Patents

Literature

35 results about "Freeform surface machining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

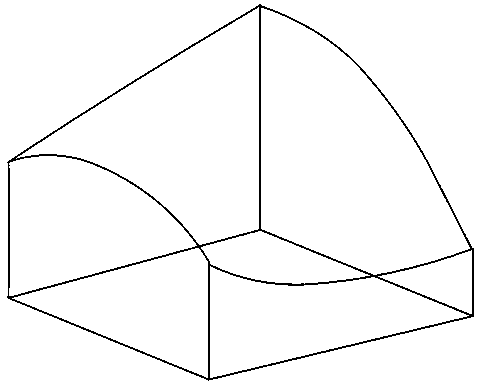

Freeform surface or complex surfaces are widely manufactured nowadays. The industries which most often manufactures free-form surfaces are basically aerospace, automotive, die mold industries, bio medical and power sector for turbine blades manufacturing. Generally 3 or 5 axis CNC milling machine is used for this purpose. The manufacturing process of free form surface is not an easy job as the tool path generation in present CAM technology is generally based on geometric computation so tool path are not optimum. The geometry can also be not described explicitly so errors and discontinuities occurrence in the solid structure cannot be avoided. Free-form surfaces are machined with the help of different tool path generation method like adaptive iso-planar tool path generation, constant scallop tool path generation, adaptive iso-parametric method, iso-curvature, isophote and by other methods. The different methods are chosen based on the parameters which is needed to be optimized.

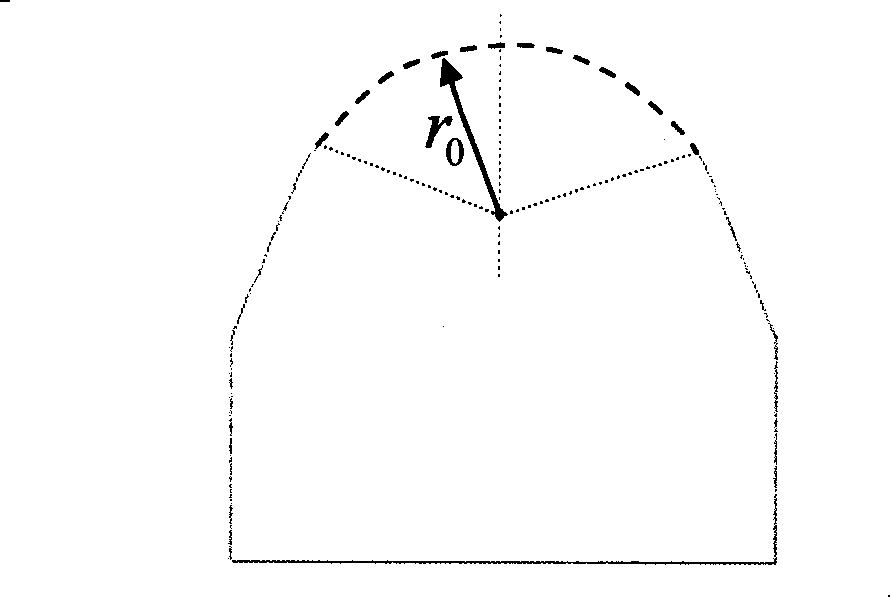

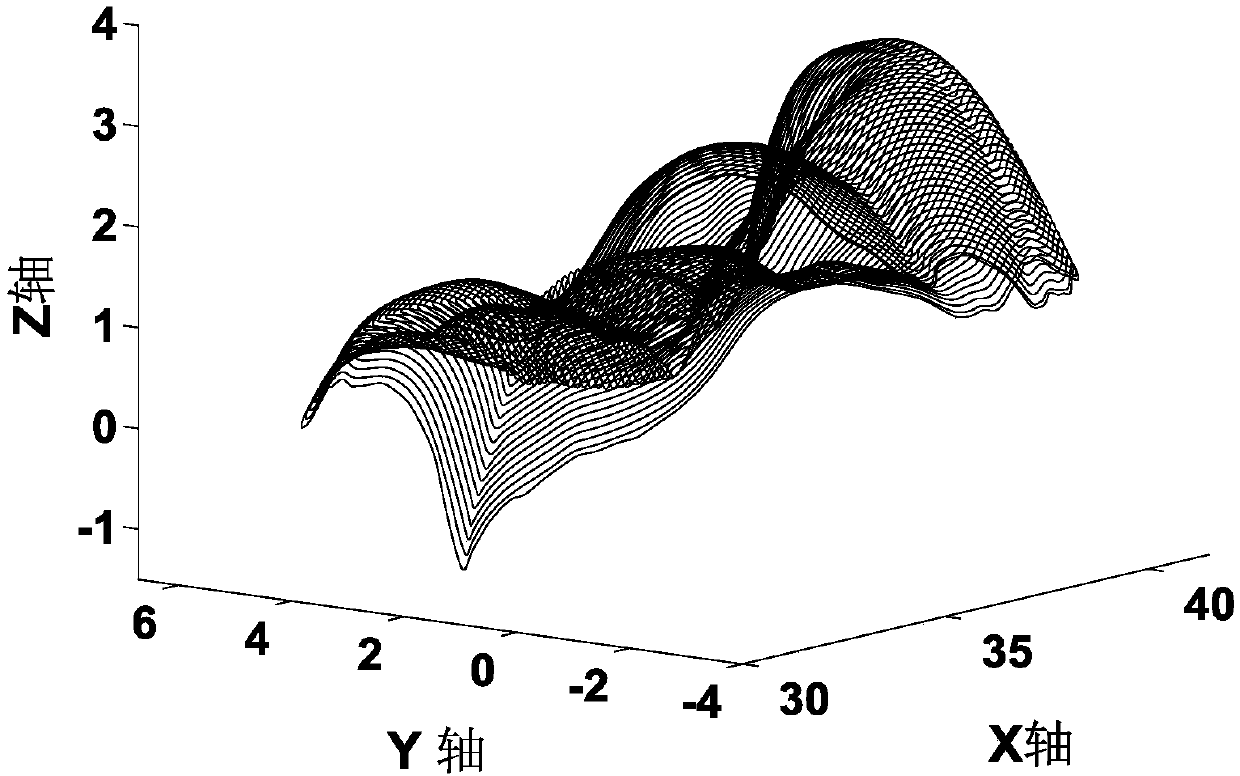

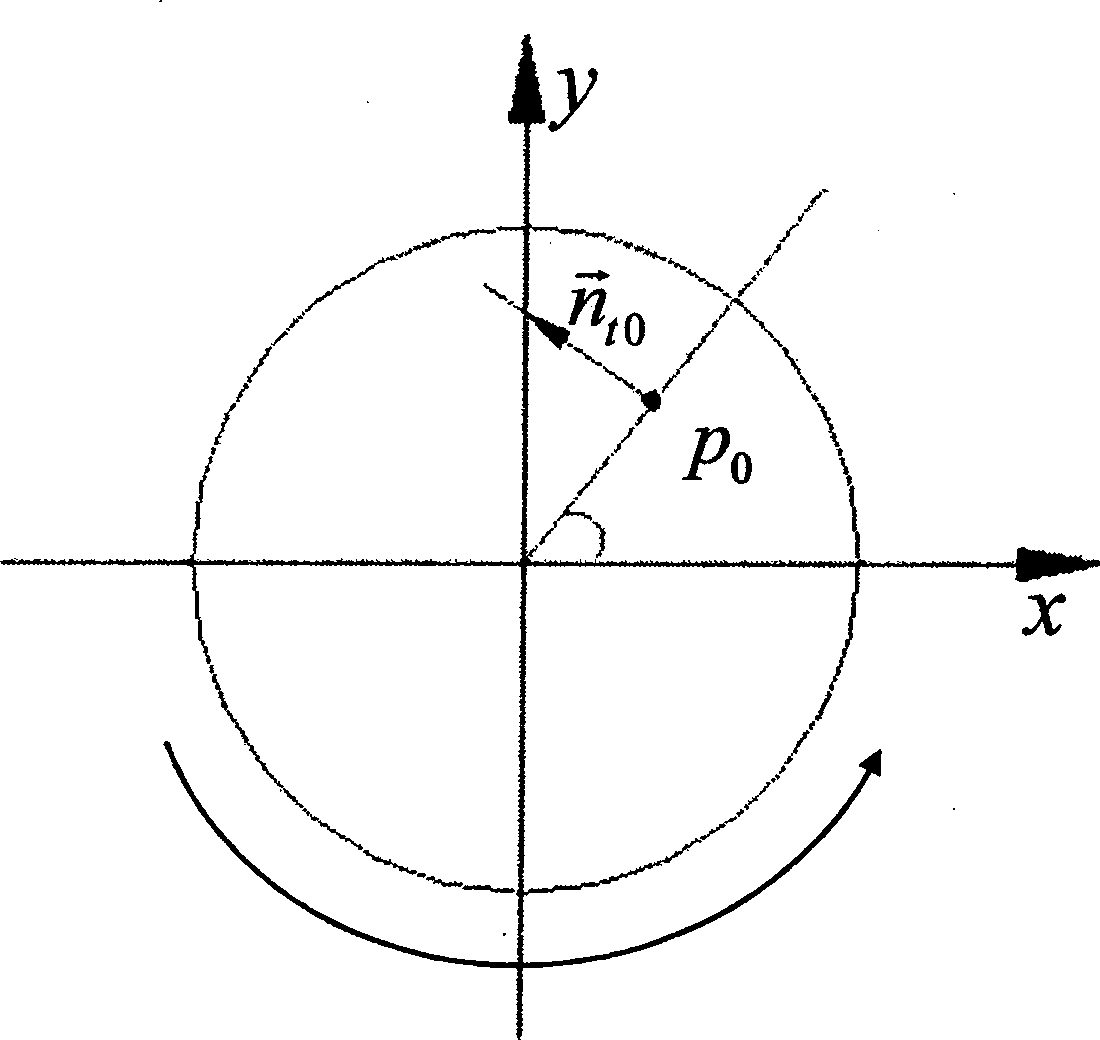

Diamond super precision lathe free curved surface processing path generation method

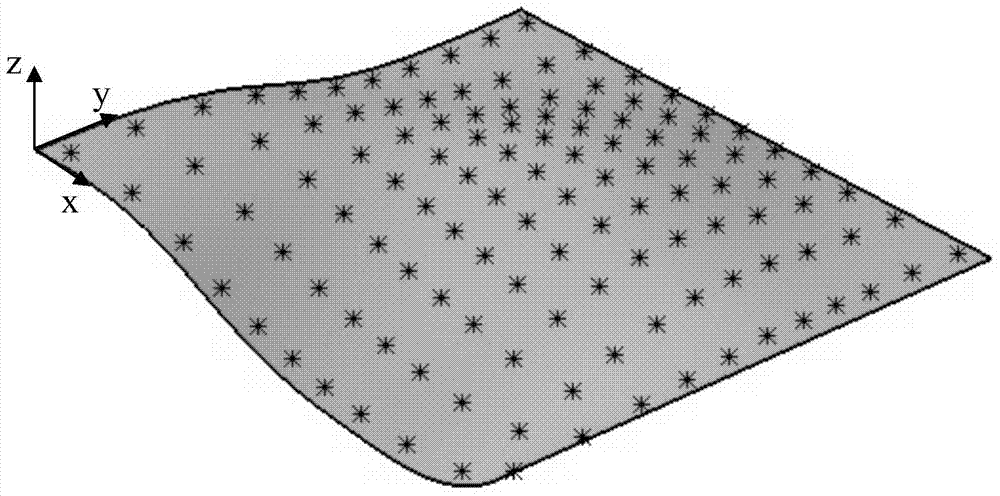

The invention belongs to the technical field of ultra-precise work and complex parts manufacturing, which relates to a path generating method of a curved face processing. The method is utilized on a diamond ultra-precise machine tool with three shafts, which comprises first, establishing a coordinate system of a free curved face model of a processing surface of a workpiece, and establishing conversion relationship between the model coordinate system and a machine tool coordinate system, second, conversing the model coordinate of a processing point on the processed free curved face to a coordinate under the coordinate system of the machine tool, third, solving and processing a normal vector of cutting face of a cutter when the point is processed, fourth, projecting the normal vector of the point of the curved face on the cutting face, and compensating a circular arc radius of the cutter on the projection vector direction, and getting a coordinate of the arc center of the cutting edge under the cutting edge coordinate system, traversing the processing point on the free curved face, at last generating a processing path. The limitation of processing the free curved face on the machine tool with three shafts can be broken by adopting the path generating method which is provided by the invention, the invention can achieve ultra-sophisticated processing of the free curved face.

Owner:TIANJIN UNIV

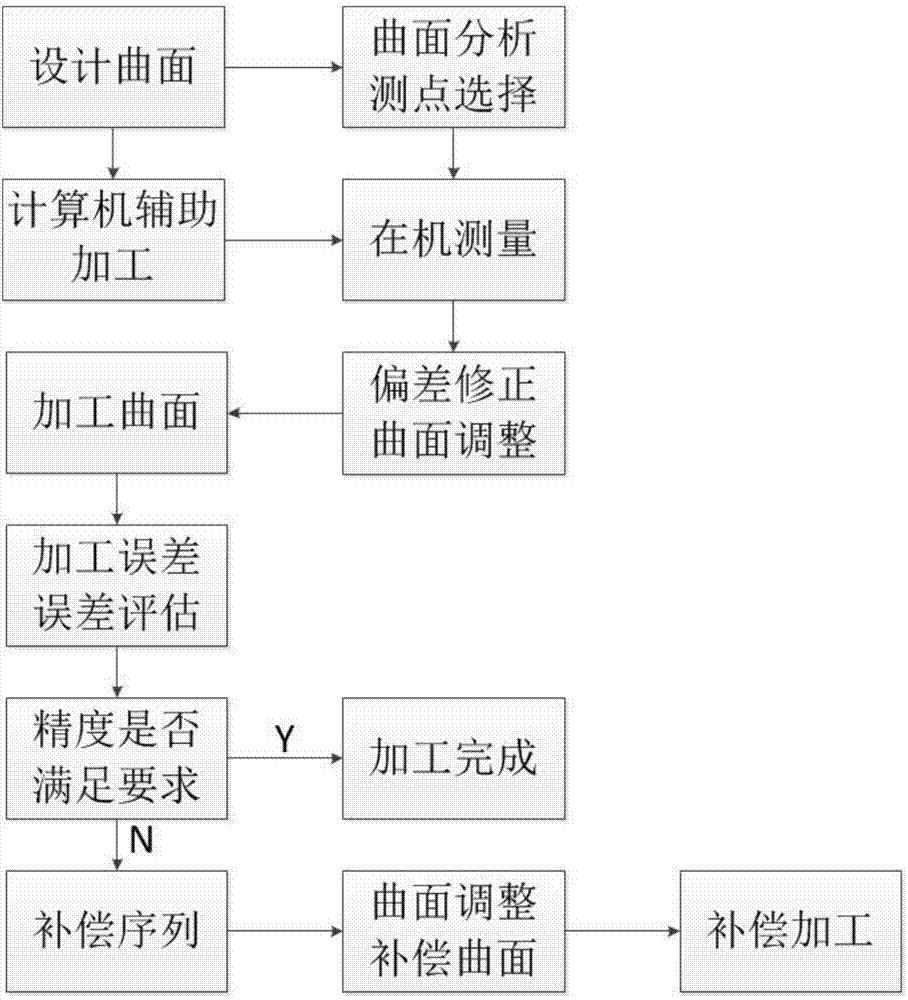

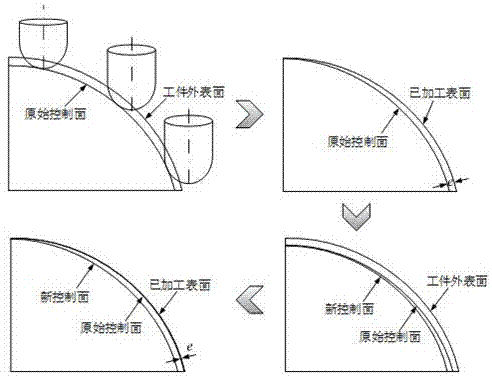

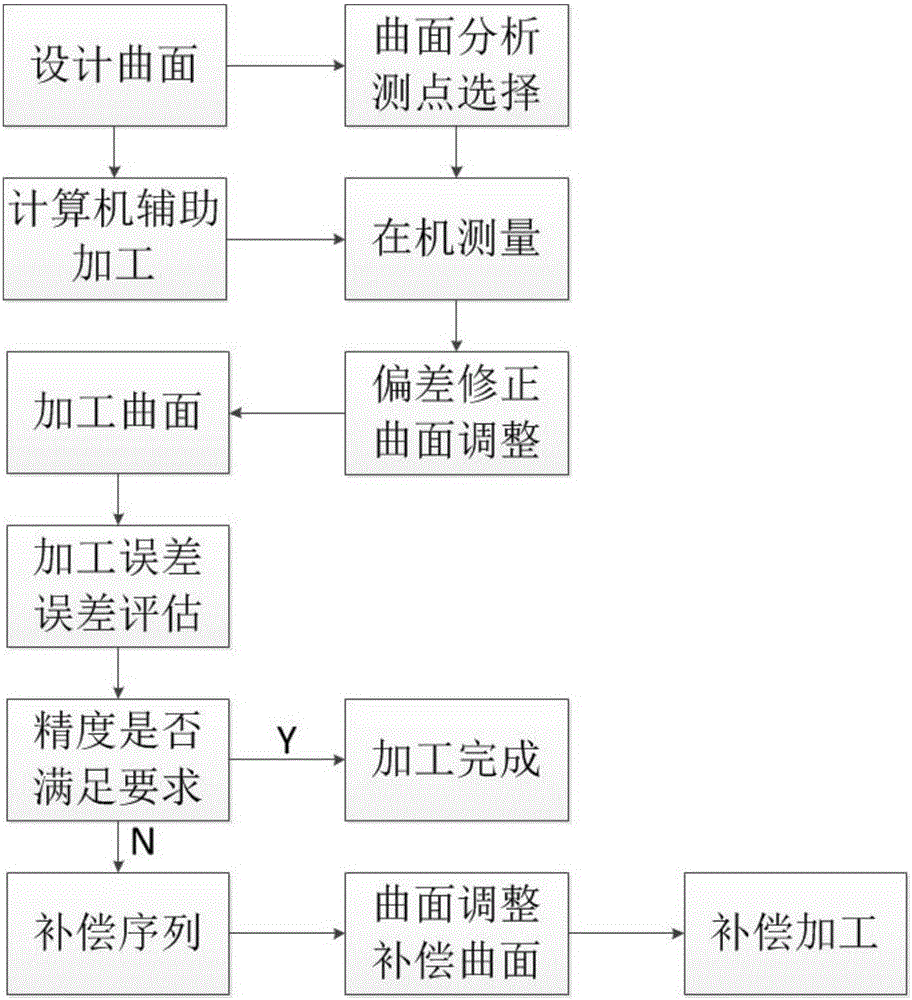

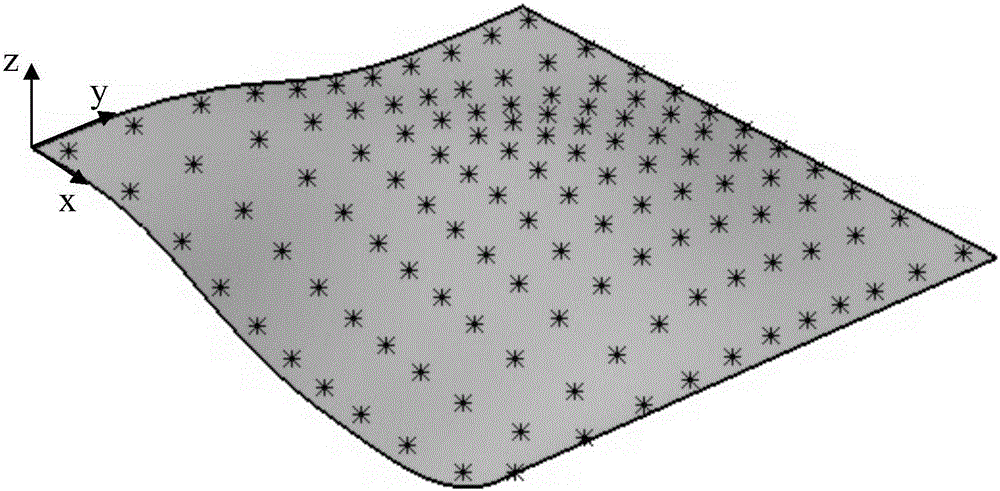

Machining error rapid detection and compensation method based on NURBS curved surface

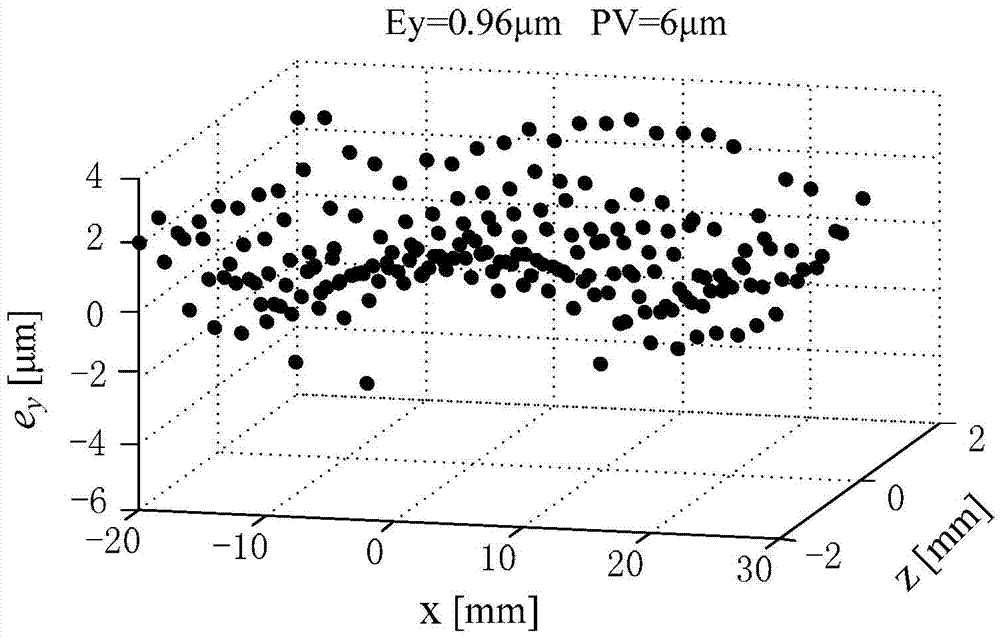

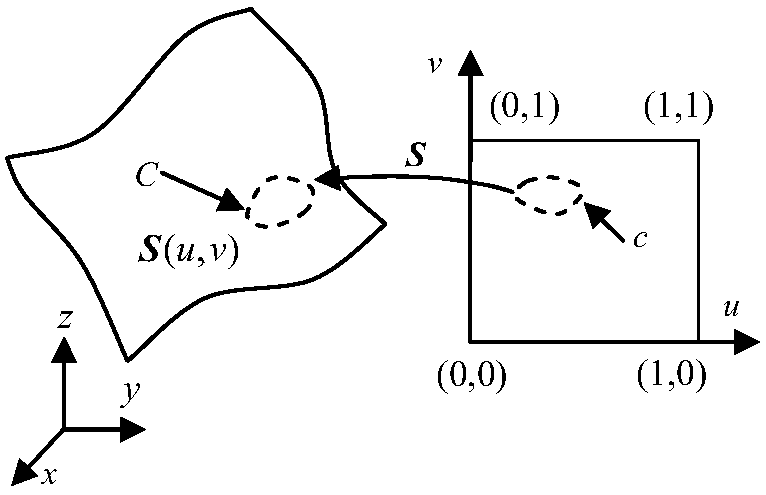

The invention discloses a machining error rapid detection and compensation method based on an NURBS curved surface. The method comprises the steps that a designed NURBS curved surface is analyzed, and a series of characteristic points are selected as a sequence P to be measured; according to a machine tool processing curved surface applied to the designed NURBS curved surface, points to be measured in the sequence P to be measured are measured to acquire an actually measured sequence Q'; the deviation between the actually measured sequence Q' and the sequence P to be measured is computed; if the deviation is less than or equal to the machining accuracy, adjusting is not needed; if the deviation is greater than the machining precision, the sequence P to be measured is adjusted according to the deviation to acquire a compensation sequence W; 4) a control point C is adjusted according to the compensation sequence W to acquire a compensation curved surface; and machining is carried out according to the compensation curved surface to acquire a machining curved surface, wherein the error between the machining curved surface and the designed NURBS curved surface is small. According to the method provided by the invention, the efficiency of the detection of an on machine measurement method on the machining accuracy of a free curved surface is improved, and compensation machining can be carried out on the free curved surface.

Owner:ZHEJIANG UNIV

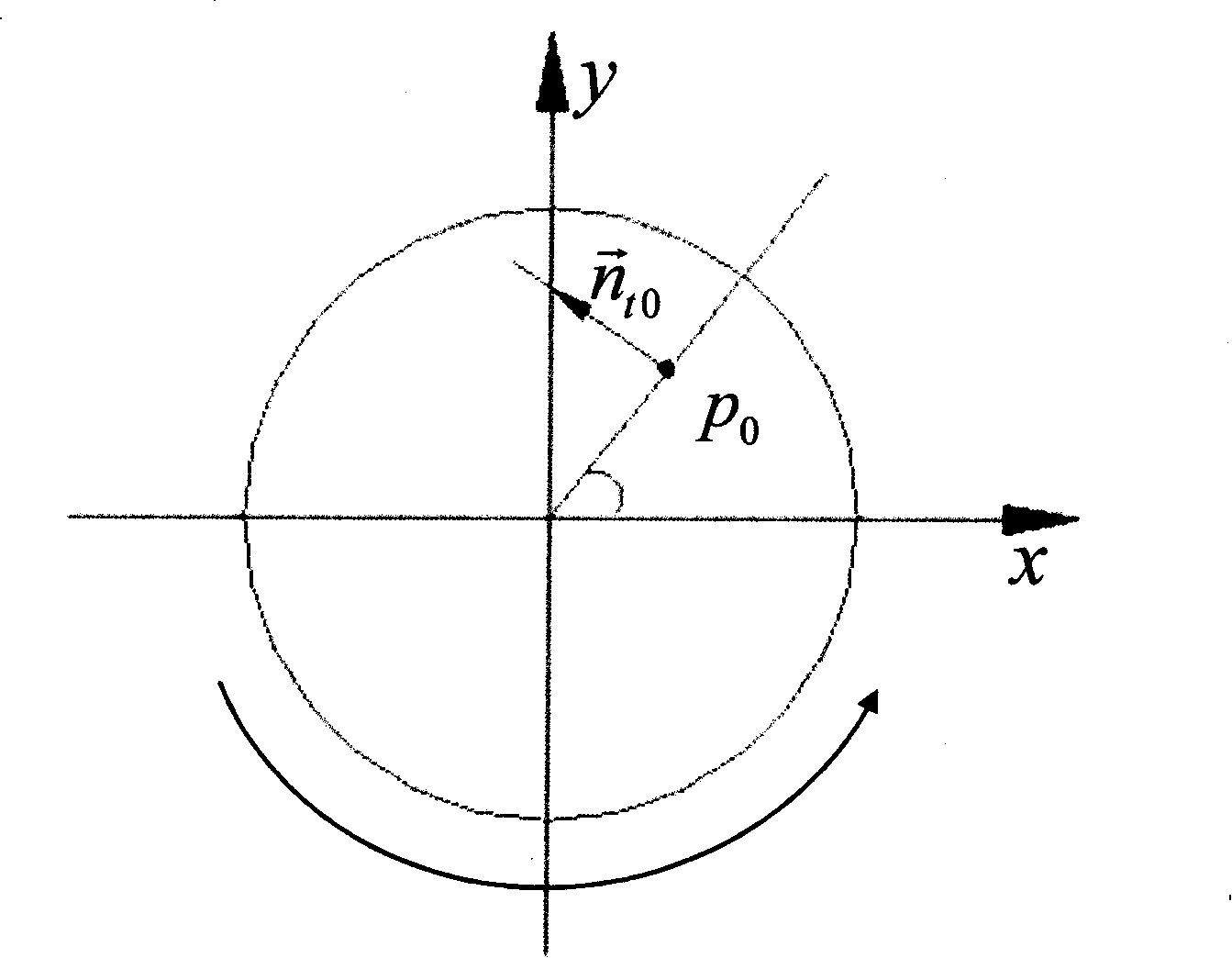

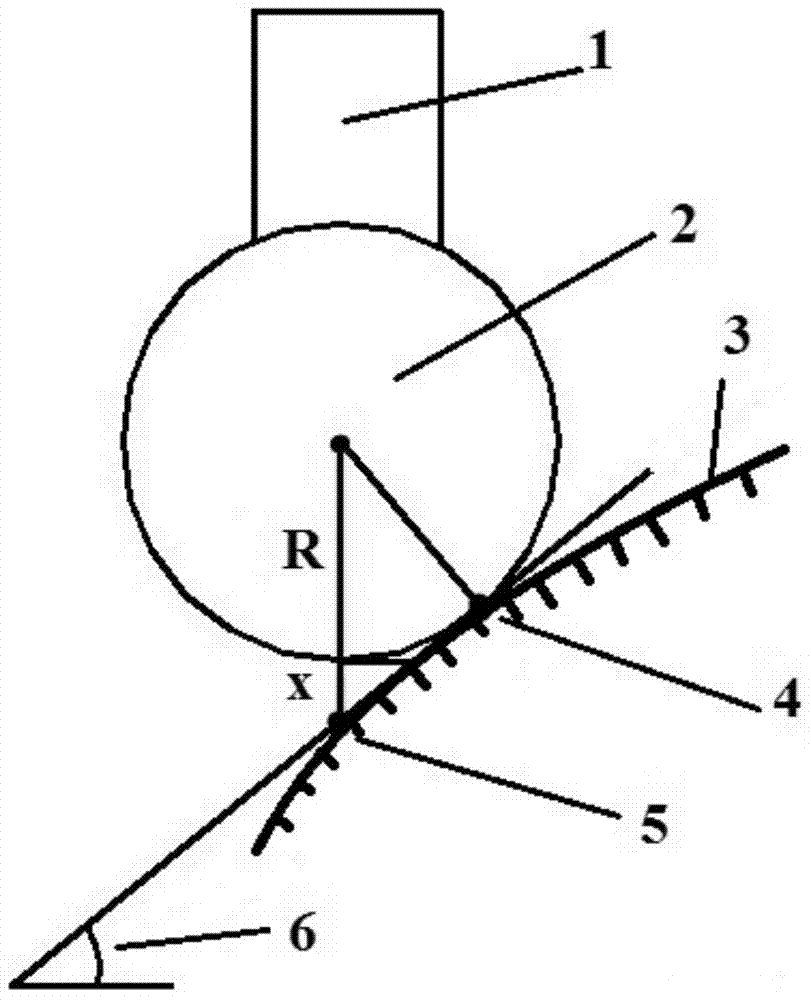

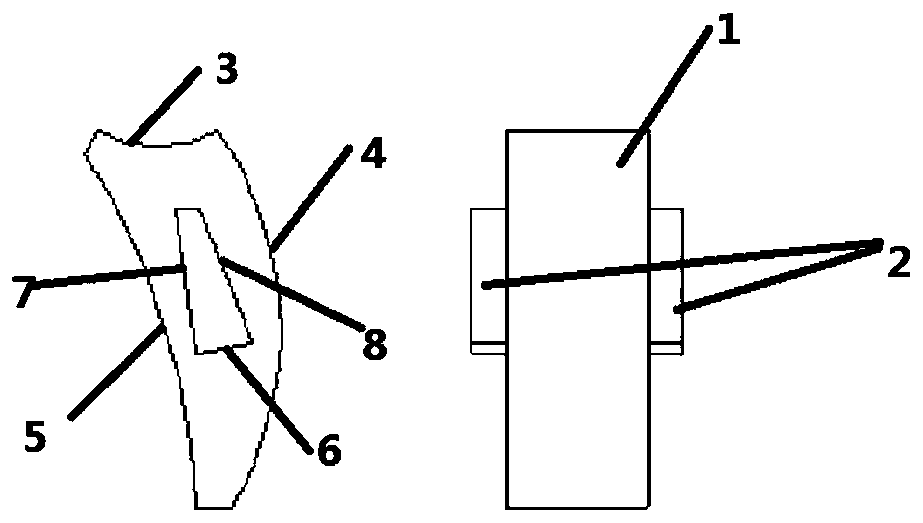

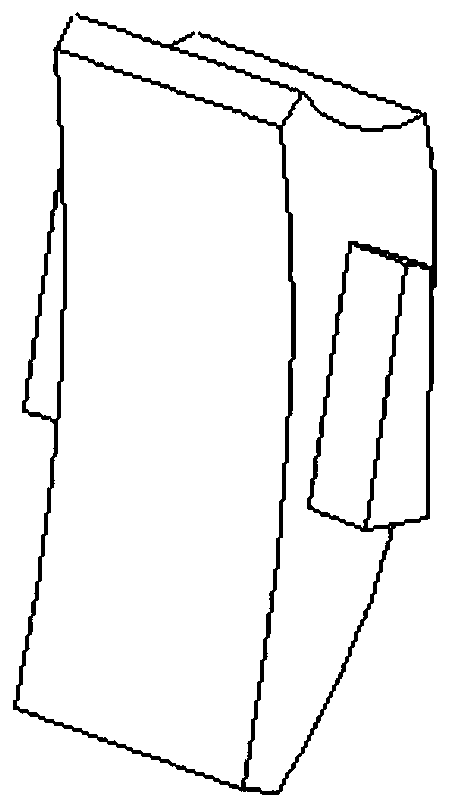

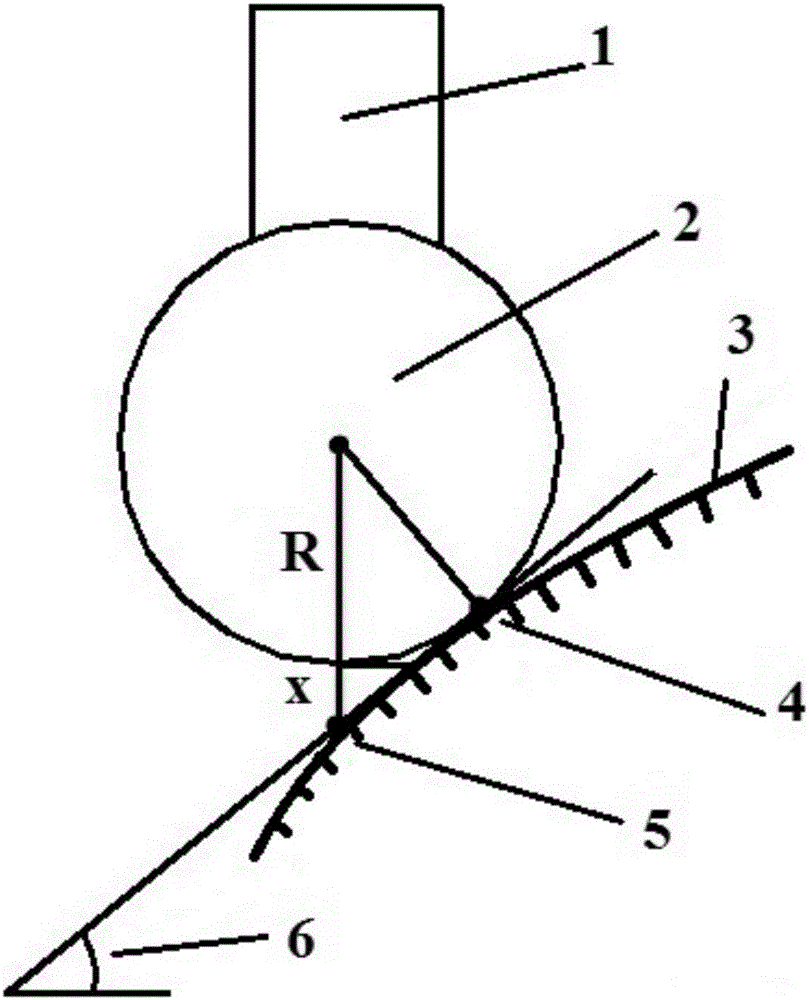

Method for curve surface grinding with cylindrical grinding wheel at virtual ball cutter radius

ActiveCN106853598AInterference handling is simpleImprove processing precisionGeometric CADOther manufacturing equipments/toolsRotational axisSurface roughness

The invention discloses a method for curve surface grinding with a cylindrical grinding wheel at a virtual ball cutter radius. The method includes the steps that 1, the attitude angle of the cylindrical grinding wheel is designed, and the inclination angle of the axis of the cylindrical grinding wheel on a curve surface tangency point normal vector is designed through a virtual ball cutter model; 2, a cutter path is planned and determined according to the curved surface tangency point normal vector and the virtual ball cutter model, and the set inclination angle in the step 1 is guaranteed through a rotating shaft of a machine tool; 3, by the adoption of an axial feeding mode, a workpiece is subjected to grinding machining according to the cutter path. The cylindrical or quasi-cylindrical grinding wheel can be used for four-axis machining of a free curved surface, and the method has the advantages that planning of the cutter path is simple and flexible, the precision of a machining shape is high, and surface roughness is low, and is suitable for machining free curve surfaces of optical glass and other hard brittle materials.

Owner:SOUTH CHINA UNIV OF TECH

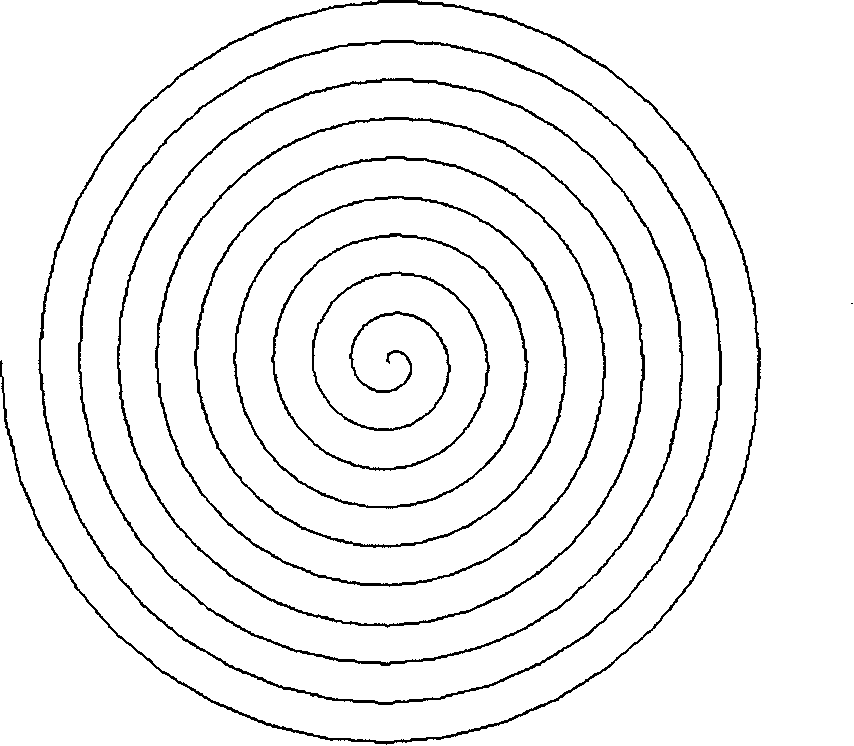

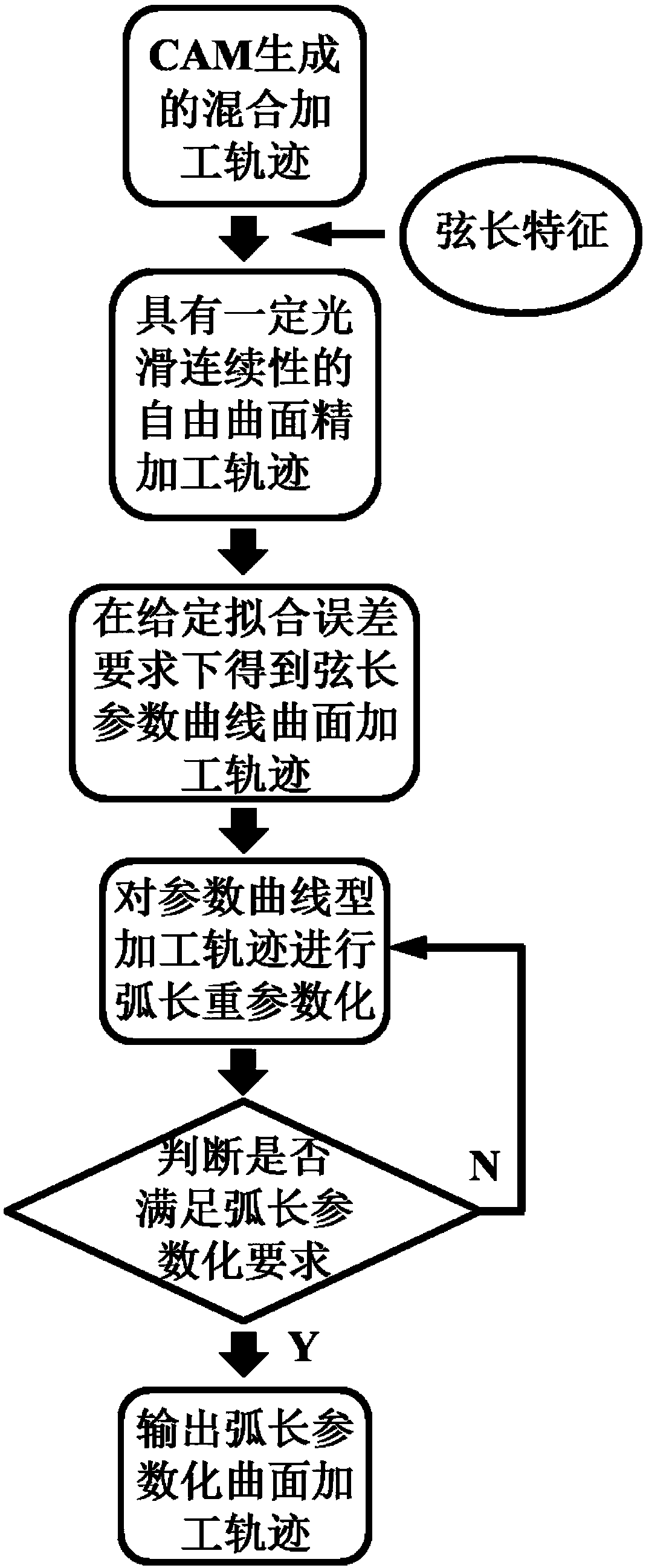

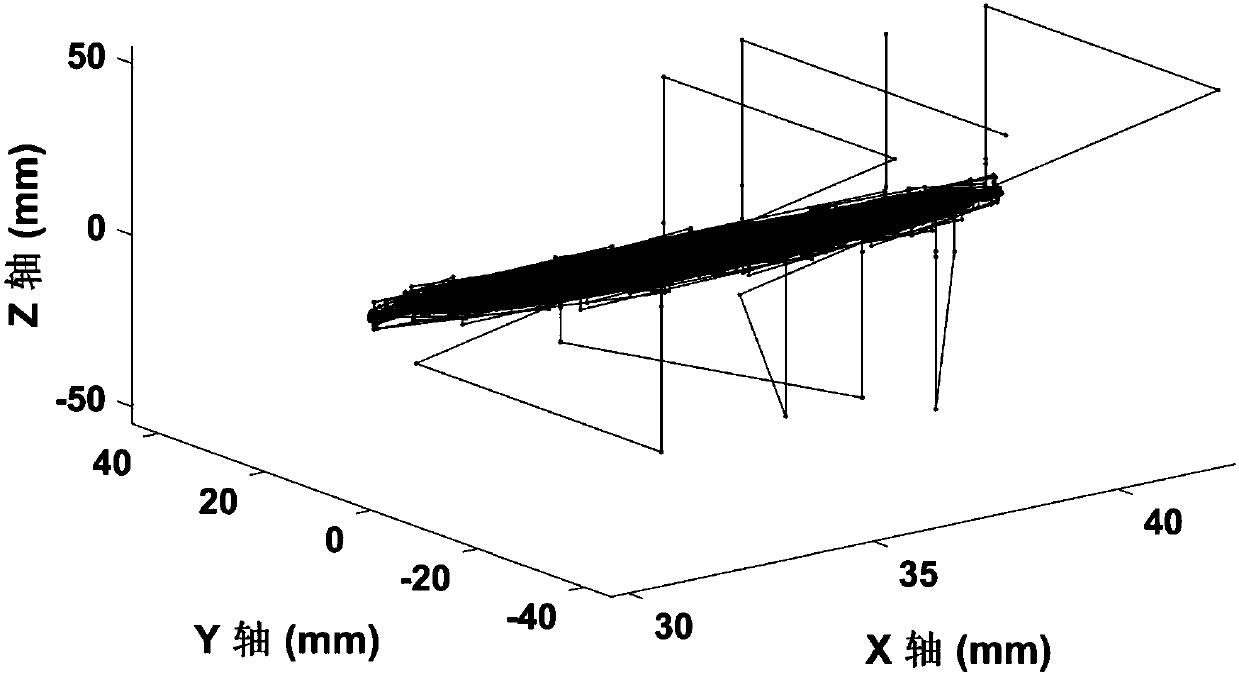

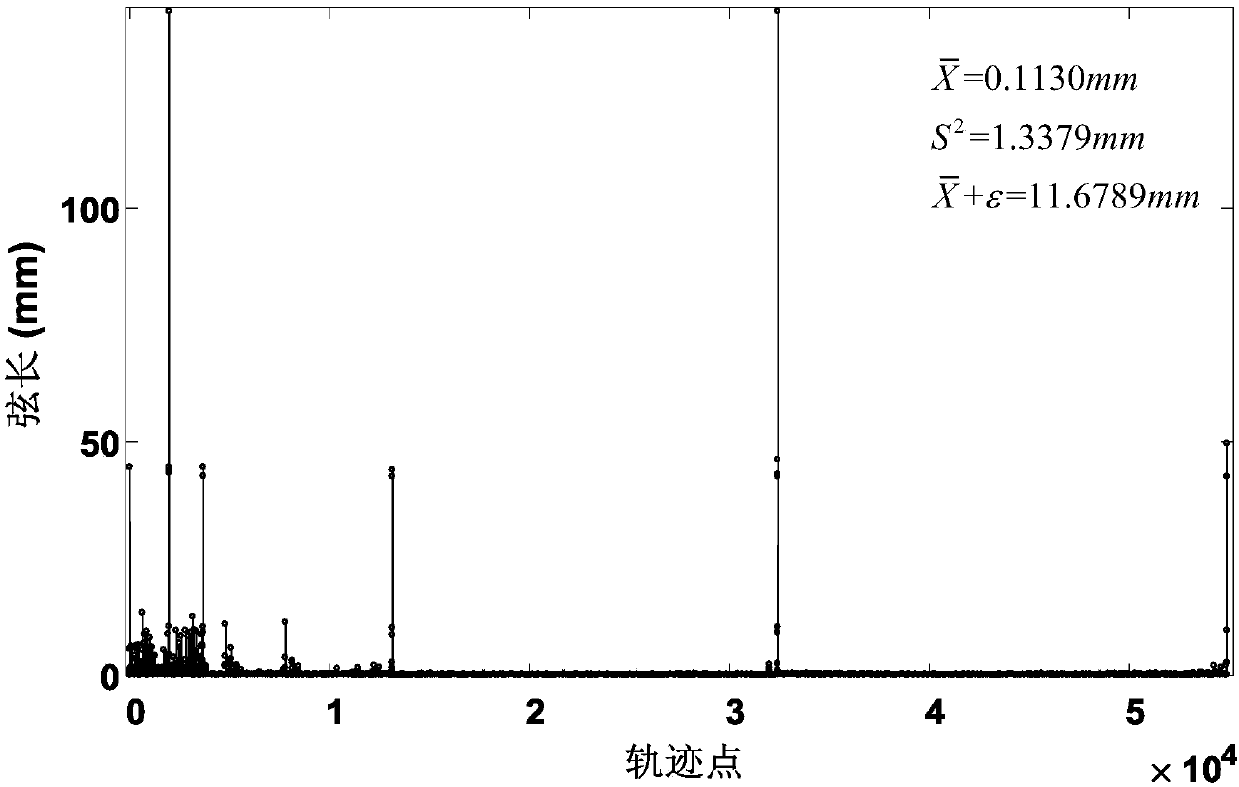

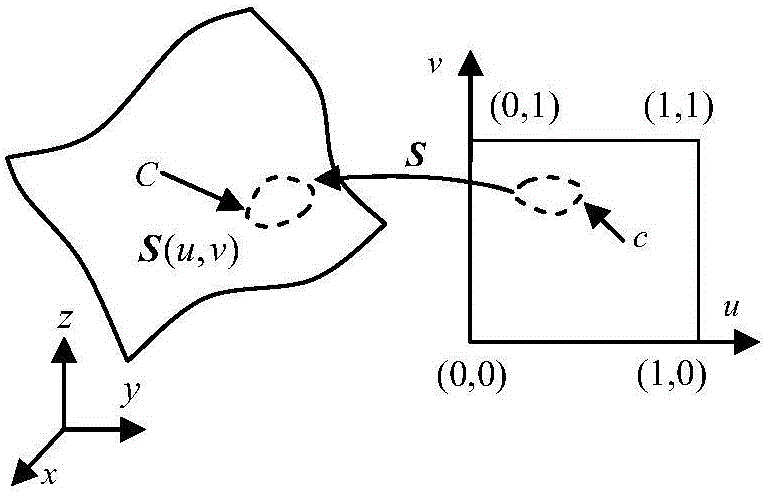

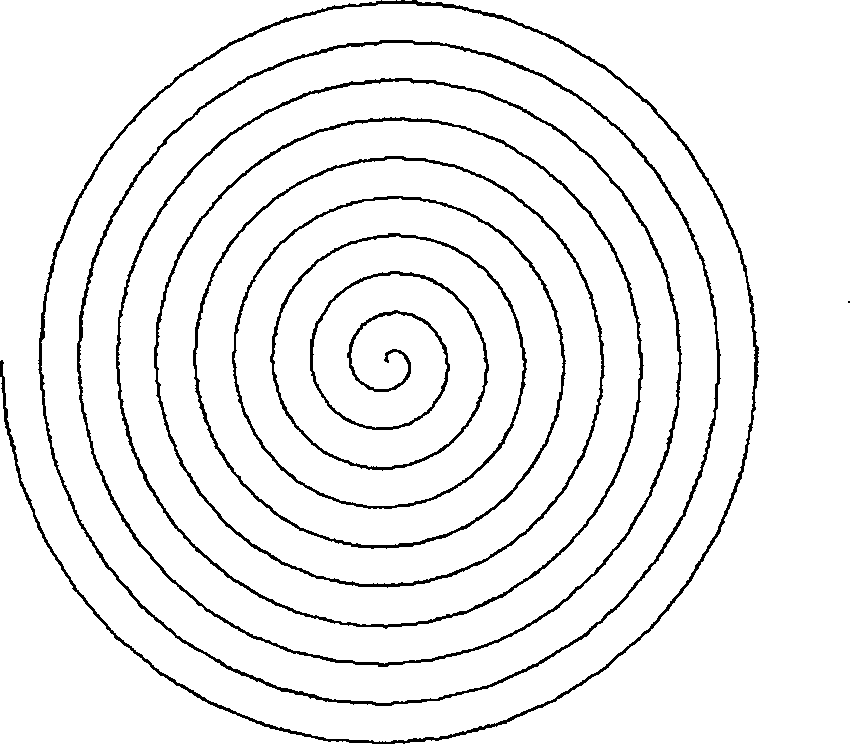

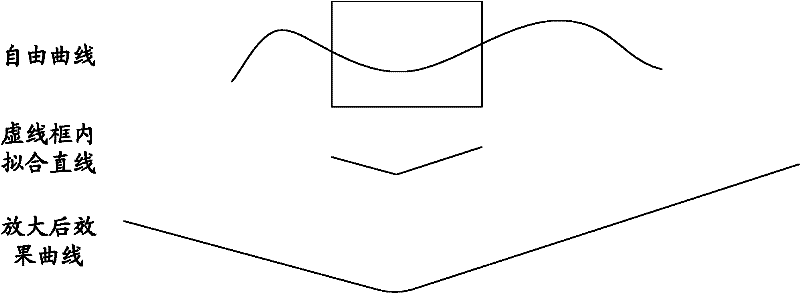

Arc length parameter curve processing track generation method of free curved surface

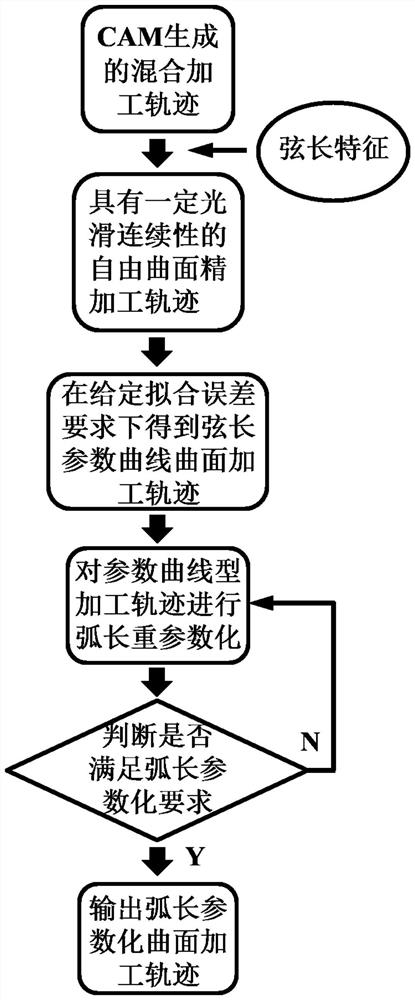

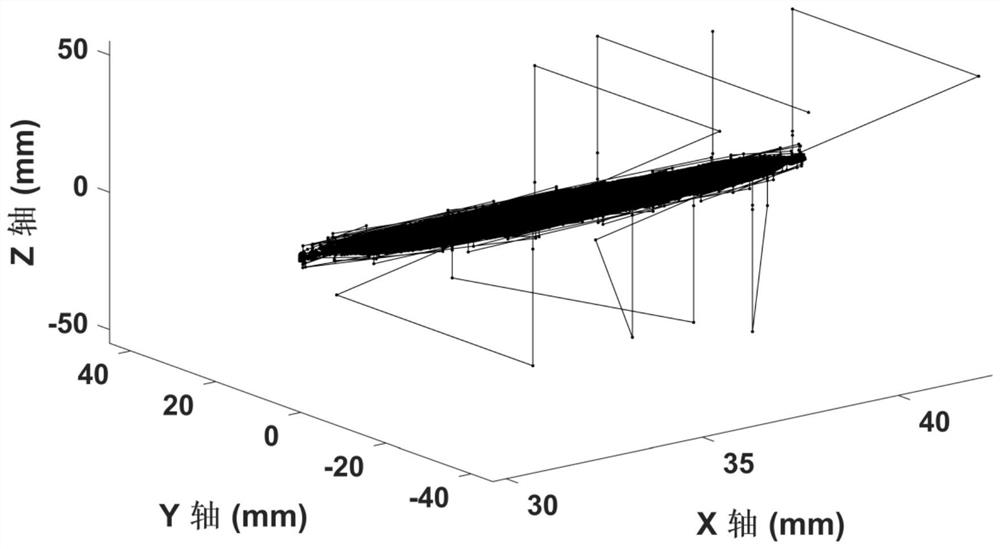

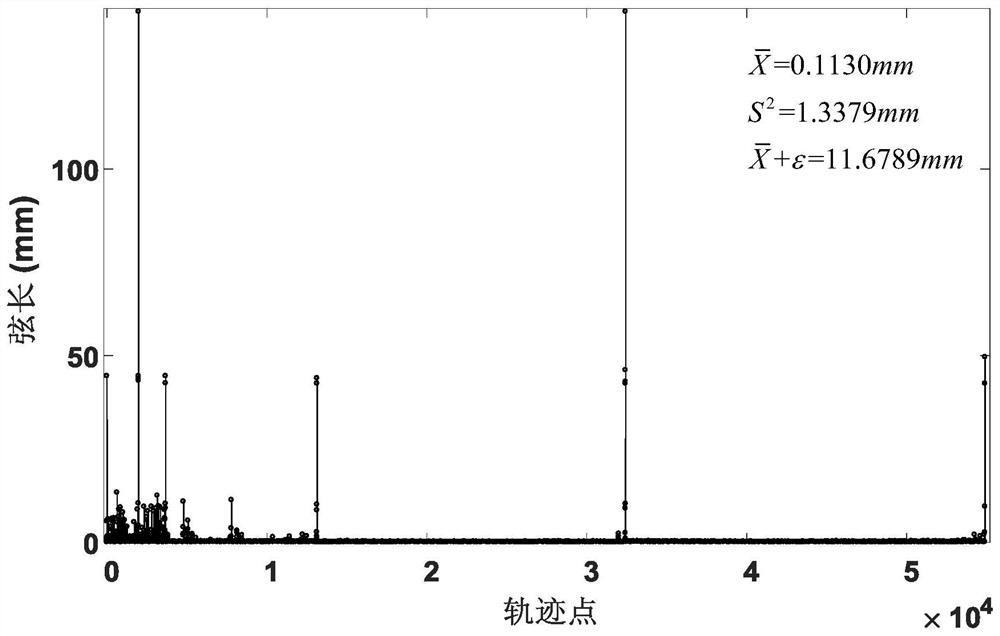

ActiveCN108549325AAvoid complex calculationsReduce difficultyProgramme controlComputer controlCamComputer vision

The invention relates to an arc length parameter curve processing track generation method of a free curved surface. The method comprises following steps of smooth and continuous characteristic curve processing track extraction, given precision parameter curve processing track generation and processing track arc length parameterization. In the step (1), processing tracks generated by computer aidedmanufacturing software (CAM) are classified according to arc length characteristics; and discrete free curve processing tracks with smooth and continuous characteristics are extracted; in the step (2), fitting is performed on the extracted discrete free curve processing tracks under the given precision, so parameter curve processing tracks meeting a geometric representation precision requirementare obtained; and in the step (3), by use of the method of continuous iteration arc length re-parameterization, arc length re-parameterization is performed on the parameter curves obtained in the step(2), and finally, the arc length parameter curve free curved face processing track is obtained. According to the invention, the difficulty level in real-time interpolation and speed planning in freecurved face processing is reduced; and smoothness and processing precision in the processing process are improved.

Owner:HEFEI UNIV OF TECH

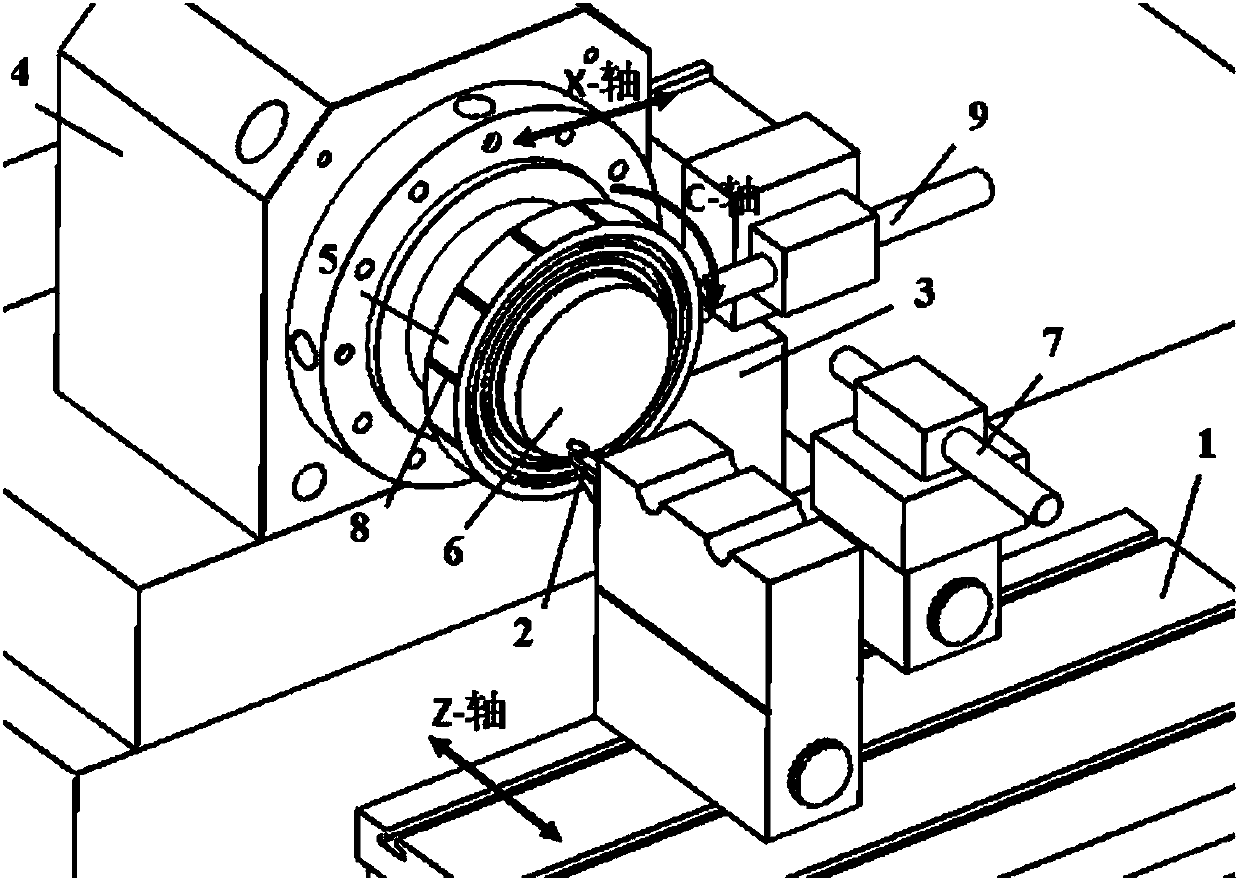

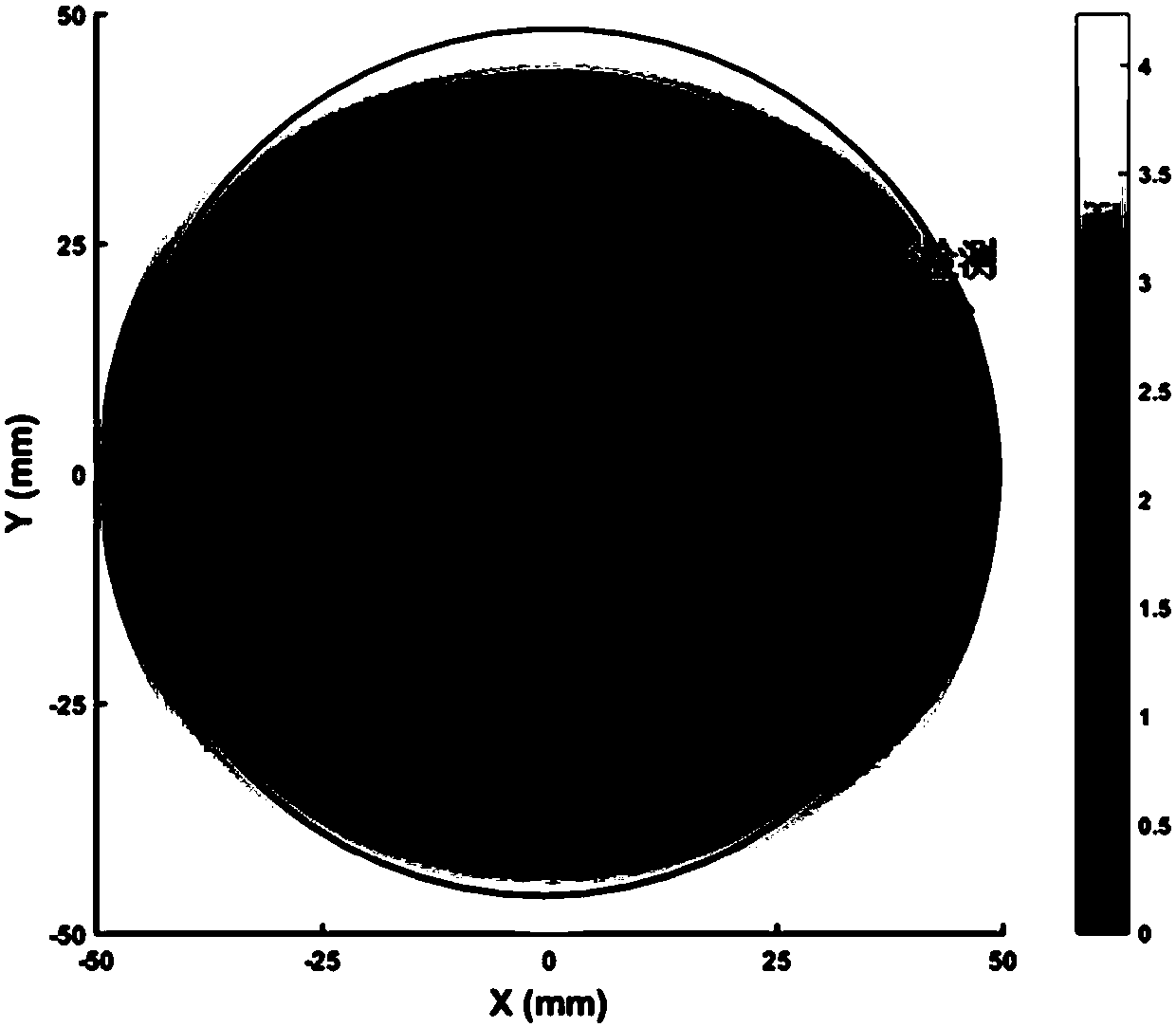

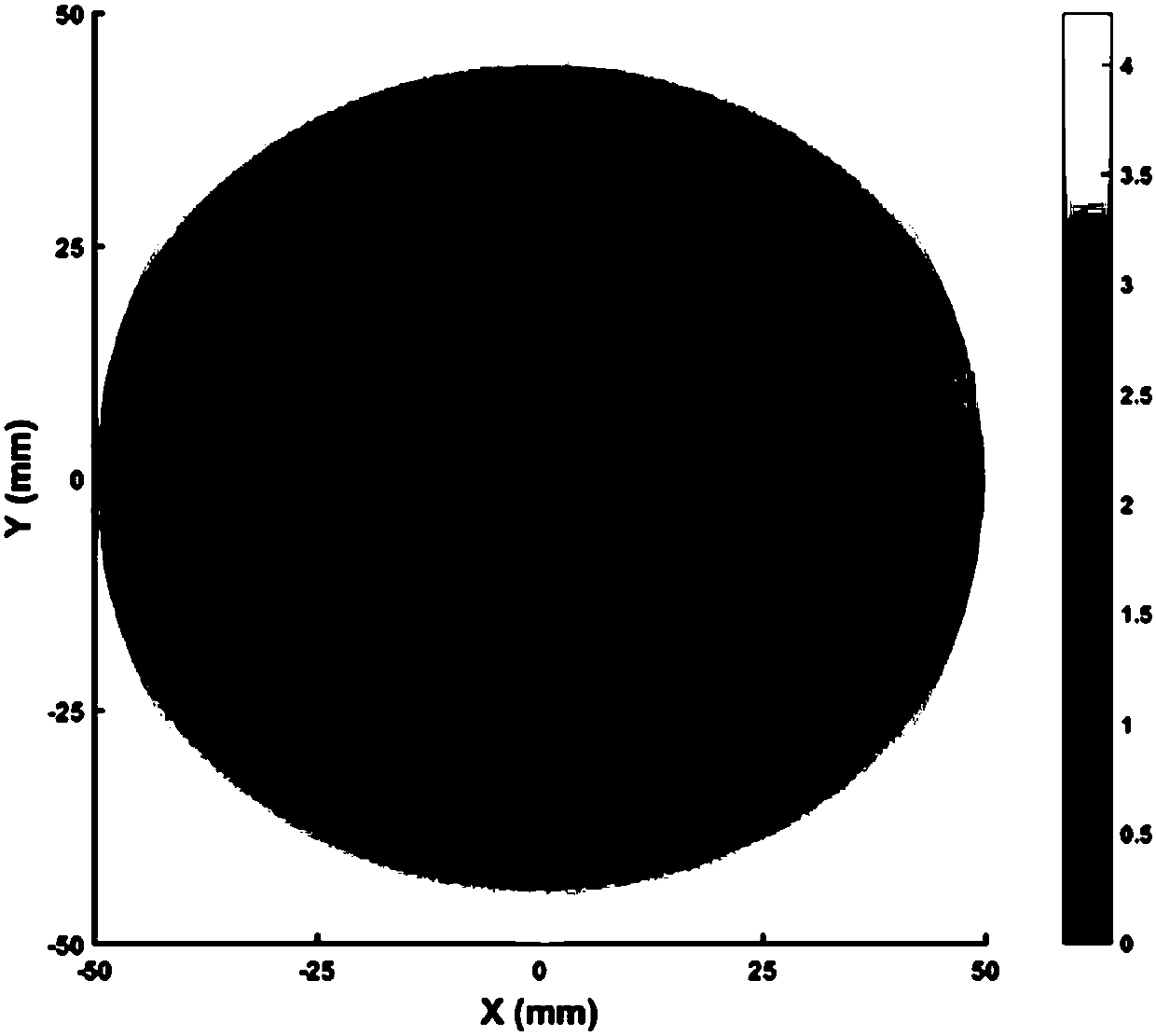

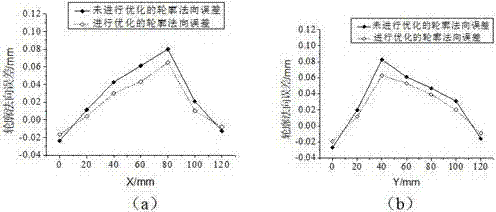

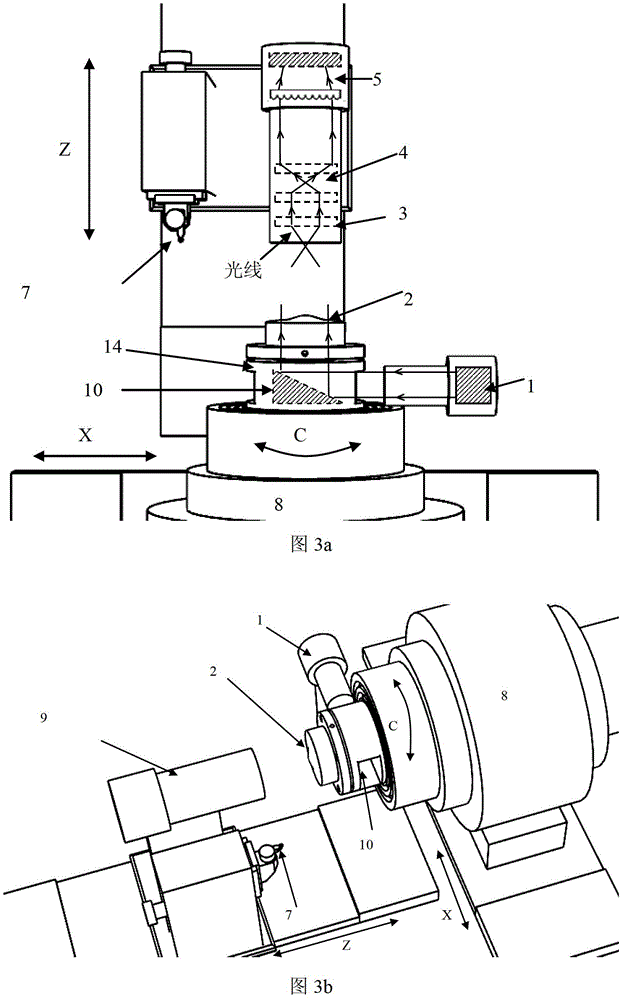

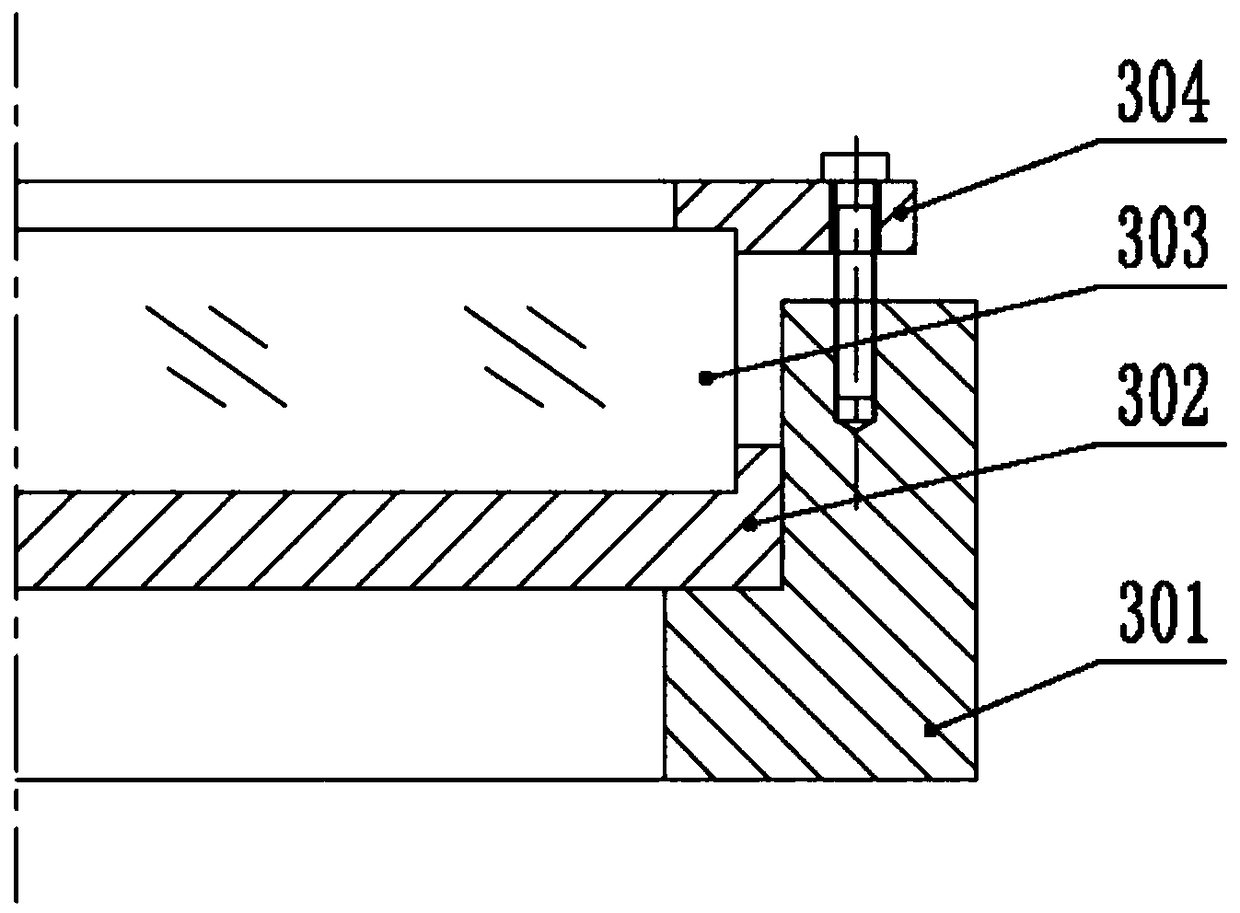

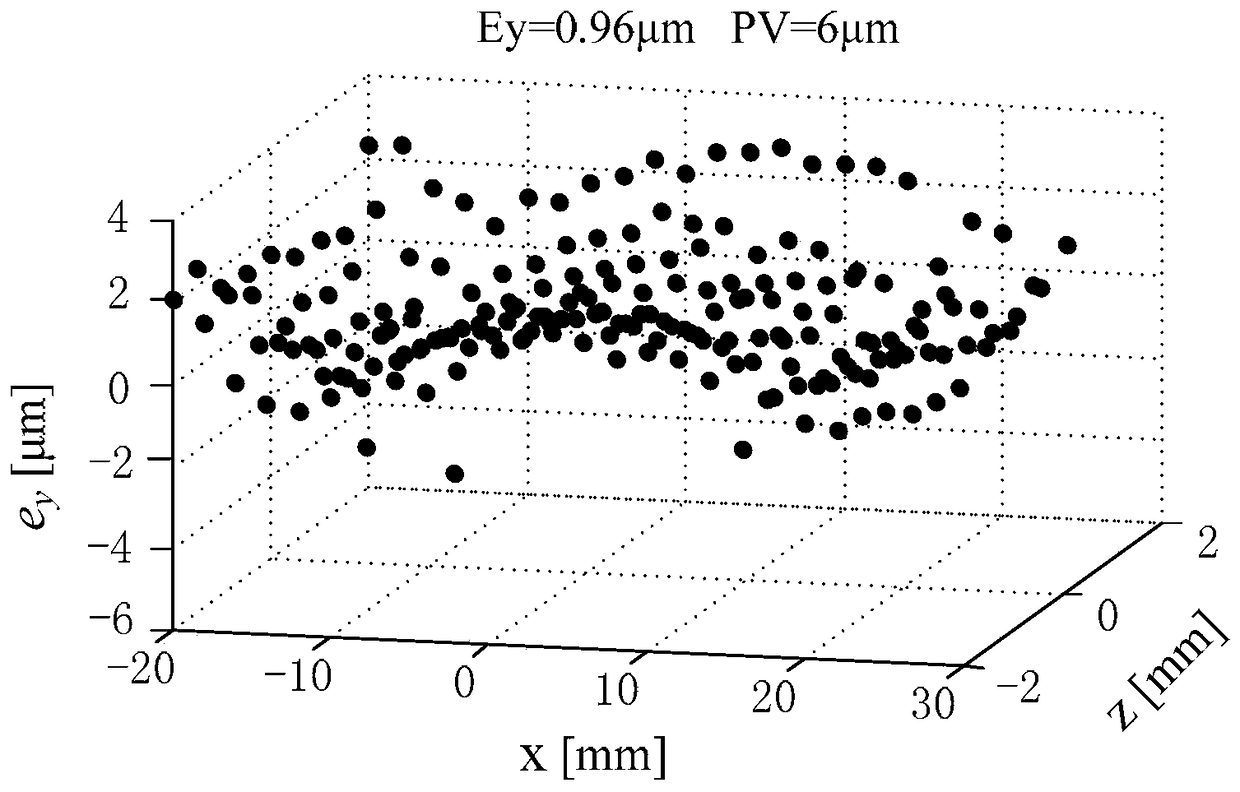

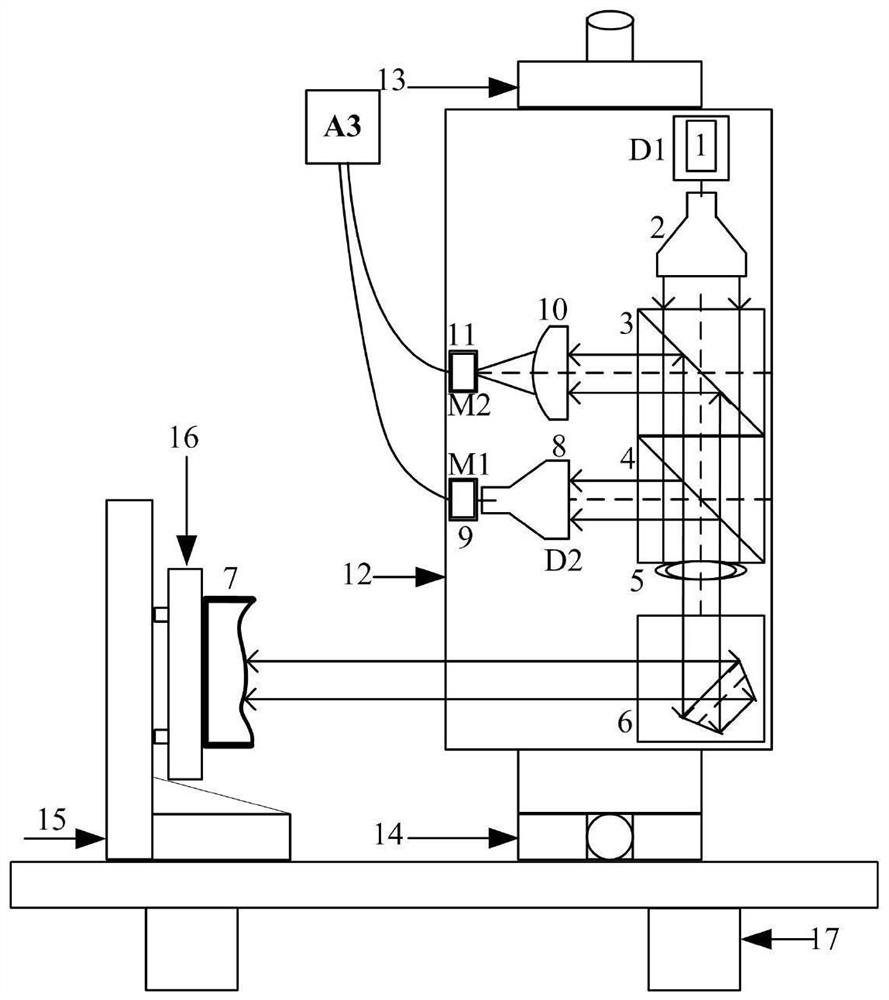

Free-form surface machining method and device based on two-step online detection and compensation technology

The invention relates to a free-form surface machining method and device based on a two-step online detection and compensation technology. The method comprises the steps that a machined workpiece is initially machined according to a design path, and a designed free-form surface is obtained; the surface-shaped error and rotation direction angle of the designed free-form surface are detected synchronously; the design path is amended on the basis of the surface-shaped error and rotation direction angle, and a primary amended machining path is obtained; the designed free-form surface is subjectedto primary compensation machining on the basis of the primary amended machining path, and a primary compensation free-form surface is obtained; radial detection through a center point is conducted onthe primary compensation free-form surface; the primary amended machining path is amended on the basis of the radial detection data, and a secondary amended machining path is obtained; and the primarycompensation free-form surface is subjected to secondary compensation machining on the basis of the secondary amended machining path. Compared with the prior art, the free-form surface machining method and device based on the two-step online detection and compensation technology have the advantages of being high in detection precision, high in compensation precision and the like.

Owner:TONGJI UNIV

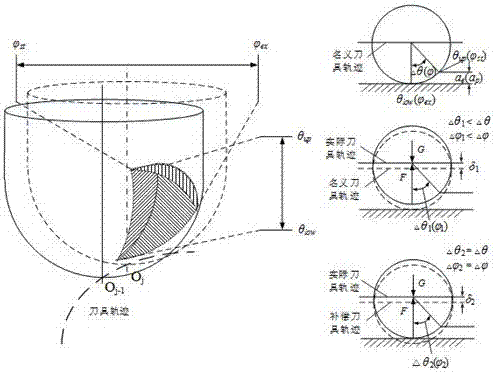

Integrated optimization method for process of milling free-form surface hardened steel mold using ball end

InactiveCN107422648AImprove processing efficiencyAchieve consistencySimulator controlProcess integrationFree form

The invention provides an integrated optimization method for the process of milling a free-form surface hardened steel mold using a ball end. Based on the machining features of a free-form surface, the machining area of the free-form surface is divided. For an area with large curvature, a cutter back-off error trajectory compensation method based on cutter contact area consistency is presented. For an area of the surface of which the curvature changes suddenly, an interpolation step length optimization method based on chord height error control is presented. In order to ensure the efficiency of machining, a feed rate optimization method is given for a flat area. Thus, an integrated technology optimization method for the process of milling a free-form surface hardened steel mold using a ball end is formed. The invention aims to improve the stability of the process of milling a free-form surface hardened steel mold using a ball end, and ensure the consistency of machining accuracy.

Owner:HARBIN UNIV OF SCI & TECH

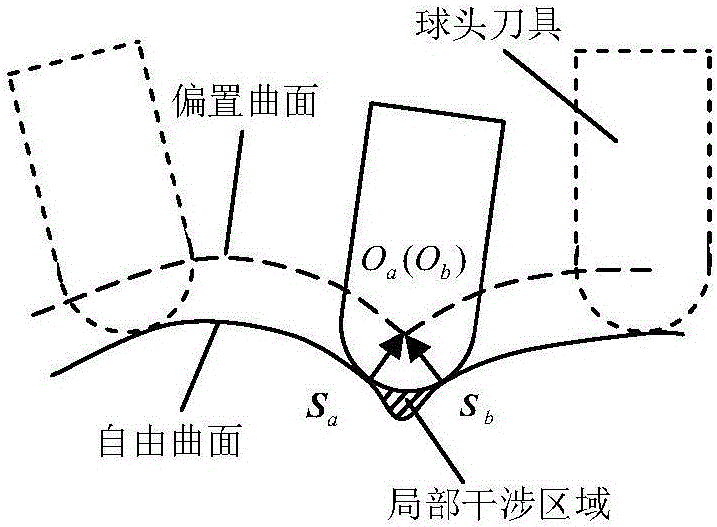

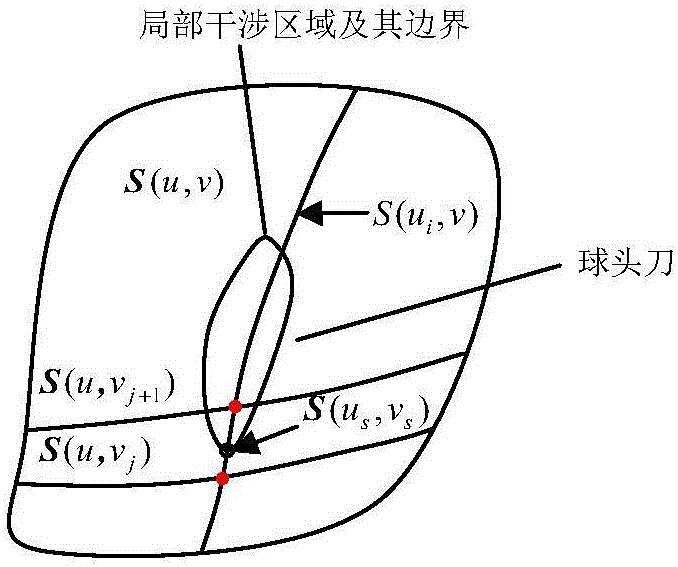

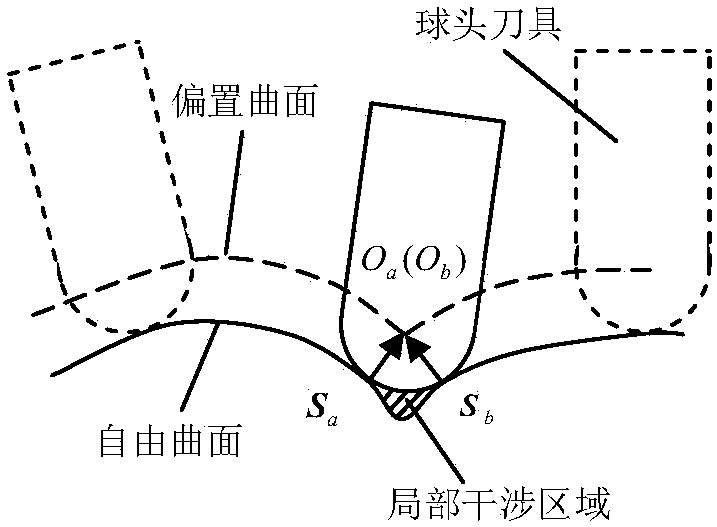

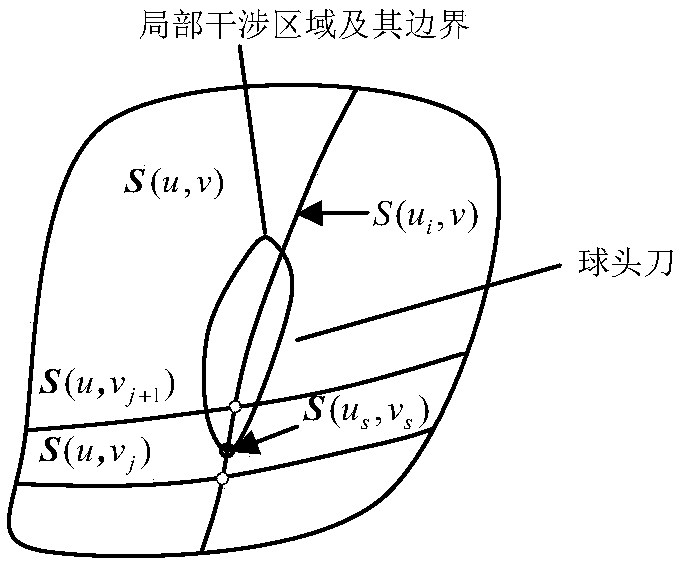

Tracing method for determining local interference region boundary of free-form surface machining

The invention discloses a tracing method for determining a local interference region boundary of free-form surface machining. Through analysis of principal curvatures of a free-form surface and an isometric offset surface, the local interference region boundary condition of the free-form surface machining is obtained. A tracing initial point of the local interference region boundary is obtained through combination of a surface discrete method and a dichotomy method. A rough point of the local interference region boundary is obtained through tracking along an osculating circle of the interference region boundary from the initial point. A precision point of the local interference region boundary is calculated through iteration by using a gradient method. Two tracing judgmental end conditions are obtained according to the condition that whether the local interference region boundary is enclosed on the surface. The tracing method for determining local interference region boundary of the free-form surface machining has the advantages that the tracing method is suitable for fast tracing and determining the interference region boundary of the complex free-form surface machining, a tool path track is regionally planned, a total length of the tool path track is reduced, and the surface machining efficiency is improved.

Owner:YANCHENG INST OF TECH

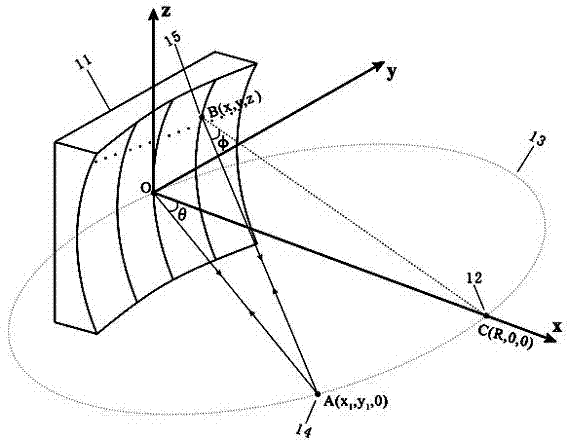

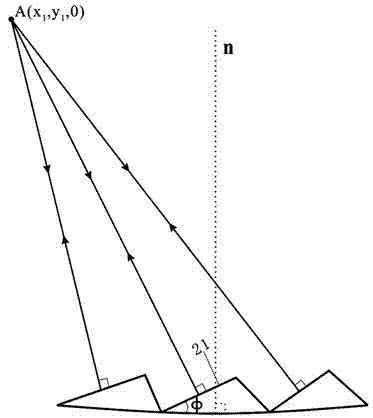

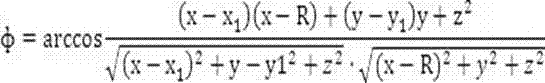

Design method of grating with glaring concave surface

InactiveCN102866445AVisibly sparkle enhancing effectEasy to implementDiffraction gratingsGratingDesign software

The invention relates to design method of a grating with a glaring concave surface. For a concave substrate with the preset radius R, carving grooves with preset angles and intervals are carved on the substrate so as to obtain the grating with the glaring concave surface. Incident light is spherical wave sent out by a point light source, the point light source is located on a Rowland circle, angles of curving groove surfaces are designed so as to enable the incident light to be perpendicular to the carving groove surfaces, the interval of the carving grooves is designed so as to enable optical path difference of adjacent carving grooves to be integral multiple of preset wavelength, carving grooves with corresponding angles and interval are carved one by one on the concave substrate by using a free curved-surface processing instrument, and the required grating with the glaring concave surface is obtained. The designed concave grating has remarkable glaring enhancement effect on the preset wavelength lambda, the design method is convenient to implement, only relates to calculation of elementary mathematics, dose not need professional optical design software, and the designed grating with the glaring concave surface can be widely applied to the technical field of a spectrum analysis instrument, optical detection, optical measurement and the like.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

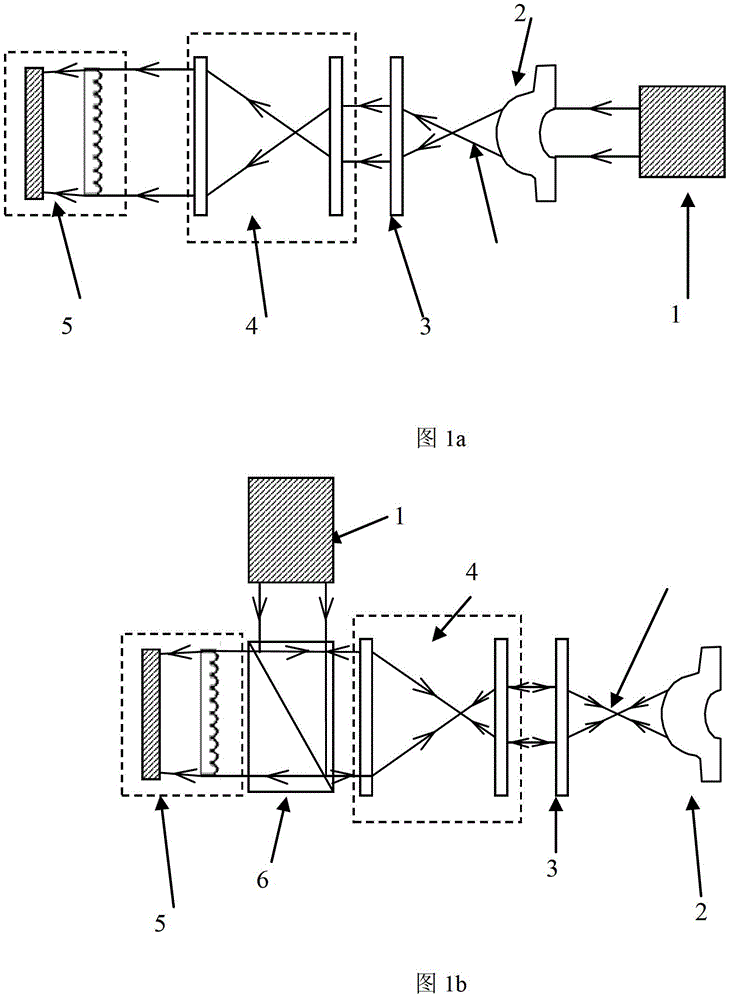

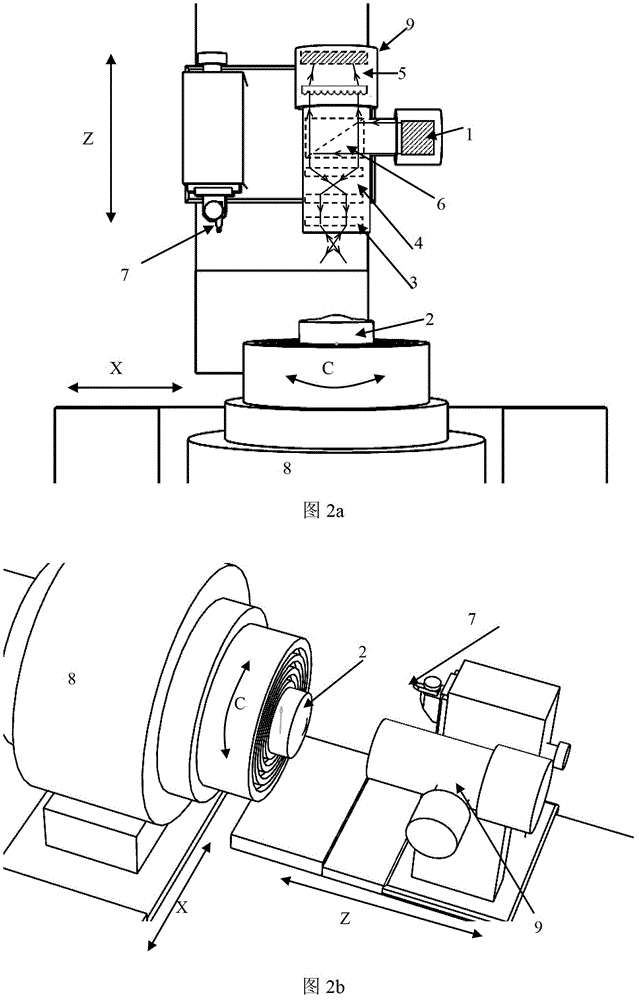

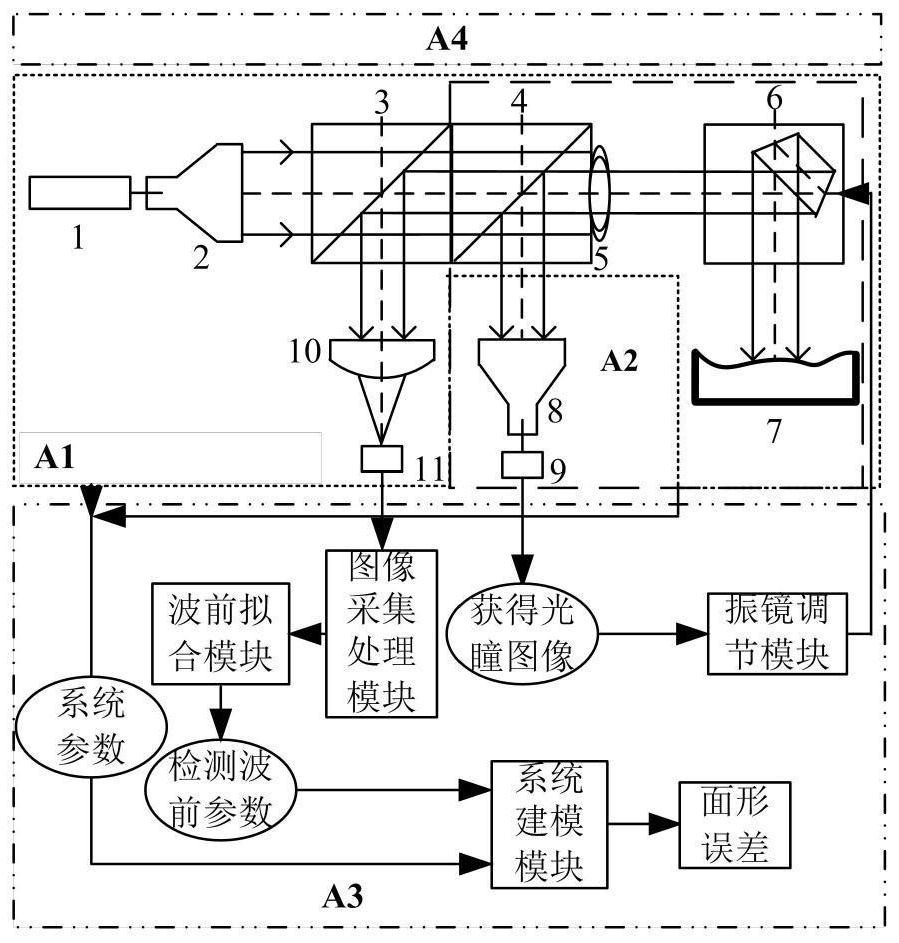

In-situ measurement method for optical free-form surface

InactiveCN102717305AMeet application needsSimple structureAuxillary equipmentMeasurement/indication equipmentsFree formImaging quality

The invention belongs to the technical field of manufacture of parts with optical free-form surfaces in advanced manufacture, and relates to an in-situ measurement method for an optical free-form surface. The in-situ measurement method includes 1), building a wave-front aberration measuring system and fixing the measuring system and a first machining cutter onto an ultra-precision machining lathe together; 2), testing optical quality of a machined device by the wave-front aberration measuring system after the optical free-form surface is machined, and obtaining wave-front aberration data; and 3), solving various parameters of a Zernike polynomial according to the measured wave-front aberration data of the machined workpiece and computing basic imaging quality evaluation indexes, a modulation transfer function and a point spread function which are used for comprehensively evaluating optical quality. The optical imaging quality is used as a direct measuring object, the in-situ measurement method is different from a traditional mode for measuring surface shape data and can effectively meet actual application requirements, and errors introduced by secondary clamping and the like are avoided.

Owner:TIANJIN UNIV

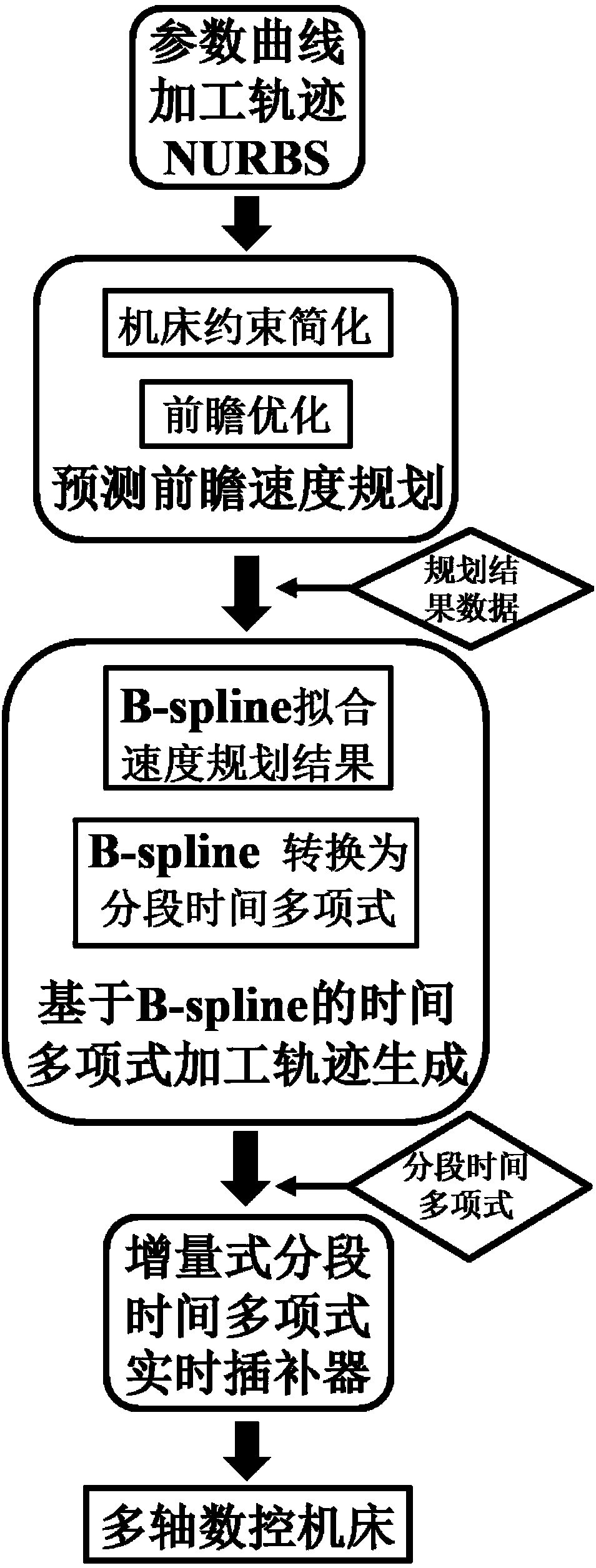

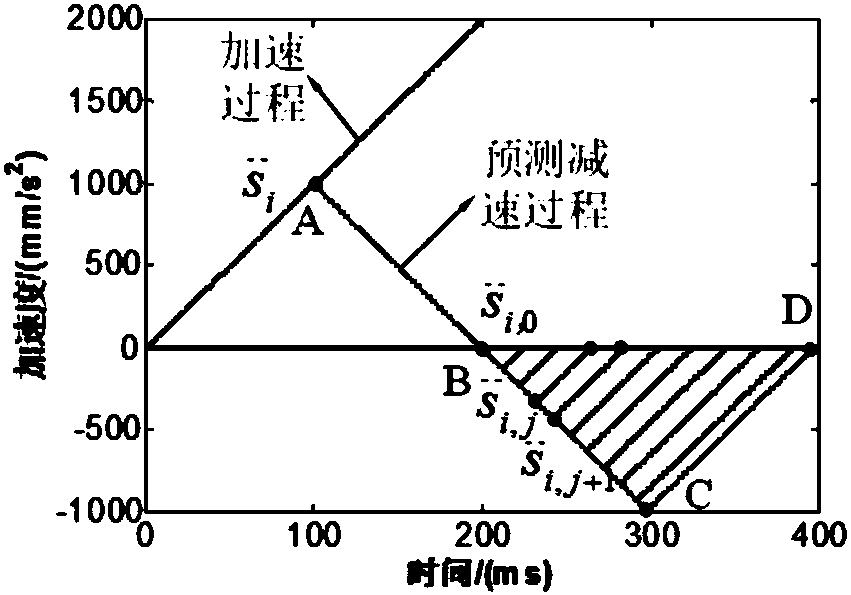

Numerically-controlled machining method using time parameter polynomial interpolation of free curved surfaces

ActiveCN108227630AImprove simplicityEnhanced effect is goodProgramme controlComputer controlTime controlMachining process

Owner:HEFEI UNIV OF TECH

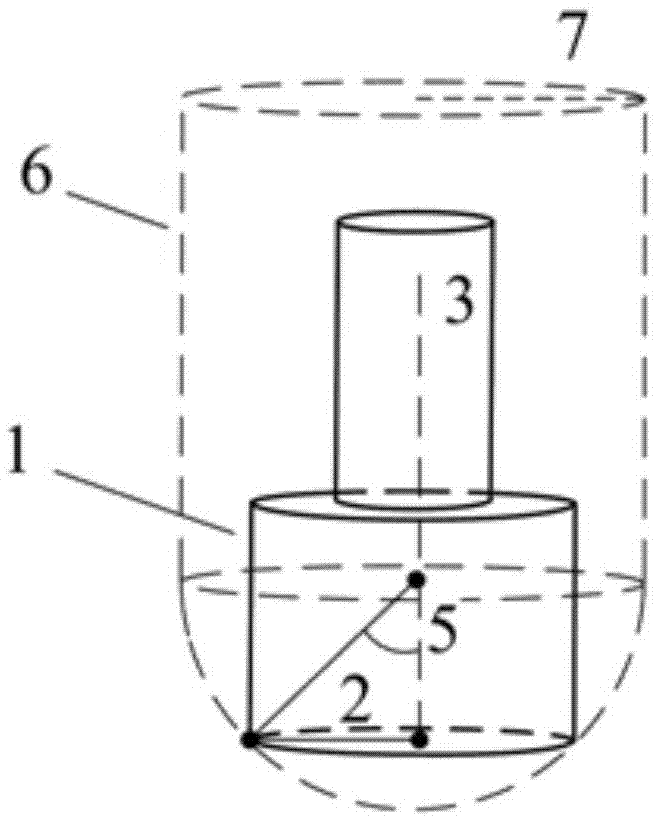

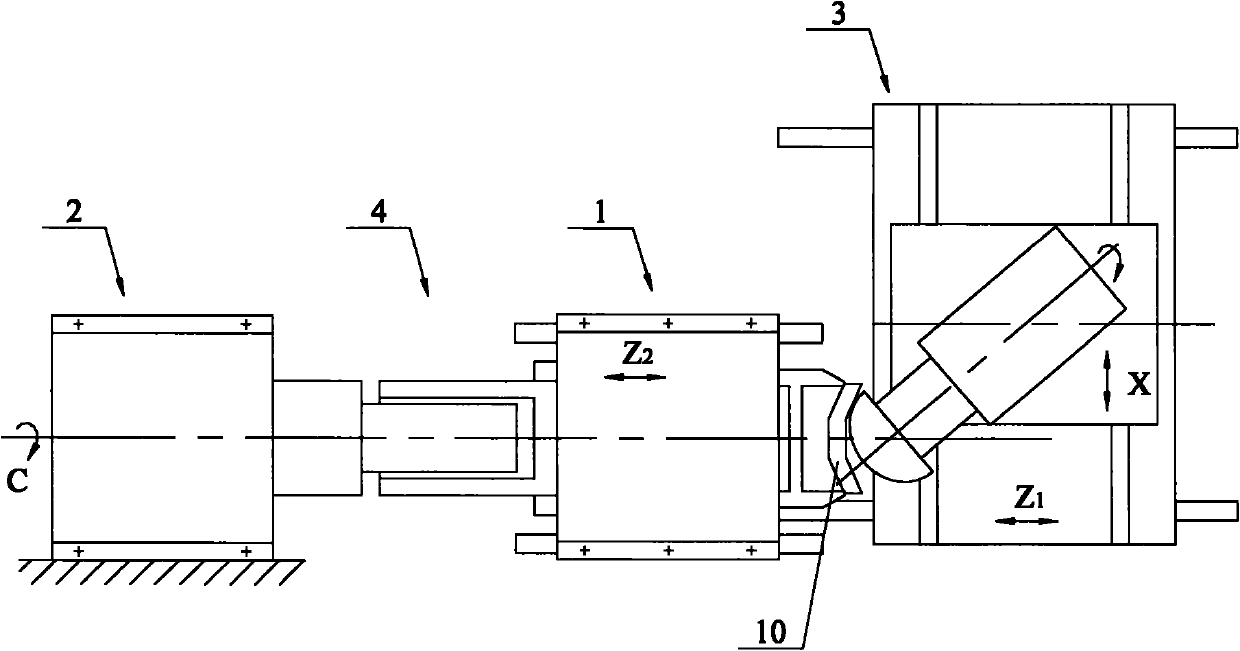

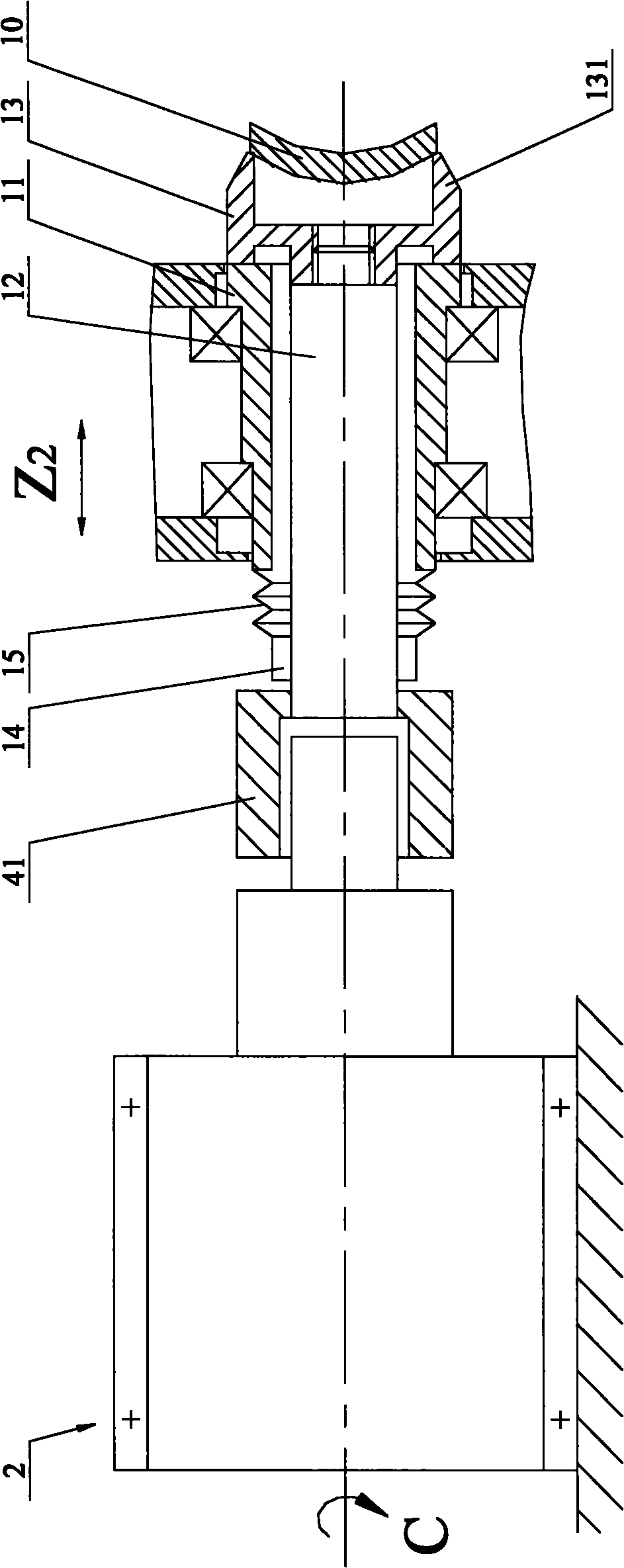

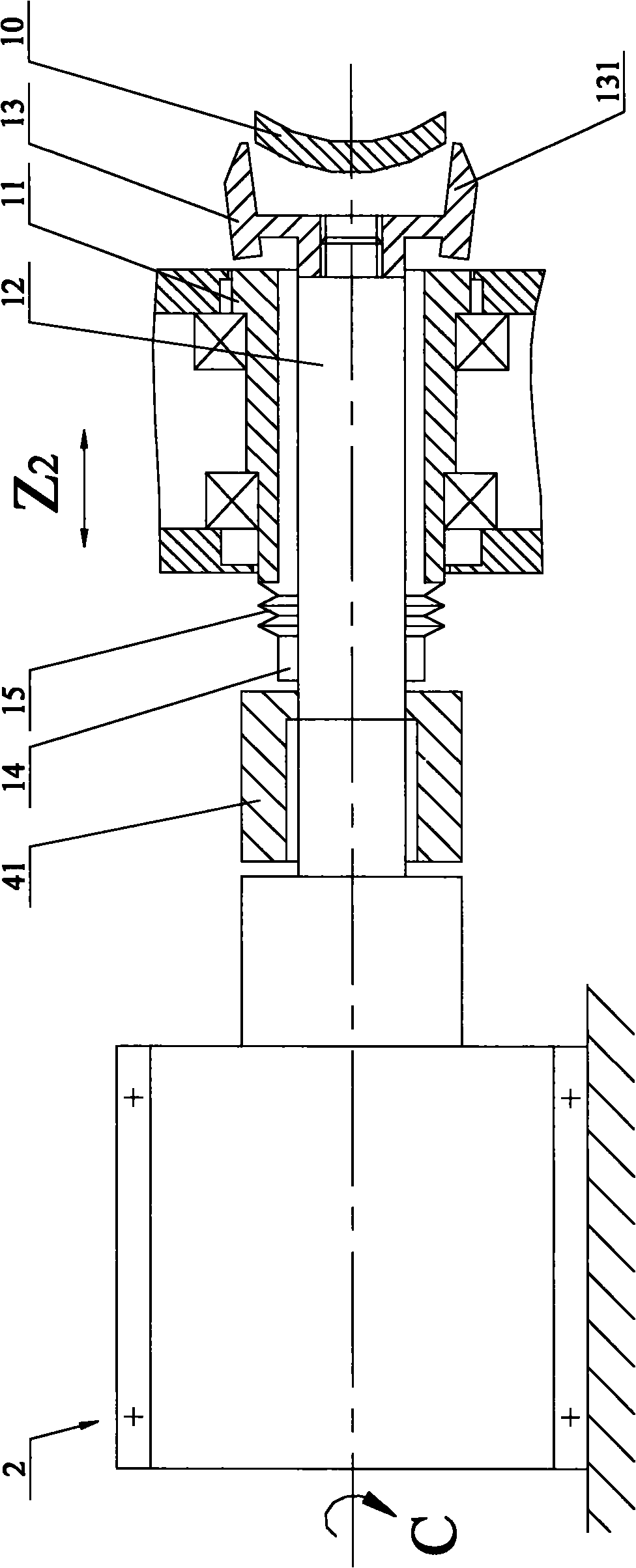

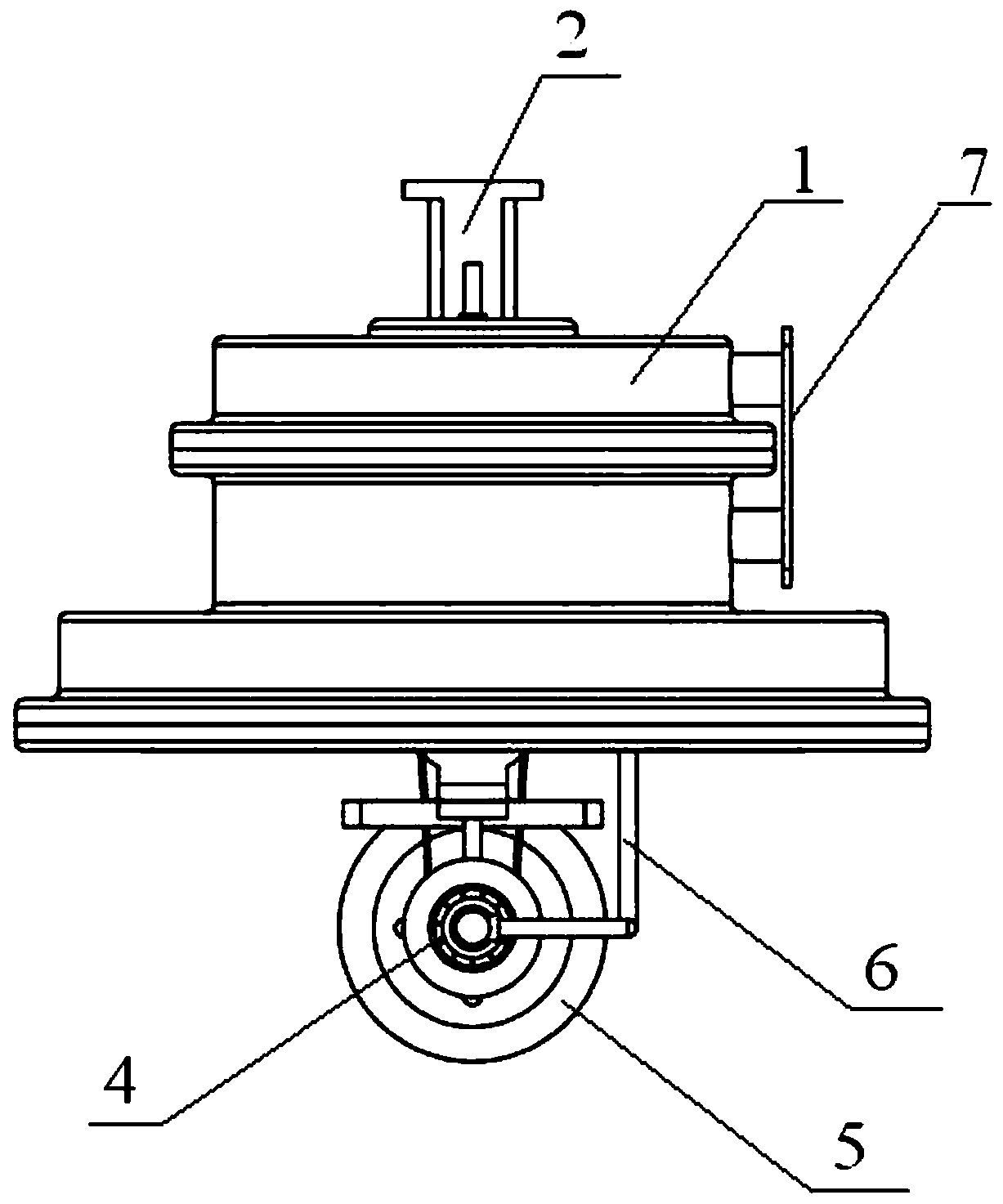

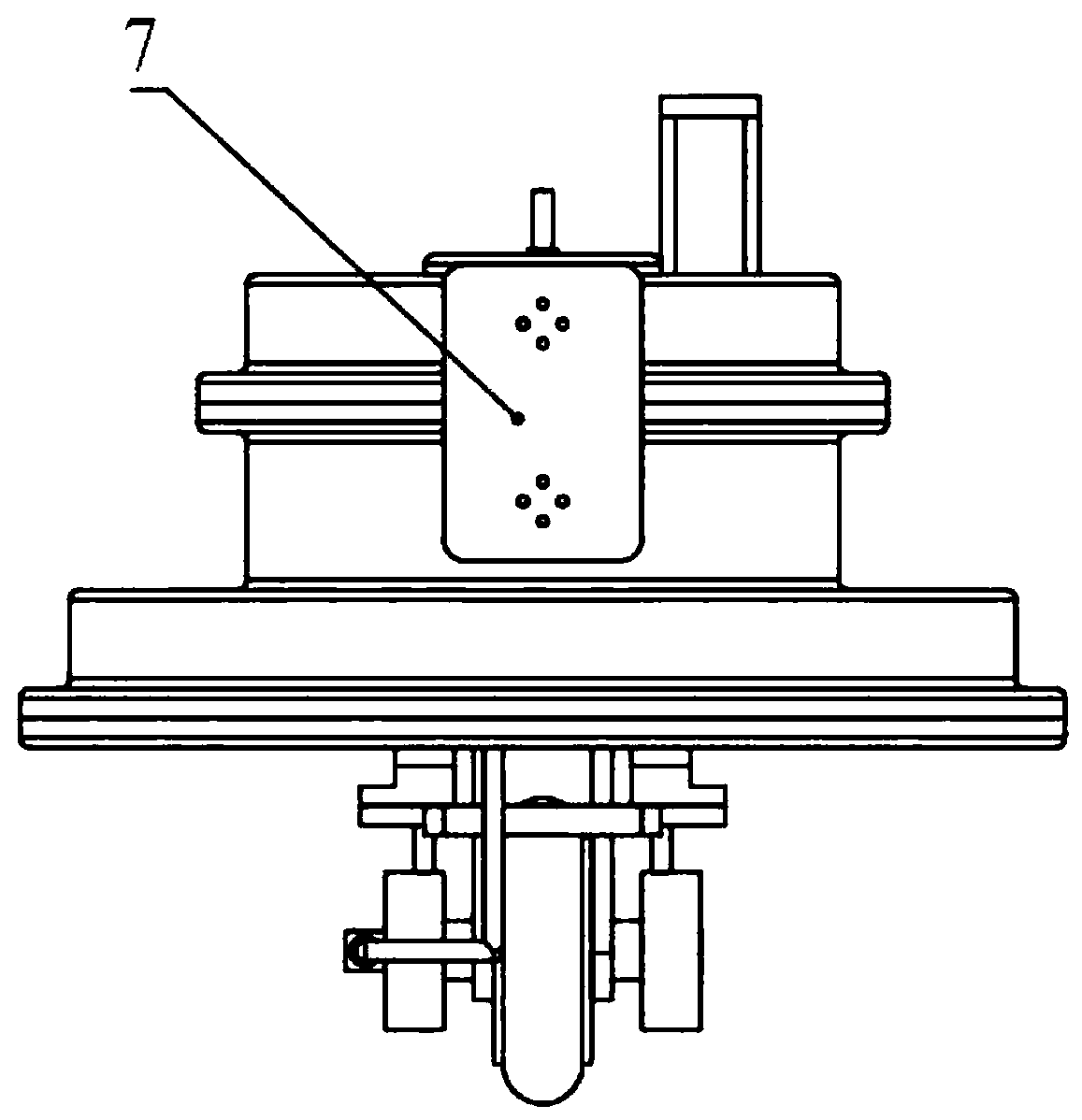

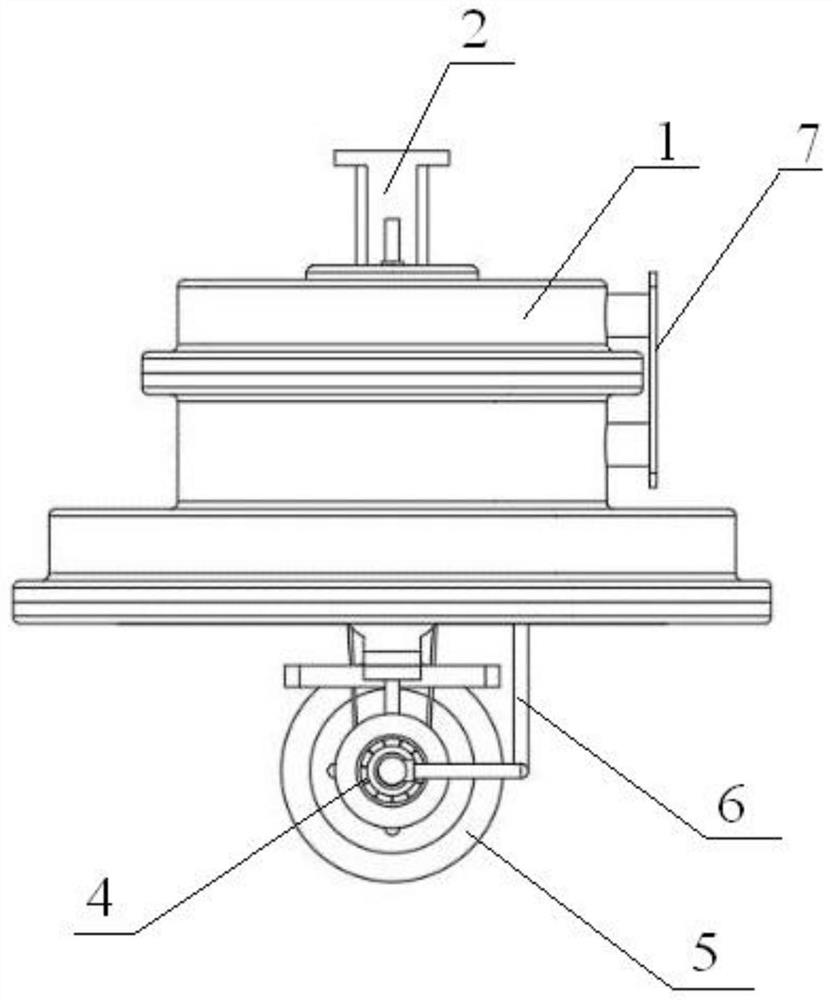

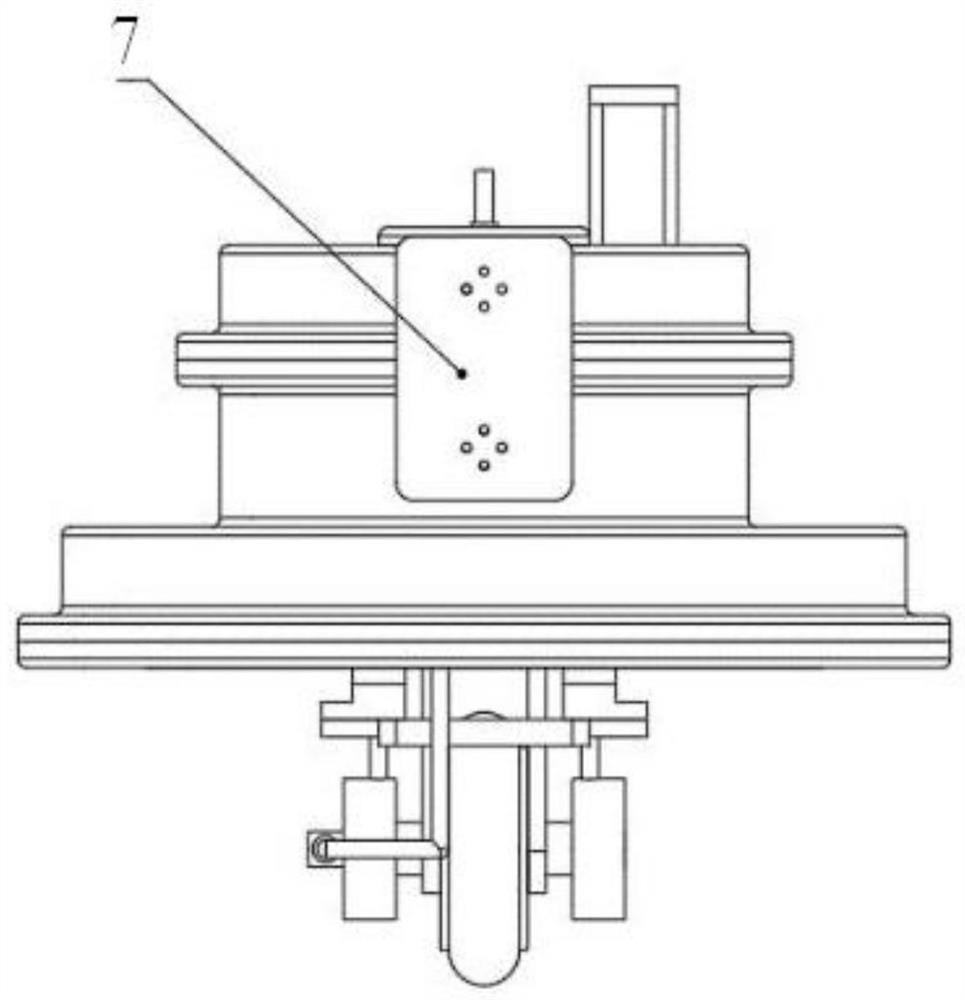

Free-form surface processing device

The invention discloses a free-form surface processing device which comprises a workpiece shaft unit, a drive unit for driving the workpiece shaft unit to rotate, a workpiece shaft feeding unit for driving the workpiece shaft unit to rapidly axially displace, a cutter unit and a cutter feeding unit for driving the cutter unit to slowly axially and radially displace. The free-form surface processing device also comprises a coupler arranged between the workpiece shaft unit and the drive unit, wherein the drive unit is fixedly arranged and the workpiece shaft unit can axially displace relative to the drive unit. Compared with the prior art, the drive unit used for driving the workpiece shaft unit to rotate is relatively fixedly arranged, and the coupler is arranged between the workpiece shaft unit and the drive unit, therefore, the workpiece shaft feeding unit can drive the workpiece shaft unit to axially displace relative to the drive unit, the mass of the rapid displacing part is reduced furthest, thus the rapid feeding acceleration can be reliably improved when in same power, and the purposes of improving the workpiece rotating speed and further enhancing the processing efficiencycan be realized.

Owner:陈耀龙

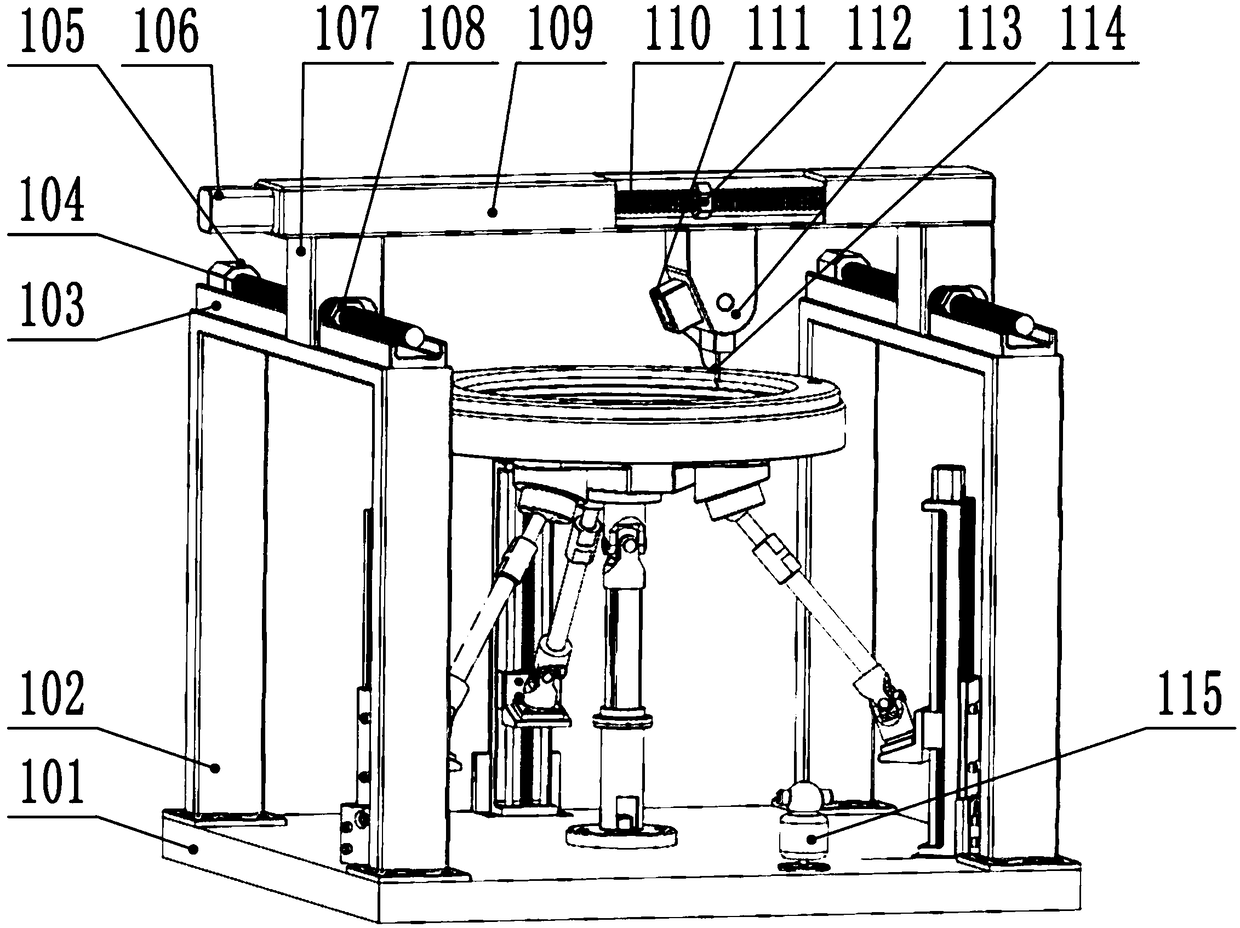

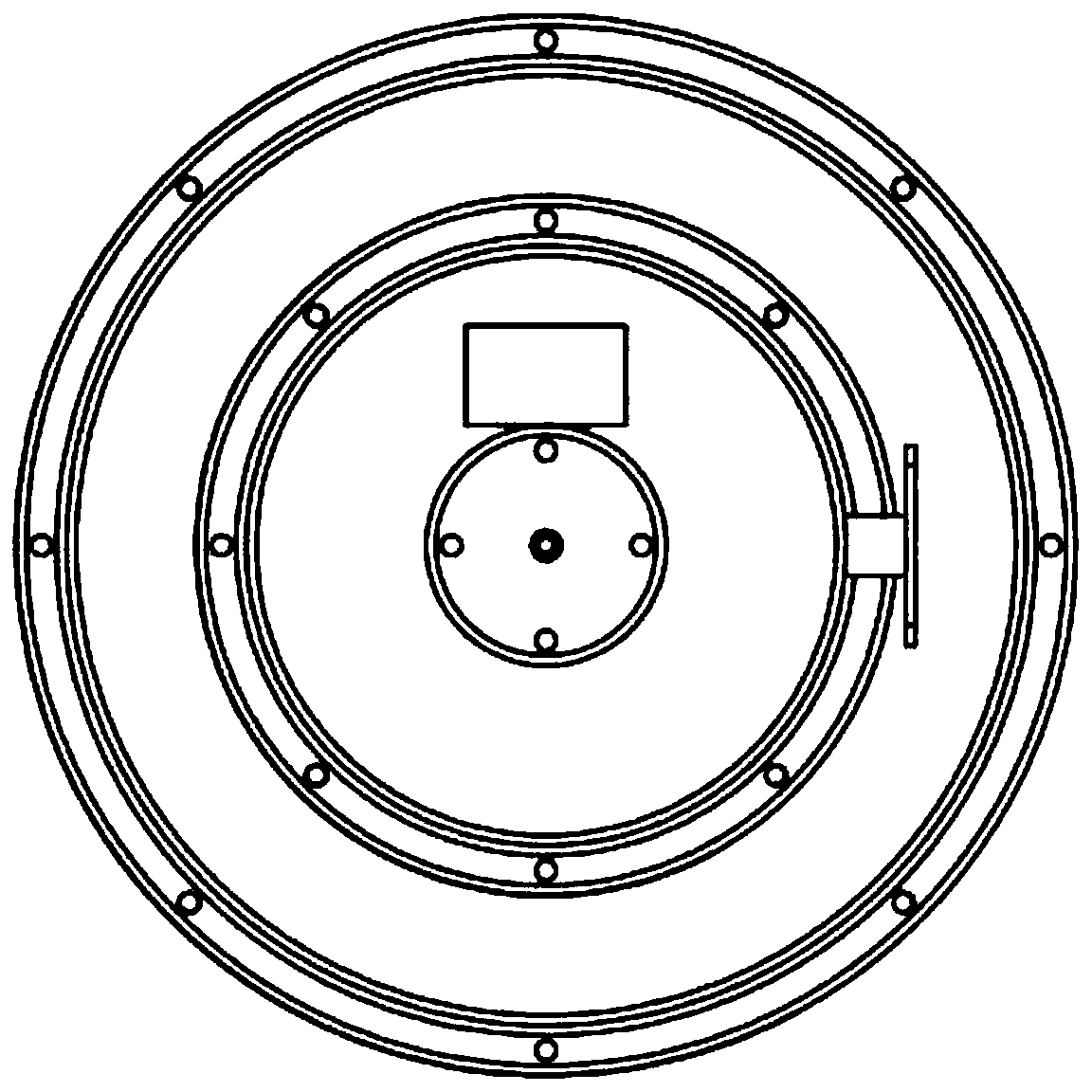

Machining device for large-caliber optic free curved surface

InactiveCN109352459AIncrease the machinable angleProcess controllableOptical surface grinding machinesAutomatic grinding controlFreeform surface machiningCaliber

The invention discloses a machining device for the large-caliber optic free curved surface. The machining device comprises a machining unit, an optic free curved surface supporting unit and an optic free curved surface clamping unit. The machining unit comprises a machining cutter and a drive mechanism for providing a machining path for the machining cutter. The drive mechanism comprises an X-direction drive mechanism and a Y-direction drive mechanism. The optic free curved surface supporting unit comprises a 3HUS+PU parallel mechanism, a moving platform connected to the upper end of the 3HUS+PU parallel mechanism and three sets of linear modules. The parallel mechanism drives the moving platform to move in the vertical direction to machine the curved surface, then the parallel mechanism rotates around the X-axis direction and the Y-axis direction, and then the posture of the free curved surface to be machined can be further adjusted. While the machining precision is ensured, the machining angle of the free curved surface can be increased. The machining device is high in overall equipment rigidity, small in accumulative error, high in machining precision and large in machining range, the optic free curved surface with the high complex degree can be machined, control is easy, and the machining efficiency is improved effectively.

Owner:SHANDONG ZHONGHENG OPTOELECTRONIC TECH CO LTD

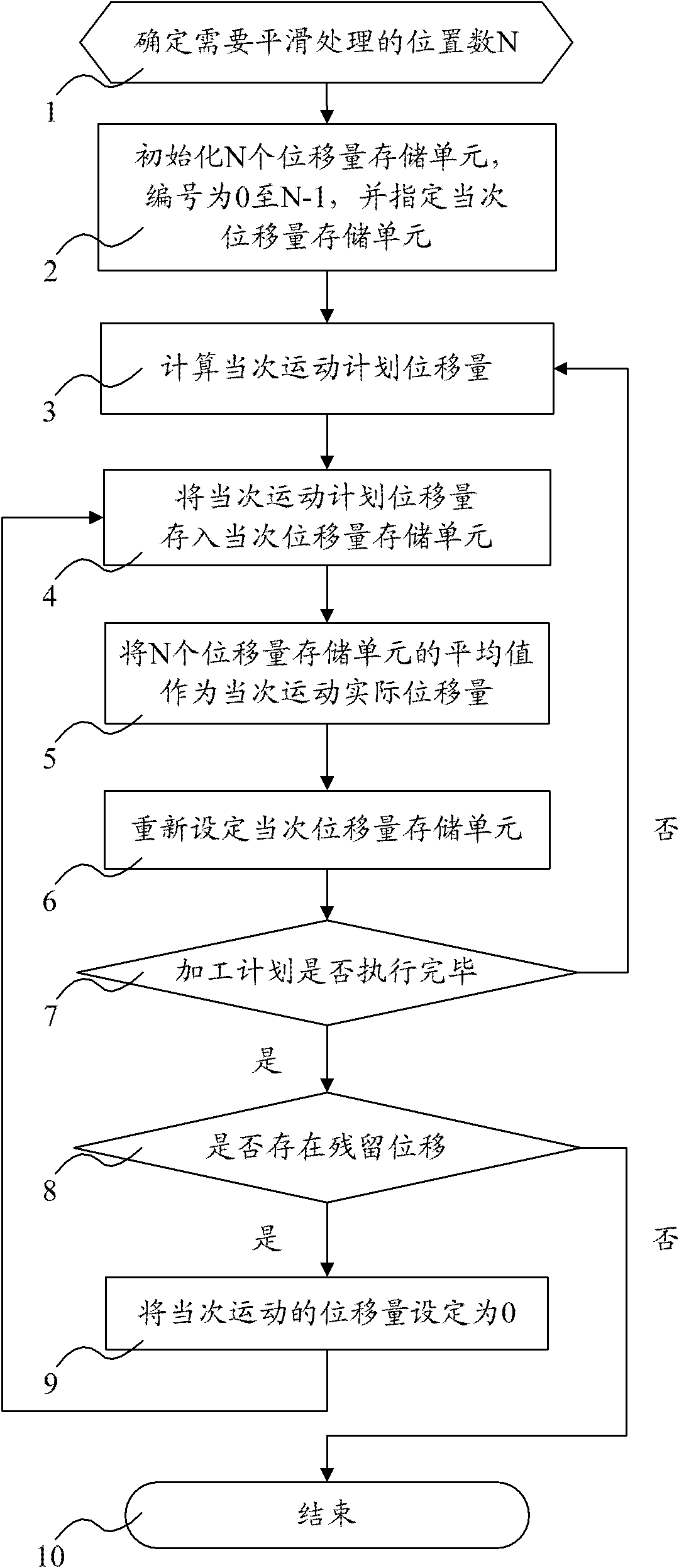

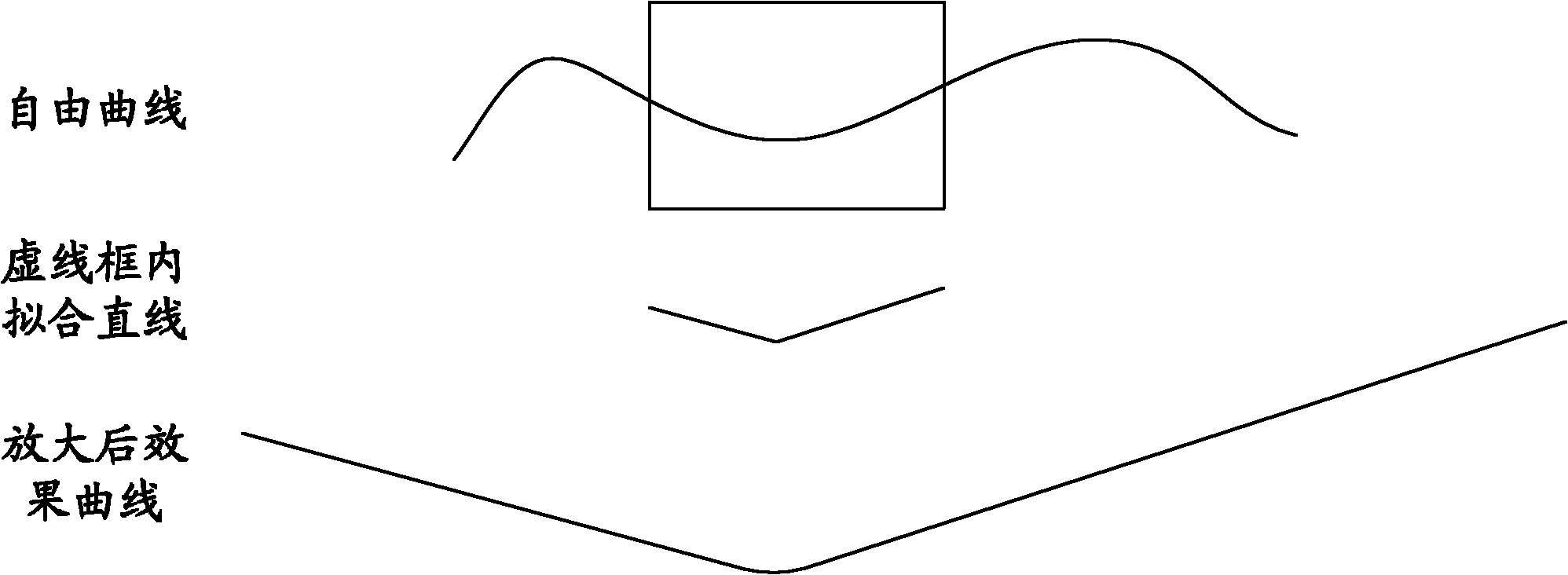

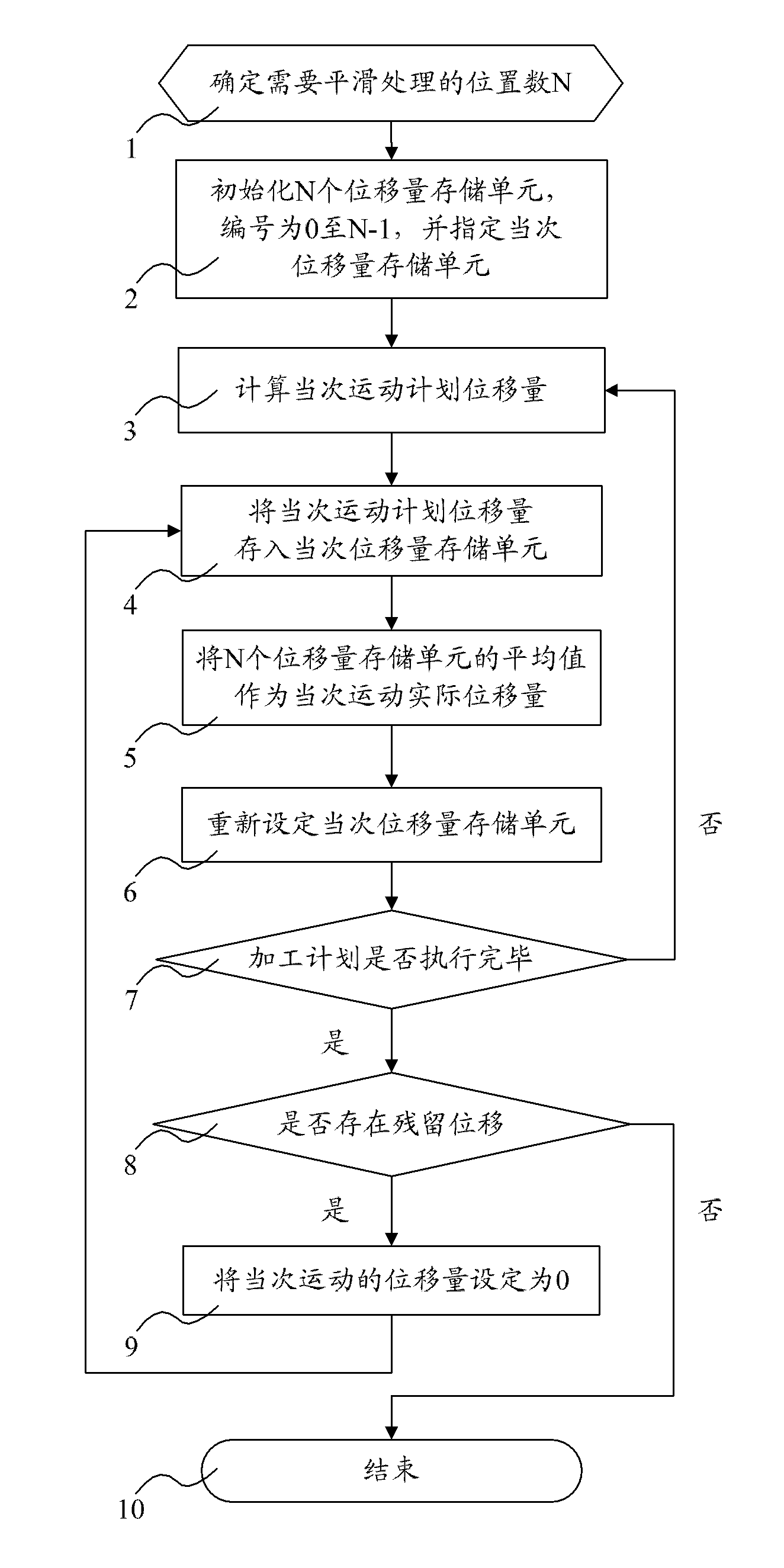

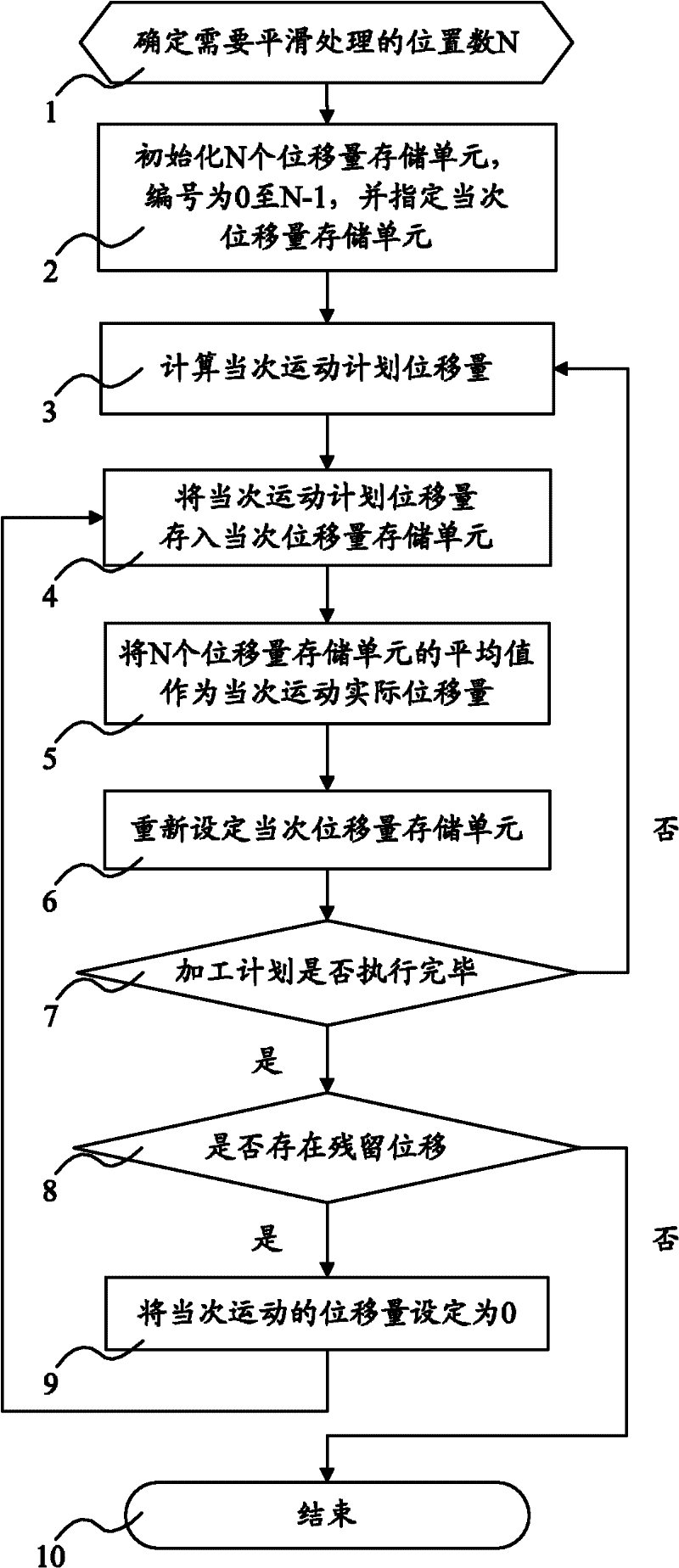

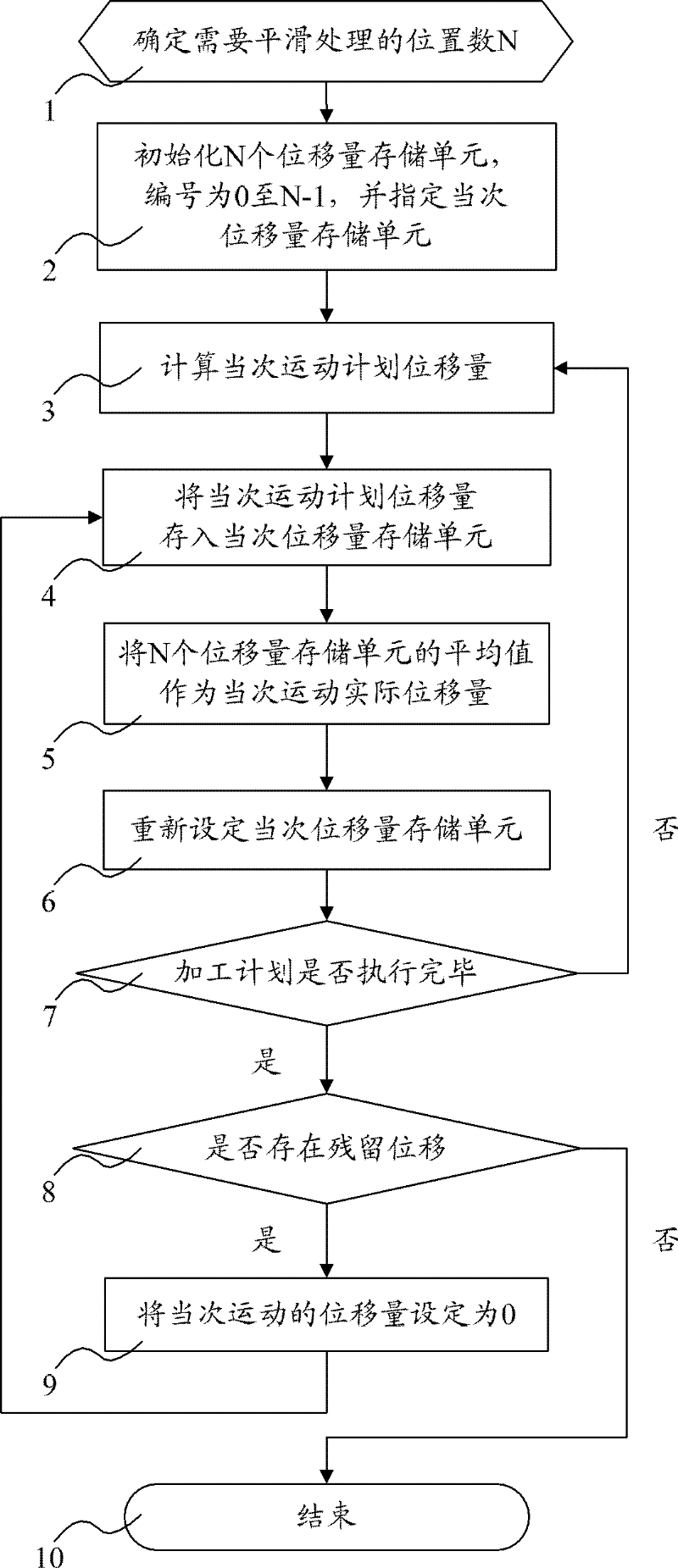

Method for controlling machining track of numerically-controlled machine tool

The invention relates to a method for controlling a machining track of a numerically-controlled machine tool. The method comprises the following steps of: determining the number N of positions to be smoothly machined; initialing N displacement storage units and storing the planned displacement of current movement in a machining plan into a current displacement storage unit; taking an average value of the N displacement storage units as the actual displacement of the current movement; and circulating the process to finish the machining. By utilizing the method disclosed by the invention, the displacement in single time of movement in the machining plan is realized by being dispersed into N times of movements so that the displacement variables among multiple times of close movements are reduced, the fitting degree of a machined free-form surface is better, and the degree of finish of the machined surface is higher; therefore, with the method disclosed by the invention, under the condition that a machining file does not need to be lengthened, the degree of finish of the machined free-form surface is increased, the increase of data processing amount of the numerically-controlled machine tool is avoided, and the cost of the numerically-controlled machine tool is reduced under the condition that application requirements are same.

Owner:SHANGHAI WEIHONG ELECTRONICS TECH

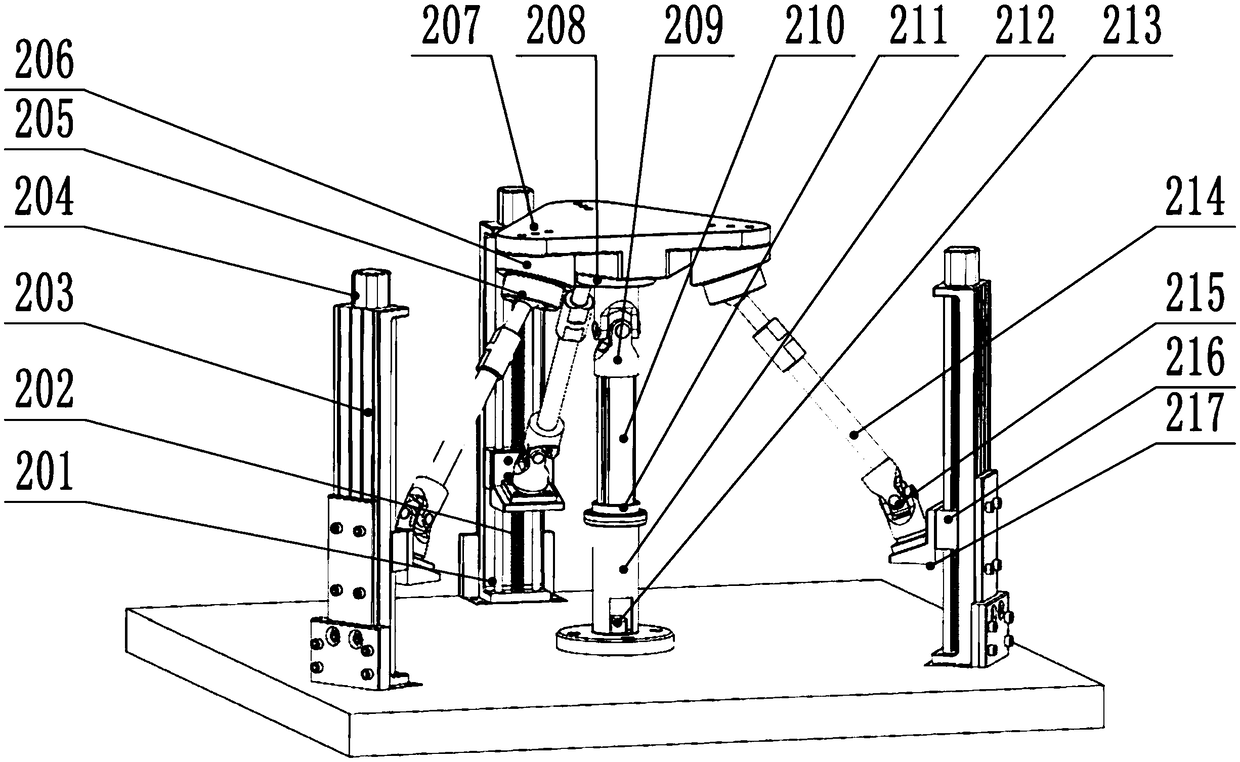

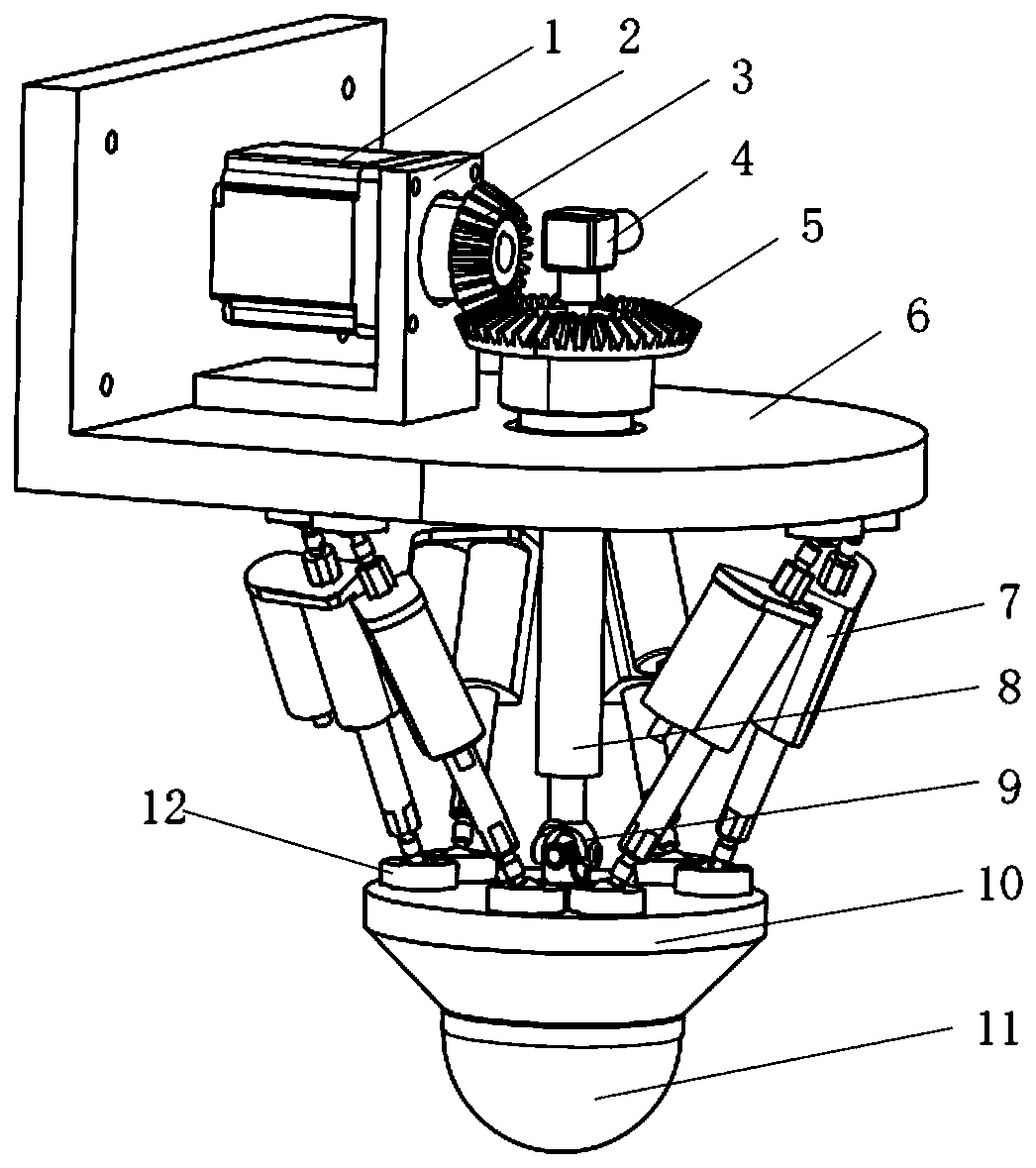

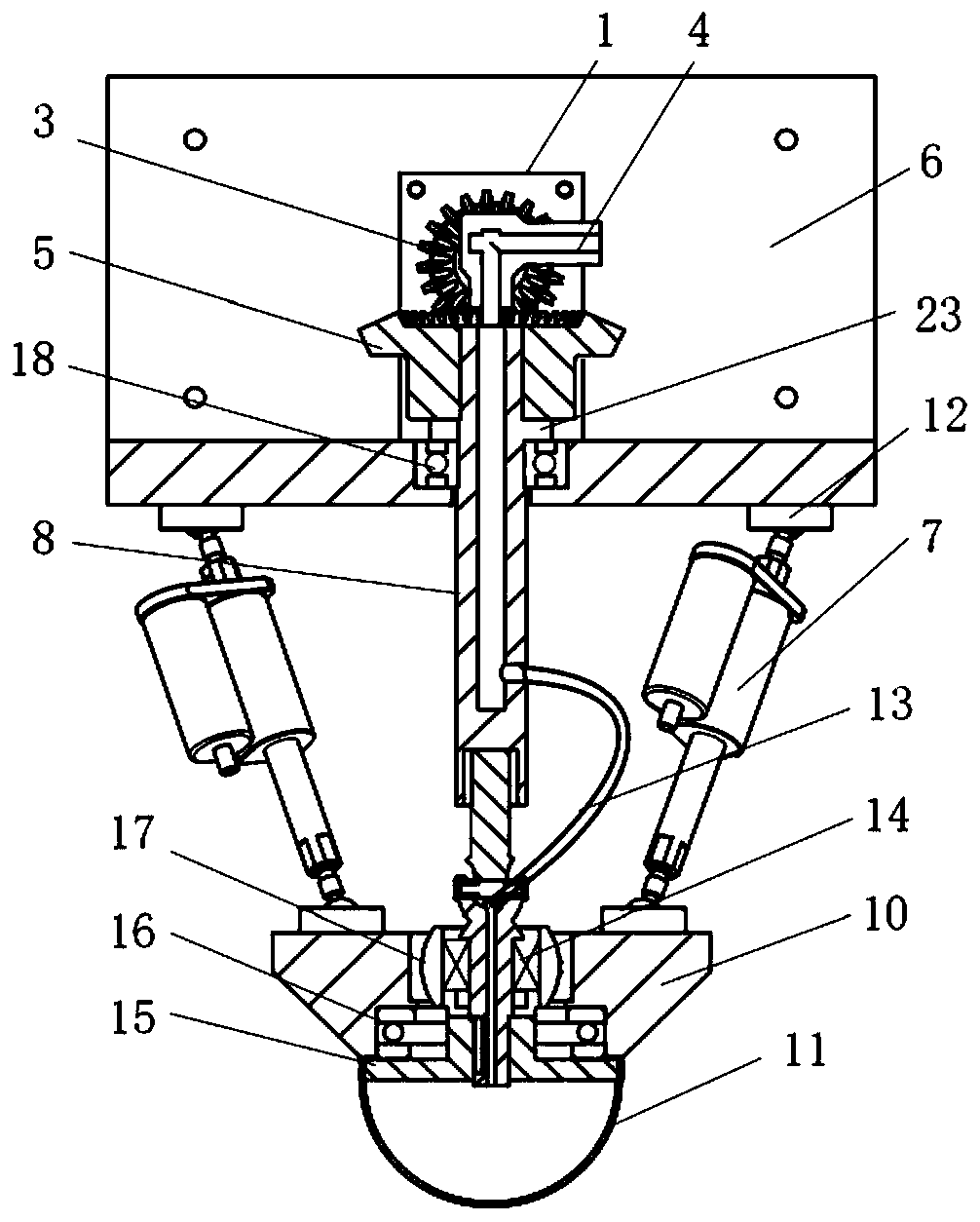

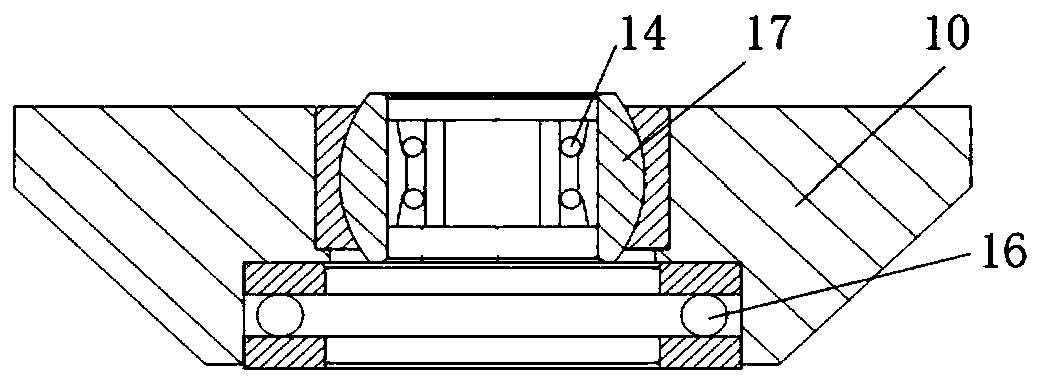

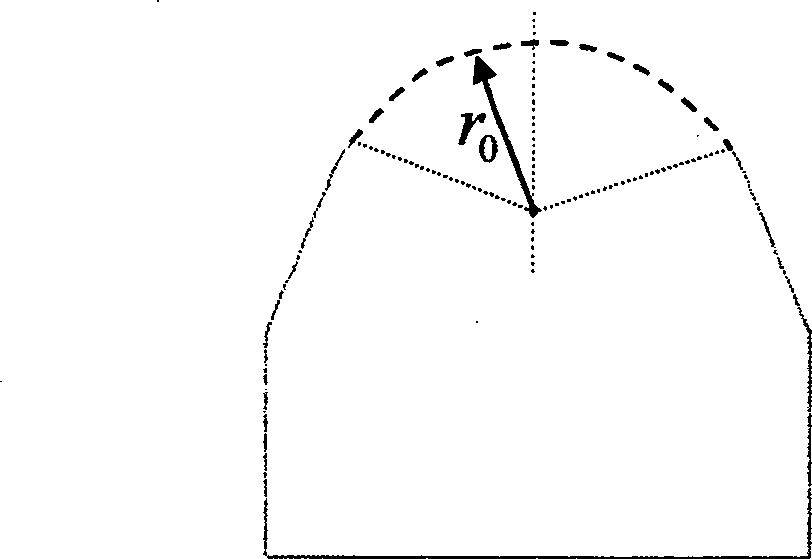

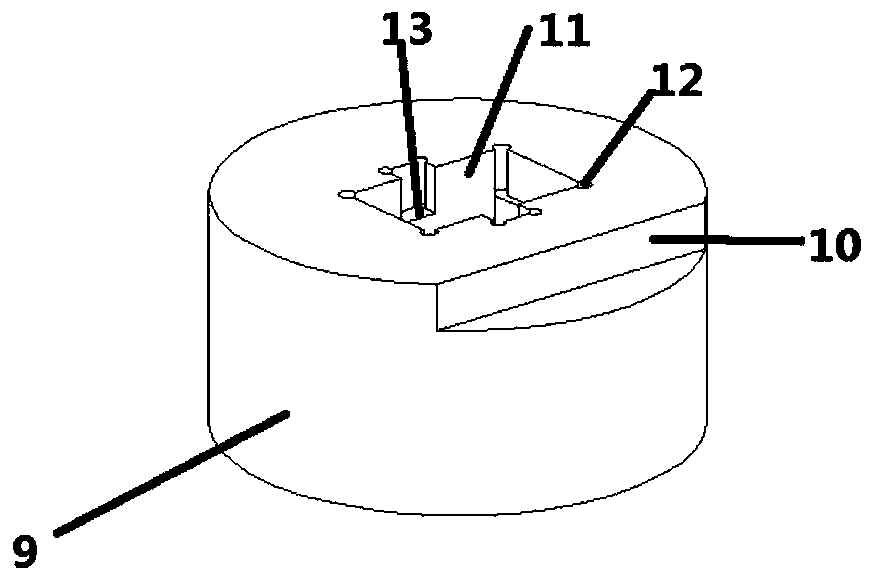

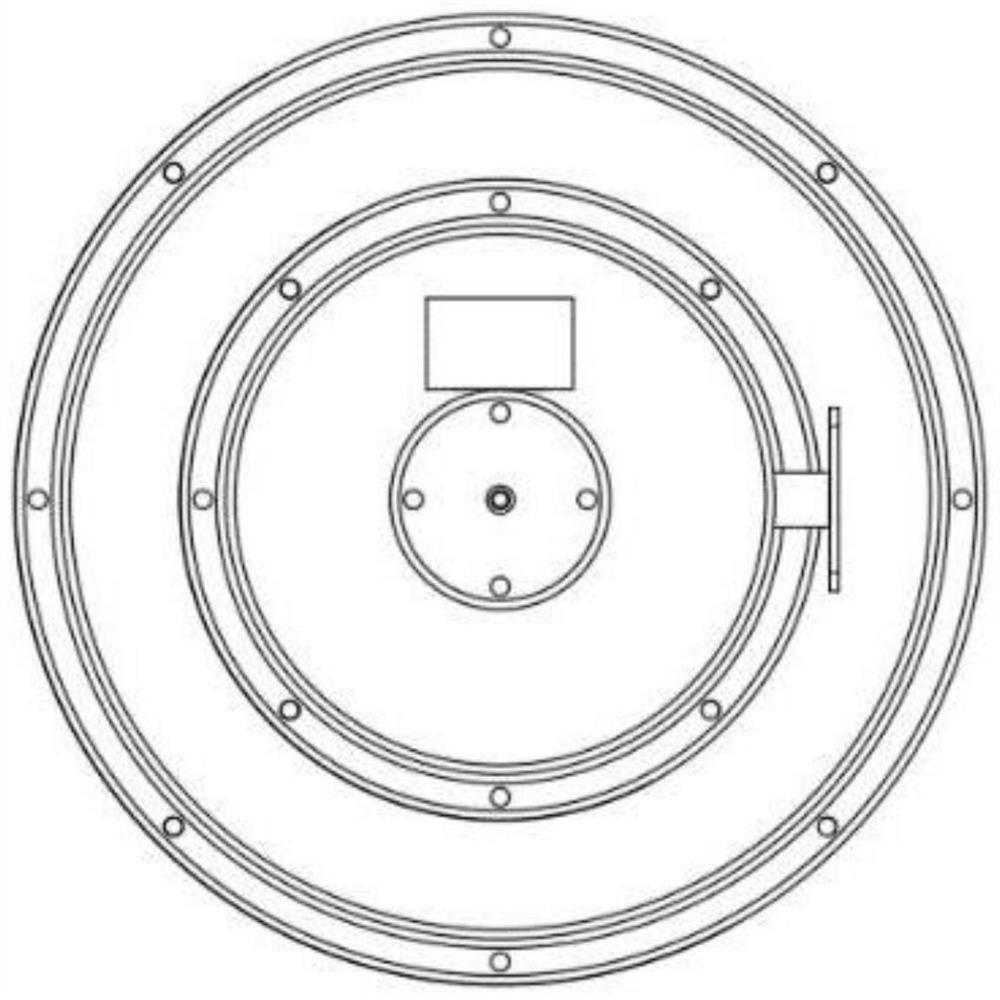

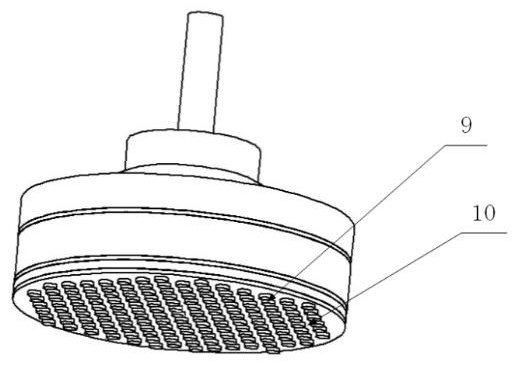

Single-motor double-degree-of-freedom speed change wheel type airbag polishing device

InactiveCN110497287AReduce structural redundancyEasy loading and unloadingOptical surface grinding machinesMotor driveAtmospheric pressure

The invention relates to a single-motor double-degree-of-freedom speed change wheel type airbag polishing device, and belongs to the field of precise free curved surface machining. A revolving drivingunit is fixed at the upper part of a shell unit; a rotation driving unit is fixed under the revolving driving unit; a tool driving unit is fixed under the rotation driving unit; an airbag polishing tool unit is fixed on the tool driving unit; and air pressure control units are integrated in the revolving driving unit and the tool driving unit. The device has the following advantages: the revolving and rotation double-degree-of-freedom movement is performed on the surfaces of workpieces to form Gaussion like removing functions; and single motor drives double-degree-of-freedom airbags for polishing movement, so that the structure redundancy is reduced, the driving chain stacking problem is improved, the maintenance of stable revolving and rotation speed ratio is facilitated, and the stability of device removing functions is improved.

Owner:JILIN UNIV

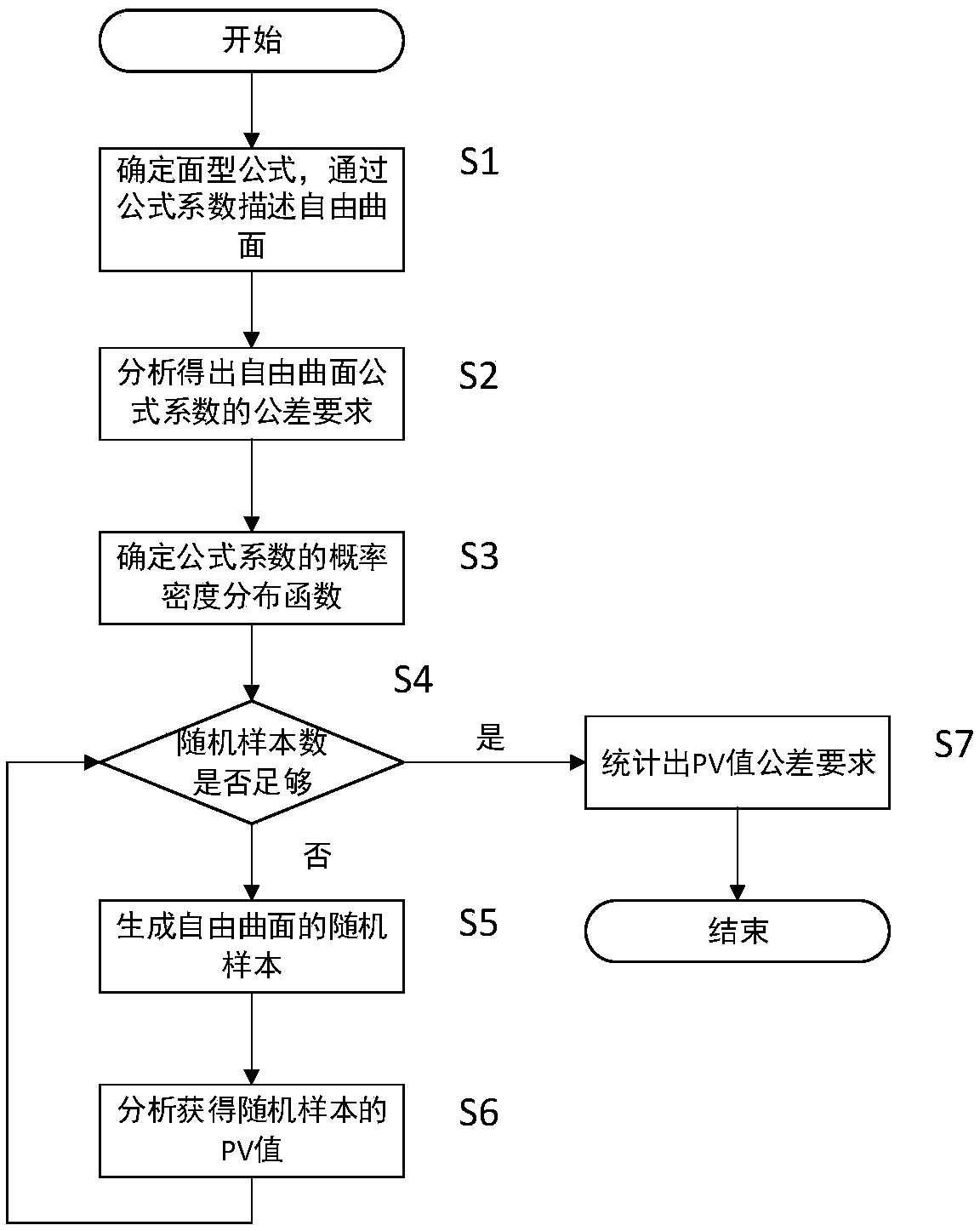

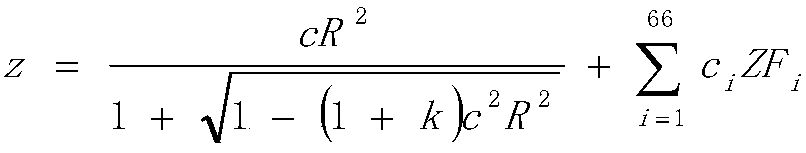

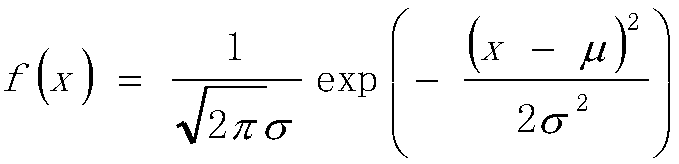

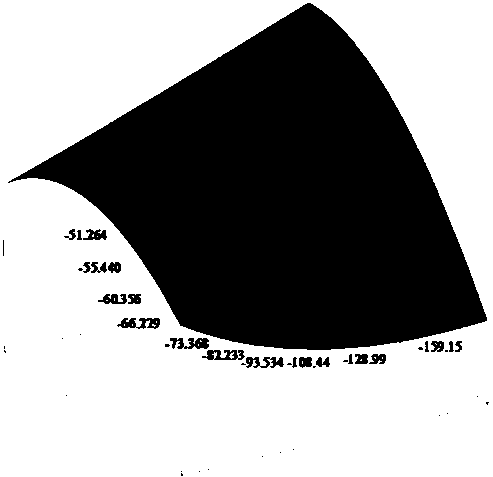

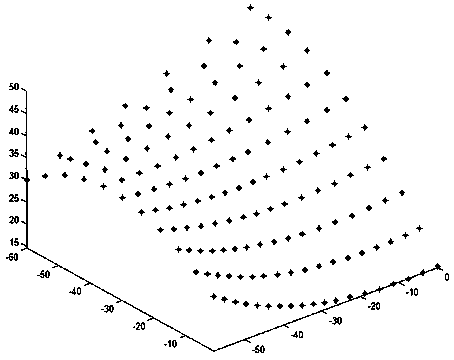

Analysis method for free surface tolerance

The invention relates to an analysis method for free surface tolerance, which is used for guiding the free surface machining. The analysis method is characterized in that the tolerance of the formulacoefficients of the formula is converted to the PV value tolerance by a statistical method for the free surface described by a specific formula. Compared with a traditional analysis method for free surface tolerance, the analysis method for free surface tolerance has the following advantages: (1) clarifying the conversion method of the tolerance requirement of the design process to the tolerance requirement of the machining process; (2) is more suitable for guiding the free surface machining.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

Quench hardening steel free curved surface test piece and milling process

PendingCN110394487AEliminate the effects of surface position errorsHigh quality processingAutomatic control devicesFeeding apparatusPoint cloudMachined surface

The invention discloses quench hardening steel free curved surface test piece and a milling process, designs the quench hardening steel test piece at the upper surface of a free curvature according tothe NURBS curve and provides a machining cutter path planning method of a free curved surface. The UG fixed-axis profile milling is adopted, and intrinsic geometric features of the curved surface ofa workpiece are described, so that a milling path planning method coupled by three driving manners composed of regular curve driving, adaptive sampling point cloud driving and benchmark surface projection curve driving described by intrinsic geometric features is put forward. Since the curvature of complex quench hardening steel profile surface is variable, machining compensation for profile surfaces of different curvatures cannot be directly carried out at a manufacturing site, the position error fluctuation of a machining surface of the curved surface is large, the accuracy of profile surface size is reduced, thus failing to meet machining quality requirement of the quench hardening steel profile surface. According to the method, the above problem can be solved, and meanwhile, the service life of the cutter as well as the machining precision and efficiency can be ensured.

Owner:HARBIN UNIV OF SCI & TECH

Self-inclined airbag polishing device

ActiveCN110919519AReduce dependenceLower fixed costsPolishing machinesGrinding machine componentsNumerical controlLinear motion

The invention discloses a self-inclined airbag polishing device. The self-inclined airbag polishing device is characterized in that an inclined base performs two-dimensional rotating inclination around a ball bearing rotating center through adjusting a telescopic quantity of an electric push rod mounted between a mounting base and the inclined base; through inclination of the inclined base, a toolbase and an airbag tool head are also inclined, and a machining axis of the airbag tool head is overlapped with a normal of a point to be machined; three linear motion shafts of a numerical control machine tool are shifted, so that the rotating center of the inclined base of the device is overlapped with the normal of the point to be machined, the distance from the point to be machined is a certain value, and an airbag is contacted with the machined point; and through control of the rotating speed of the airbag tool head and internal air pressure, the removal of materials on optical surfacesis realized. The device can realize two-dimensional inclination of the tool head, only needs the numerical control machine tool to possess three orthogonal linear motion shafts to realize tracking ofnormals of optical non-spherical surfaces or free curved surfaces, reduces dependence on a five-axle numerical control machine tool or a precise machine hand, reduces fixed cost investment, and is a low-cost and high-precision optical non-spherical surface and free curved surface machining device.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Diamond super precision lathe free curved surface processing path generation method

The invention belongs to the technical field of ultra-precise work and complex parts manufacturing, which relates to a path generating method of a curved face processing. The method is utilized on a diamond ultra-precise machine tool with three shafts, which comprises first, establishing a coordinate system of a free curved face model of a processing surface of a workpiece, and establishing conversion relationship between the model coordinate system and a machine tool coordinate system, second, conversing the model coordinate of a processing point on the processed free curved face to a coordinate under the coordinate system of the machine tool, third, solving and processing a normal vector of cutting face of a cutter when the point is processed, fourth, projecting the normal vector of the point of the curved face on the cutting face, and compensating a circular arc radius of the cutter on the projection vector direction, and getting a coordinate of the arc center of the cutting edge under the cutting edge coordinate system, traversing the processing point on the free curved face, at last generating a processing path. The limitation of processing the free curved face on the machine tool with three shafts can be broken by adopting the path generating method which is provided by the invention, the invention can achieve ultra-sophisticated processing of the free curved face.

Owner:TIANJIN UNIV

Free hook face prism positioning design and machining method

ActiveCN110744389AGuaranteed high precision processingGuaranteed accuracyOptical surface grinding machinesEngineeringPrism

The invention provides a free hook face prism positioning design and machining method so as to solve the problems about high-precision-requirement free hook face machining, detection and adjustment reference consistency control. Based on free hook face prism machining, detection offline detection process repeated positioning and other requirements, a specially-designed auxiliary reference processtable is arranged on a free hook face prism and provided with a positioning reference face, and accordingly machining reference and adjustment reference consistency is achieved. By adoption of the method, uniformity of machining, detecting and even later adjustment reference can be achieved, consistency control of free hook face machining, detecting and adjustment reference is achieved, and the final optical system performance is guaranteed.

Owner:西安应用光学研究所

A Surface Grinding Method of Cylindrical Grinding Wheel with Virtual Ball Cutter Radius

ActiveCN106853598BInterference handling is simpleImprove processing precisionGeometric CADOther manufacturing equipments/toolsRotational axisSurface roughness

The invention discloses a method for curve surface grinding with a cylindrical grinding wheel at a virtual ball cutter radius. The method includes the steps that 1, the attitude angle of the cylindrical grinding wheel is designed, and the inclination angle of the axis of the cylindrical grinding wheel on a curve surface tangency point normal vector is designed through a virtual ball cutter model; 2, a cutter path is planned and determined according to the curved surface tangency point normal vector and the virtual ball cutter model, and the set inclination angle in the step 1 is guaranteed through a rotating shaft of a machine tool; 3, by the adoption of an axial feeding mode, a workpiece is subjected to grinding machining according to the cutter path. The cylindrical or quasi-cylindrical grinding wheel can be used for four-axis machining of a free curved surface, and the method has the advantages that planning of the cutter path is simple and flexible, the precision of a machining shape is high, and surface roughness is low, and is suitable for machining free curve surfaces of optical glass and other hard brittle materials.

Owner:SOUTH CHINA UNIV OF TECH

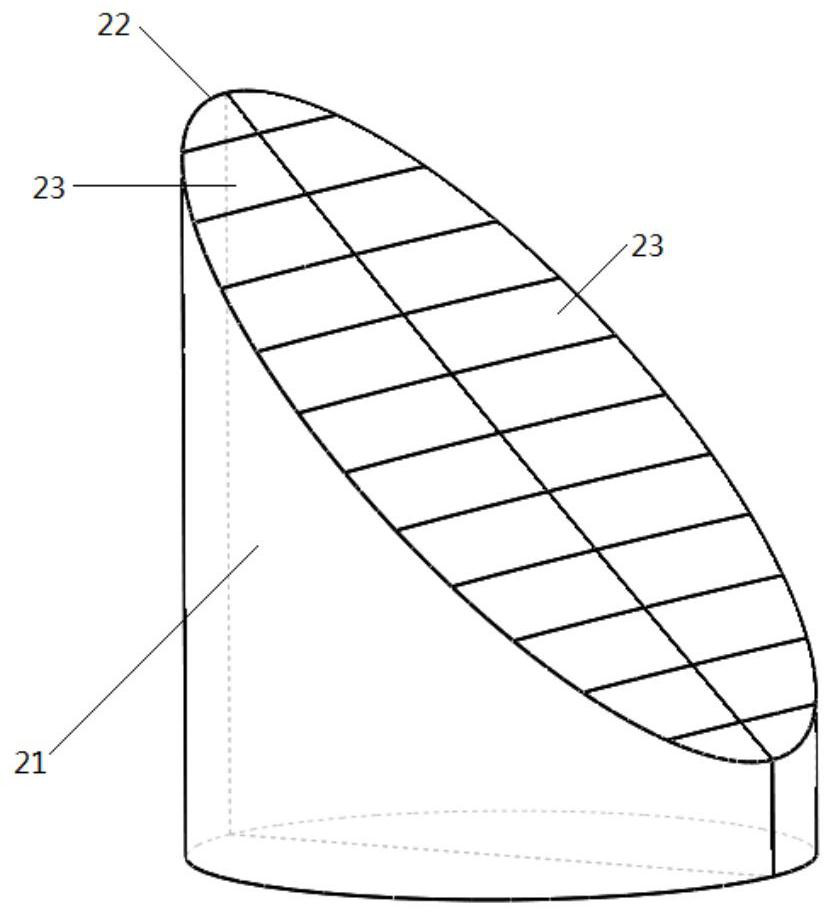

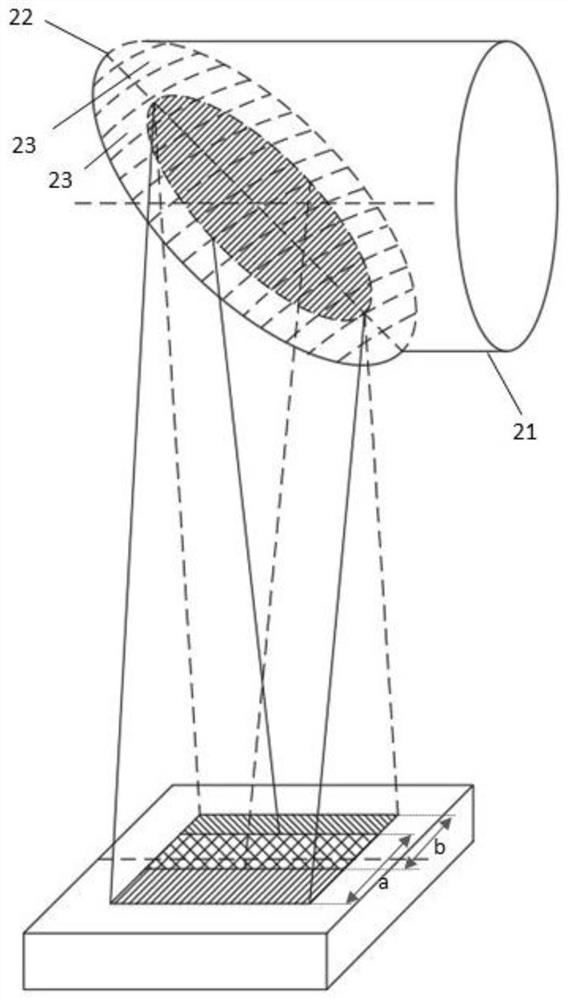

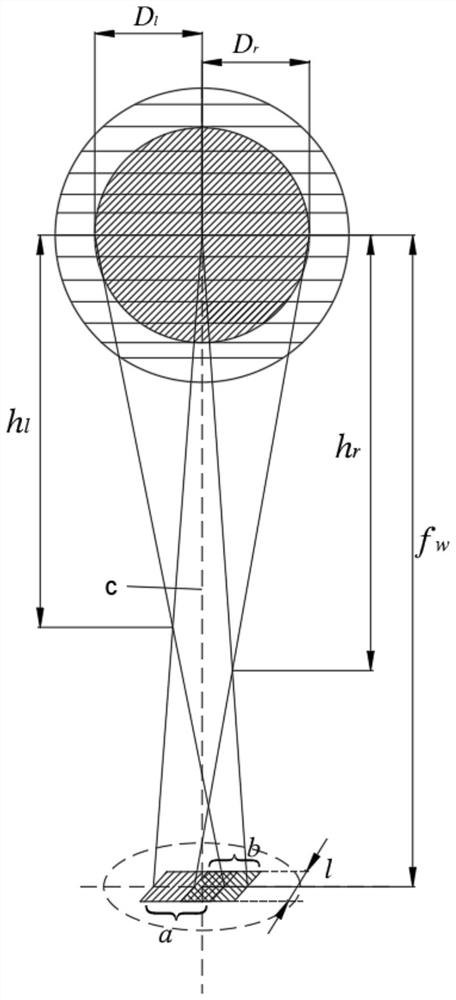

Reflection-type homogenizing mirror for generating flat-top-like rectangular light spots and homogenizing system

PendingCN113485018AIncrease profitReduce the effect of vignetteOptical elementsRotational axisMirror reflection

The invention discloses a reflection type homogenizing mirror for generating flat-top-like rectangular light spots and a homogenizing system, and belongs to the field of laser processing. The reflection type homogenizing mirror for generating flat-top-like rectangular light spots comprises a mirror body and a reflection mirror surface, the reflection mirror surface comprises a left rotating curved surface set and a right rotating curved surface set, the distance fw between the rotating curved surface sets and a working face, the vertical distances hl and hr between the rotating curved surface sets and respective rotating shafts, and the distances dl and dr between the left rotating shaft and the right rotating shaft and the central axis of the two rotating curved surface sets meet the relations shown in the following formulas, uniform-like light spots can be obtained in the uniform-like direction, D1 is the left half width of incident light on the reflecting mirror surface, and Dr is the right half width of the incident light on the reflecting mirror surface. The light spot edge in the quasi-uniform direction drops steeply, so that the virtual light influence caused by Gaussian distribution can be greatly reduced, the utilization rate of Gaussian beam edge energy is effectively improved, and the application range is wider. According to the device, a high-precision rotating lathe can be adopted for machining, an expensive high-precision free-form surface machining machine tool is not needed, and the machining cost can be reduced.

Owner:HUAZHONG UNIV OF SCI & TECH +1

A Tracking Method for Determining the Boundary of Local Interference Region in Free-form Surface Machining

The invention discloses a tracing method for determining a local interference region boundary of free-form surface machining. Through analysis of principal curvatures of a free-form surface and an isometric offset surface, the local interference region boundary condition of the free-form surface machining is obtained. A tracing initial point of the local interference region boundary is obtained through combination of a surface discrete method and a dichotomy method. A rough point of the local interference region boundary is obtained through tracking along an osculating circle of the interference region boundary from the initial point. A precision point of the local interference region boundary is calculated through iteration by using a gradient method. Two tracing judgmental end conditions are obtained according to the condition that whether the local interference region boundary is enclosed on the surface. The tracing method for determining local interference region boundary of the free-form surface machining has the advantages that the tracing method is suitable for fast tracing and determining the interference region boundary of the complex free-form surface machining, a tool path track is regionally planned, a total length of the tool path track is reduced, and the surface machining efficiency is improved.

Owner:YANCHENG INST OF TECH

Device and method for detecting low-frequency-band aberration in optical free-form surface

ActiveCN114353694ASolve the technical problem of low-frequency aberration detectionHigh precisionUsing optical meansGalvanometerLow frequency band

The invention discloses a device and a method for detecting low-frequency band aberration in an optical free-form surface, relates to the technical field of optical free-form surface detection, adopts a method for detecting the low-frequency band aberration in the optical free-form surface based on transverse translation difference phase recovery, and designs a system for detecting the low-frequency band aberration in the optical free-form surface, which gives consideration to high precision and large measurement range. The objective of the invention is to solve the problem that a conventional interferometer cannot detect non-axisymmetric and non-rotational symmetric free-form surfaces. The surface shape machining of the free-form surface optical element in the grinding stage is guided, and finally technical support is provided for high-precision and high-performance optical free-form surface machining and detection. Comprising a middle-low frequency band aberration detection system, a pupil image monitoring system, a surface shape error reconstruction system and an optical path clamping and adjusting system. The device is assisted by fine adjustment of the high-precision galvanometer, and high-precision measurement of low-frequency band aberration in the whole free-form surface is achieved. The contradiction that the dynamic range and the detection precision cannot be obtained at the same time in free-form surface detection is effectively solved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Method for controlling machining track of numerically-controlled machine tool

The invention relates to a method for controlling a machining track of a numerically-controlled machine tool. The method comprises the following steps of: determining the number N of positions to be smoothly machined; initialing N displacement storage units and storing the planned displacement of current movement in a machining plan into a current displacement storage unit; taking an average value of the N displacement storage units as the actual displacement of the current movement; and circulating the process to finish the machining. By utilizing the method disclosed by the invention, the displacement in single time of movement in the machining plan is realized by being dispersed into N times of movements so that the displacement variables among multiple times of close movements are reduced, the fitting degree of a machined free-form surface is better, and the degree of finish of the machined surface is higher; therefore, with the method disclosed by the invention, under the condition that a machining file does not need to be lengthened, the degree of finish of the machined free-form surface is increased, the increase of data processing amount of the numerically-controlled machine tool is avoided, and the cost of the numerically-controlled machine tool is reduced under the condition that application requirements are same.

Owner:SHANGHAI WEIHONG ELECTRONICS TECH

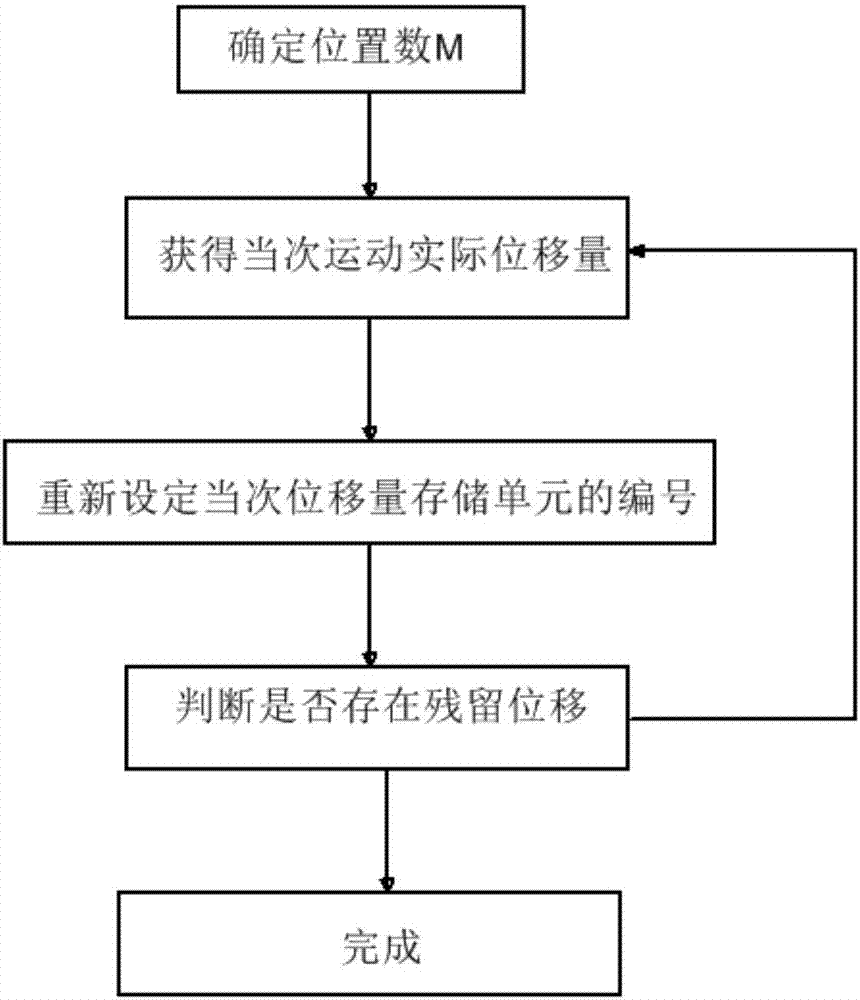

Method for controlling track of numerically-controlled machine tool

The invention discloses a method for controlling the track of a numerically-controlled machine tool, and aims to solve the problem that the motion track of a machine tool cannot be accurately controlled and thus it is difficult to control the degree of parts machining. The displacement of a single movement in the machining plan is realized by being dispersed into M movements so that the variationof displacement for multiple times of close movements is reduced, the fitting degree of a machined free-form surface is better, and the degree of finish of the machined surface is higher. Therefore, the method disclosed by the invention can improve the degree of finish of the machined free-form surface, avoids the increase in data processing amount of the numerically-controlled machine tool and reduce the cost of the numerically-controlled machine tool under the same application requirement without lengthening a machining file. The method for controlling the machining track of a numerically-controlled machine tool has the advantages of simple steps, simple application and wide application scope, and is applicable to the field of numerically-controlled machining.

Owner:MIANYANG JIANCHENG ELECTRONICS CO LTD

A Method for Generating Machining Trajectory of Free-form Surface Arc Length Parameter Curve

ActiveCN108549325BAvoid complex calculationsReduce difficultyProgramme controlComputer controlEngineeringComputer-aided

The invention relates to an arc length parameter curve processing track generation method of a free curved surface. The method comprises following steps of smooth and continuous characteristic curve processing track extraction, given precision parameter curve processing track generation and processing track arc length parameterization. In the step (1), processing tracks generated by computer aidedmanufacturing software (CAM) are classified according to arc length characteristics; and discrete free curve processing tracks with smooth and continuous characteristics are extracted; in the step (2), fitting is performed on the extracted discrete free curve processing tracks under the given precision, so parameter curve processing tracks meeting a geometric representation precision requirementare obtained; and in the step (3), by use of the method of continuous iteration arc length re-parameterization, arc length re-parameterization is performed on the parameter curves obtained in the step(2), and finally, the arc length parameter curve free curved face processing track is obtained. According to the invention, the difficulty level in real-time interpolation and speed planning in freecurved face processing is reduced; and smoothness and processing precision in the processing process are improved.

Owner:HEFEI UNIV OF TECH

A single-motor double-degree-of-freedom variable-speed wheel airbag polishing device

InactiveCN110497287BReduce structural redundancyEasy loading and unloadingOptical surface grinding machinesPolishingElectric machinery

The invention relates to a single-motor double-degree-of-freedom variable-speed wheel airbag polishing device, which belongs to the field of precision free-form surface processing. The revolution drive unit is fixed on the upper part of the shell unit, the autorotation drive unit is fixed under the revolution drive unit, the tool drive unit is fixed under the autorotation drive unit, the airbag polishing tool unit is fixed on the tool drive unit, and the air pressure control unit is integrated between the revolution drive unit and the in the tool drive unit. The advantage is that the airbag performs two-degree-of-freedom motion on the surface of the workpiece, forming a Gaussian-like removal function. The single-motor drives the two-degree-of-freedom airbag polishing movement, which not only reduces structural redundancy and improves the stacking problem of the drive chain, but also helps maintain a stable The public rotation speed ratio increases the stability of the removal function of the device.

Owner:JILIN UNIV

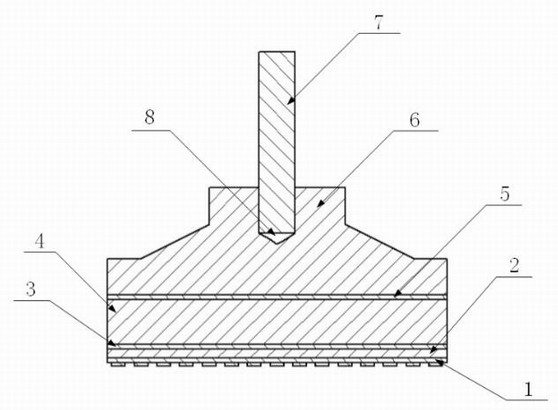

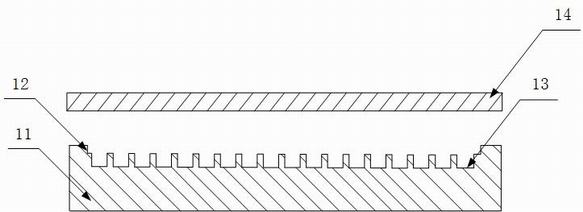

Elastic milling and polishing tool for free-form surface machining and manufacturing method of elastic milling and polishing tool

InactiveCN112171532AAdaptableReduce manufacturing costBonded abrasive wheelsGrinding devicesPolishingMachining

The invention discloses an elastic milling and polishing tool for free-form surface machining and a manufacturing method of the elastic milling and polishing tool. The elastic milling and polishing tool for free-form surface machining comprises an abrasive layer, a cloth base body layer, an elastic layer, a rigid base body disc and a connecting rod, and is characterized in that the abrasive layeris directly cured on the cloth base body layer; the cloth base body layer and the elastic layer are connected through a bonding layer; the elastic layer is connected with the rigid base body disc through a bonding layer; and the rigid base body disc and the connecting rod are fixedly connected through threads. The preparation process of the elastic milling and polishing tool comprises the following steps that an abrasive layer raw material is prepared; the abrasive layer is evenly smeared on a plane mold with a groove, the abrasive layer is then covered with the cloth base body layer, mold covering is conducted, and hot-pressing curing molding is carried out; the cloth base body layer is bonded to the elastic layer; and the elastic layer is bonded to the rigid base body disc, and the elastic milling and polishing tool is obtained. The elastic milling and polishing tool has the advantages of being simple in preparation process, short in process route, low in cost, high in milling and polishing efficiency, good in process flexibility, stable in machining performance, environmentally friendly in manufacturing process and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

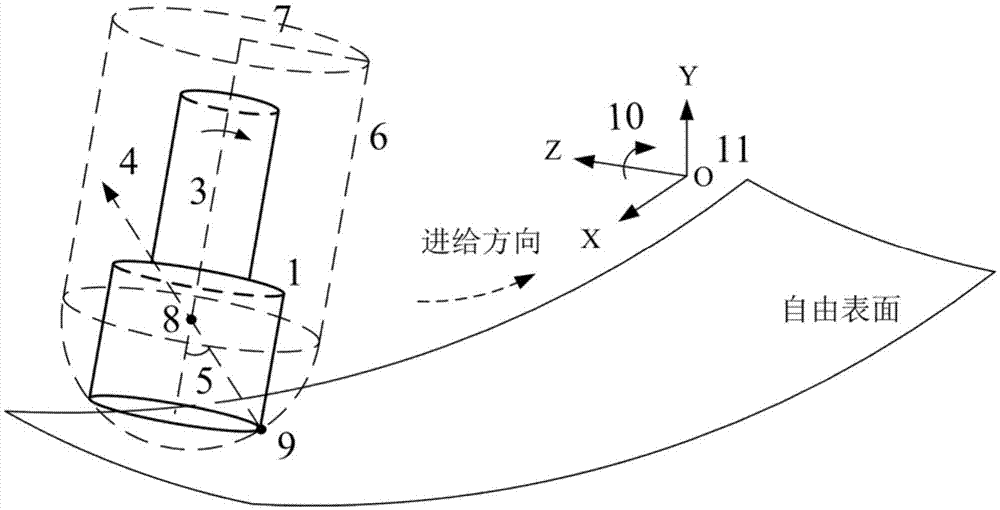

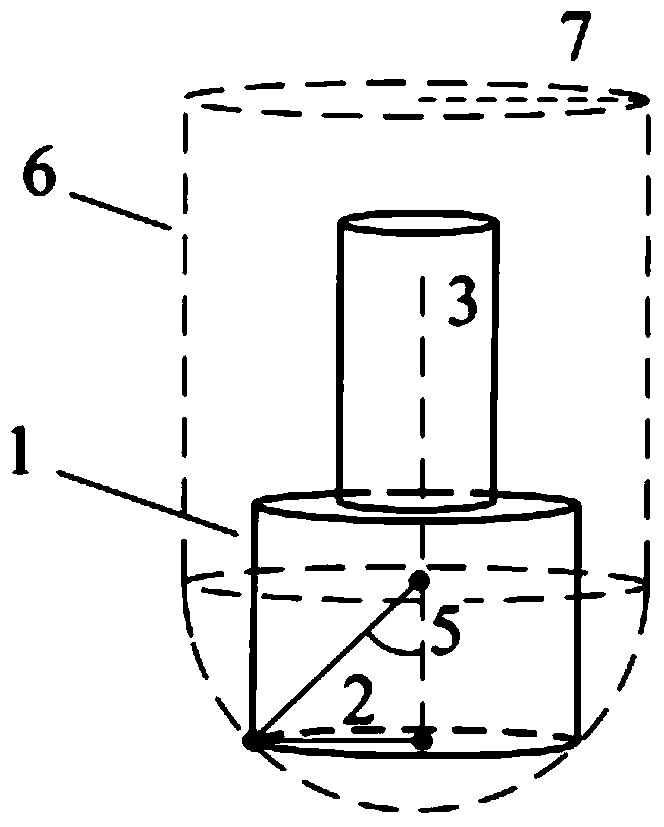

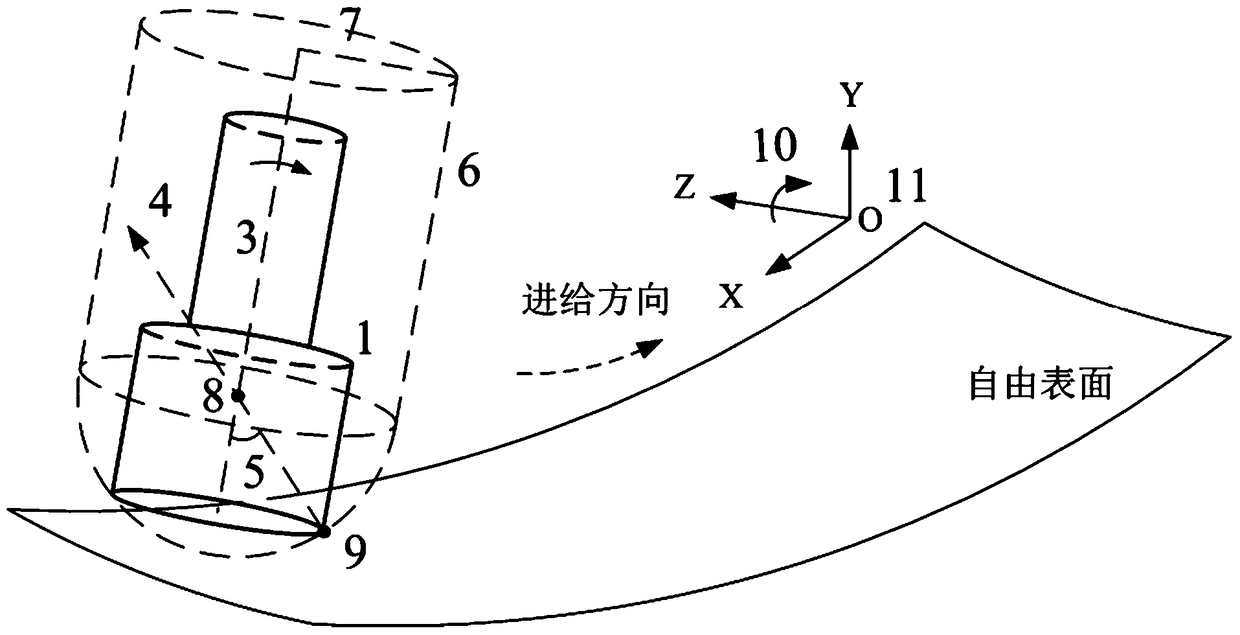

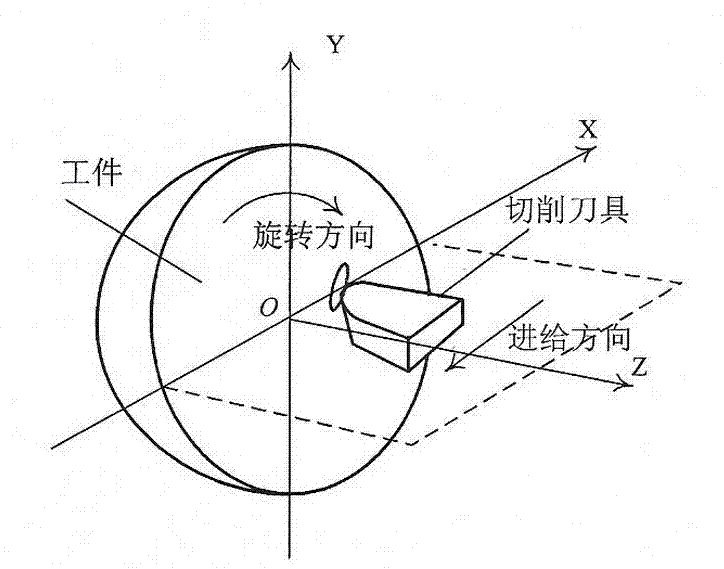

Generating method of three-dimensional elliptical vibrating cutting optical freeform surface machining path

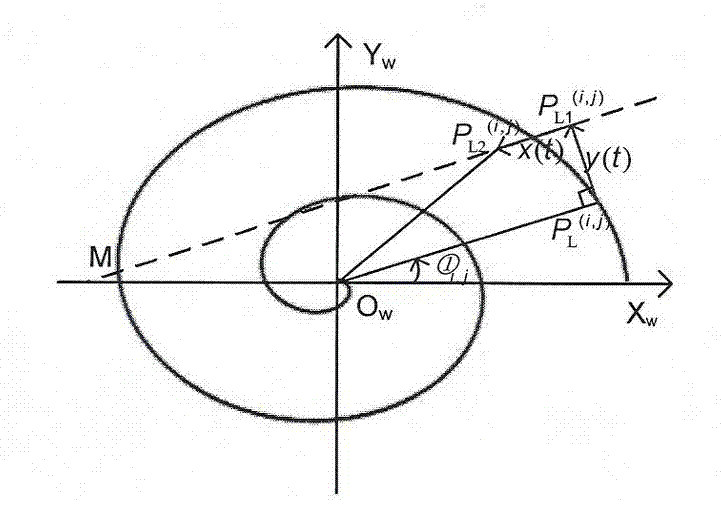

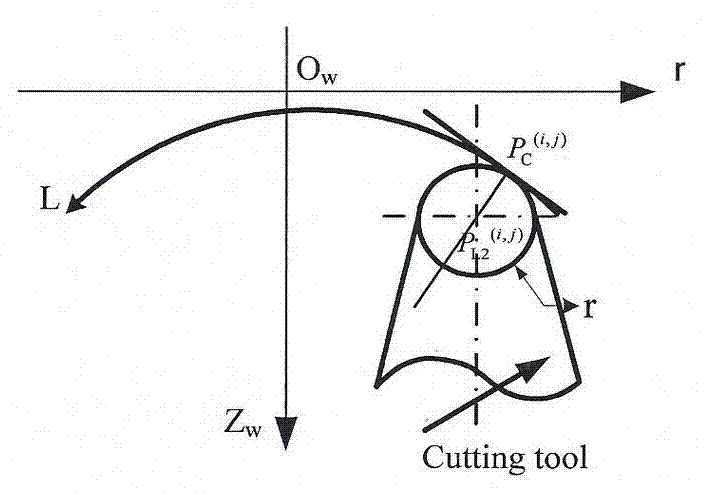

The invention discloses a generating method of a three-dimensional elliptical vibrating cutting optical freeform surface machining path. The generating method is used on a triaxial diamond ultra-precision machine tool and an elliptical vibration generating device. A machine tool spindle can perform rotary motion, a working table can perform X-direction and Z-direction motions, and simultaneously a diamond cutter performs three-dimensional elliptical motion through the elliptical vibration generating device. The generating method of a cutter path track comprises building a workpiece Cartesian coordinate system, and obtaining an expression of the predesigned free optical curved surface S under the workpiece Cartesian coordinate system and a cylindrical coordinate system; determining coordinate values of xi, j(L) and yi, j(L) of a cutter location point PL (i, j); solving coordinate values of xi, j(L2) and yi and j(L2) of a new cutter location point PL2 (i, j) adding to elliptical y-directional displacement and x-directional displacement; solving the z coordinate value zi, j(L2) of a cutter location point PL2 (i, j) according to the coordinate values of xi, j(L2) and yi, j(L2) of the cutter location point PL2 (i, j); solving z coordinate value zi, j(L3) of a new cutter location point PL3 (i, j) added to elliptical z-directional displacement; and performing processing motion according to the steps, traversing processing points of the freeform surface, and finally generating the processing path.

Owner:CHANGCHUN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com