Environment-friendly, energy-saving and efficient annular sintering machine trolley

An environment-friendly, energy-saving, and high-efficiency technology, which is applied to furnace types, furnaces, lighting, and heating equipment, can solve problems such as incomplete unloading, easy material jamming, and difficult removal, so as to avoid collision interference, increase sintering area, and improve Effect of sinter yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

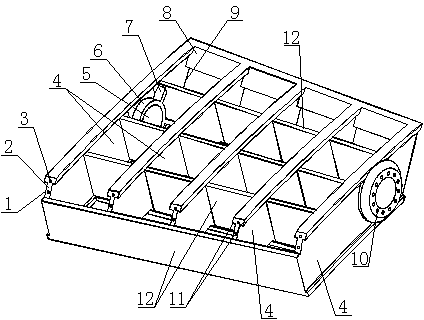

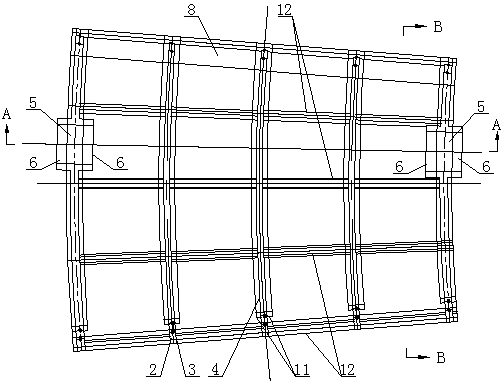

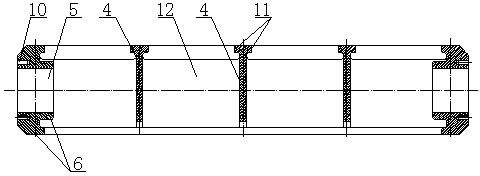

[0026] Depend on Figure 1-Figure 6 The car body of an environment-friendly, energy-saving and high-efficiency ring burning machine shown includes sub-beams 4 arranged at intervals from the inside to the outside and main beams 12 connected between the sub-beams 4, and the sub-beams 4 are vertically arranged extending forward and backward. arc-shaped bent plate, all sub-beams 4 are set concentrically, that is, all sub-beams 4 in the trolley body are bent in the same direction, the notch points to the direction of the ring center, and the rear end connection lines of all sub-beams 4 and the front ends of all sub-beams 4 The connecting lines all extend radially, so that when working, all the trolley bodies are arranged in a ring from the beginning to the end.

[0027] The rear end surface of the sub-beam 4 is a first inclined plane 14, the rear end edge of the sub-beam 4 is a first hypotenuse 9, the bottom of the first hypotenuse 9 is inclined forward, and the top edge of the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com