Design method of grating with glaring concave surface

A technology of blazed grating and design method, applied in diffraction grating and other directions, can solve the problem that the blaze effect of concave blazed grating is not very obvious, and achieve the effect of significant blaze enhancement effect and convenient implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

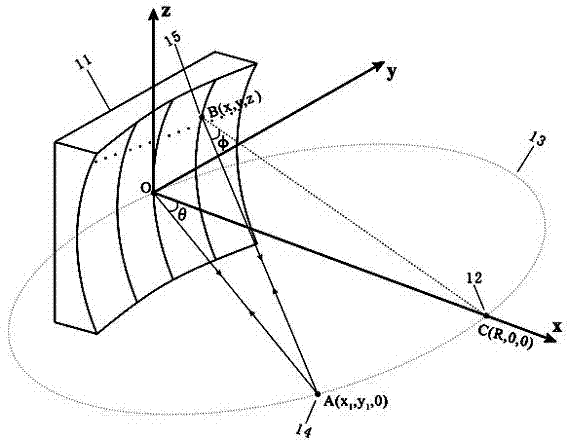

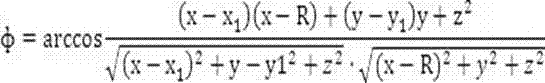

[0015] figure 1 Shown is the optical path diagram for the use of concave blazed gratings. 11 is a concave blazed grating, its radius of curvature is R, 12 is its center of curvature C (R,0,0), and 13 is a Rowland circle, which is a concave spherical surface whose diameter is equal to the radius and is tangent to the concave spherical surface at point O (0 ,0,0), at the same time, the circle is located in the main section xOy plane, 14 is the incident point A (x 1 ,y 1 , 0), the incident angle of the central ray is θ, 15 is any point B (x, y, z) on the concave spherical surface, and x, y, z satisfy the equation (x-R) 2 +y 2 +z 2 =R 2 .

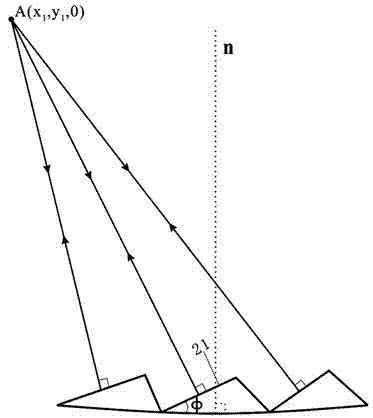

[0016] figure 2 is a local enlarged view of the groove surface of the concave blazed grating. For any point B on the concave spherical surface, its normal line n passes through the curvature center of the concave surface, that is figure 1 BC in; on the other hand, in order to improve the efficiency of the grating, it is required that a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com