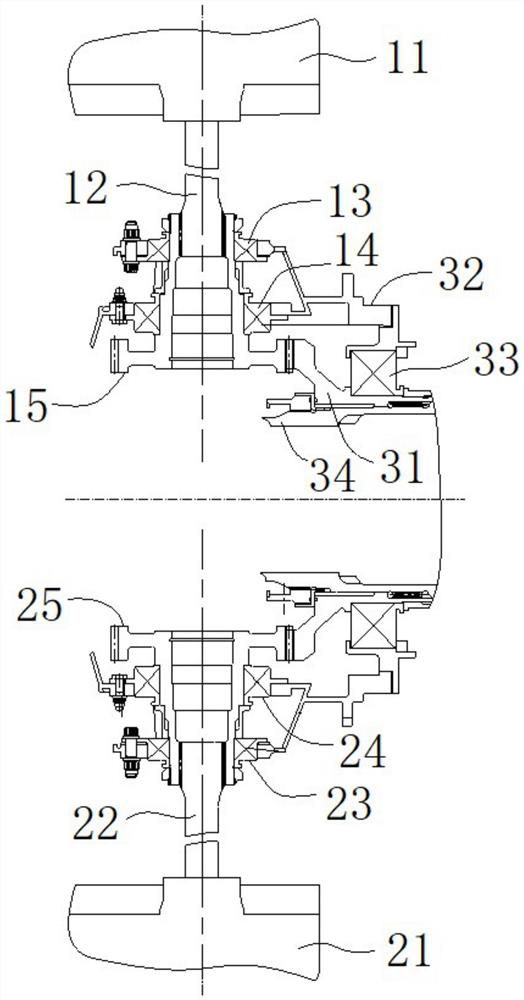

Aero-engine central transmission structure adopting face gear for power division

A technology of aero-engine and transmission structure, applied in the direction of machine/engine, gas turbine device, transmission device parts, etc., to achieve the effect of reducing design difficulty, reducing repair cost, and shortening troubleshooting cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

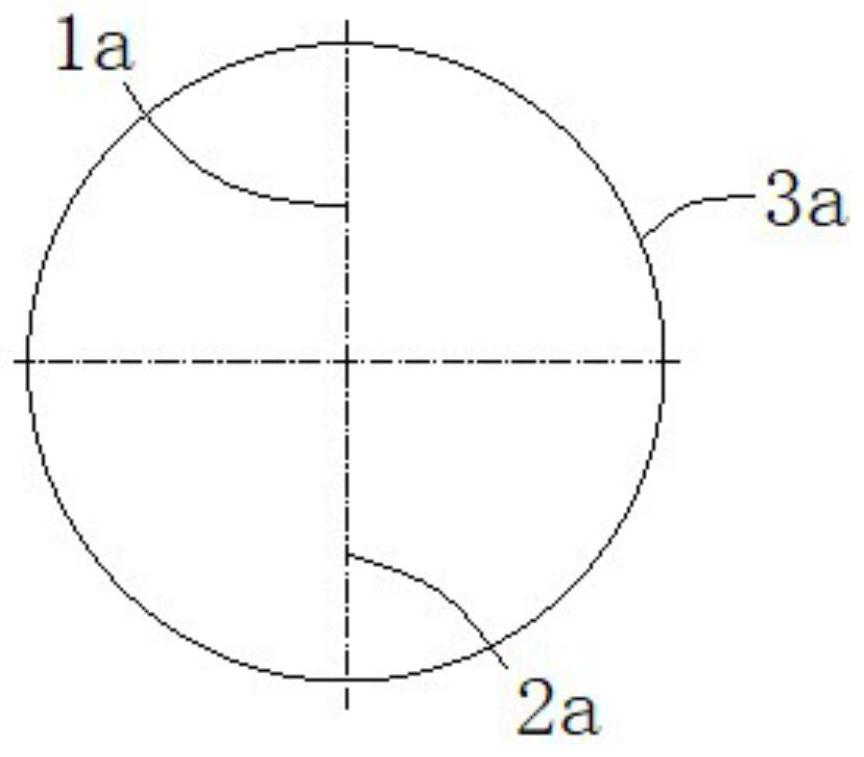

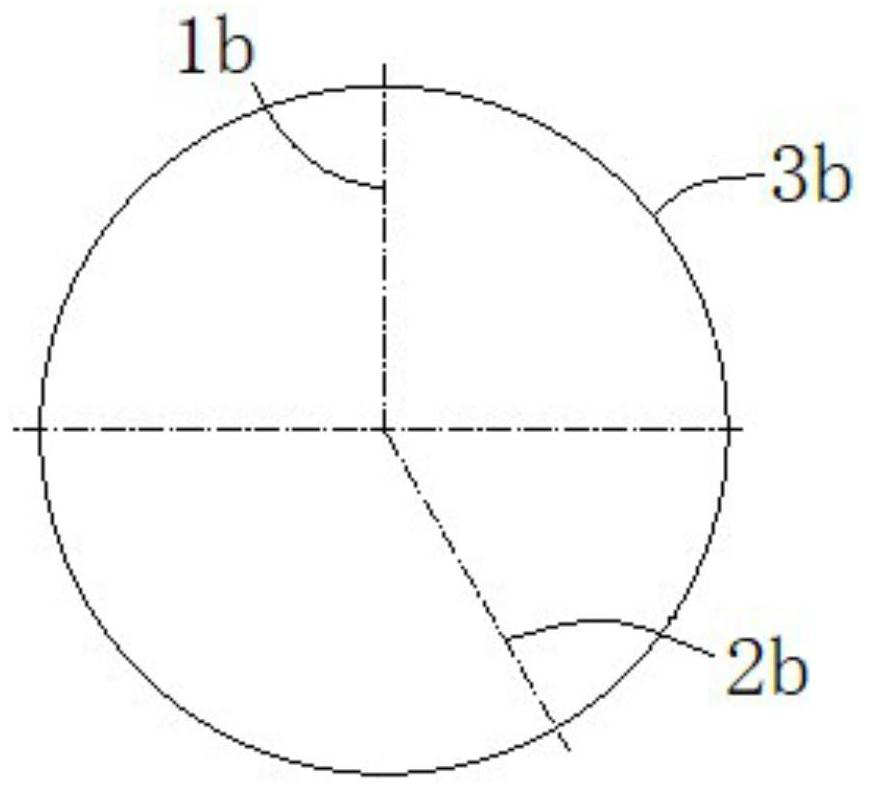

Embodiment Construction

[0035] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution in the embodiment of the application will be described in more detail below in conjunction with the drawings in the embodiment of the application.

[0036] In order to overcome the following shortcoming that the central drive of existing aero-engine has:

[0037] 1) The central transmission has only one output interface, and the output speed of the driven bevel gear needs to take into account the speed-up and speed-down transmission chains in the accessory gearbox. The design of the transmission chain is difficult. When the speed difference between the speed of the accessories and the speed of the input shaft is large Limited by the transmission ratio of the single-stage transmission (the transmission ratio of the cylindrical gear is generally not more than 2), the fall wheel is required for transition, and the added fall wheel increases the number of sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com