Single-motor double-degree-of-freedom speed change wheel type airbag polishing device

A technology of airbag polishing and degree of freedom, which is applied in the direction of grinding/polishing equipment, optical surface grinder, metal processing equipment, etc., and can solve the problem of redundant structure, instability of the double-motor wheel airbag polishing device, and driving chain stacking revolution speed Ratio and other issues, to achieve the effect of reducing the difficulty of device control, facilitating loading and unloading and maintenance, and reducing structural redundancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

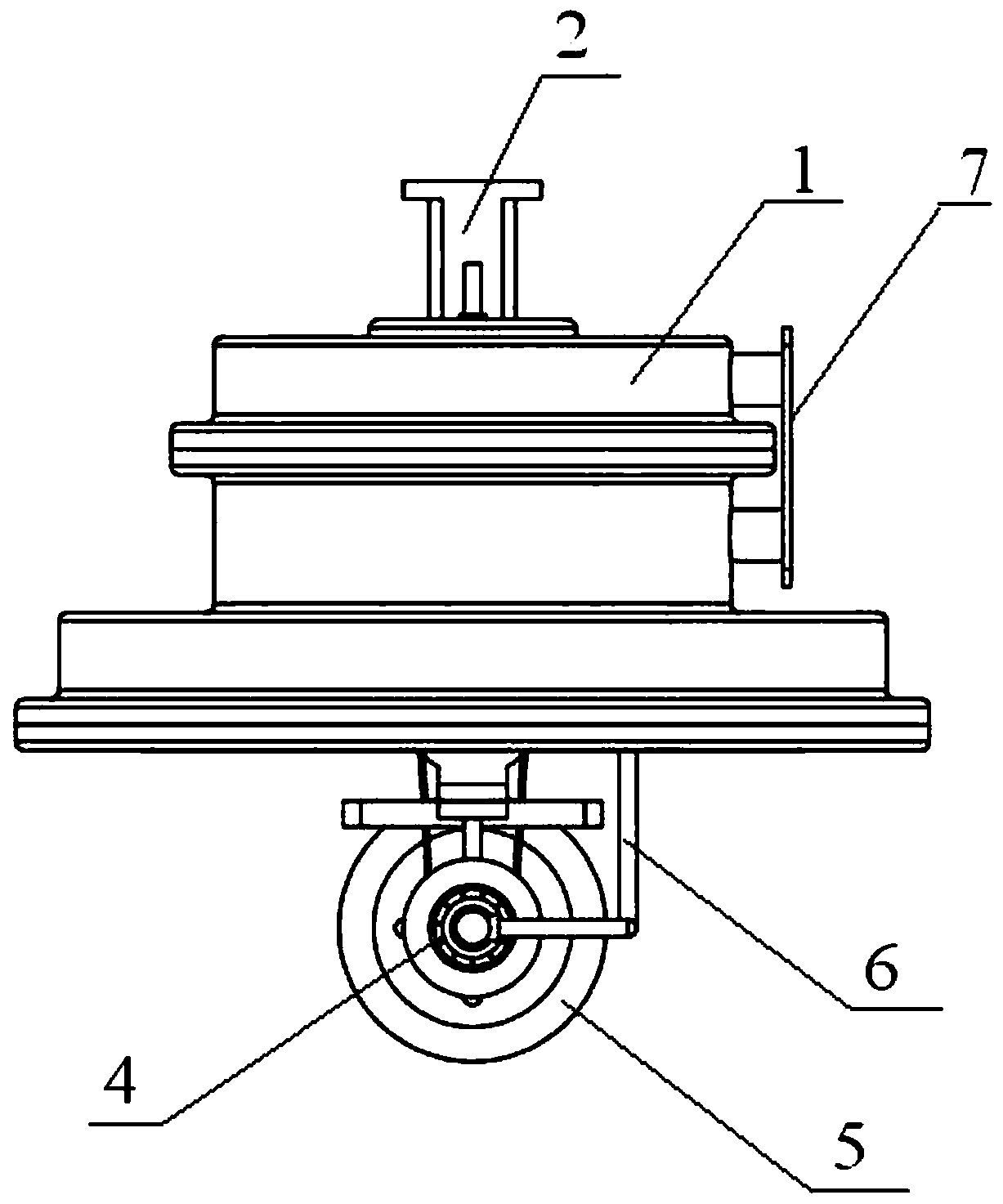

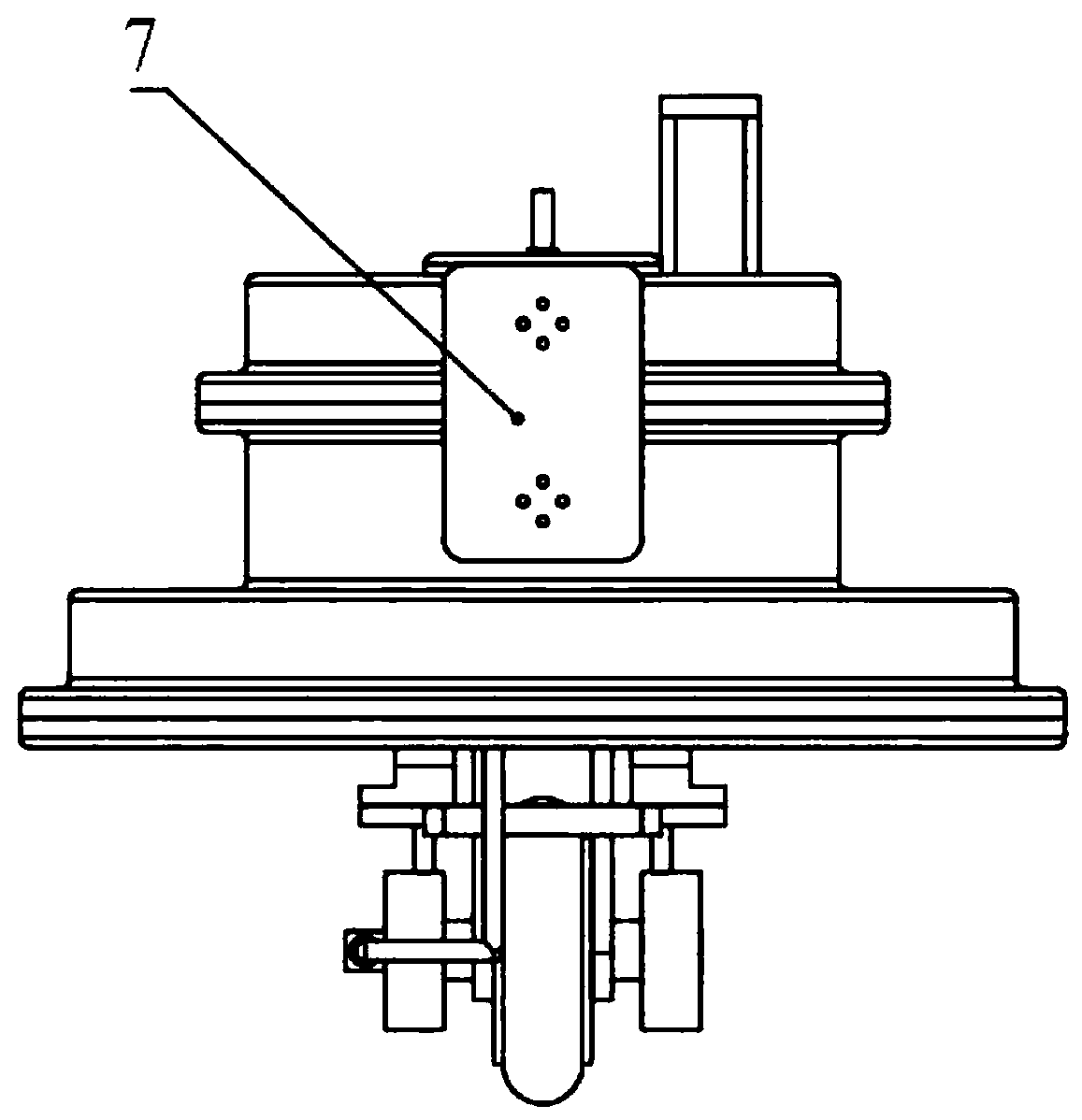

[0030] Such as figure 1 , 2 , 3, the revolution drive unit 2 is fixed on the upper part of the housing unit 1, the rotation drive unit 3 is fixed below the revolution drive unit 2, the tool drive unit 4 is fixed below the rotation drive unit 3, and the airbag polishing tool unit 5 is fixed on the tool drive On the unit 4, the air pressure control unit 6 is integrated in the revolution drive unit 2 and the tool drive unit 4;

[0031] The adapter plate 7 is fixedly connected to the outer side of the upper part of the housing unit 1;

[0032] Such as Figure 4 Shown:

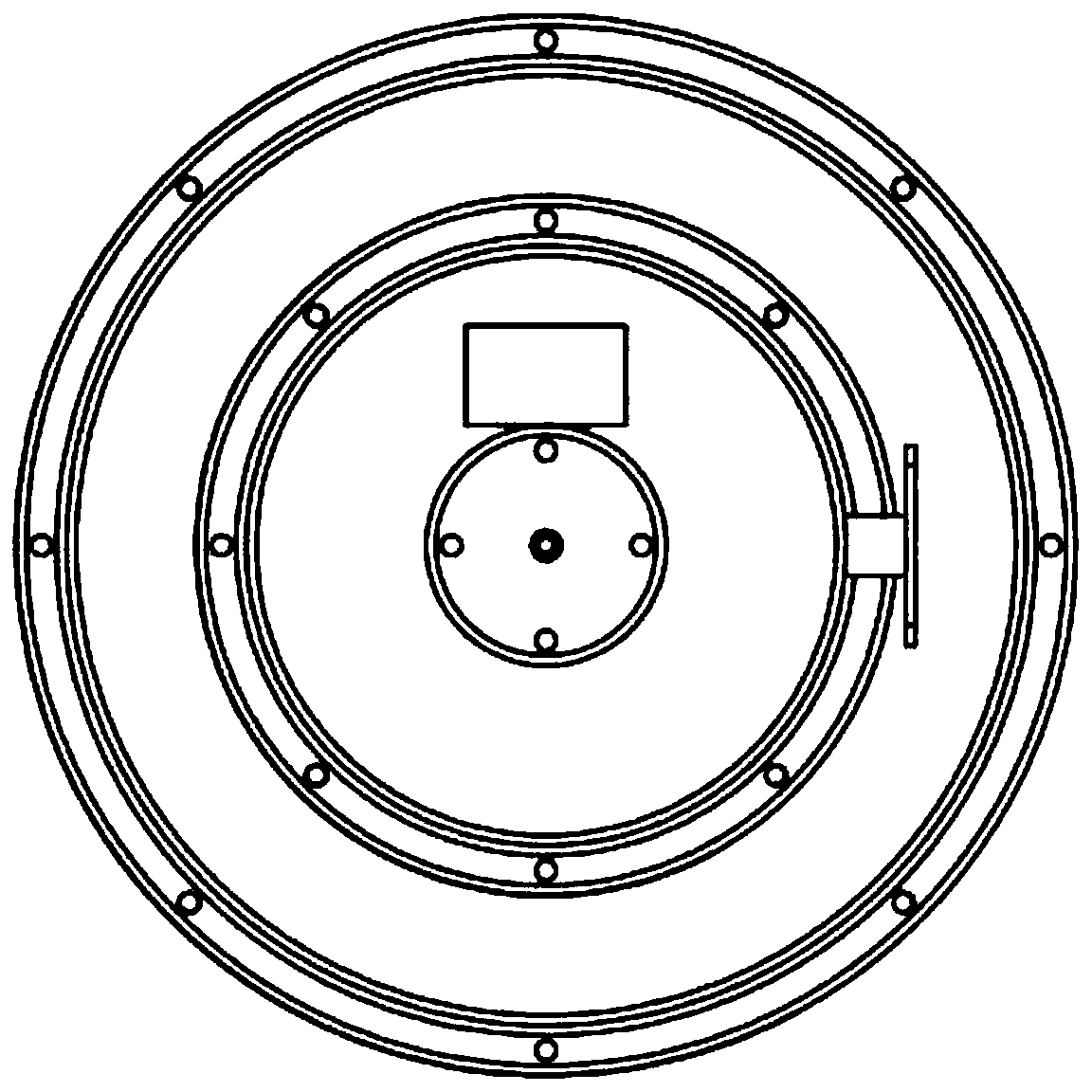

[0033] The housing unit 1 is divided into an upper housing 101, a lower housing 102 and a track housing 103, and the housings are connected by bolts;

[0034] The revolution drive unit 2 includes a motor 201, a first revolution drive gear 202, a revolution shaft end cover 203, a revolution sleeve 204, a second revolution drive gear 205, a revolution shaft 206, a revolution bearing 207, an autorotation shaft sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com