Double-sided milling-machine cutter-fixing device

A fixing device and cutting tool technology, applied in the field of milling machine parts, can solve the problems of inability to process, the space occupied by the fixture 2 is large, etc., and achieve the effects of avoiding collision interference, simple structure, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described below in conjunction with accompanying drawing.

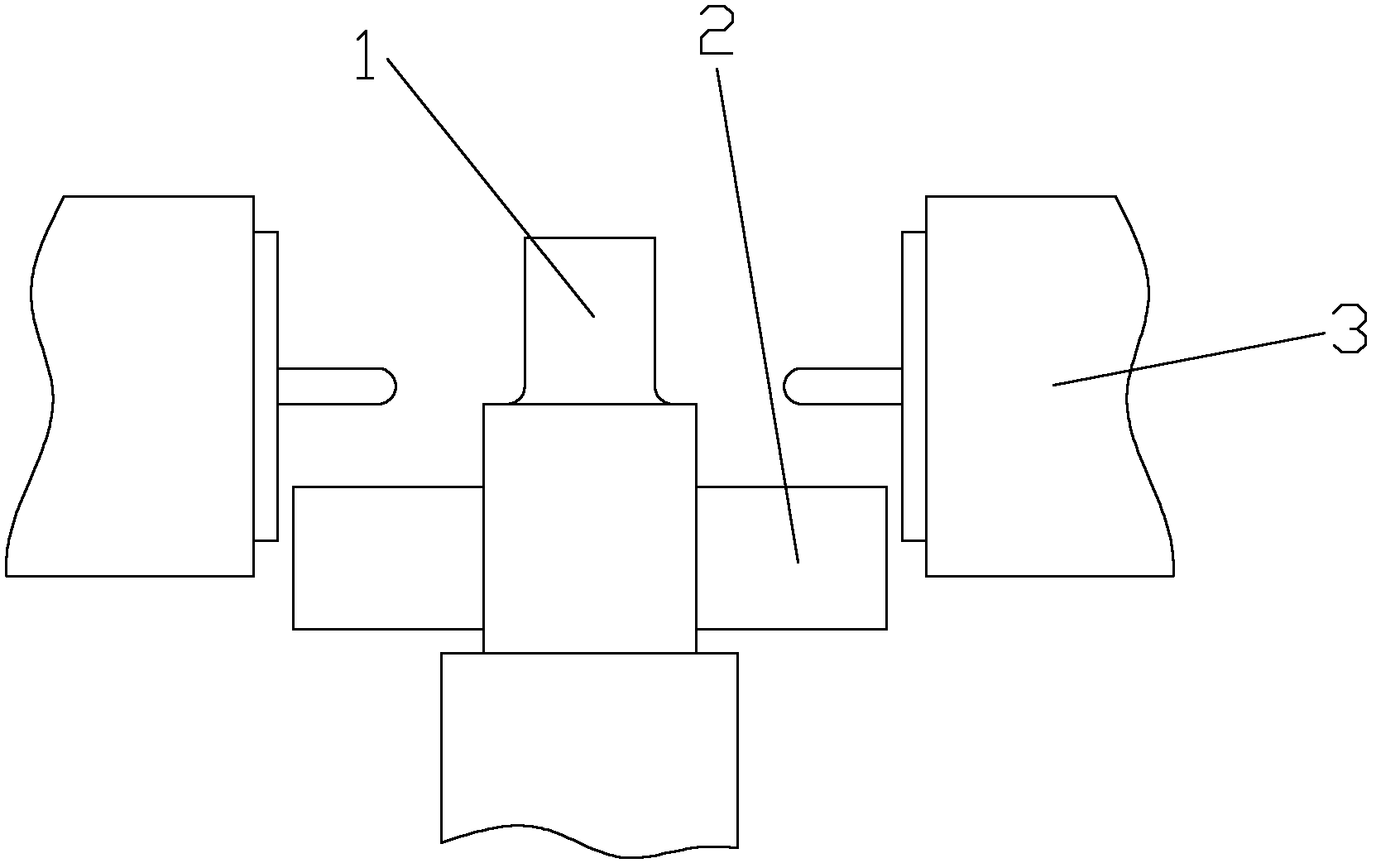

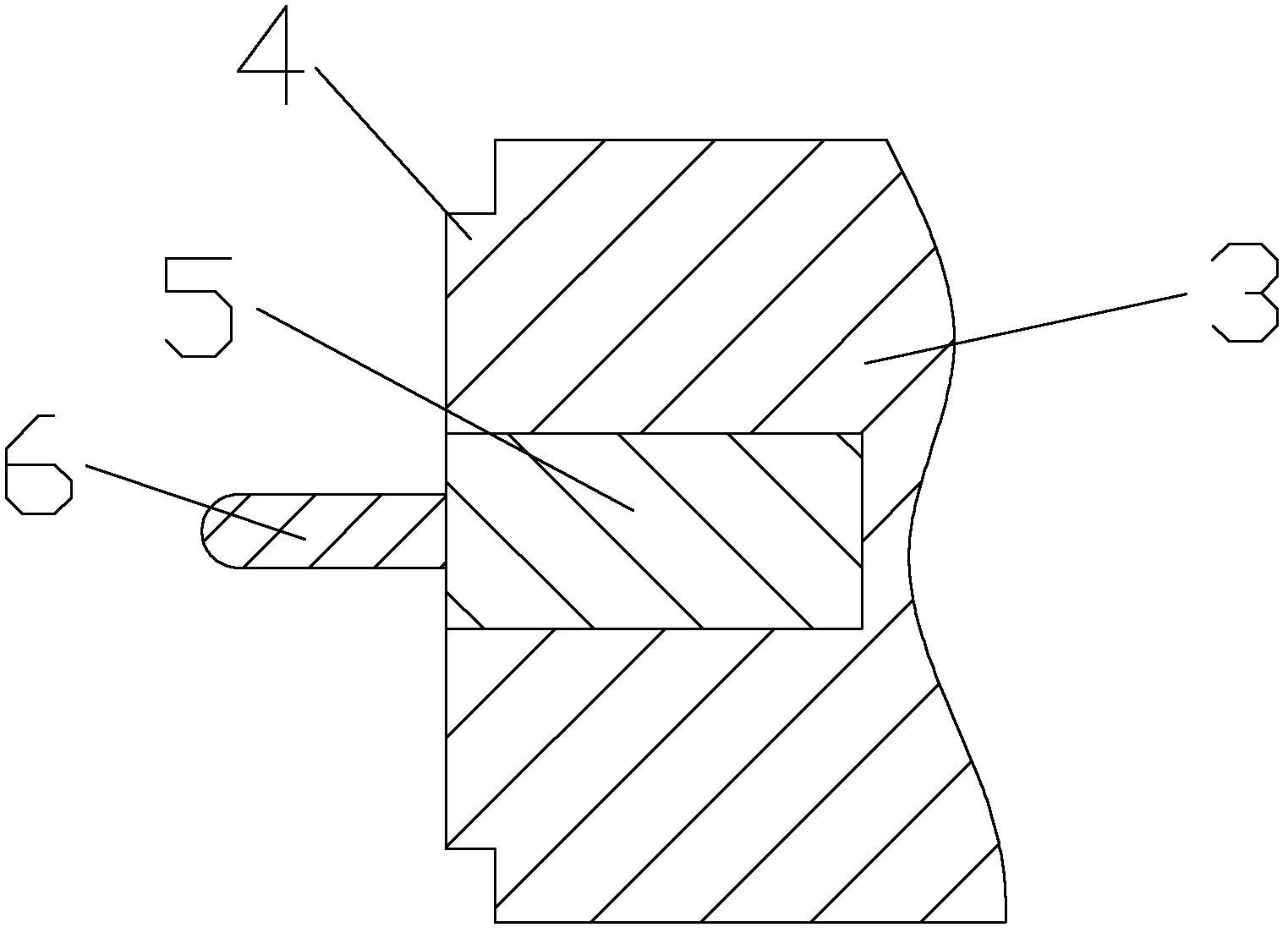

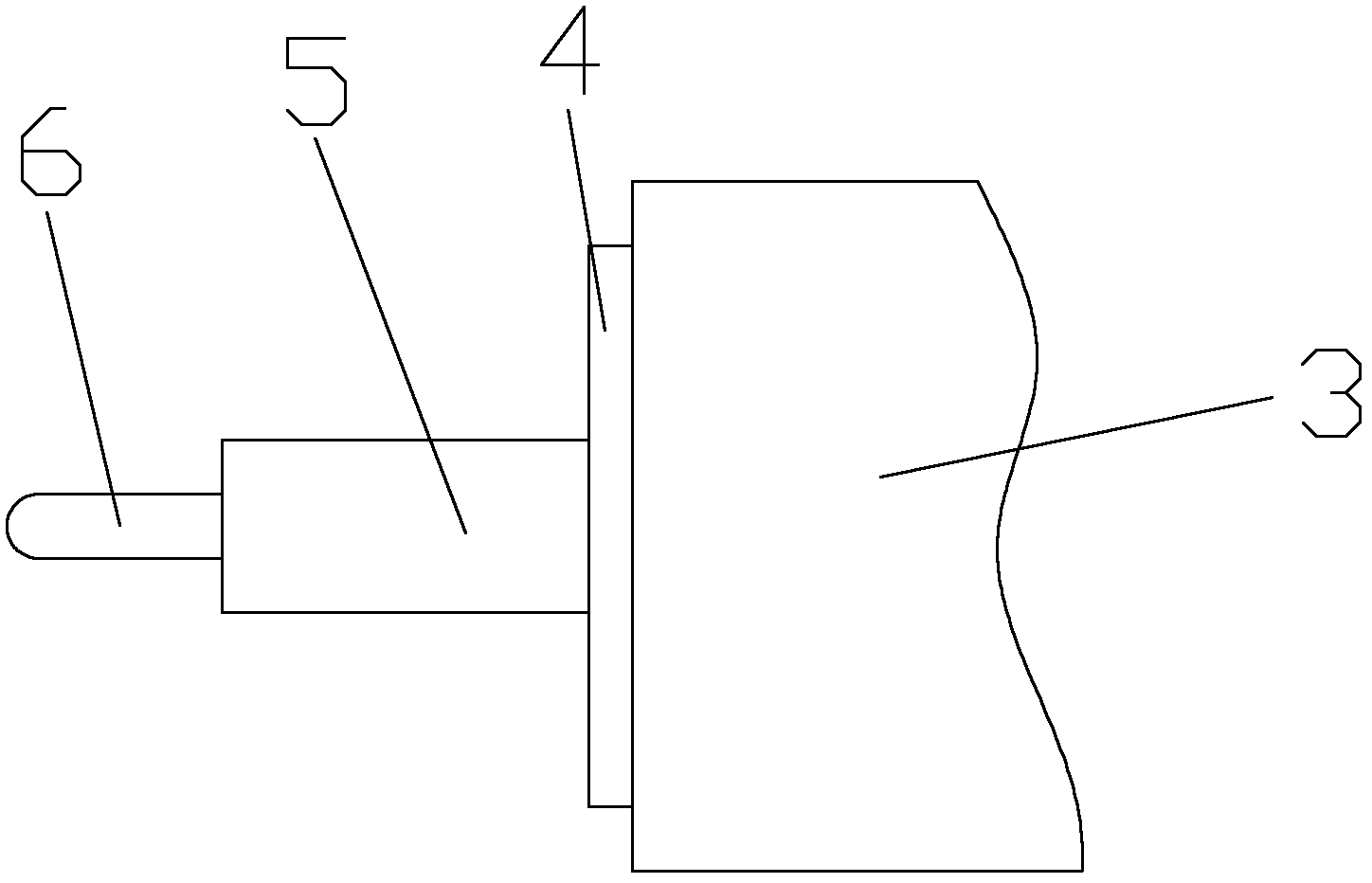

[0016] as attached figure 2 , 3 The shown a kind of double-sided milling machine tool fixing device of the present invention comprises square ram 3, and the outer end of described square ram 3 is provided with buffer boss 4; Square ram 3 is horizontally telescopic tool fixing rod 5; milling cutter 6 is housed on said tool fixing rod 5.

[0017] as attached Figure 4 As shown, when the double-sided milling machine is milling the arc at the root of the journal of the roll 1, when the journal of the processed roll 1 is long, it is milled according to the normal processing method, that is, the tool fixing rod does not protrude from the square ram 3 .

[0018] as attached Figure 5 As shown, when the double-sided milling machine is milling the arc at the root of the journal of roll 1, when the journal of the processed roll 1 is short, after the roll 1 is clamped by the clamp 2 of the do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com