Inclinedly-pushing part arranging mechanism and part arranging method thereof

A propulsion mechanism and oblique push technology, which is applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of large space occupation and complex flipping propulsion mechanism, so as to avoid collision interference, improve welding quality, and reduce The effect of deformation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

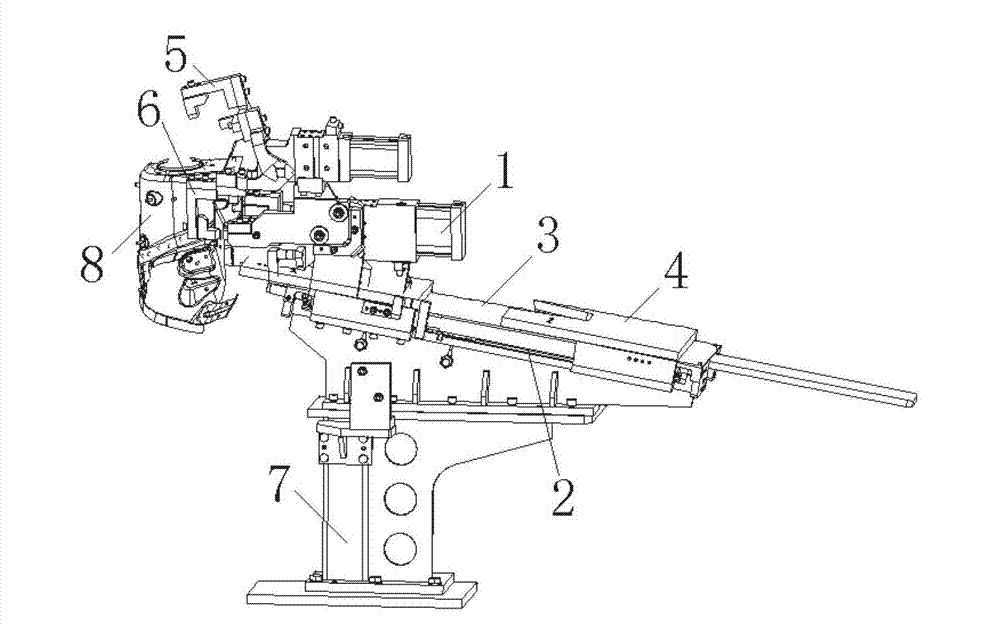

[0018] Such as figure 1 As shown, an oblique push-up mechanism includes a base 7, an inclined-plane propulsion mechanism is provided on the base 7, and an assembly clamping mechanism for fixing the wheel house outer panel reinforcement plate 8 with a clamp is provided at the end of the inclined-plane propulsion mechanism. .

[0019] The mounting clamping mechanism includes a fixture body 6, on which are provided positioning pins for positioning the wheelhouse outer panel reinforcement 8 and grippers 5 for clamping and fixing, the wheelhouse outer panel reinforcement 8 can be quickly loaded In the mounting clamping mechanism.

[0020] Inclined propulsion mechanism comprises the inclined guide frame 3 that is located on the base 7, on the inclined guide frame 3 is provided with the inclined gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com