Numerically-controlled machining method using time parameter polynomial interpolation of free curved surfaces

A time parameter, surface processing technology, applied in general control systems, program control, computer control, etc., to achieve the effect of improving simplicity, reducing computational complexity, and promoting applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

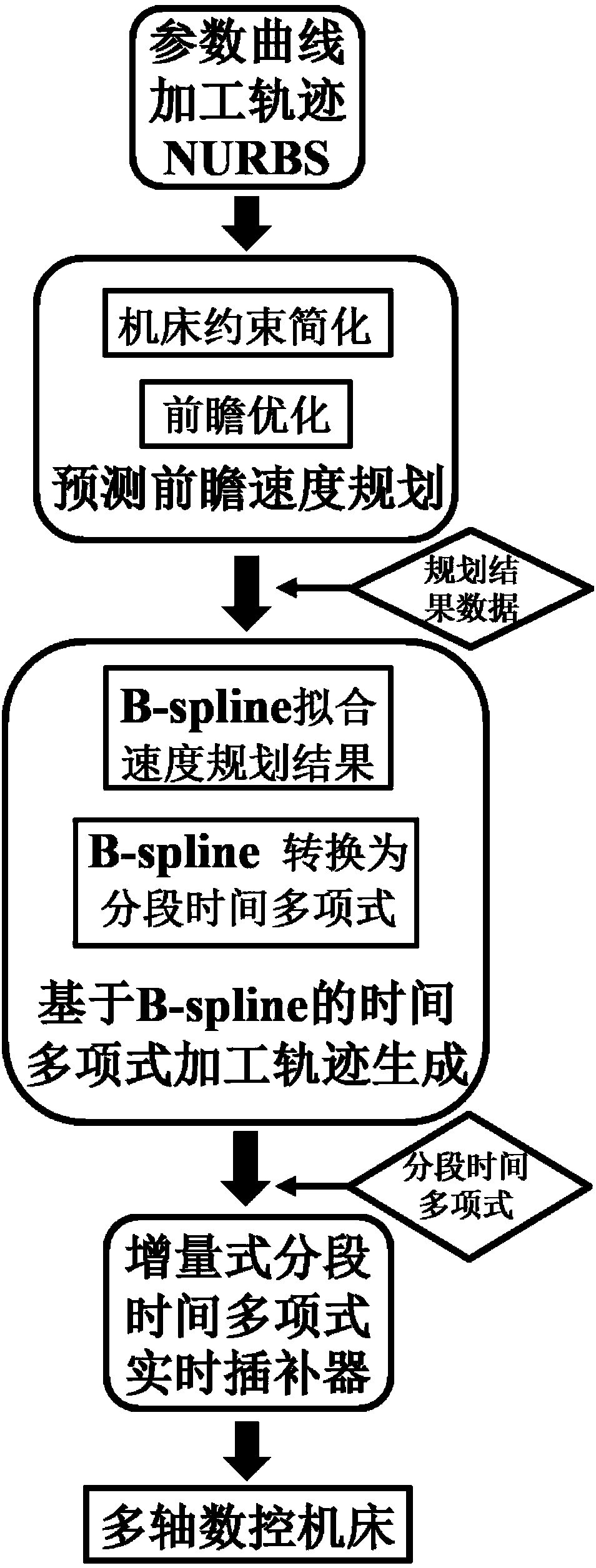

Method used

Image

Examples

Embodiment 1

[0100] The numerical control machine tool used in this embodiment includes a real-time machine tool controller and a machine tool body, and the machine tool body includes a workbench and three motion axes.

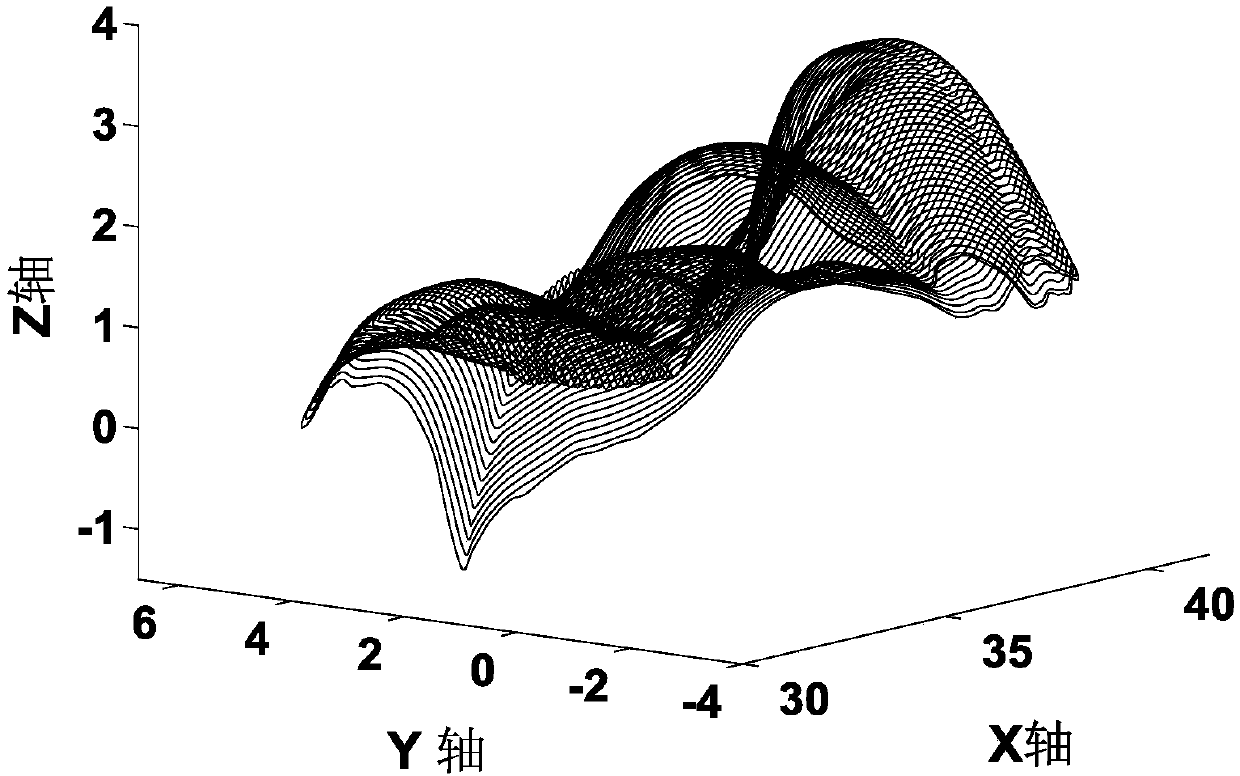

[0101] 1. Use such as figure 2 The machining trajectory of a parametric denture crown surface is shown in the experiment. At first adopt the present invention to carry out velocity planning to this section trajectory:

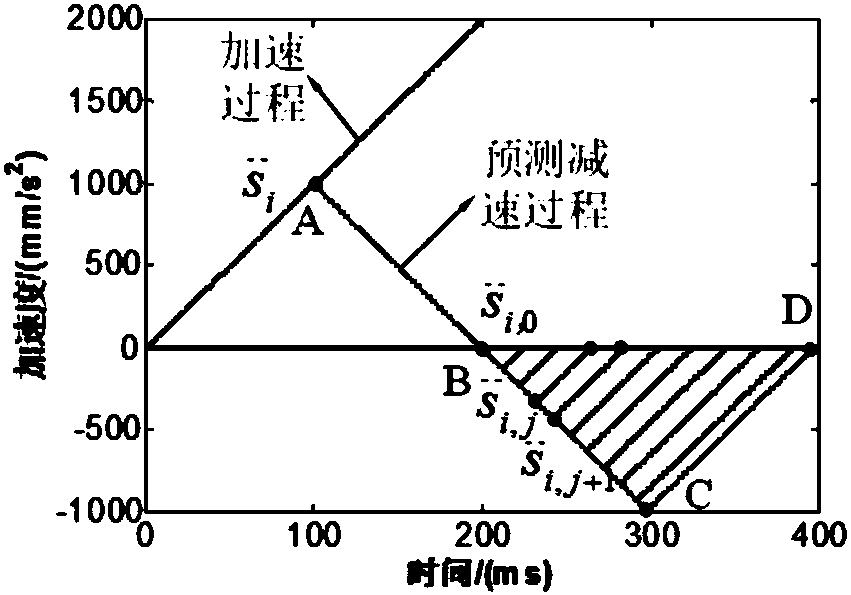

[0102] (1) Speed planning model

[0103]

[0104]

[0105]

[0106] In the formula and is the velocity, acceleration and jerk of the trajectory space; F lim ,A lim ,J lim is the velocity, acceleration and jerk constraints of the trajectory space, Indicates the velocity, acceleration and jerk of the i-th axis; Indicates the constraint of the velocity, acceleration and jerk of the i-th axis.

[0107] In this embodiment, according to the processing accuracy and equipment characteristics, the selection constraints are:

[0108] Table 1...

Embodiment 2

[0165] The CNC machine tool used in this embodiment is the same as that in Embodiment 1.

[0166] In order to further illustrate the versatility of the present invention, choose as Figure 10 The machining trajectory of a parametric denture root surface is shown in the experiment. The selected constraints and conversion factors are the same as in Embodiment 1. Adopt the present invention to carry out speed planning to this section track, the result of speed planning is as follows Figure 11 As shown, the average speed is 9.78mm / s, and the speed loss rate is 73%. The continuity of the speed curve can be seen from the partial enlarged picture. Similarly, in order to reduce the amount of data and improve the practicability of the speed planning results. The present invention is used to characterize the relationship of each axis position with time in the speed planning result, and the data compression amount is 83%. according to Figure 12 , Figure 13 , Figure 14 The cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com