In-situ measurement method for optical free-form surface

An in-situ measurement, free technology, applied in measurement devices, optical devices, measurement/indication devices, etc., can solve problems affecting the manufacture of high-quality optical free-form surfaces, achieve good application value, avoid errors, and simple system structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

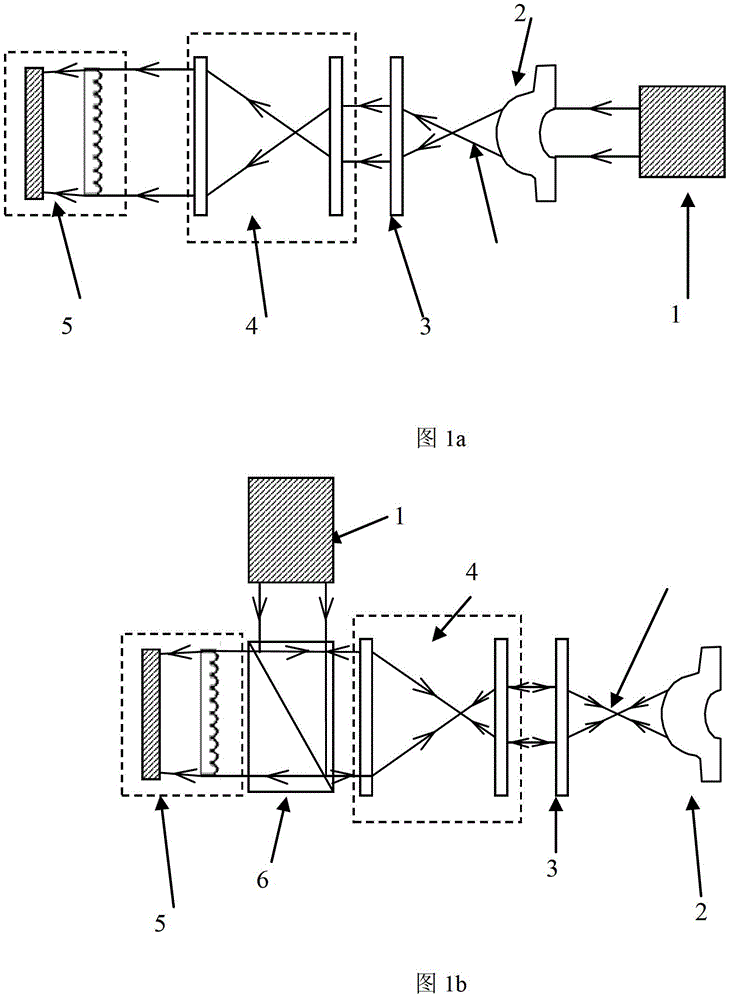

[0016] Wavefront aberration is an important evaluation parameter to evaluate the imaging quality of optical devices. The best analysis method of wavefront aberration is Zernike polynomial decomposition method. Each Zernike item obtained by decomposition has a specific optical index meaning, such as traditional geometric optics describing the position error, primary aberration, and advanced aberration of imaging quality, and the basic imaging quality evaluation index can be obtained through polynomial combination. Focus, spherical aberration, coma, etc.) and comprehensive evaluation functions (modulation transfer function, point spread function, etc.) to evaluate the optical quality of the system. Therefore, wavefront aberration measurement can be used as an important measure of optical quality. Wavefront aberrations can be measured using interference theory and ray tracing theory, and the most commonly used are Twyman-Green interference and Shack-Hartmann wavefront sensor (SHW...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com