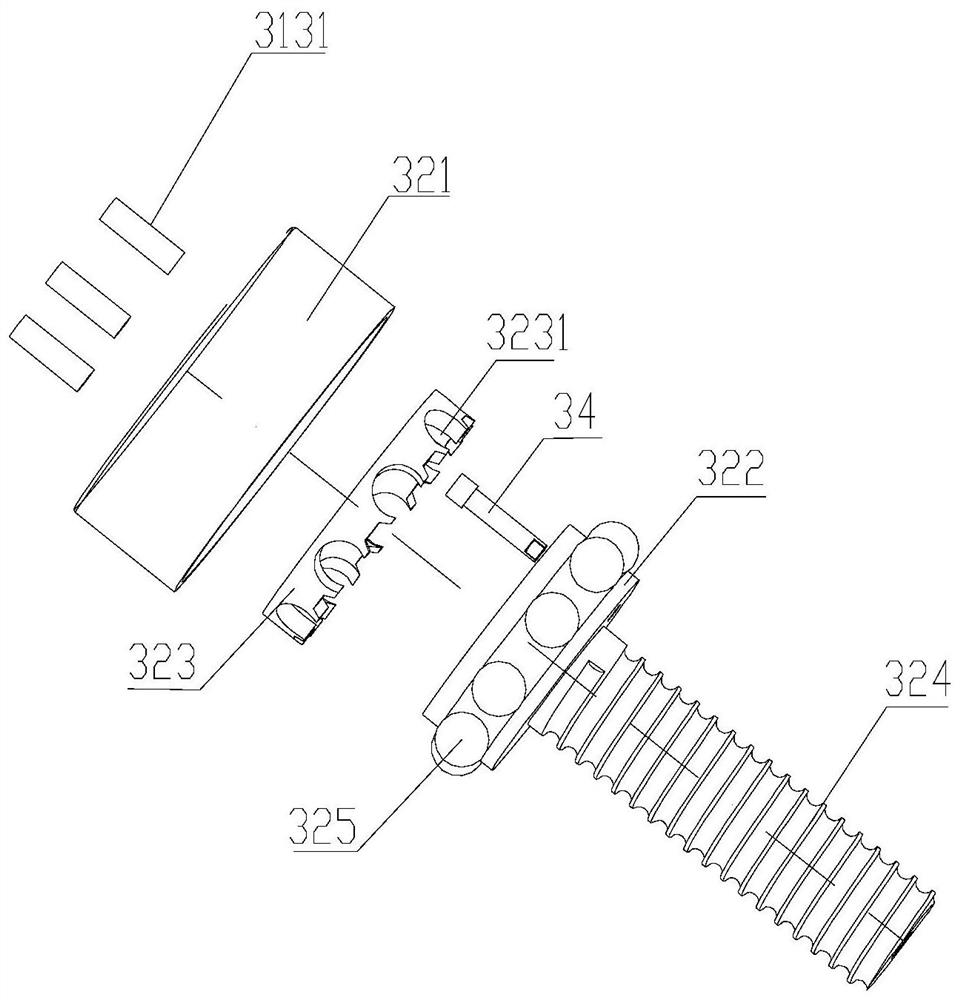

Piston pump set for brake system and control method thereof

ActiveCN112664440AEnough pressureAvoid collision interferencePositive displacement pump componentsFluid braking transmissionGear wheelBraking system

The invention is applicable to the technical field of hydraulic braking, and discloses a piston pump set for a brake system. The piston pump set comprises a piston, a pump body with a working cavity and a transmission mechanism for driving the piston to move in the working cavity, wherein the transmission mechanism comprises a lead screw transmission assembly, a driven part and a planetary gear assembly for transmitting power to the lead screw transmission assembly; the driven part is fixedly connected with the piston; the lead screw transmission assembly is used for driving the driven part to move relative to the working cavity; and a limiting component used for limiting movement of the driven part is arranged between the lead screw transmission assembly and the driven part. The invention further provides a control method for controlling the piston pump set for the brake system. According to the piston pump set for the brake system and the control method provided by the invention, the effect of pumping out high-pressure liquid can be better achieved, stable brake pressure is provided for the brake system, and the working stability is high.

Owner:BYD CO LTD

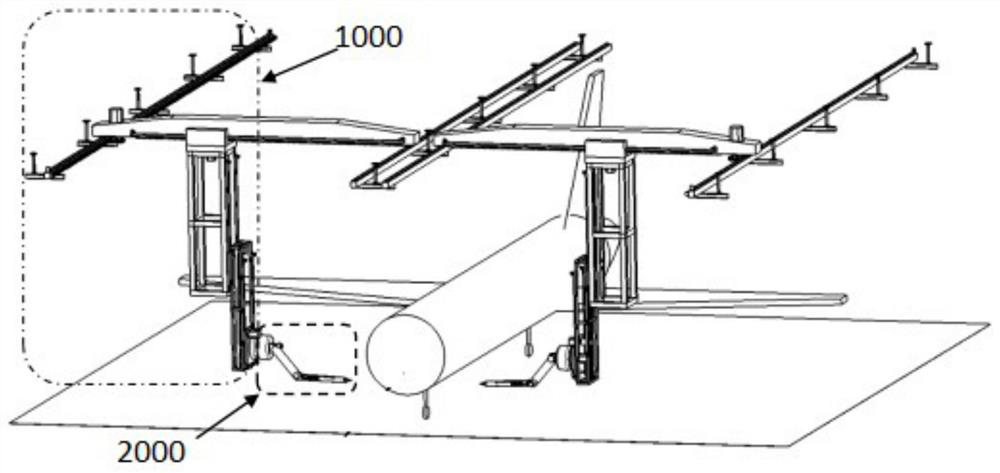

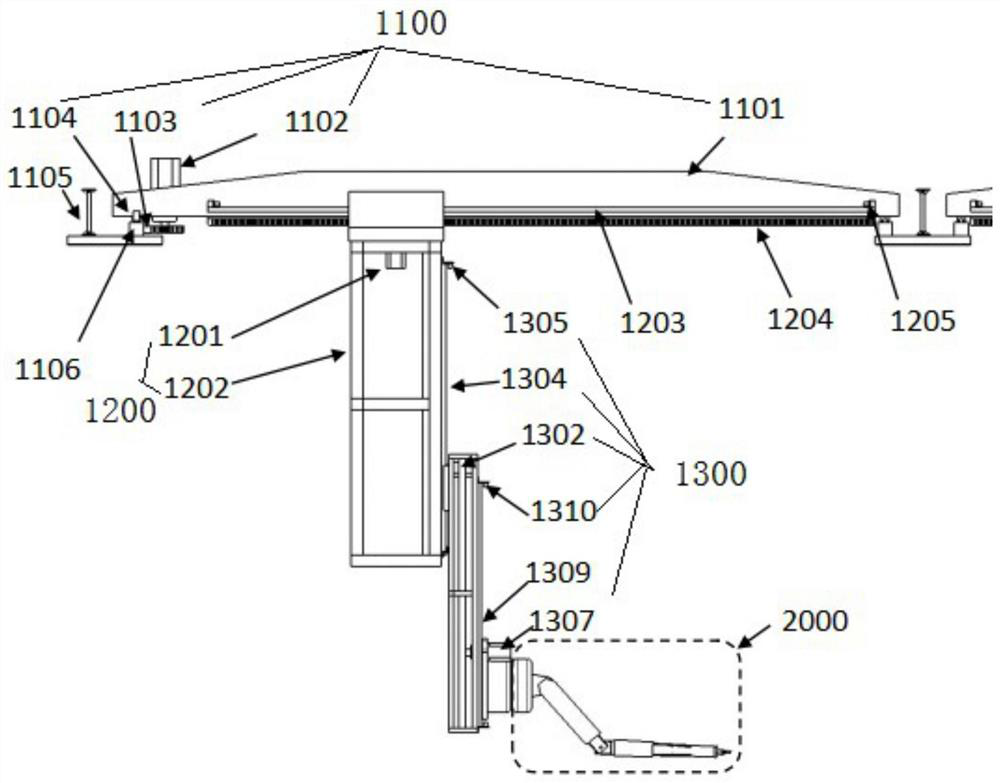

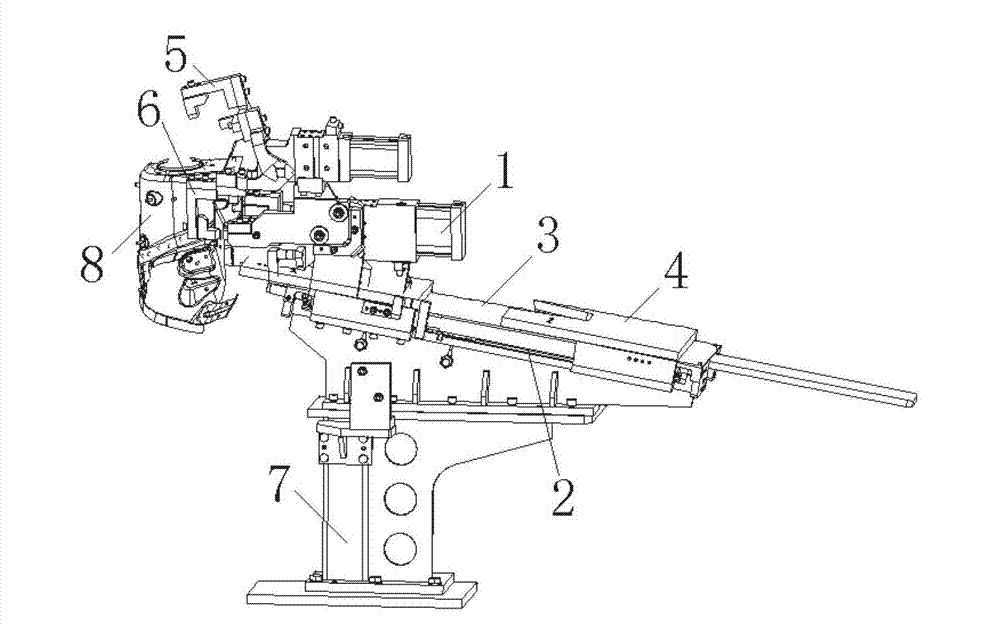

Series-parallel robot for linkage spraying of large surface structure

ActiveCN112916260AAvoid layeringAvoid continuitySpraying apparatusManipulatorLinkage (mechanical)Engineering

The invention discloses a series-parallel robot for linkage spraying of a large surface structure. The series-parallel robot comprises an air three-degree-of-freedom moving mechanism and a spraying mechanical arm, the air three-degree-of-freedom moving mechanism comprises an X-direction moving mechanism, a Y-direction moving mechanism and a Z-direction moving mechanism, the two ends of an X-direction moving truss of the X-direction moving mechanism move on X-direction guiding sliding rails in a guiding mode, the X-direction guiding sliding rails are fixedly connected with a workshop steel structure, the Y-direction moving mechanism is installed on the X-direction moving truss in a guiding mode through a guiding assembly at the upper end of a Y-direction moving frame, a Z-direction moving mechanical arm platform of the Z-direction moving mechanism is installed on the Y-direction moving frame in a guiding mode, a base of the spraying mechanical arm is installed on the Z-direction moving mechanical arm platform of the air three-degree-of-freedom moving mechanism, and the air three-degree-of-freedom moving mechanism drives the spraying mechanical arm to achieve translational motion in three directions in the space. The paint spraying device has the advantages of high paint spraying efficiency, uniformity in paint spraying, large movement space, accuracy in positioning, stable gravity center, small shaking, capability of effectively avoiding long-term injury of paint to human bodies and the like.

Owner:HEFEI UNIV OF TECH

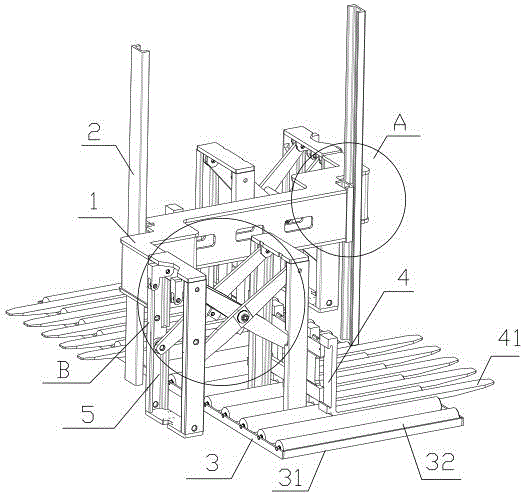

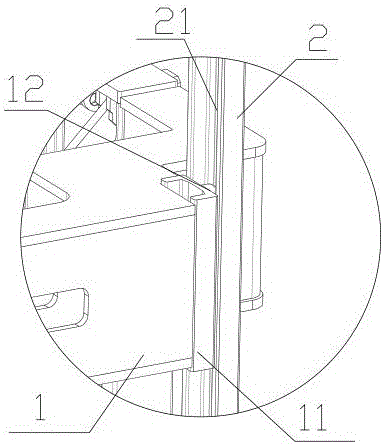

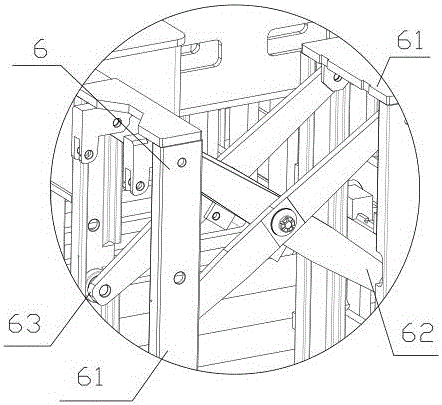

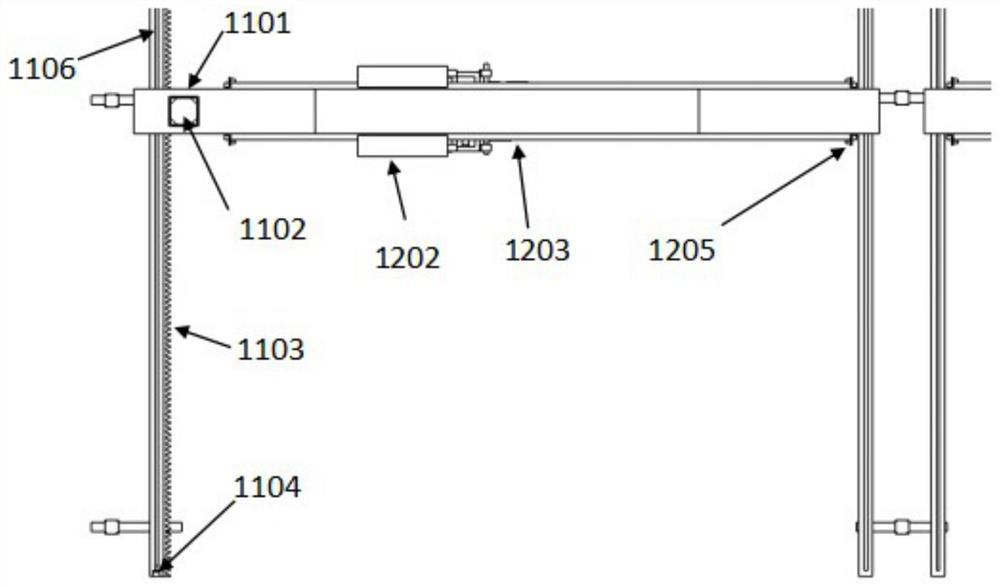

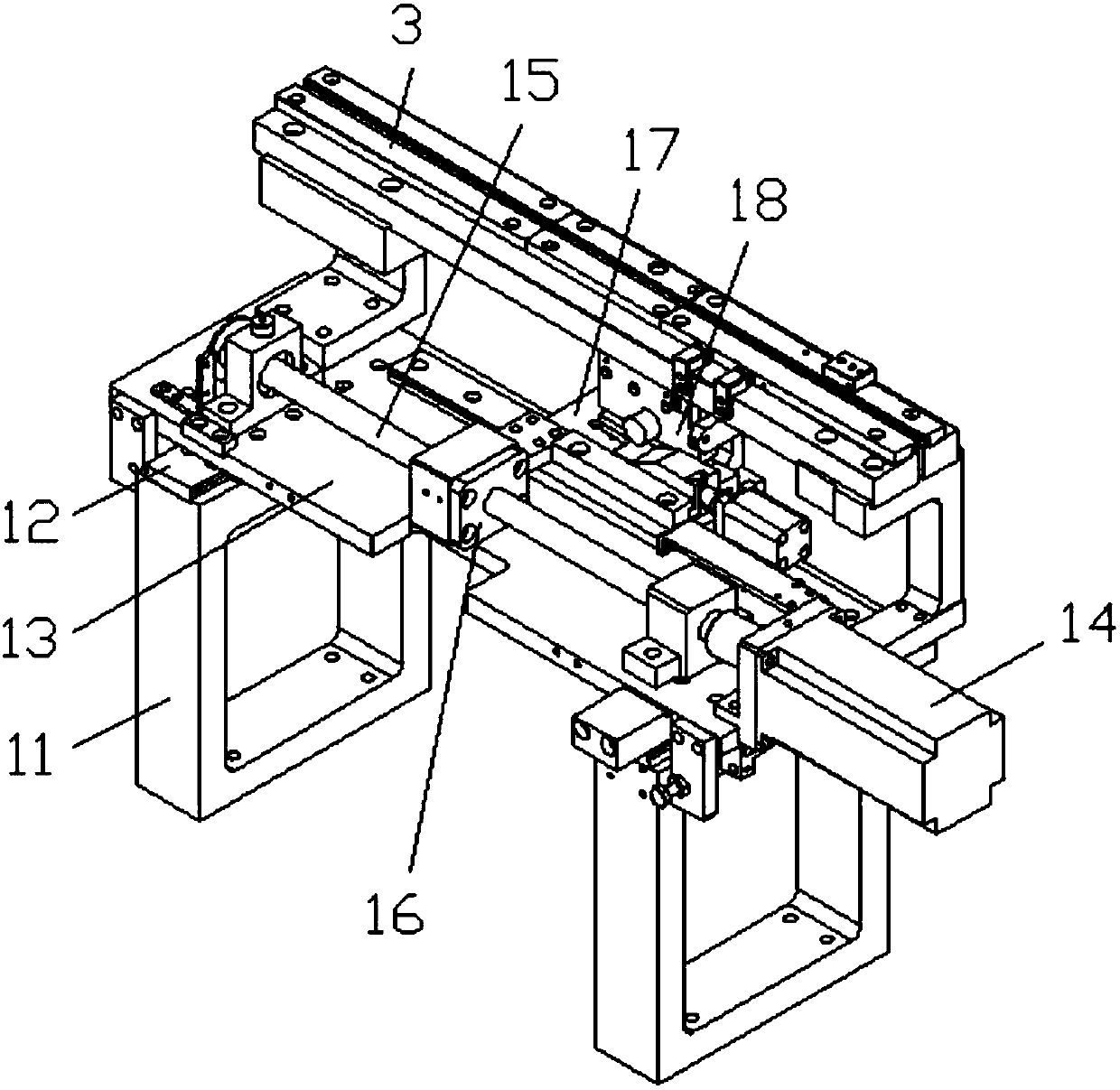

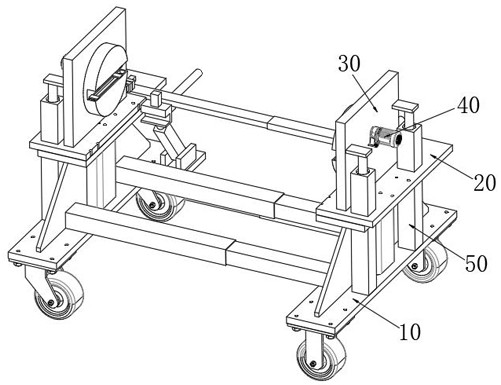

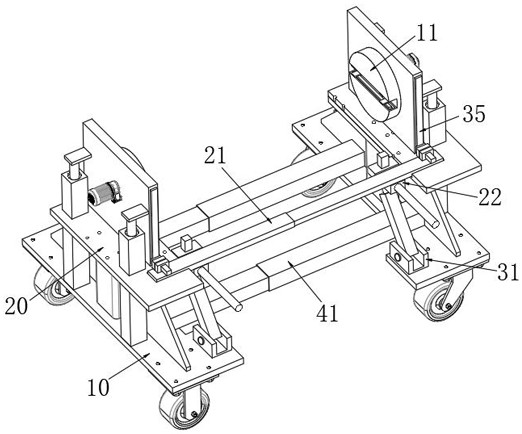

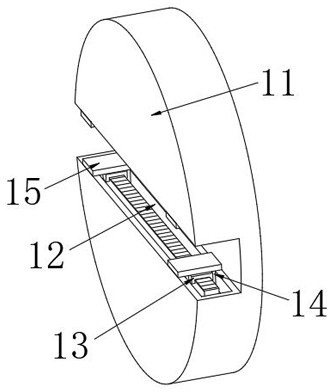

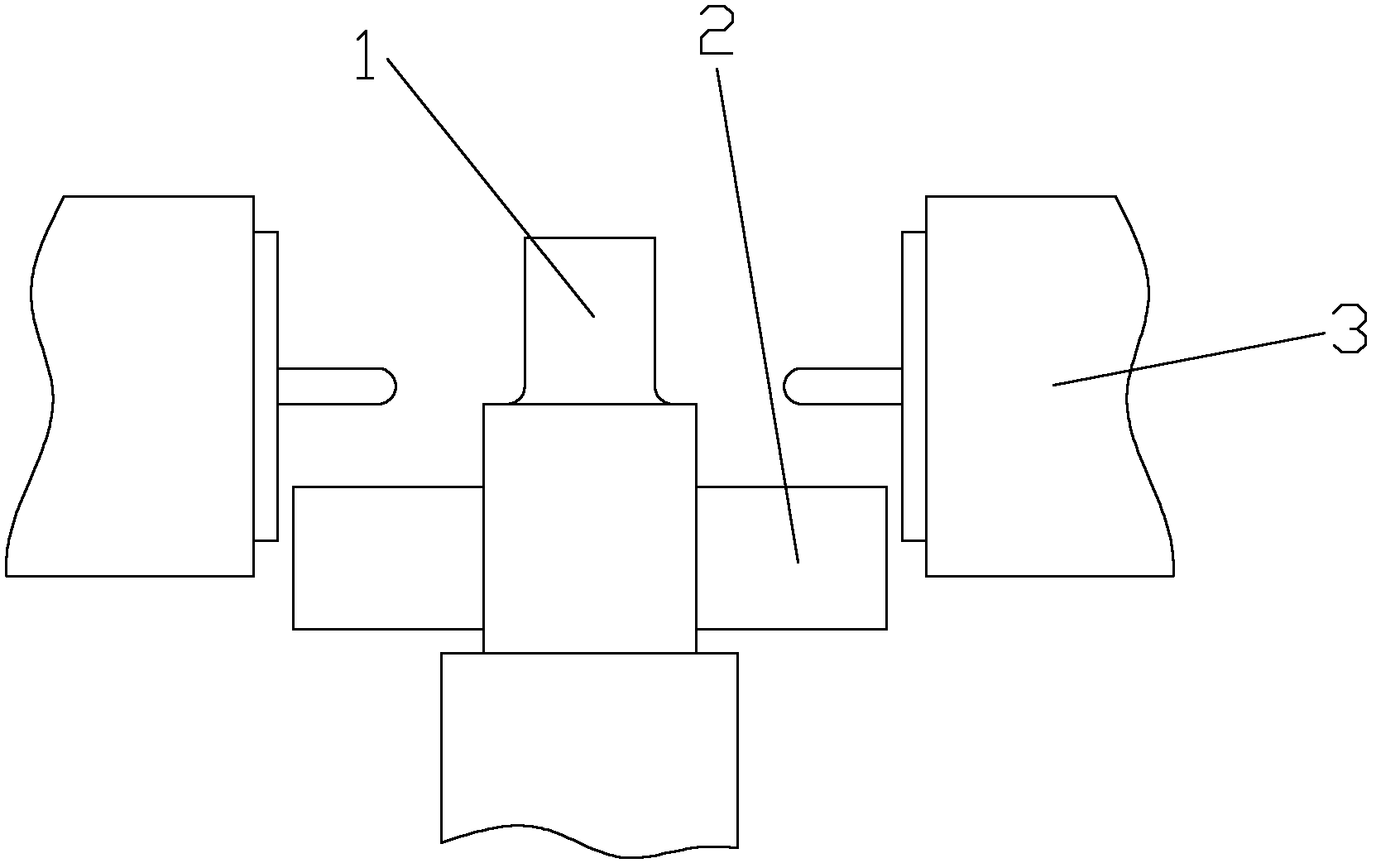

Installation platform for sheet light source emitter in small wind tunnel PIV measurement system and using method of installation platform

The invention discloses an installation platform for a sheet light source emitter in a small wind tunnel PIV measurement system and a using method of the installation platform. The installation platform comprises a bottom installation platform, a leading screw motion system, a telescopic bending type support system and a hollow rotating installation system; the laser sheet light source emitter isfixedly mounted on a hollow rotation platform, and moves in a 3D space via the hollow rotation platform, the telescopic bending type support system and the bottom leading screw motion system. Thus, the laser sheet light source emitter is fixedly mounted, rotates and moves during a PIV experiment so that the sheet light source is arranged at any angle vertical to the bottom surface and two side surfaces of a wind tunnel, a developing paper arrangement platform is arranged to obtain an optimal irradiation distance of the sheet light source in a to-be-measured object, and thus, flow field data indifferent measurement planes can be collected accurately during small wind tunnel PIV test. The device can be suitable for PIV measurement experiments with different measurement plane requirements.

Owner:ZHEJIANG UNIV

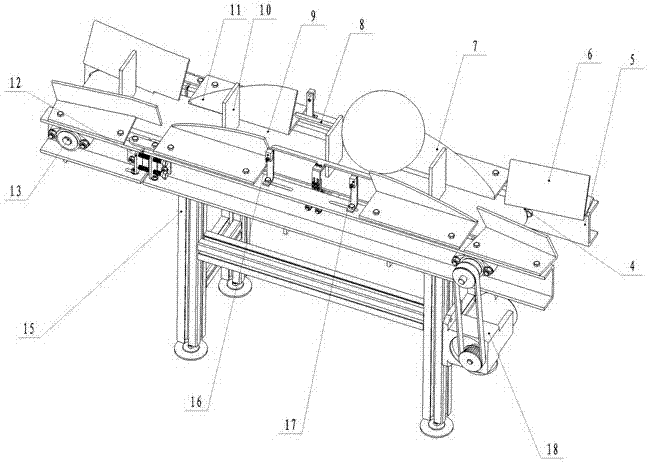

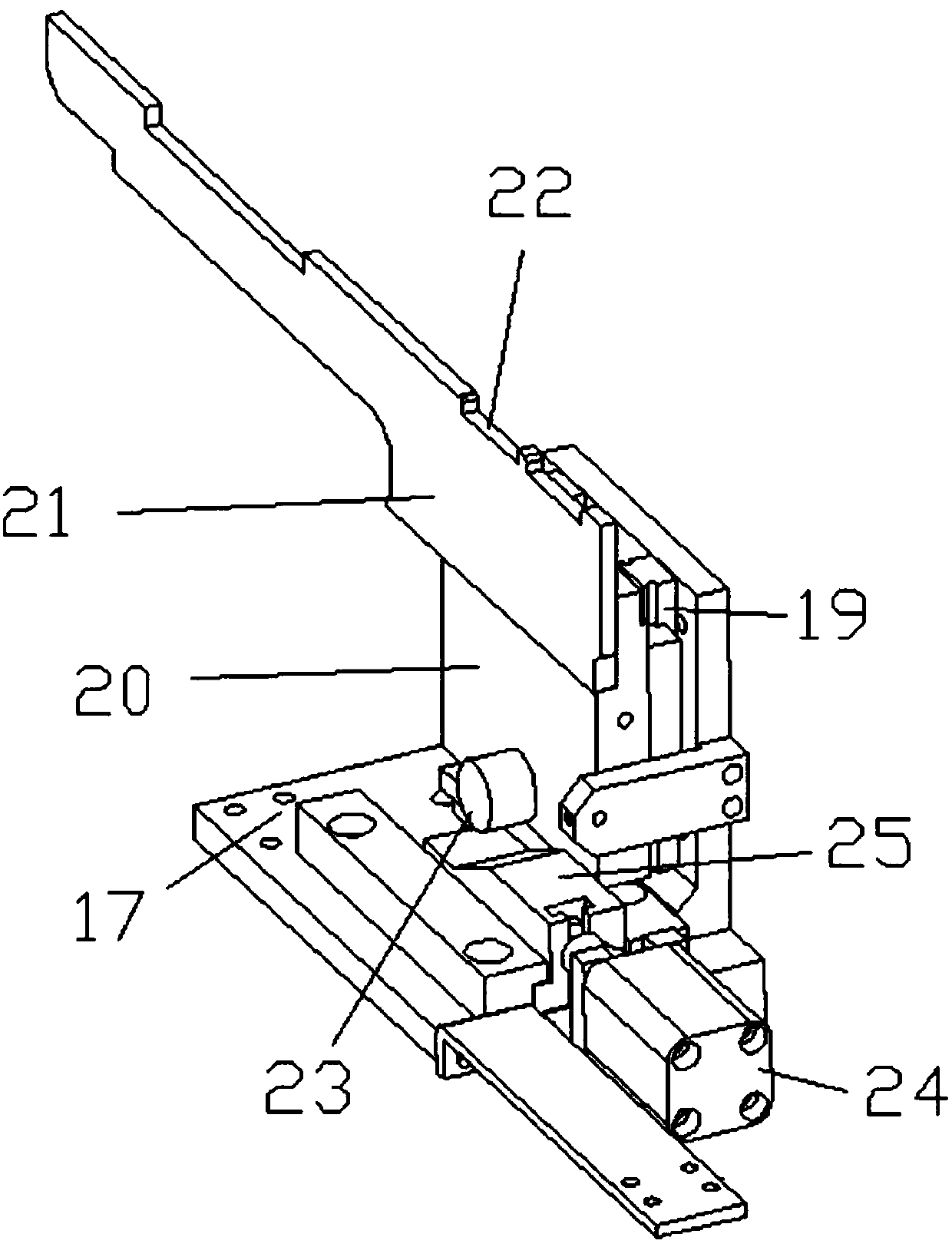

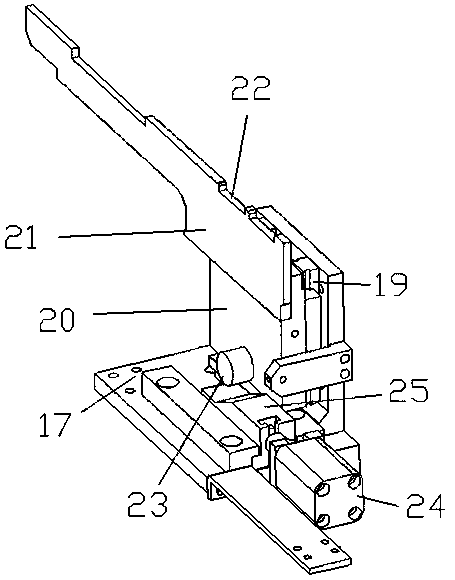

Inclinedly-pushing part arranging mechanism and part arranging method thereof

ActiveCN102962612AAvoid collision interferenceReduce deformation requirementsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses an inclinedly-pushing part arranging mechanism, which comprises a base, wherein an inclined plane pushing mechanism is arranged on the base; the end part of the inclined plane pushing mechanism is provided with a part arranging and clamping mechanism; the inclined plane pushing mechanism comprises a guide inclined frame on the base; an inclined guide plate is arranged on the guide inclined frame; the arranged part clamping mechanism is arranged at the end part of the inclined guide plate; the part arranging and clamping mechanism comprises a fixture body arranged at the end part of the inclined guide plate; the fixture body is provided with a positioning pin and a jaw clip used for clamping and fixing; and a part is arranged by inclinedly pushing through the inclined guide plate, so that a wheel cover outside plate reinforcing plate is avoided from colliding and interfering with peripheral parts, the deformation amount is reduced, the deformation requirements of an overlapping part of a front wheel cover and the wheel cover outside plate reinforcing plate are lowered, and the welding quality is improved.

Owner:CHERY AUTOMOBILE CO LTD

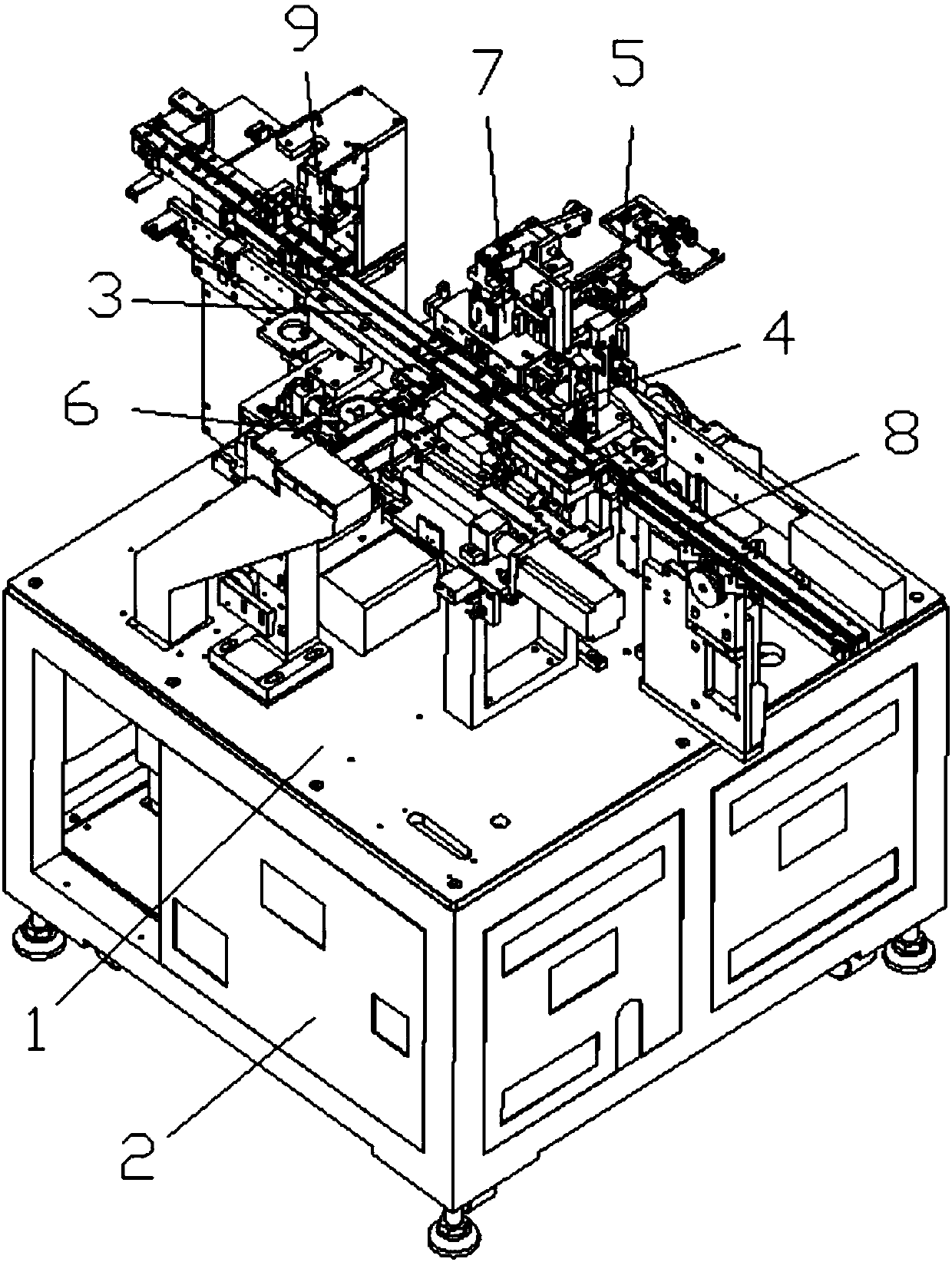

Continuous pin insertion machine for dipolar plug

ActiveCN107749548AHigh precisionRealize vertical conveyingContact member manufacturingContact member cases/bases manufactureEngineeringManipulator

The invention relates to a continuous pin insertion machine for a dipolar plug. A frame is provided with a feeding groove and a feeding device, wherein an upper portion of the feeding groove is provided with a pin insertion mechanism and a carrier belt pin conveying device which are mutually matched, the carrier belt pin conveying device comprises a carrier belt pin conveying seat arranged on theframe, the carrier belt pin conveying seat is provided with a carrier belt pin conveying guiding cylinder and a carrier belt pin conveying groove, the carrier belt pin conveying groove is internally further provided with a carrier belt feeding sliding groove, the middle portion of the carrier belt pin conveying groove is matched with a carrier belt feeding ratchet, the carrier belt feeding ratchetis connected with a carrier belt feeding motor, the carrier belt pin conveying groove is provided with a pin insertion groove at an upper portion of the feeding groove, and the pin insertion groove is matched with a pin insertion block of the pin insertion mechanism. The continuous pin insertion machine is advantaged in that the carrier belt pin conveying device is employed to realize vertical conveying of carrier belts, vertical conveying of the insertion pins can be further realized, the carrier belt pin conveying device is matched with a material casing feeding device and the pin insertionmechanism, continuous pin insertion can be realized, work efficiency is improved, compared with a manipulator for pin insertion, the error rate is substantially reduced, and pin insertion accuracy isimproved.

Owner:新沂市邵店众创工贸发展有限公司

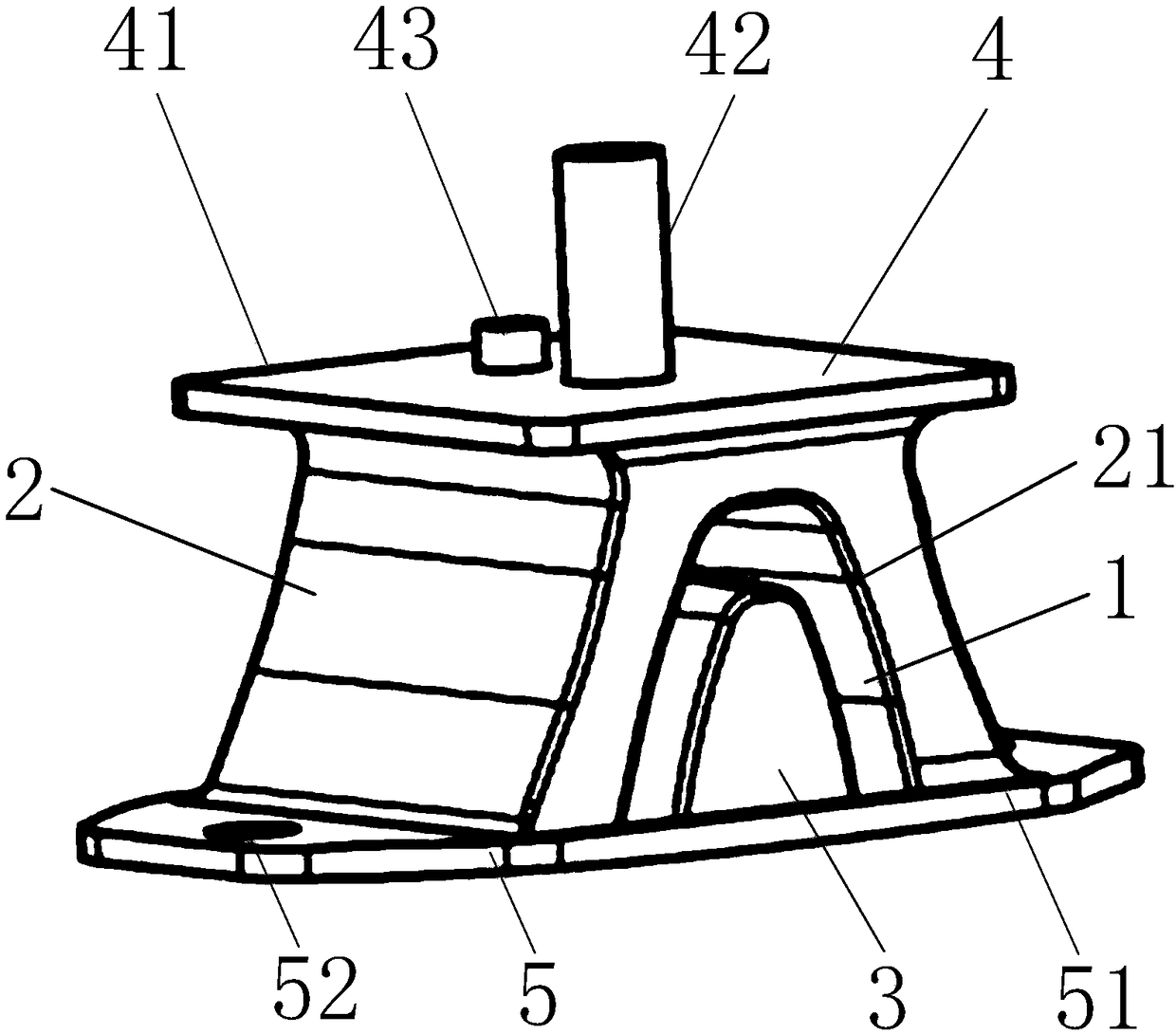

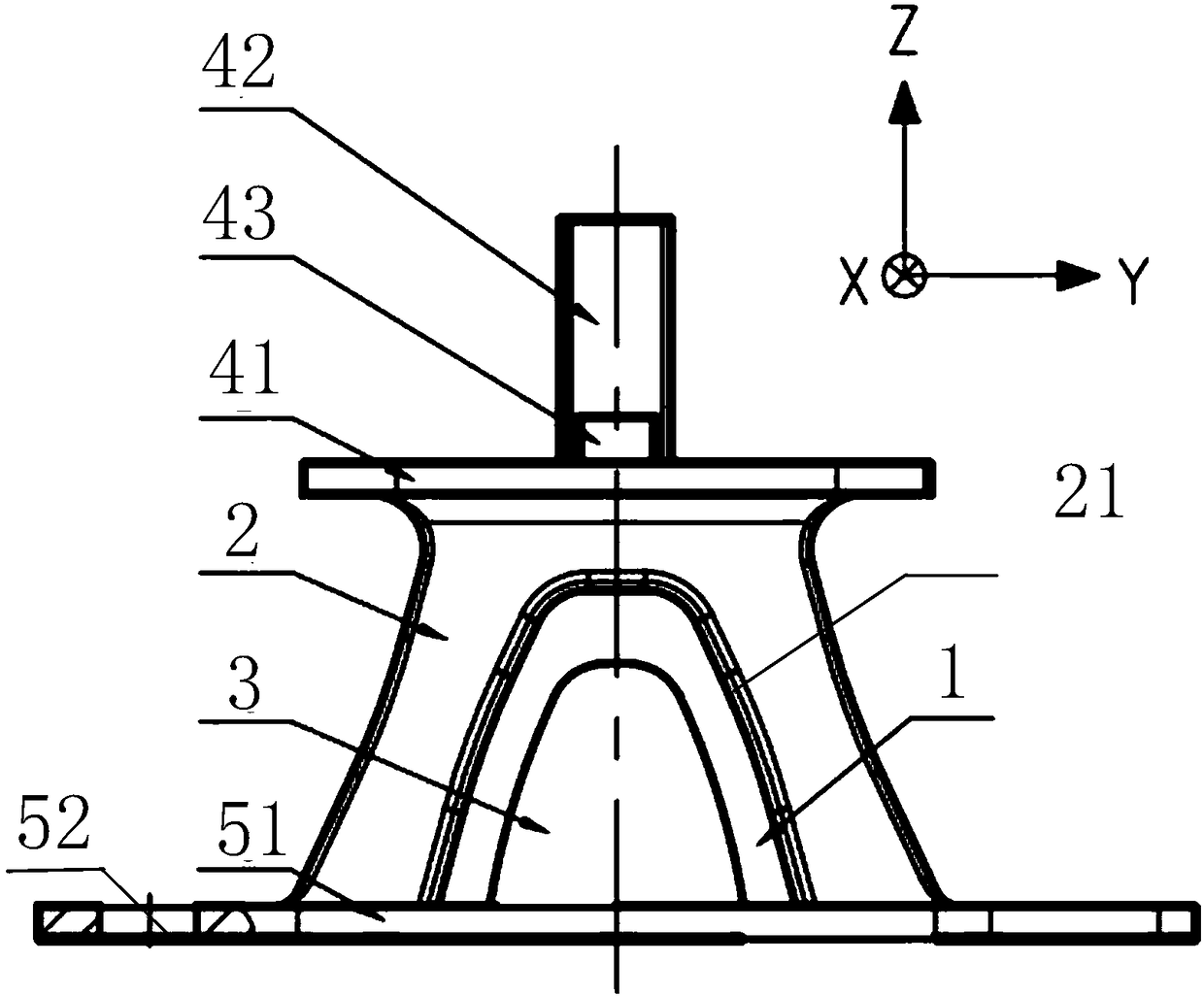

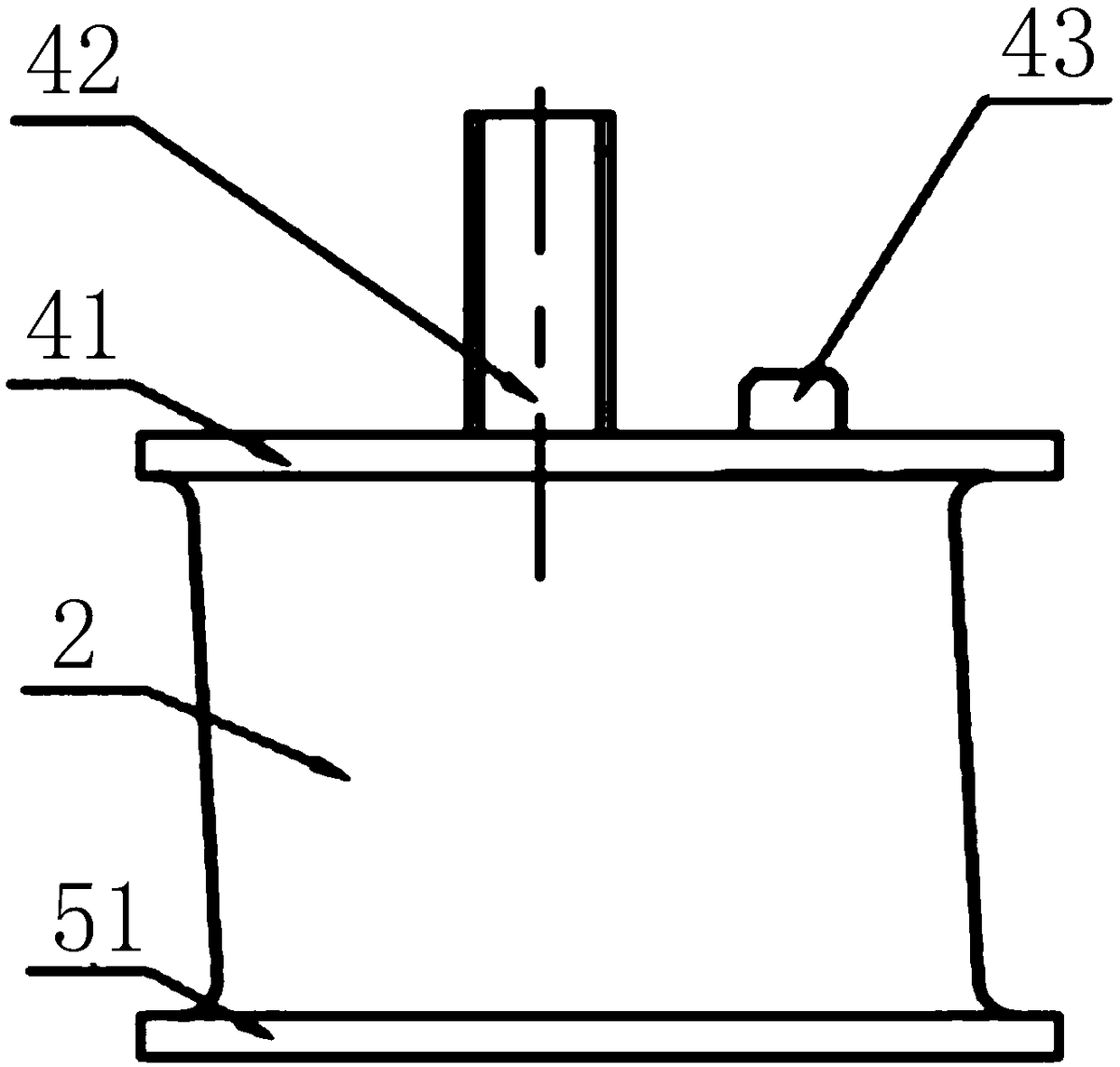

Engine mounting pad assembly

InactiveCN108995522AEffectively limit displacementReduce noise and abnormal soundJet propulsion mountingInternal combustion mountingVehicle frameHardness

The invention provides an engine mounting pad assembly. The assembly includes an upper installing plate assembly connected with an engine and a lower installing plate assembly connected to a vehicle frame. A rubber assembly is disposed between the upper installing plate assembly and the lower installing plate assembly. The rubber assembly includes a rubber body used for engine load and vibration reduction and a limit rubber block for limiting under extreme working conditions; the shore hardness of the rubber body is 40 degrees-60 degrees; and the shore hardness of the limit rubber block is more than 65 degrees. The engine mounting pad assembly has the advantages of a compact structure and effectively meeting requirements of support, limit and vibration isolation reduction.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

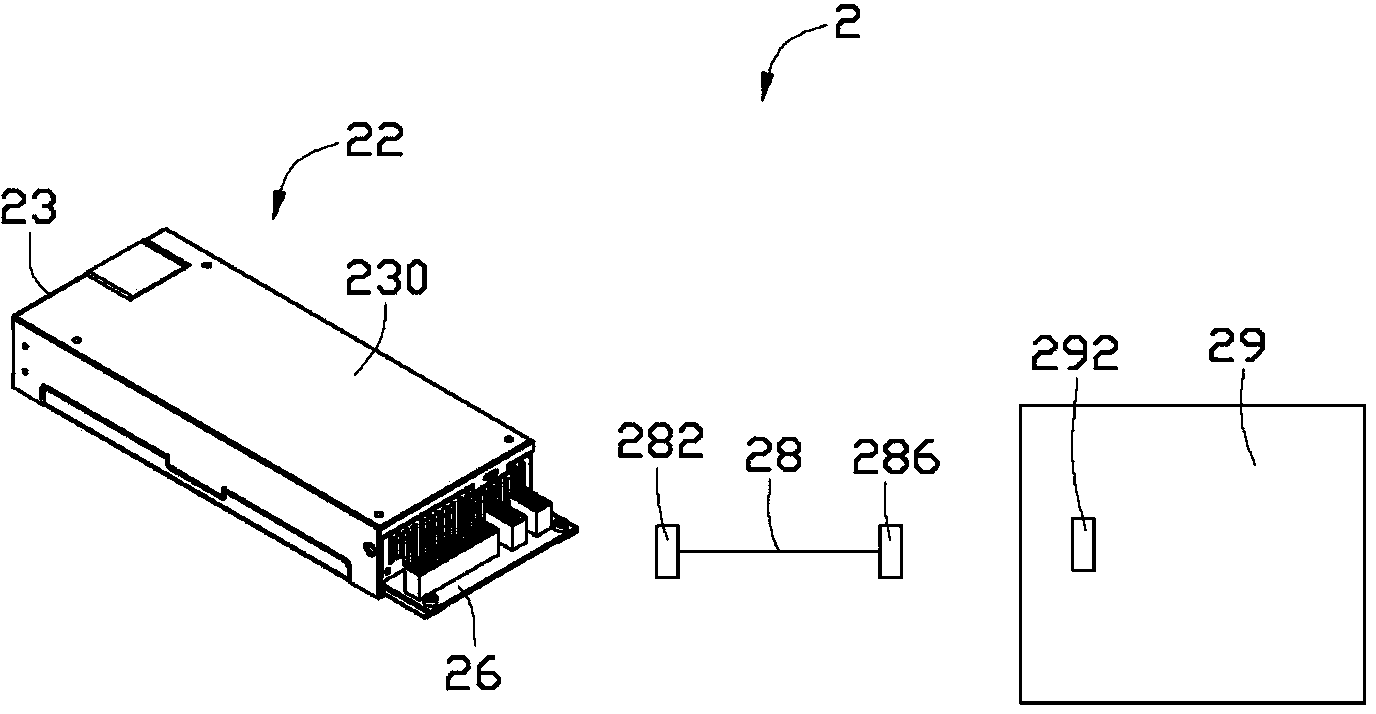

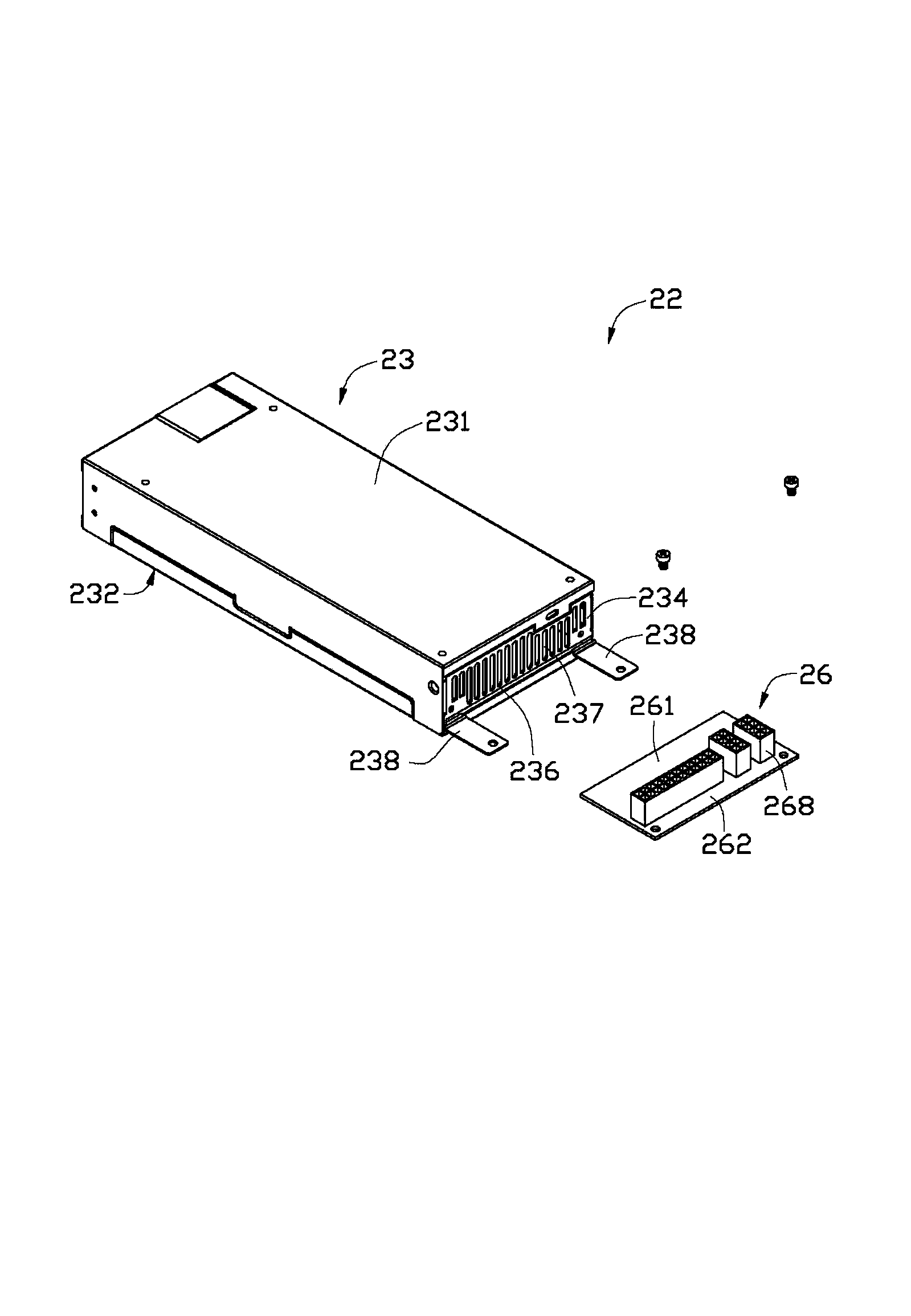

Electronic device and electronic part having connector

InactiveCN103515805AEasy to set upAvoid collision interferenceServersDigital data processing detailsElectric signalEngineering

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Dipolar plug continuous pin inserting device capable of detecting

ActiveCN111180978AHigh precisionRealize vertical conveyingContact member manufacturingContact member cases/bases manufactureRatchetEngineering

Owner:DEZHOU LINGCHENG POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

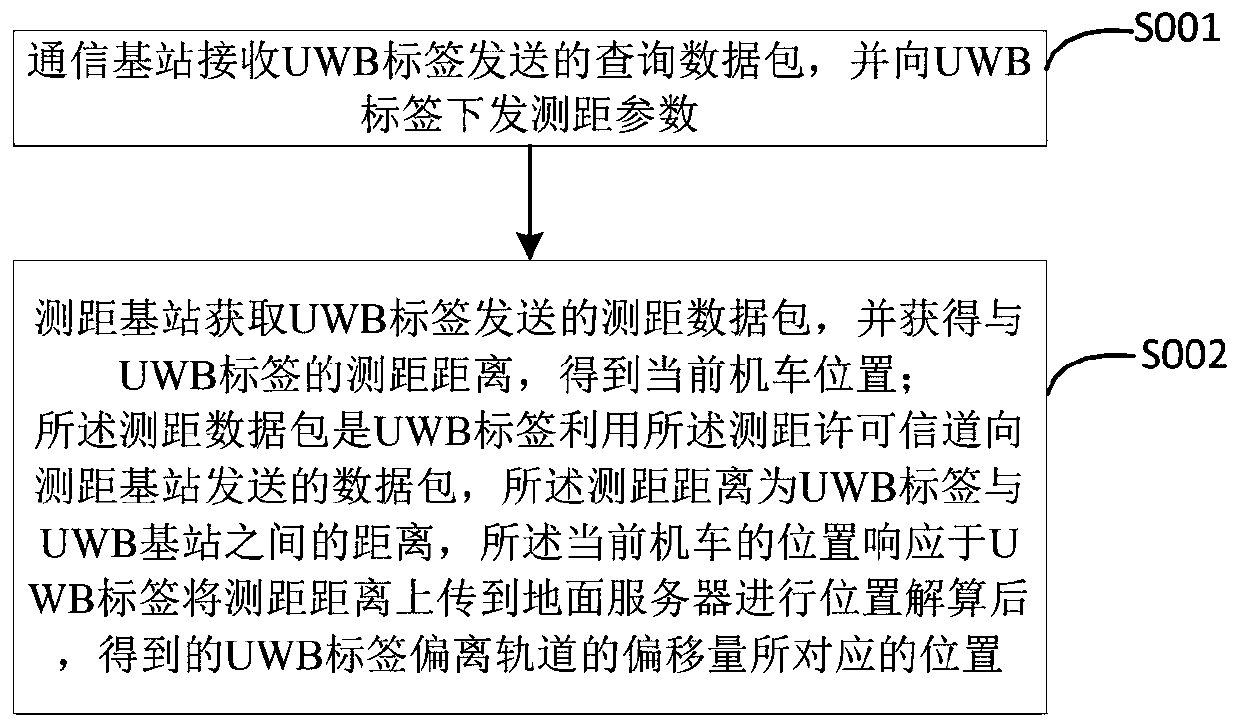

A UWB ultra-wideband wireless communication method and system for ranging and positioning underground locomotives

ActiveCN111163431BImprove real-time performanceImprove accuracyParticular environment based servicesUltra-widebandServer

The invention discloses a UWB ultra-wideband wireless communication method and system for ranging and positioning an underground locomotive in a mine. In a ranging area, a query data packet is sent to a communication base station, and the ranging parameters issued by the communication base station are obtained. Ranging parameters include ranging permission channel, ranging time slot, ranging waiting time delay and ranging base station ID; use the ranging permission channel to send ranging data packets to ranging base station in ranging time slot, and get UWB tag The ranging distance from the ranging base station; after the ranging distance is uploaded to the ground server for position calculation, the offset of the UWB tag from the track is obtained, and the current locomotive position is obtained; the locomotive positioning in the mine The method avoids the conflict in the process of UWB tag ranging, making the positioning calculation more real-time and more accurate.

Owner:HEFEI UNIV OF TECH +1

Fixing and clamping equipment for sheet metal machining

ActiveCN114851148AAvoid collision interferenceConvenient sheet metal processingWork benchesMachine partsMetal machining

The invention relates to the technical field of machining, in particular to a fixing and clamping device for sheet metal machining, side edge clamping of a sheet metal workpiece is achieved through two side edge clamping assemblies, the sheet metal workpiece can be flexibly deflected by any angle, meanwhile, the sheet metal workpiece can be turned over, and the fixing and clamping device is convenient to use and high in practicability. According to the multi-face machining device for the metal plate machining part, multi-face machining of the metal plate machining part can be flexibly achieved, the back side of the metal plate machining part is clamped through the back side clamping assembly, the two side edges of the metal plate machining part are released, and therefore side edge machining of the metal plate machining part is achieved; according to the metal plate machining device, comprehensive machining of the metal plate machined part is flexibly achieved, the machining efficiency of the metal plate machined part is improved, meanwhile, the labor intensity of workers is reduced, and automatic clamping position adjustment of the metal plate machined part is achieved.

Owner:JIANGSU SIDA HEAVY IND

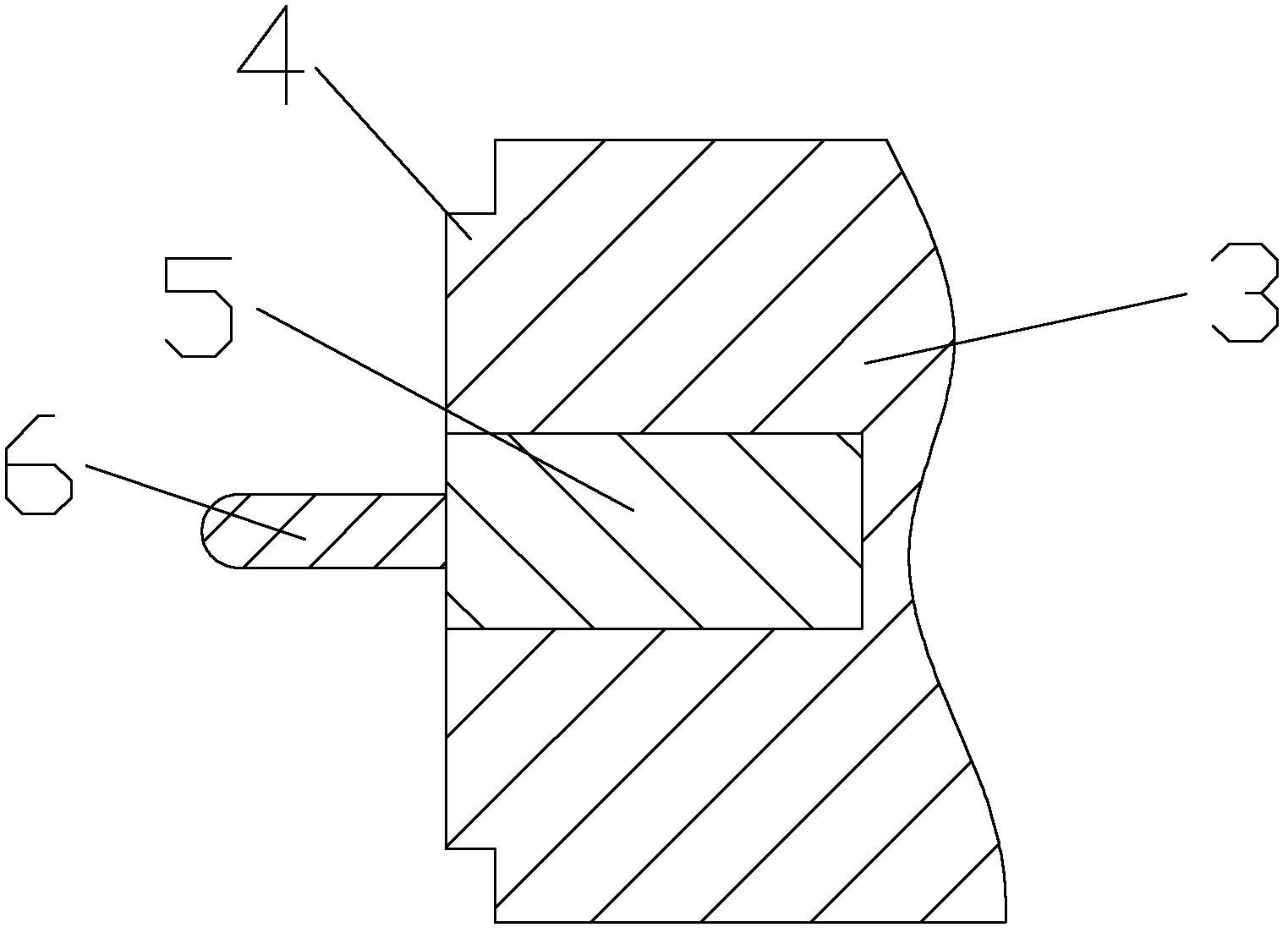

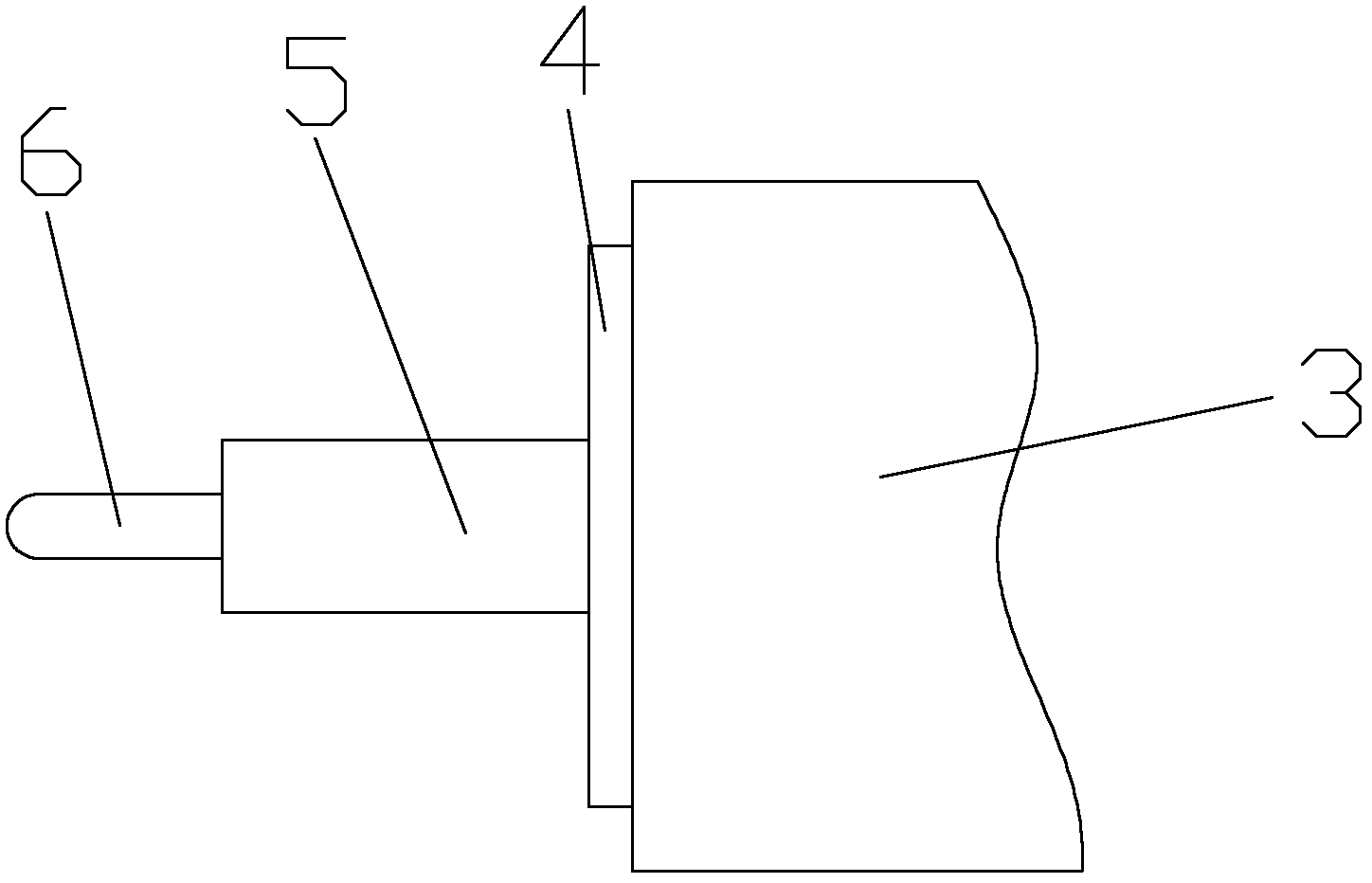

Double-sided milling-machine cutter-fixing device

InactiveCN102528144AAvoid collision interferenceSimple structureMilling cuttersMilling machinesEngineeringMilling cutter

The invention discloses a double-sided milling-machine cutter-fixing device, which comprises a square ram, wherein a cutter-fixing rod which can extend and shrink along the horizontal direction of the ram is arranged in the square ram; a milling cutter is arranged on the cutter-fixing rod; and the outer end of the square ram is provided with a buffering boss. In the double-sided milling-machine cutter-fixing device, when a circular arc at the root of a roll shaft neck is milled by a double-sided milling machine and the shaft neck of a machined roll is longer, milling is carried out according to a normal machining mode; and when the shaft neck of the machined roll is shorter, after the roll is clamped by a double-sided milling-machine clamp, the cutter-fixing rod in the square ram can extend out in the milling process, so that the occurrence of the collision and the interference of the horizontal moving direction of the square ram and the outer side of the clamp is avoided, and the machining can be normally finished. The double-sided milling-machine cutter-fixing device disclosed by the invention has a simple structure and is convenient to use, so that various rolls can be machined by the double-sided milling machine, and the machining range of the double-sided milling machine is enlarged.

Owner:SUZHOU MAIDER MACHINERY

Three-piece type through channel top plate device

PendingCN112622956AIncrease the amount of overlapImproved anti-separation performanceRailway roofsAxle-box lubricationLap jointRail transit

The invention belongs to the technical field of rail transit equipment, and particularly relates to a three-piece type through channel top plate device, wherein a main structure of the device comprises a middle top plate, a left protective plate, a right protective plate and a connecting rod mechanism. Compared to the prior art, the device is characterized in that: 1, a protective plate panel of an upper top plate is widened, and flanges are added at positions close to two ends and the middle; and 2, the middle position area of the protective plate panel of the lower top plate is widened; the lap joint amount of the protection plate panel and the middle top plate is increased, the separation and falling prevention performance of the upper top plate, the lower top plate and the middle top plate in the operation process is improved, extrusion, contact, collision and interference of the upper top plate and the lower top plate are avoided through the flanges, and the upper top plate and the lower top plate can be in smooth transition lap joint; and the three-piece type through channel top plate device is simple in structure, collision interference and stretching falling of the upper top plate and the lower top plate are avoided, the reliability of the top plate device is improved, and the applicability of the top plate device is expanded.

Owner:欧特美交通科技股份有限公司

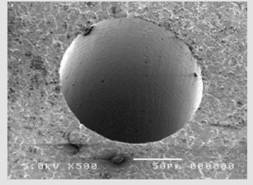

Laser machining small hole device based on scanning galvanometer

ActiveCN111375902BImprove angular accuracyOptimize connection structureLaser beam welding apparatusLaser processingMiniaturization

The invention relates to a laser processing small hole device based on a scanning galvanometer. Including: a first 45° mirror, a two-dimensional scanning galvanometer unit, a focusing objective lens, a coaxial auxiliary air blowing mechanism and a base; the two-dimensional scanning galvanometer unit, the focusing objective lens, and the coaxial auxiliary air blowing The mechanism is separately installed on the base from top to bottom, and the focusing objective lens and the coaxial auxiliary blowing mechanism move freely in the up and down direction; the two-dimensional scanning galvanometer unit and the first 45 °Reflector is used to adjust the output direction of the laser light to be vertically incident on the center of the focusing objective lens; the coaxial auxiliary air blowing mechanism includes a nozzle seat and a nozzle arranged at the lower end of the nozzle seat, and the nozzle is horizontal The direction is free to move. The device of the invention improves the efficiency of processing small holes with larger depths through the effective adjustment of the laser defocusing position, the axial precision of the small holes is higher, and is conducive to the miniaturization of the size of the coaxial blowing nozzle at the front end of the processing device.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

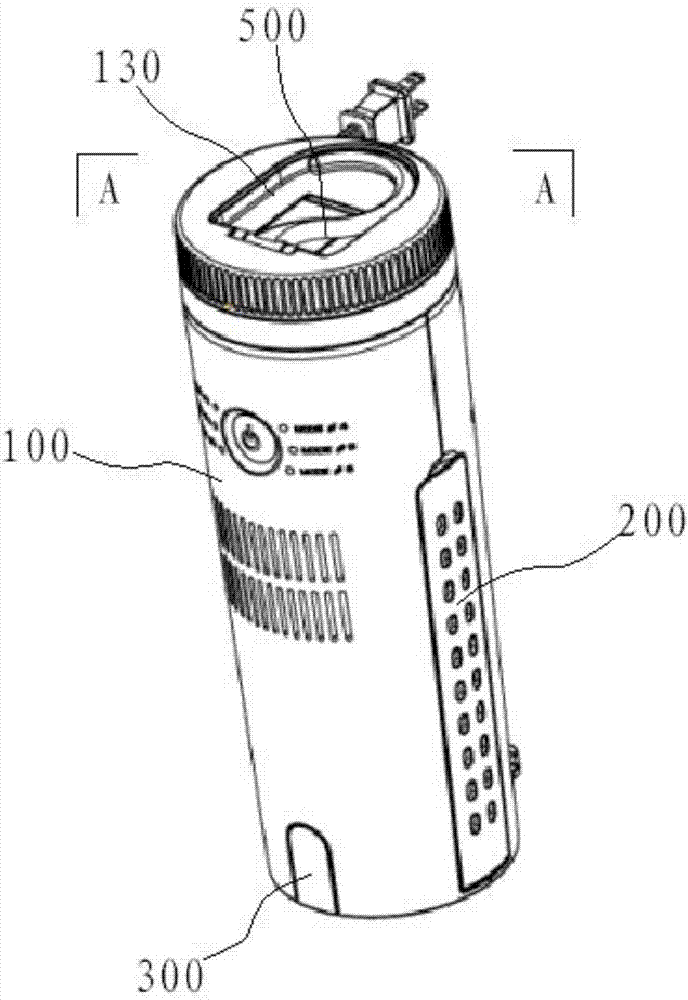

Folding clothes hanger

ActiveCN106906628AReduce volumeAchieve full collapseApparel holdersOther drying apparatusEngineeringClothes hanger

The invention discloses a folding clothes hanger comprising a hanger body, a hanger arm, a hanger hook, and a suspension hook. The hanger body is provided with first receiving groove, a second receiving groove and a third receiving groove staggered from each other and arranged at intervals. A first rotating shaft is arranged on the inner wall of the first receiving groove, while a second rotating shaft on the inner wall of the second receiving groove and a third rotating shaft on the inner wall of the third receiving groove. The hanger arm can be received in the first receiving groove and is flush with the opening of the first receiving groove. The hanger hook can be received in the second receiving groove and is flush with the opening of the second receiving groove. The suspension hook is rotatably arranged on the third rotating shaft and can be received in the third receiving groove and is flush with the opening of the third receiving groove. Thus, it can be achieved that the hanger body, the hanger arm, the hanger hook and the like are completely closed up, and thus, the hanger arm, the hanger hook and the like can be well hidden in the hanger body; as a result, the size of the folding clothes hanger can be reduced to an utmost extent to avoid occupation of excessive space, and the entire folding clothes hanger can be provided with a better appearance with menaced use experience.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD +1

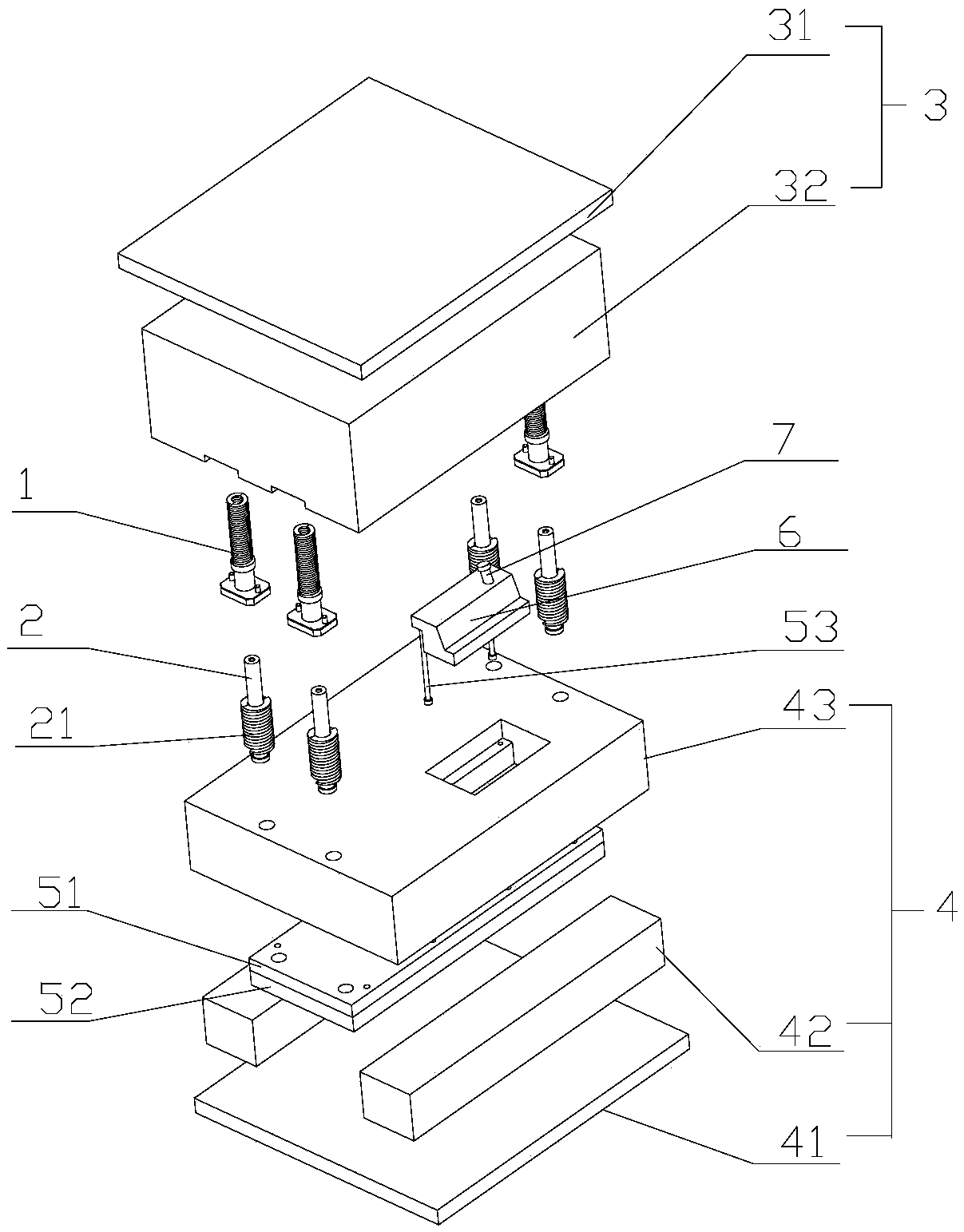

Die with thimble advanced reset mechanism

The invention relates to the field of dies, in particular to a die with a thimble advanced reset mechanism. The die with the thimble advanced reset mechanism comprises an upper die and a lower die, anadvanced reset mechanism is mounted on the upper die, and the advanced reset mechanism can stretch and contract relative to the upper die. A reset rod is mounted on the lower die, the advanced resetmechanism and the reset rod are arranged oppositely, the reset rod is fixedly connected with a thimble mechanism, and the advanced reset mechanism extends out the upper die and abuts against the resetrod to drive the thimble mechanism to reset during die assembly. Through the cooperation of the advanced reset mechanism and the reset rod, the advanced reset mechanism pushes the reset rod to drivethe thimble mechanism to reset, so that thimble advanced reset is realized, in this way, a sliding block can be prevented from hitting a thimble, and the damage to the thimble is avoided. The problemsthat the reset structure is complex and the reset structure is not suitable for the design of small-scale dies in the prior art are solved.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST

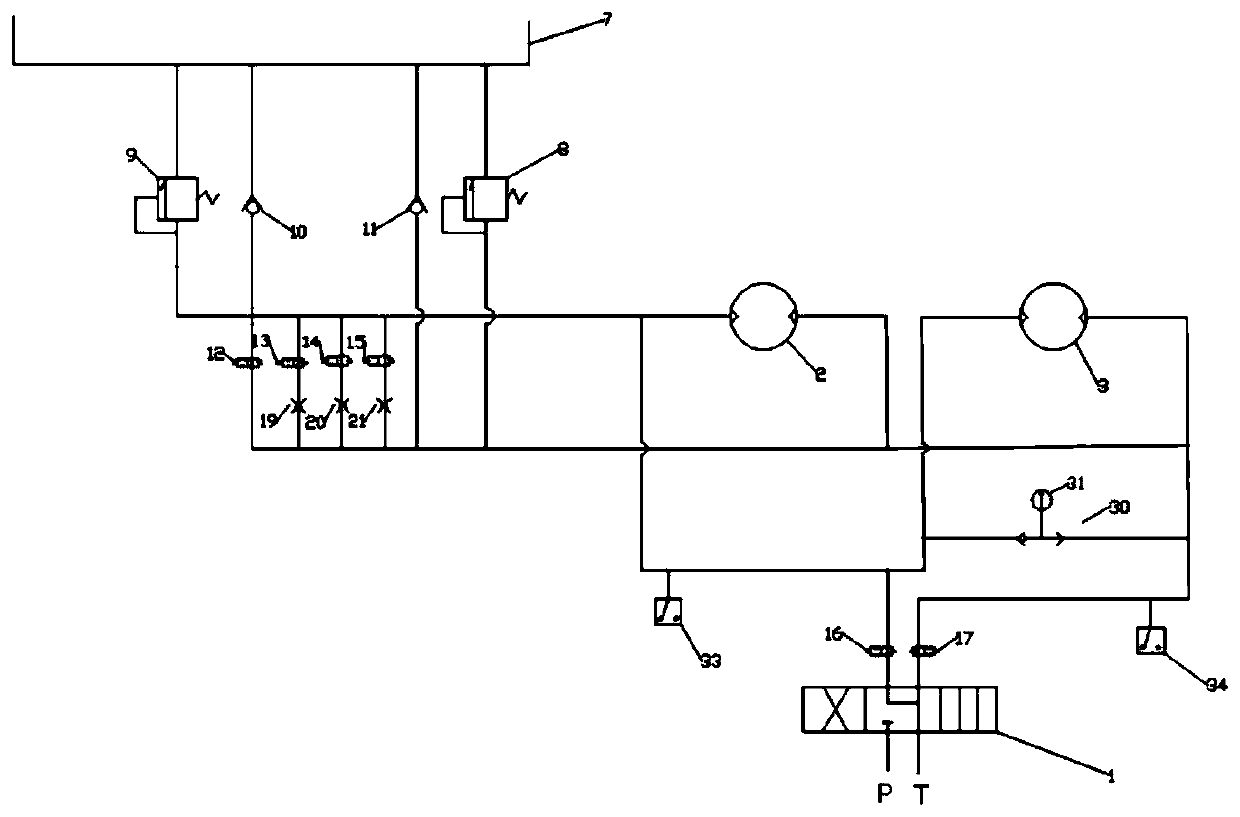

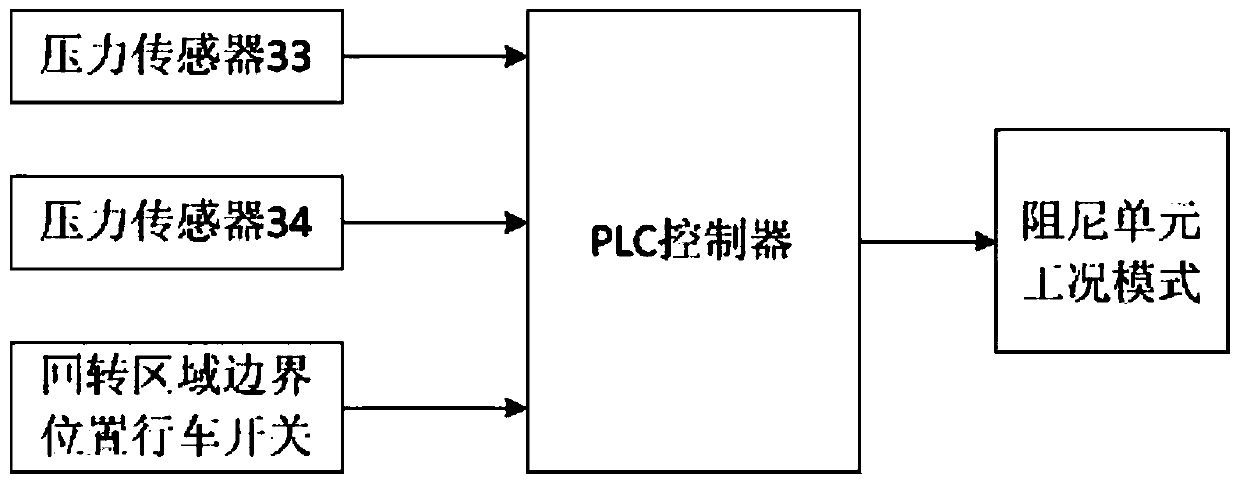

Crawler crane rotation protective device resistant to wind and waves and capable of achieving limited region automatic circulation

ActiveCN110240073AShorten the timeImprove hoisting work efficiencyFluid-pressure actuator safetyServomotor componentsEngineeringSafety valve

The invention relates to a crawler crane rotation protective device resistant to wind and waves and capable of achieving limited region automatic circulation. The crawler crane rotation protective device comprises two first electromagnetic reversing valves which are arranged on two main oil ways of hydraulic motors and a connection pipeline of a main reversing valve, a hydraulic oil tank connected with the two main oil ways of the hydraulic motors, two first safety valves which are arranged on the two main oil ways of the hydraulic motors and a connection pipeline of the hydraulic oil tank, a damping unit which is used for connecting the two main oil ways of the hydraulic motors to be connected together so that impact and shaking energy can be reduced and absorbed, two pressure sensors arranged on the two main oil ways of the hydraulic motors correspondingly, a rotation brake in the normally open state, and a controller, wherein the controller is used for controlling the damping unit to distribute high damping and low damping of the main oil ways of the hydraulic motors, then, the damping difference is formed between the two main oil ways, and the upper portion of a crane is subjected to differential damping rotation, or alternatively subjected to free damping rotation and differential damping rotation.

Owner:CHINA FIRST METALLURGICAL GROUP

An automated storage system including a conveyor line and a stacker

The invention relates to the field of automatic mechanical equipment, in particular to an automatic warehousing system comprising a conveying line and stacking machines. According to the technical scheme, the automatic warehousing system comprises the stacking machines and fork assemblies, the conveying line and guide rails are laid in the lane, the guide rails are arranged on the two sides of the conveying line, and the stacking machines move along the guide rails. The purpose of the present invention is to provide the automatic warehousing system, a cargo fork of the stacking machine is used for directly placing the goods on the conveying line in the lane through the transverse moving and lifting actions, and efficient and automatic conveying of goods is achieved, and the multiple stacking machines can be arranged on one conveying line to work at the same time and the efficiency is improved, the back and forth distance of the stacking machines is shortened, pallets can be accessed, and the pallet-free goods can also be accessed.

Owner:NOBLEELEVATOR INTELLIGENT EQUIP CO LTD

Environment-friendly, energy-saving and efficient annular sintering machine trolley

InactiveCN102564132BAvoid collision interferenceReduce intervalFurnace typesStructural engineeringMechanical engineering

Owner:陕西鼎力冶金机械传动有限公司

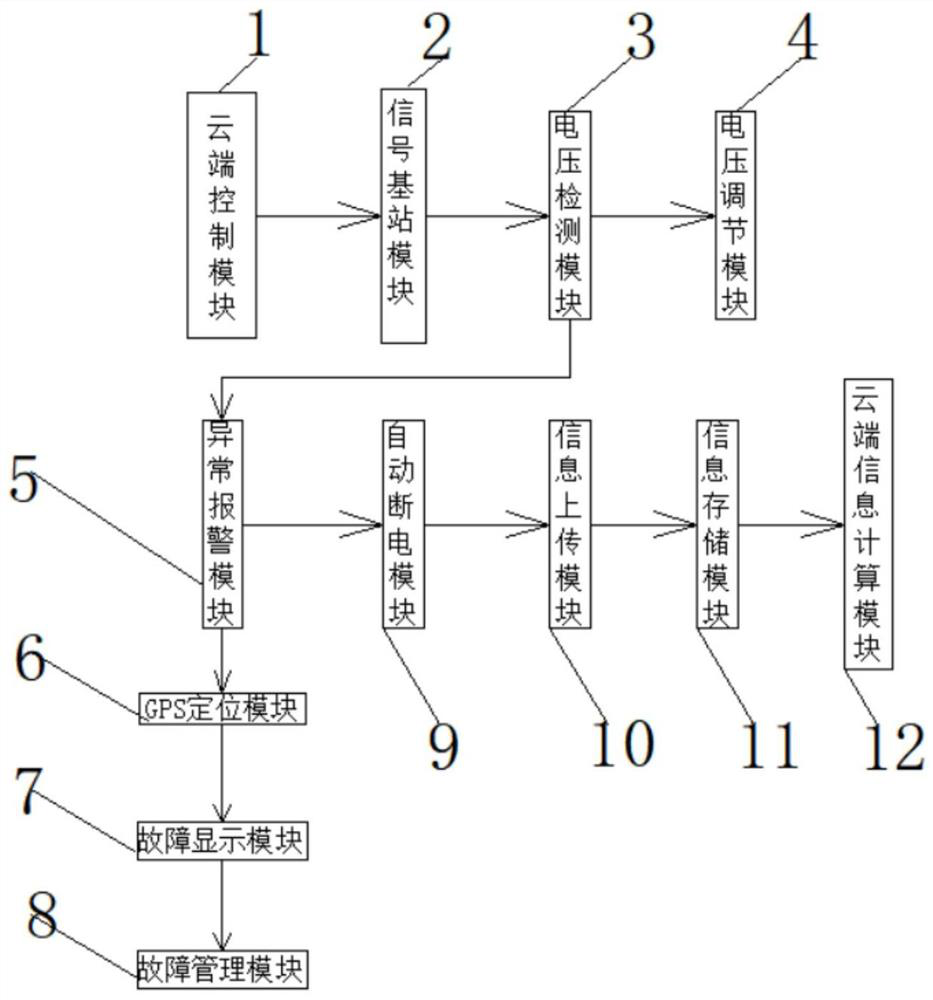

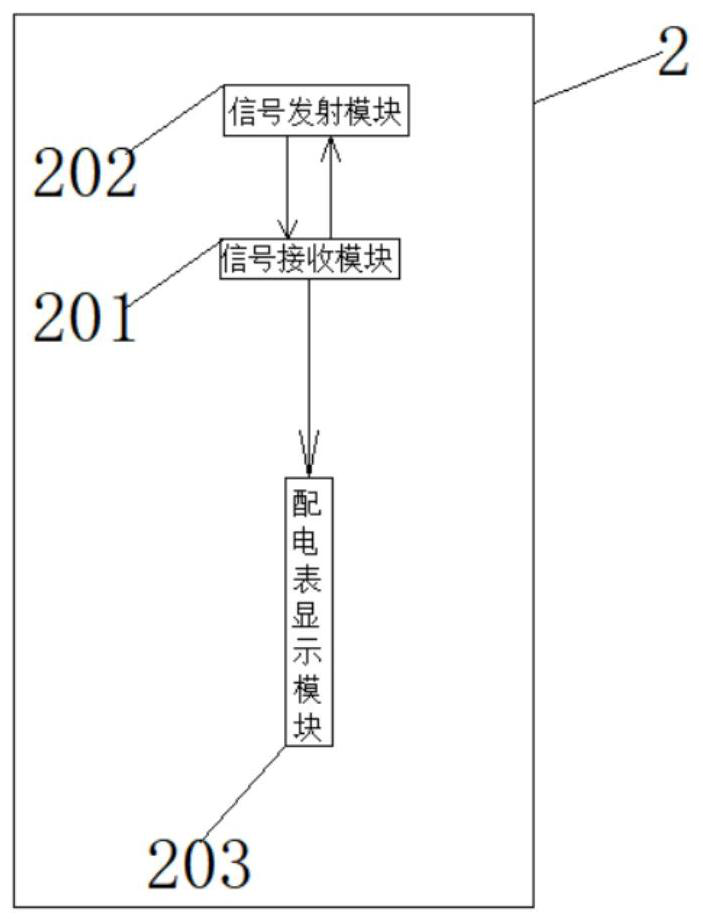

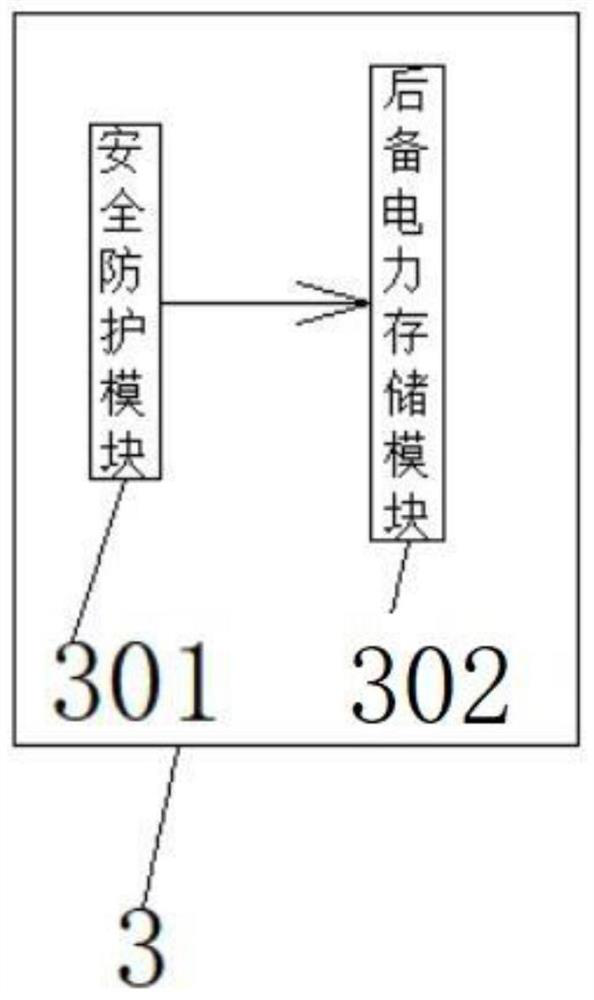

A 5G power control system with dangerous power-off function

ActiveCN111835085BGuarantee uninterrupted power supplyReduce outputPhotovoltaic supportsSolar heating energyPower control systemControl system

Owner:北京豪尔赛智慧城域科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com