Patents

Literature

38results about How to "Flexible to complete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

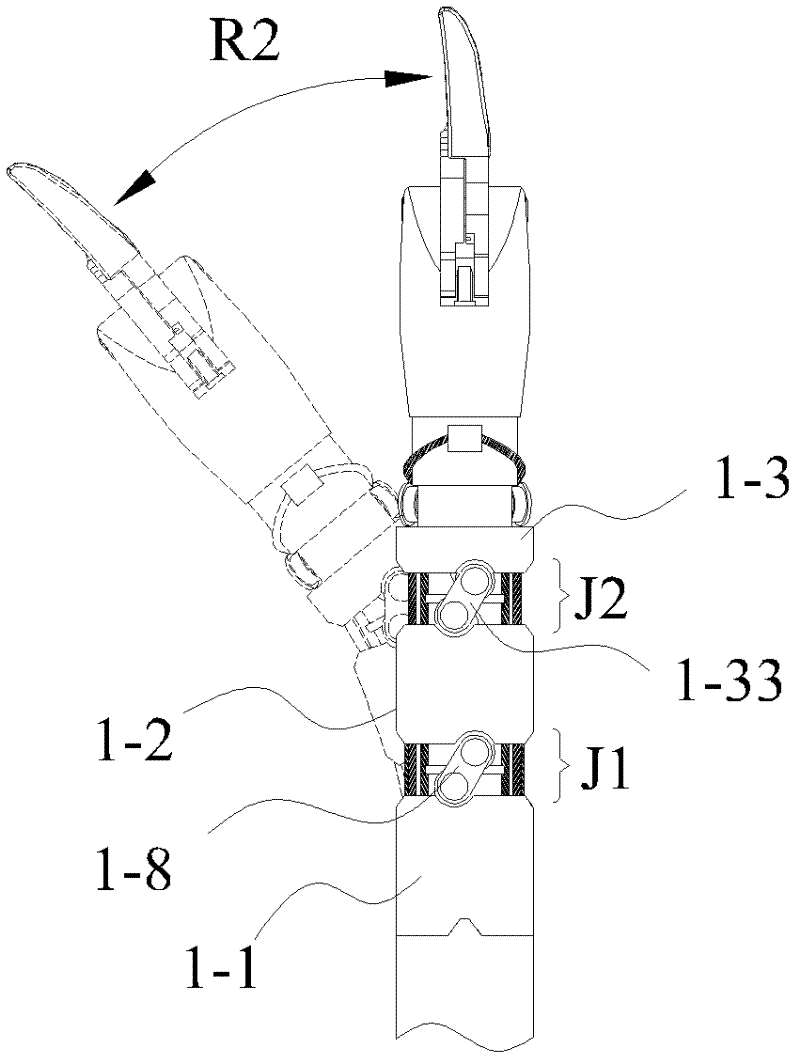

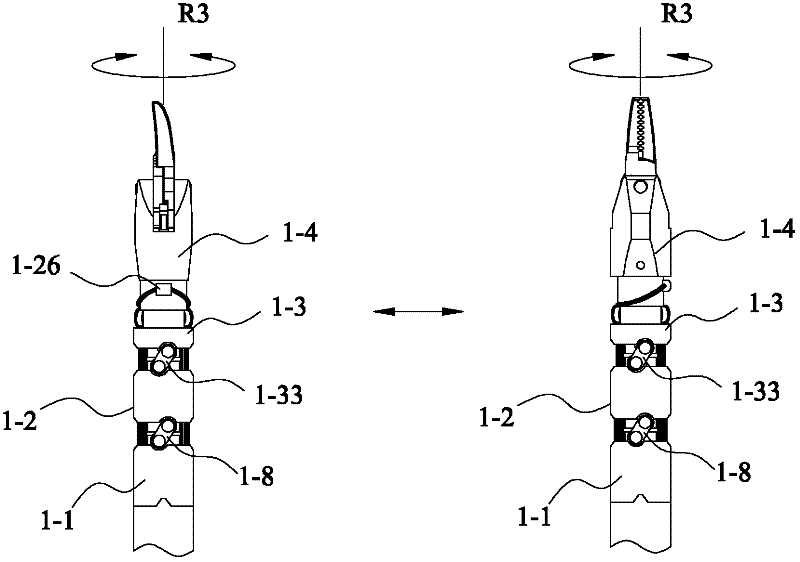

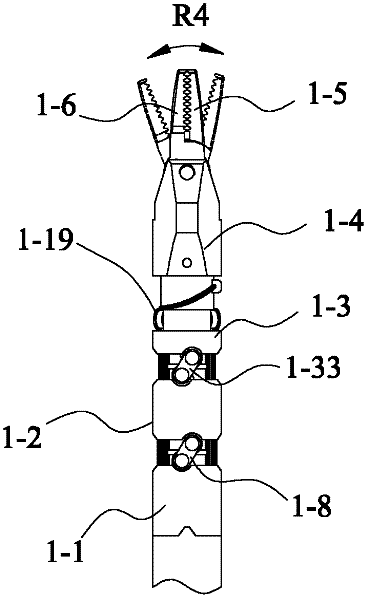

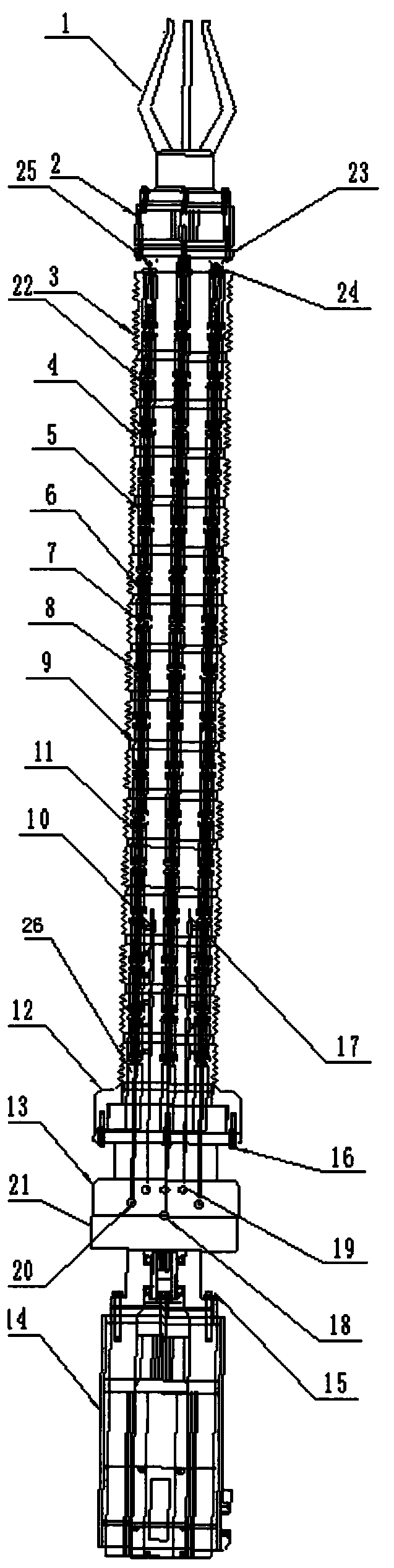

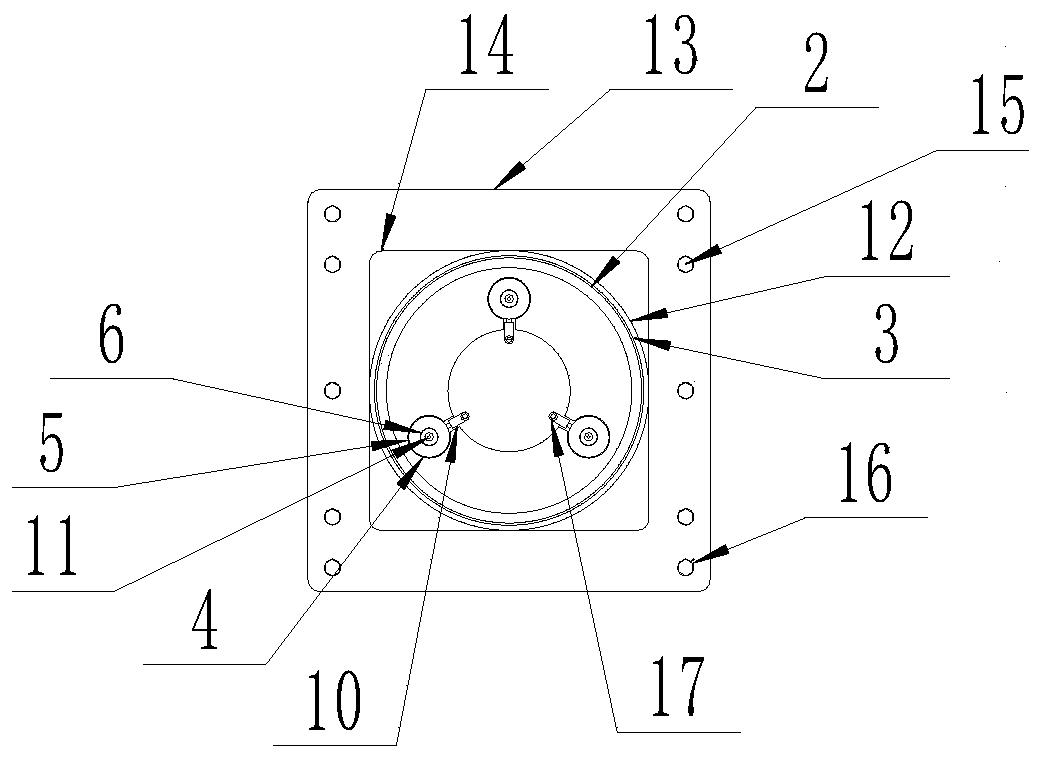

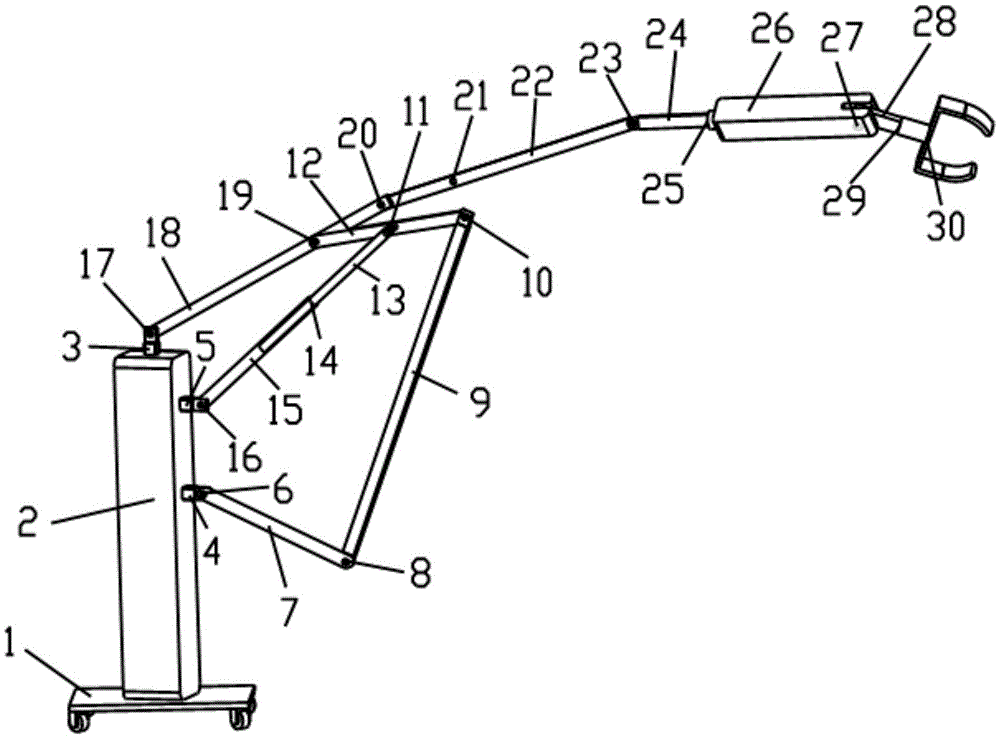

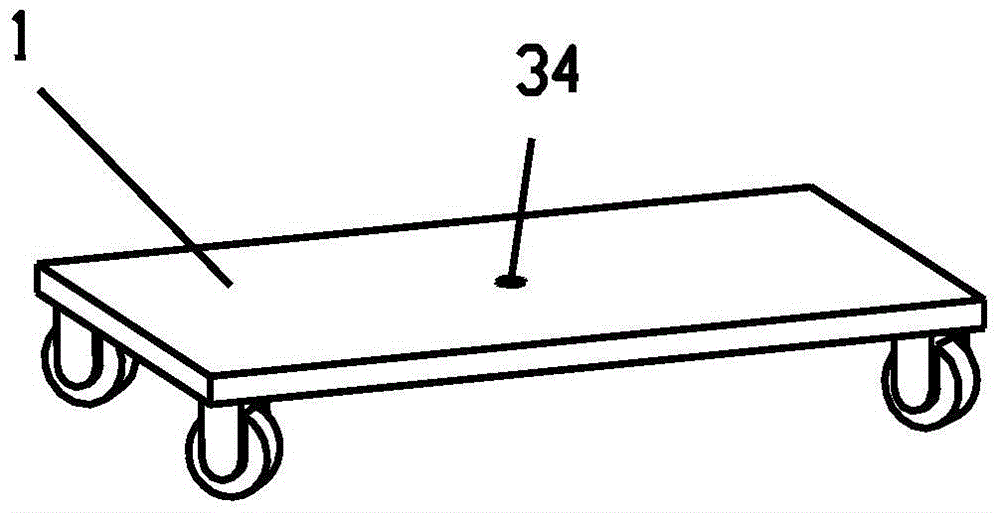

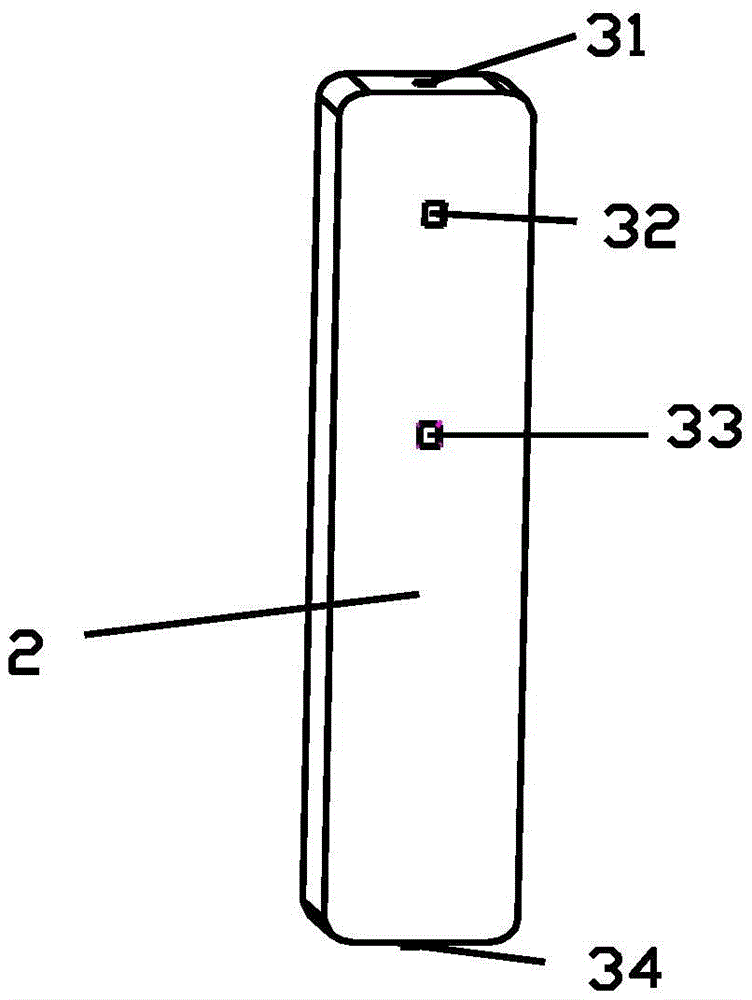

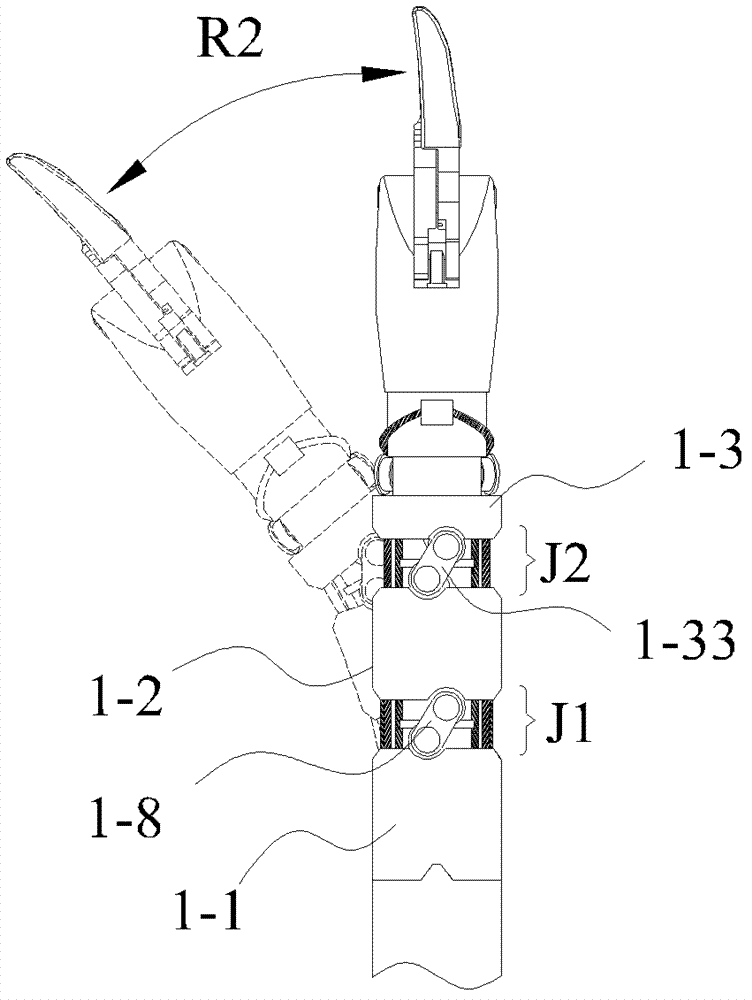

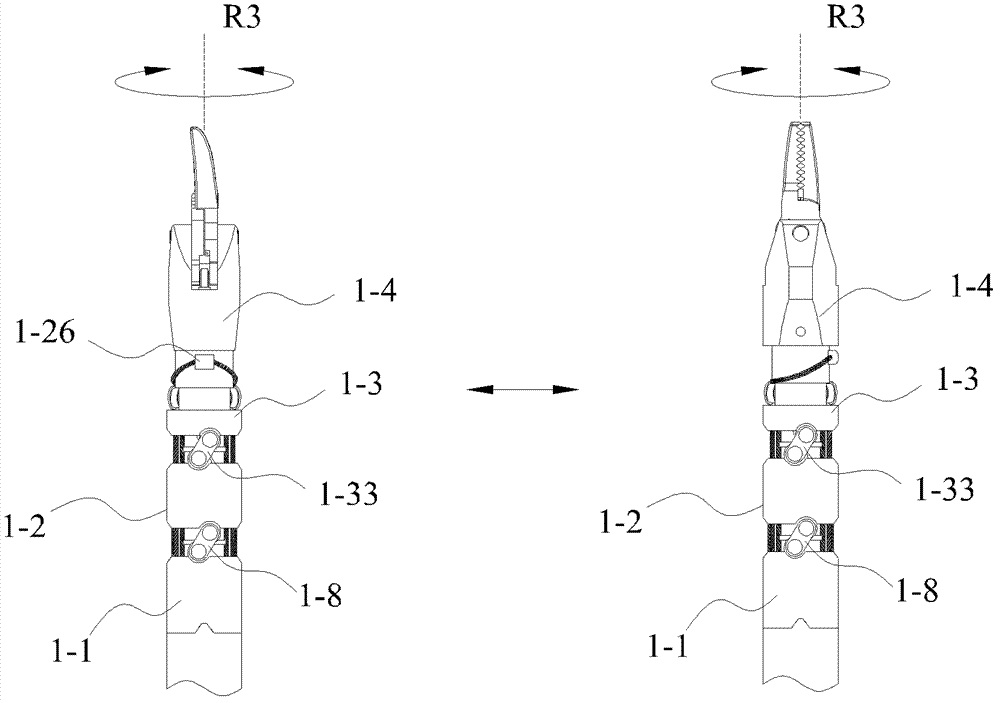

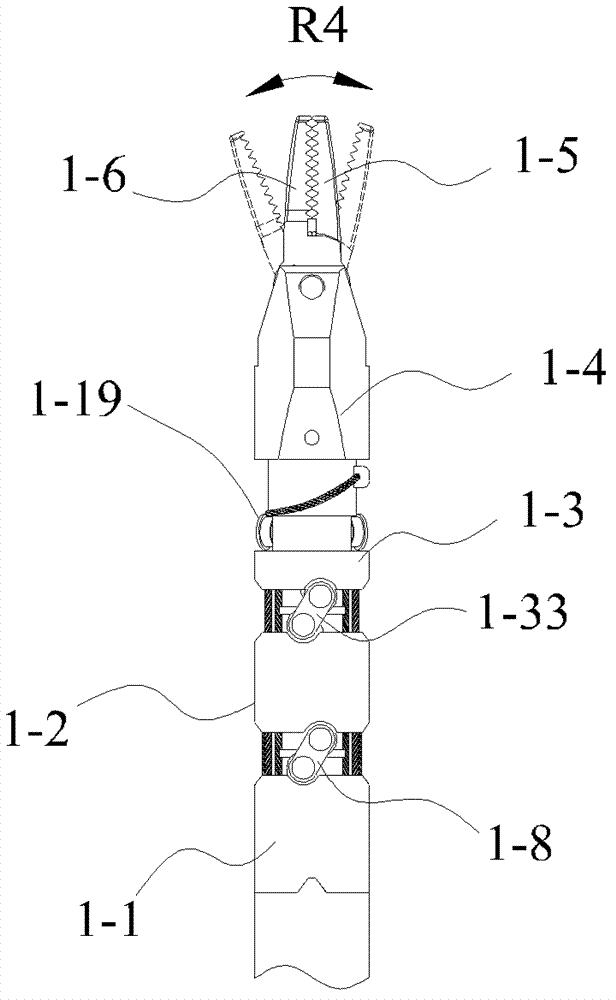

Micro instrument terminal based on module joint and used for minimally invasive surgery robot

ActiveCN102488554AFlexible to completeThe total length of the closed-loop transmission remains unchangedDiagnosticsSurgical robotsSurgical departmentTarsal Joint

The invention discloses a micro instrument terminal based on module joints and used for a minimally invasive surgery robot. The micro instrument terminal comprises a rotary module of a first four-bar mechanism consisting of a module top end part, a module bottom end part, a lower support and first left and right connection pieces, and a rotary module of a second four-bar mechanism consisting of amodule top end part, a rotary connection shaft, an upper support and second left and right connection pieces; two ends of a first steel wire rope are connected with the top surfaces of the module topend parts, and the other two ends of the first steel wire rope are sequentially connected with a first rotary actuating device through the module bottom end part; two ends of a second steel wire ropeare connected with a rotary connecting shaft, and the other two ends of the second steel wire rope are sequentially connected with the first rotary actuating device through the module top end parts and the module bottom end part; and the upper part of the rotary connecting shaft is inserted into the central hole of a rotary rod and is in clearance and running fit with the rotary rod, and the rotary rod is connected with a surgery apparatus. Complex surgery can be more flexibly completed by adopting the device.

Owner:SHANDONG WEIGAO SURGICAL ROBOT CO LTD

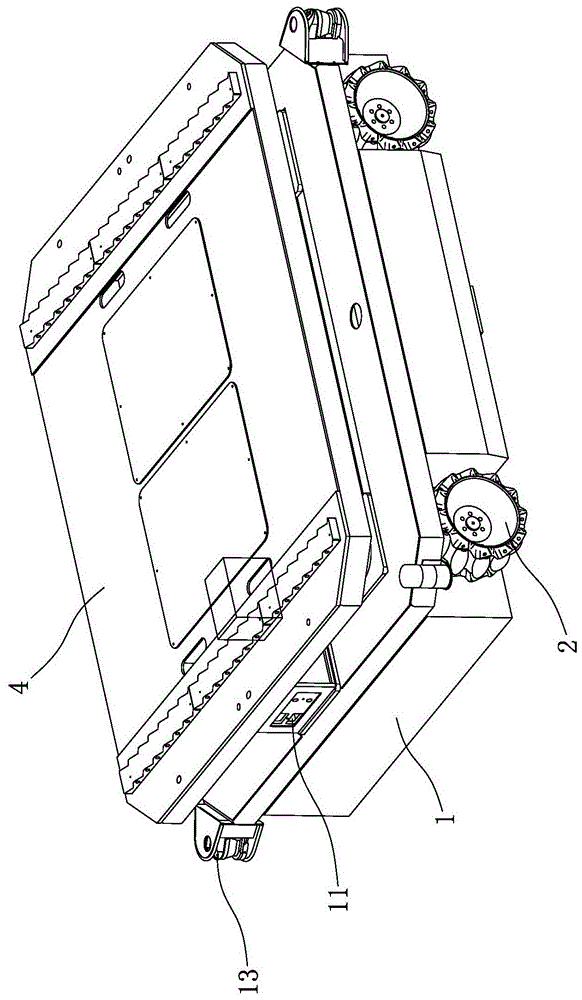

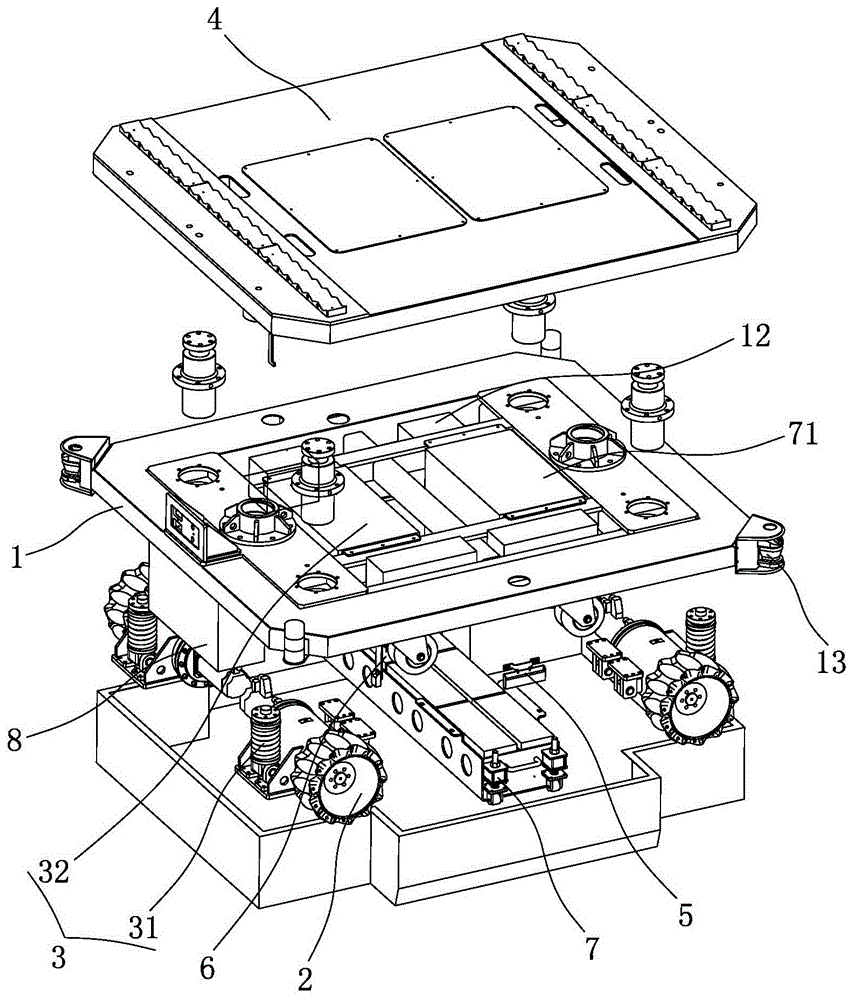

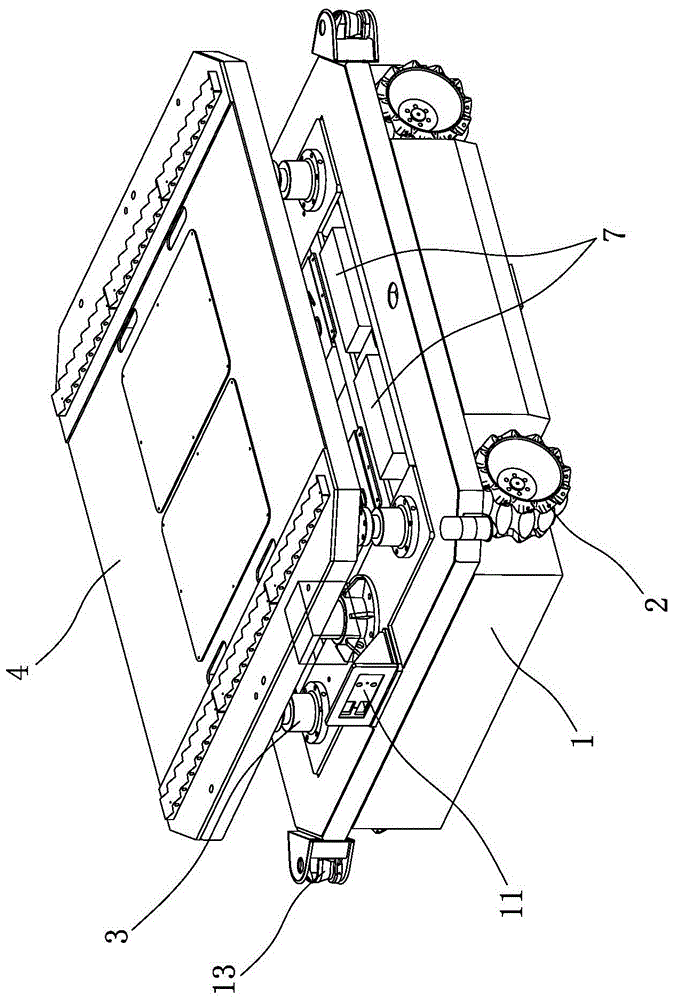

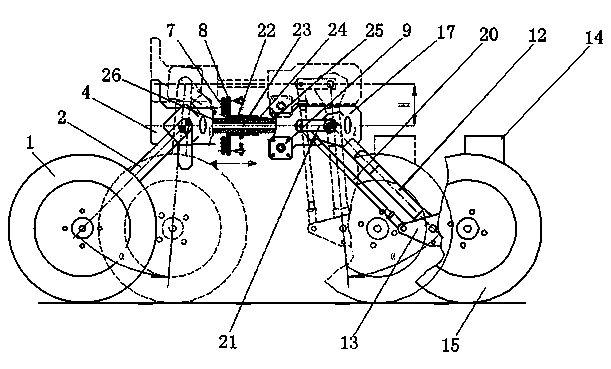

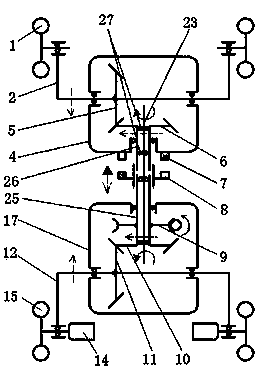

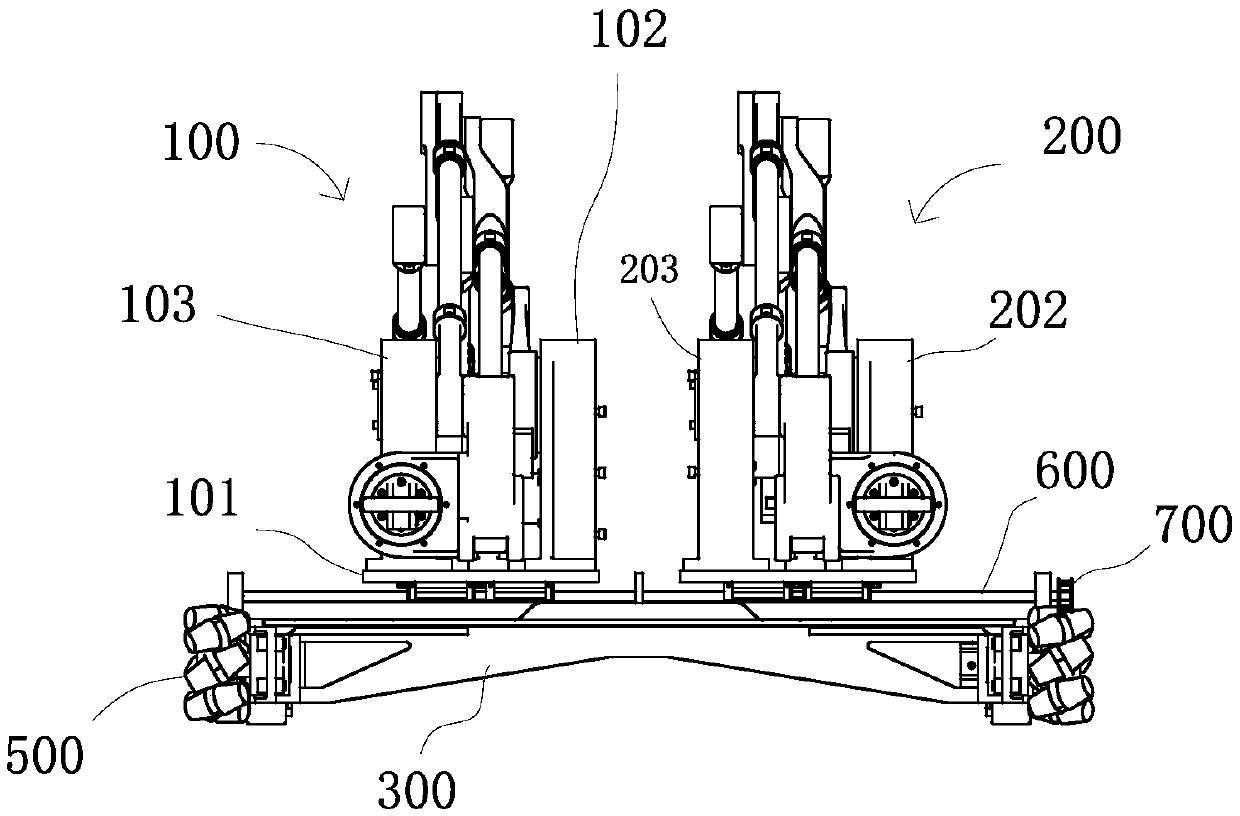

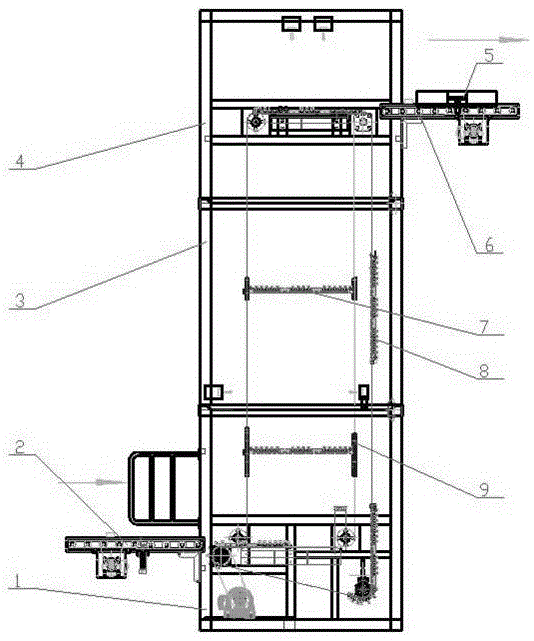

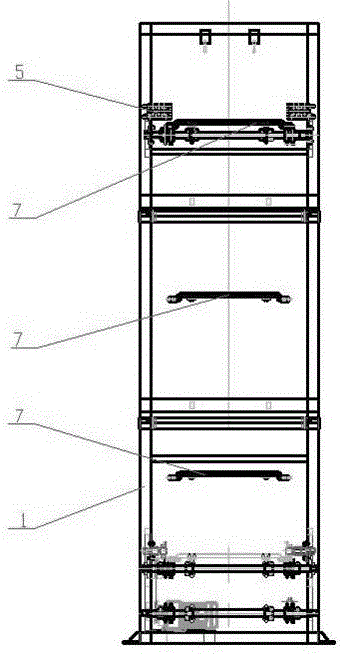

Heavy-load automated guided vehicle

The invention discloses a heavy-load automated guided vehicle. Mecanum wheel drive mechanisms are installed on the bottom of a frame and drive the frame to move in an all-dimensional mode; a lifting mechanism is installed on the frame, and a work table is installed on the lifting mechanism; a magnetic navigation sensor is installed on the bottom of the frame, detects ground magnetic stripes and drives the frame to drive along the magnetic stripe; an RFID landmark sensor is installed on the bottom of the frame, recognizes the landmark information for obtaining the position coordinates and implements the starting action, the stopping action and the turning action according to commands; a vehicle-mounted power source supplies power to the Mecanum wheel drive mechanisms, the lifting mechanism, the magnetic navigation sensor, the RFID landmark sensor and a PLC, and the PLC controls the Mecanum wheel drive mechanisms, the lifting mechanism, the magnetic navigation sensor and the RFID landmark sensor to work. The heavy-load automated guided vehicle can transfer material efficiently, accurately and flexibly, realizes logistics automation, improve the production efficiency and lower the production cost.

Owner:XIAMEN AEROSPACE SIERT ROBOT SYST CO LTD

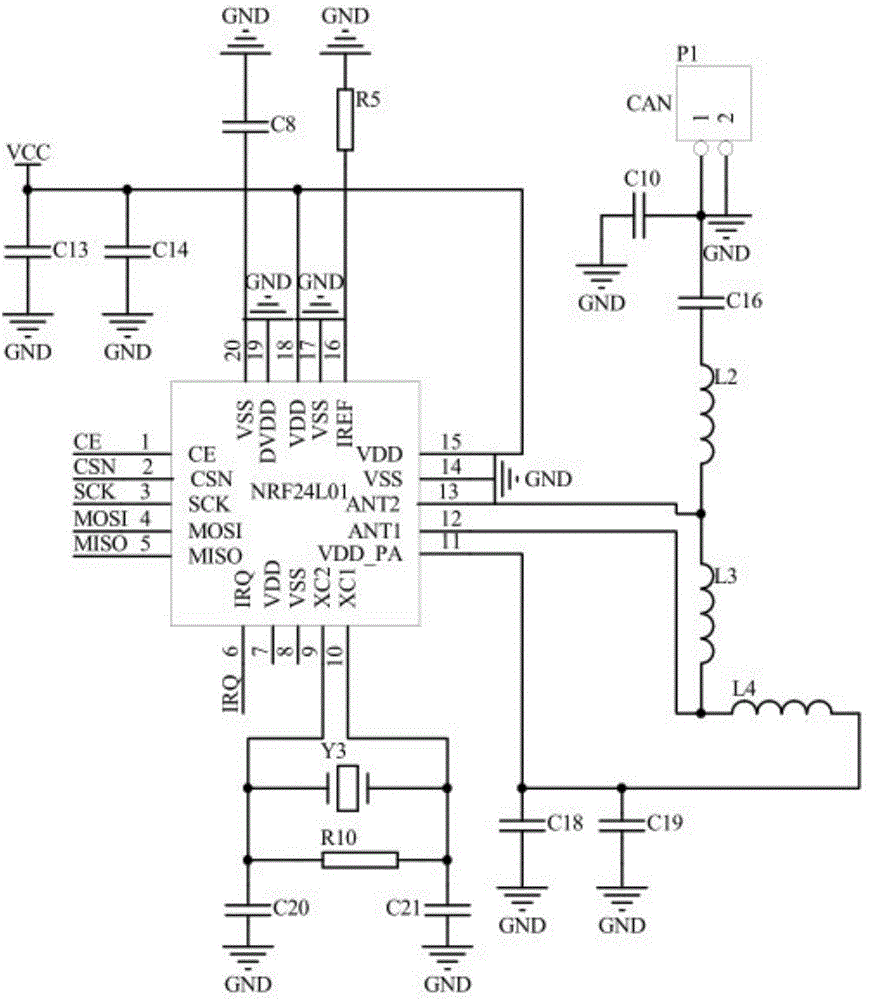

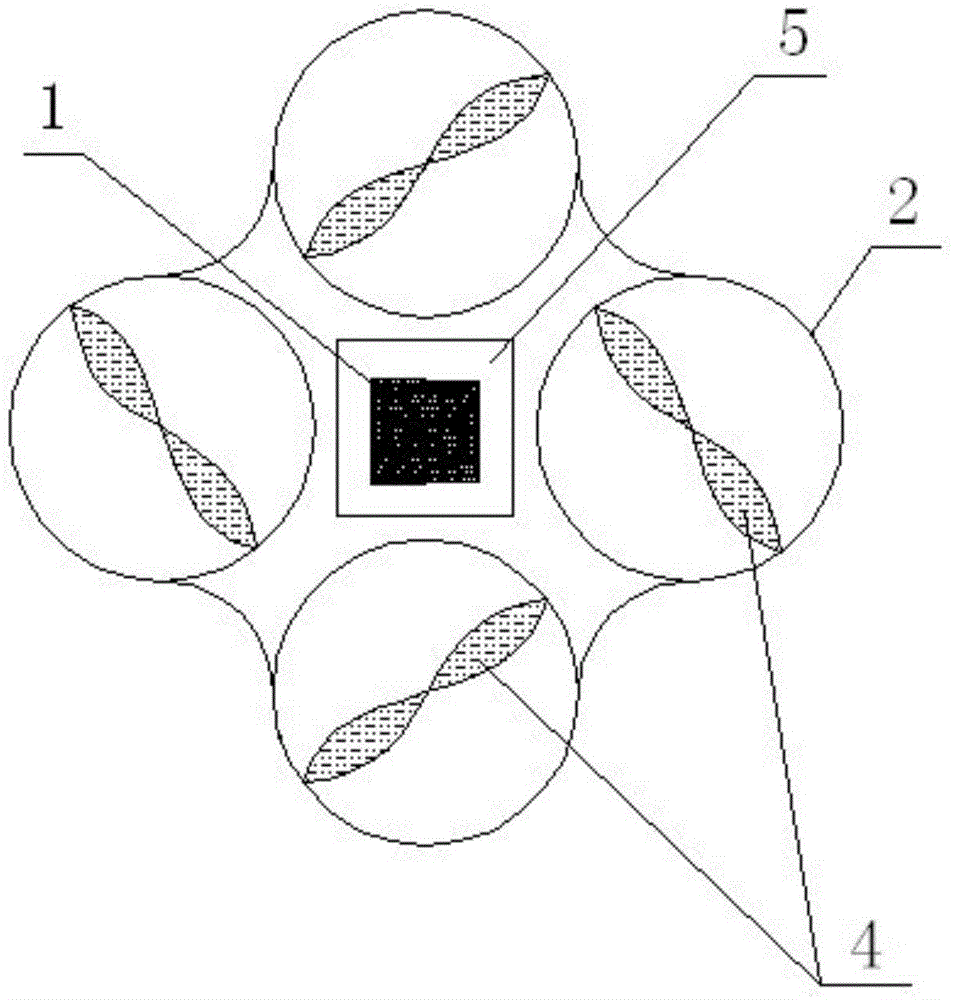

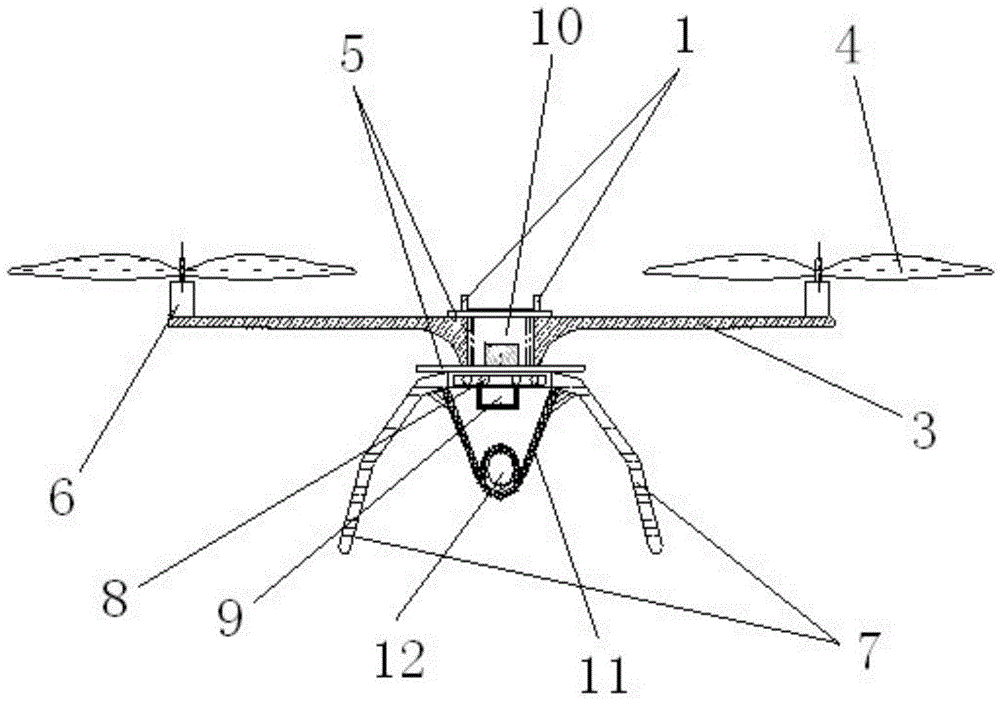

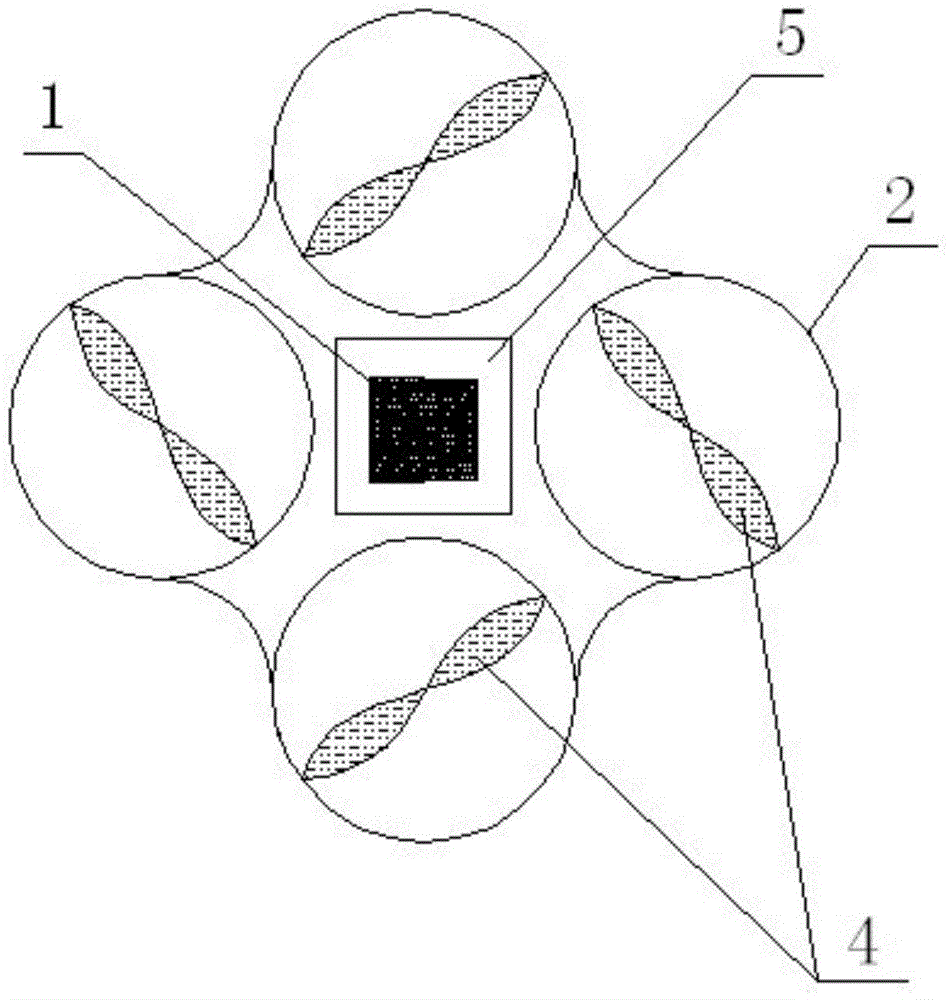

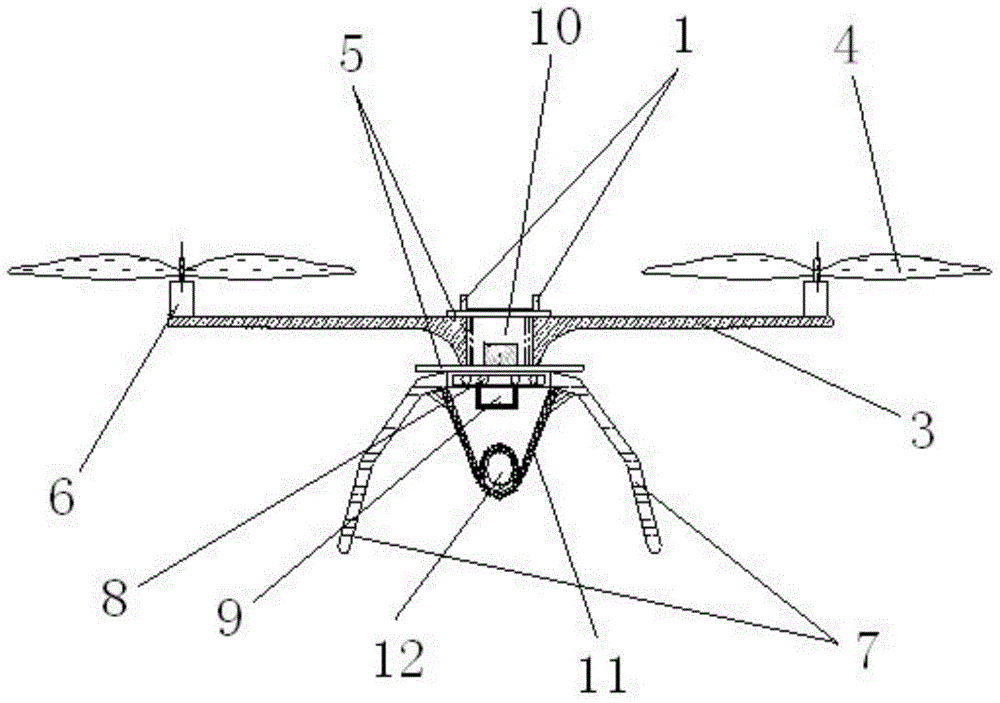

Air quality detector based on quadcopter

ActiveCN104149982AExpand the detection rangeFlexible to completeAircraft componentsPosition/course control in three dimensionsMicrocontrollerAutomatic control

An air quality detector based on a quadcopter comprises the quadcopter and control systems. The quadcopter mainly comprises a mechanical arm, a main engine body, a containing platform, a machine body cavity, a propeller, a foot stand, a camera pan-tilt and the like, the control systems comprise an onboard control system and a ground control system, the onboard control system comprises a posture measuring unit, an application measuring unit and an onboard microcontroller, and the ground control system comprises a manual control unit and an automatic driving control center. The quadcopter stable in flying and good in controllability is adopted to be carried with a camera and the detector, the quadcopter can be controlled by a ground remote control unit, meanwhile, automatic control can be achieved, the detecting range can be expanded, multi-index detection on air quality is carried out at different heights and different positions of the low altitude, the indexes are transmitted to the ground to be received, and the air quality detector has the advantages of being small in size, light, low in cost, low in requirement for the flying airspace, safe, reliable, flexible and efficient.

Owner:SHAANXI UNIV OF SCI & TECH

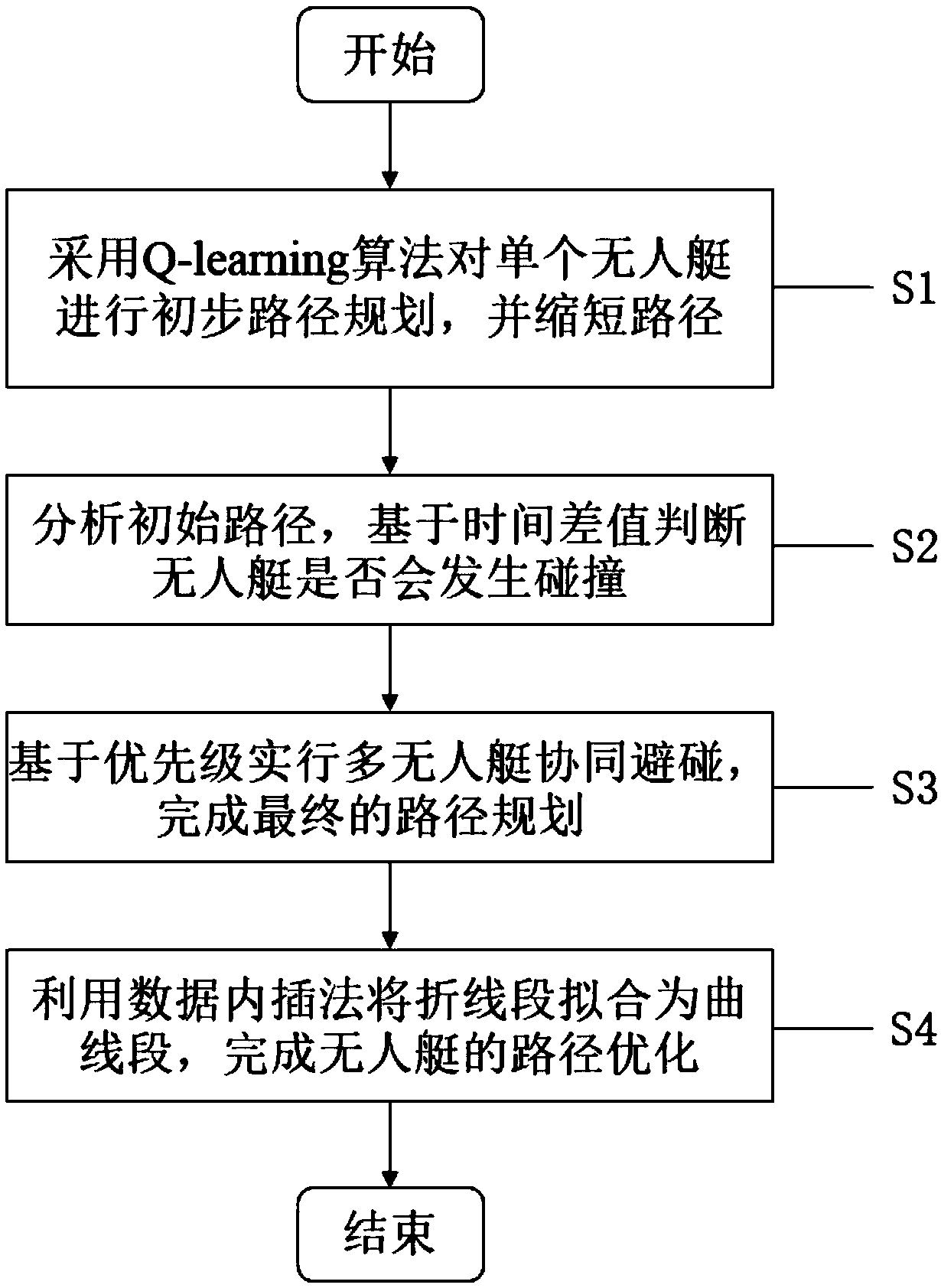

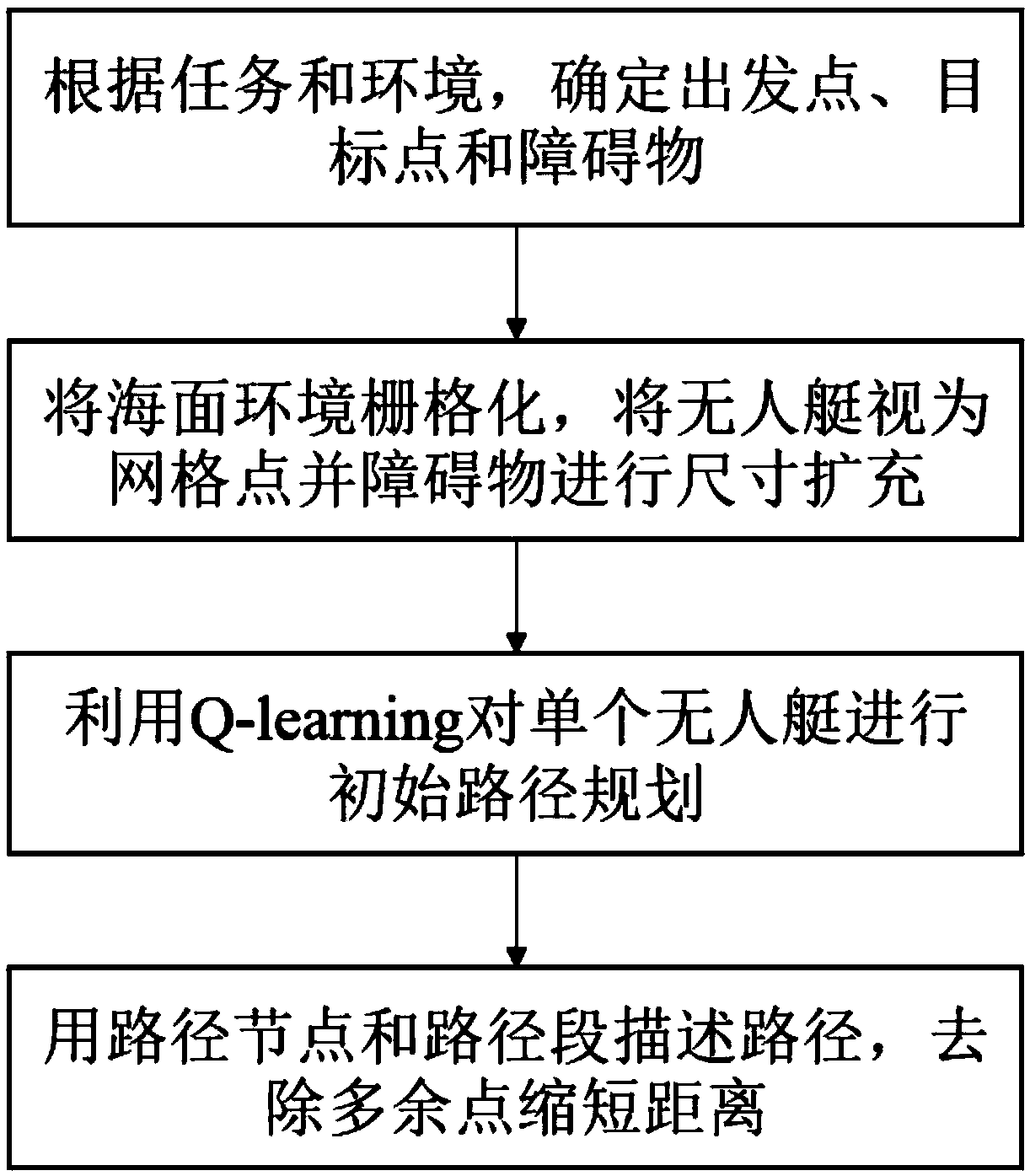

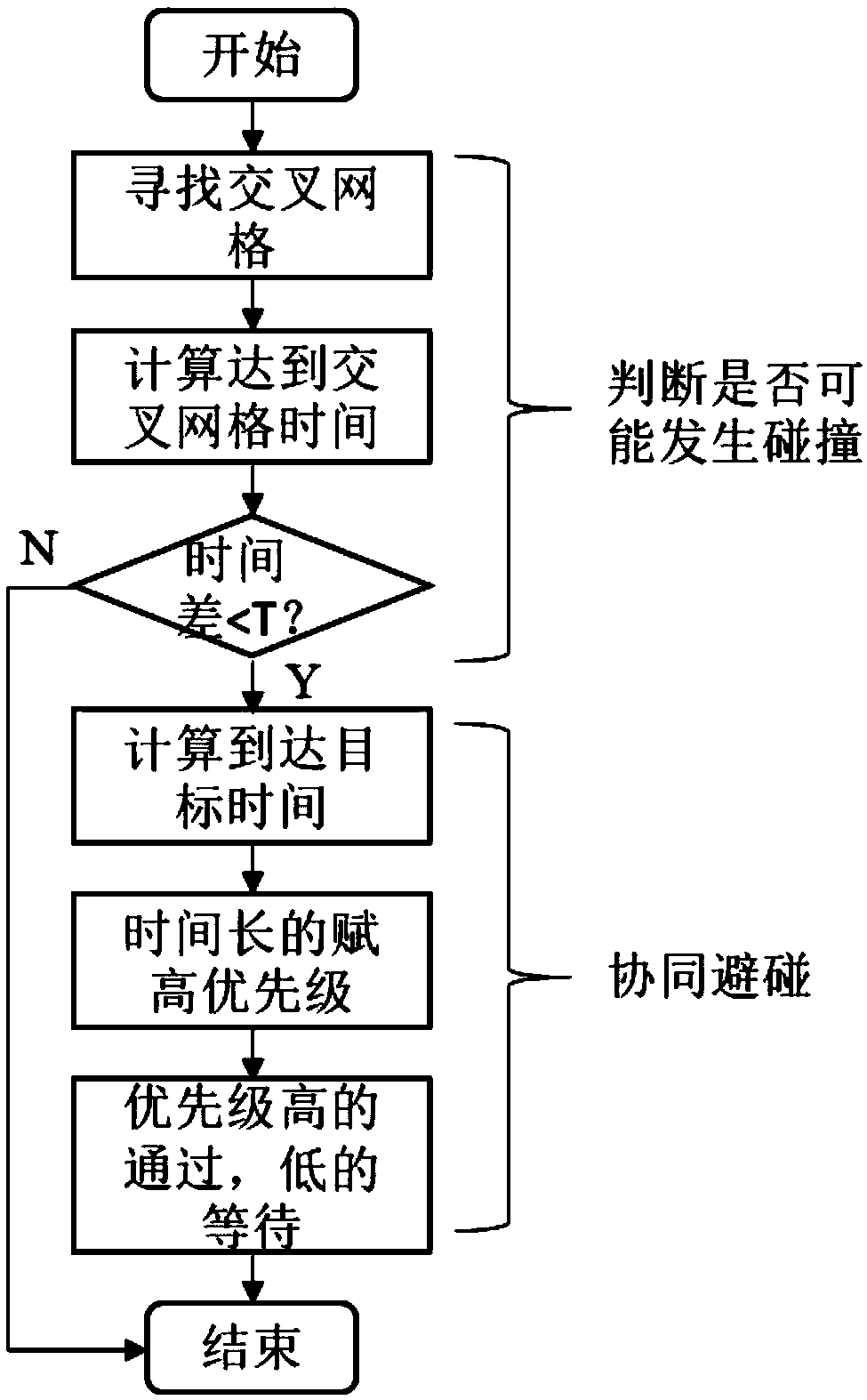

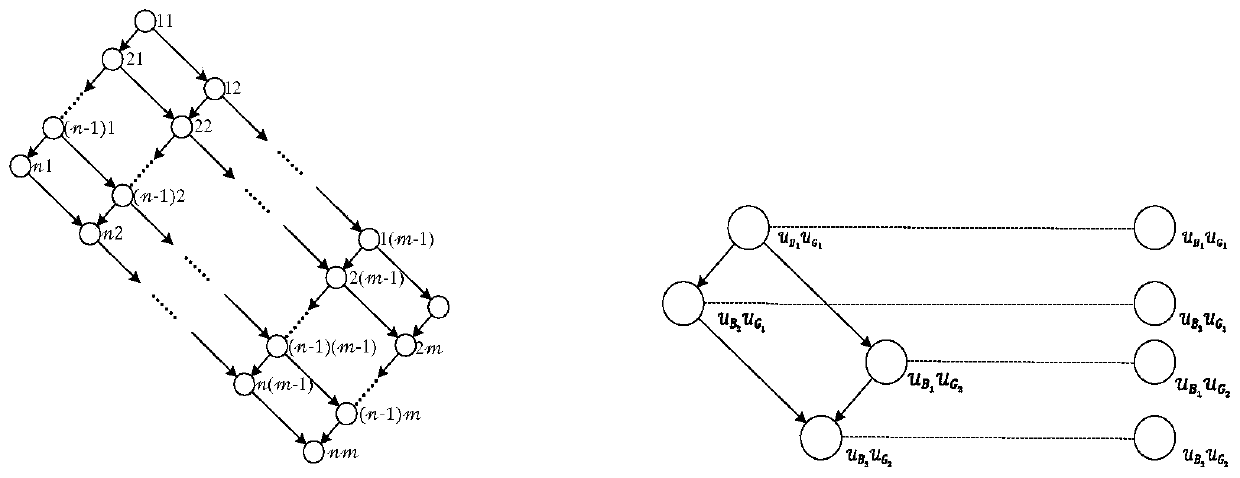

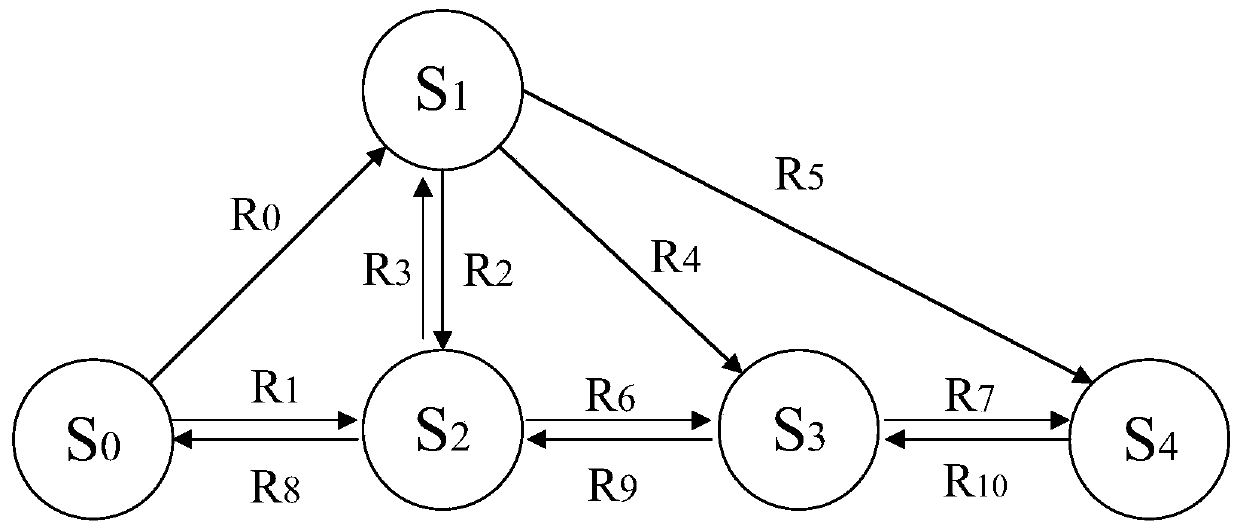

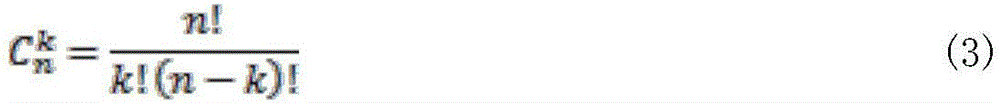

Multi-unmanned boat collaborative path planning method

InactiveCN109540136AFlexible to completeNavigational calculation instrumentsSimulationPlanning approach

The invention discloses a multi-unmanned-boat collaborative path planning method. The method comprises the following steps: S1, according to a task requirement and a navigation environment, adopting Q-learning algorithm to carry out primary path planning on a single unmanned boat and shortening the path; S2, analyzing the initial path of each unmanned boat, and judging whether collision exists between unmanned boats or not on the basis of a time difference value; S3, generating a plurality of unmanned boats which can collide with each other, giving priority to the movement time, and completingcollaborative collision avoidance of the unmanned boats to obtain a final path; S4, fitting broken line sections into a curve section through a data interpolation method, and achieving the smooth processing of the path; ending the process. According to the invention, the obstacle avoidance, the road finding, the mutual collision avoidance and the like for multiple unmanned boats can be completedefficiently and flexibly. Meanwhile, the method is safe, stable and reliable.

Owner:GUANGDONG HUST IND TECH RES INST

Electric lifting travelling mechanism

InactiveCN103786542ASimple structureStable structureVehicular energy storageResilient suspensionsDrive wheelPortal frame

The invention provides an electric lifting travelling mechanism. The electric lifting travelling mechanism comprises two front wheels and two rear wheels, wherein the two front wheels or the two rear wheels are driving wheels. The electric lifting travelling mechanism is characterized in that the two front wheels are fixed on the two lower ends of a front portal frame respectively, the two rear wheels are fixed on the two lower ends of a rear portal frame respectively, the front portal frame is connected with a front shaft sleeve through a front straight-angle turning part, the rear portal frame is connected with a rear shaft sleeve through a rear straight-angle turning part, the front shaft sleeve or the rear shaft sleeve is provided with a main transmission part, the front shaft sleeve is connected with the rear shaft sleeve through a clutch assembly, and core shafts are arranged in the front shaft sleeve, the rear shaft sleeve and the clutch assembly through sliding parts. By means of free swing of the front portal frame and the rear portal frame, it is guaranteed that the four wheels make contact with the ground all the time, travelling stability and reliability of the whole electric lifting travelling mechanism are enhanced, the height of the whole electric lifting travelling mechanism can be flexibly regulated according to requirements, the requirement for field operation of different ridging sizes and different crop heights is met, and the electric lifting travelling mechanism has no pollution, and is low in cost and high in automation and efficiency.

Owner:王猷

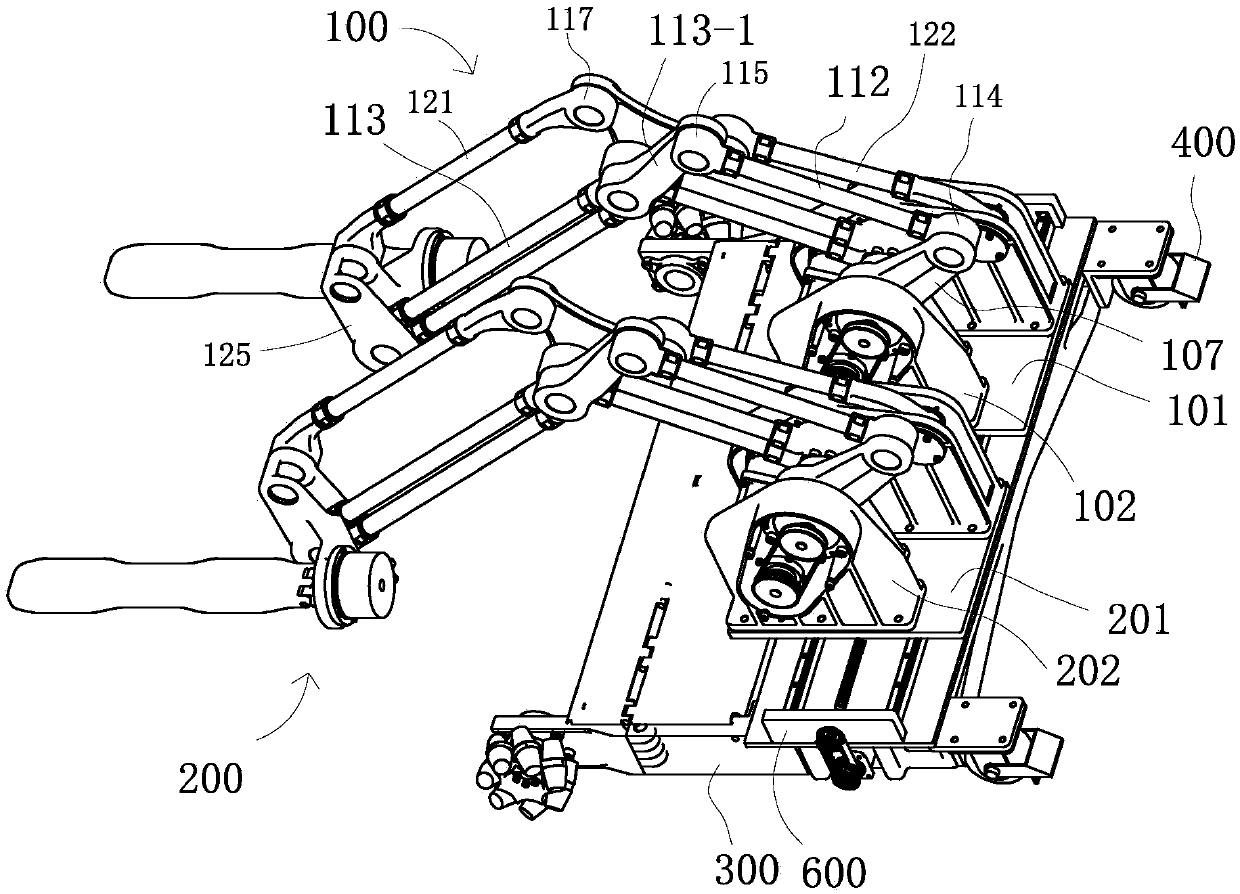

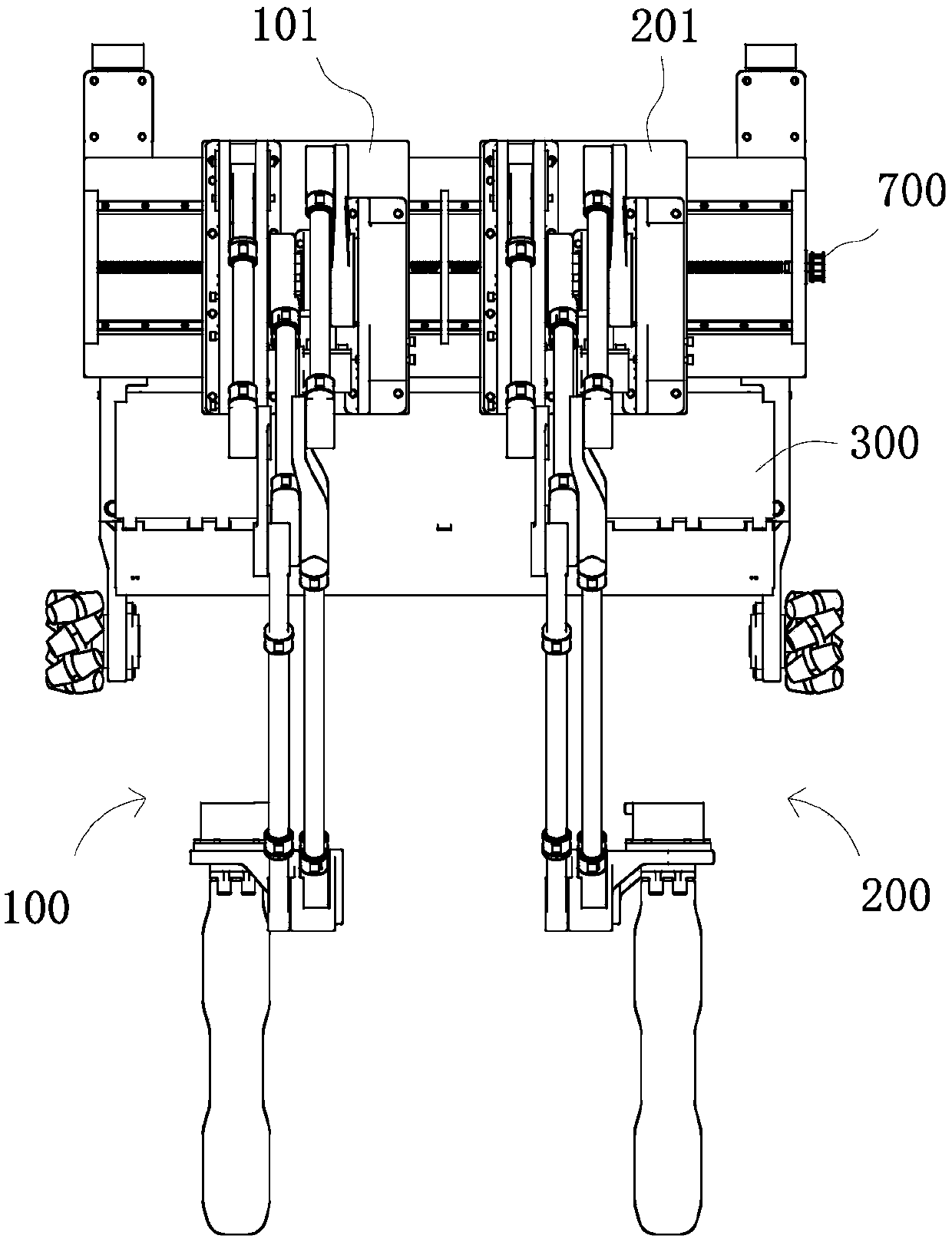

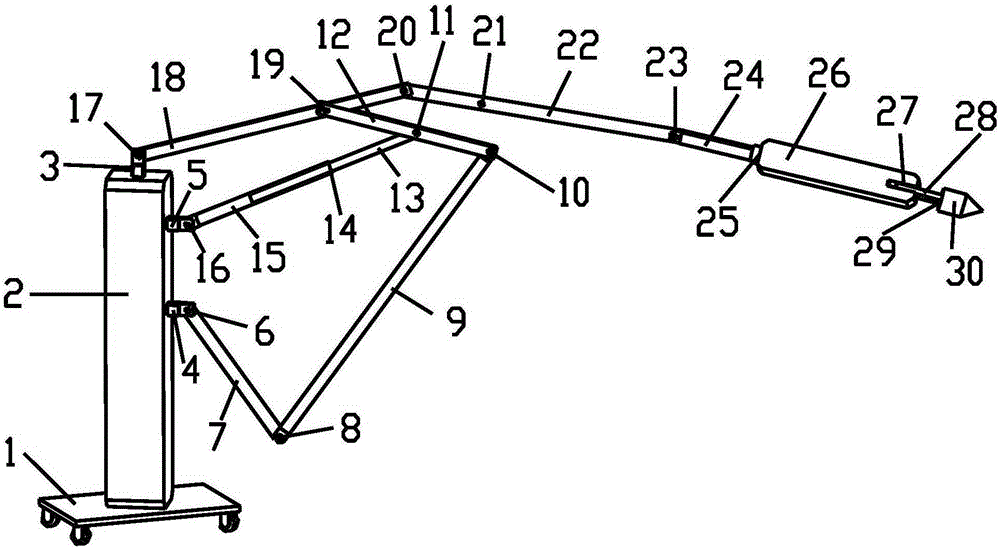

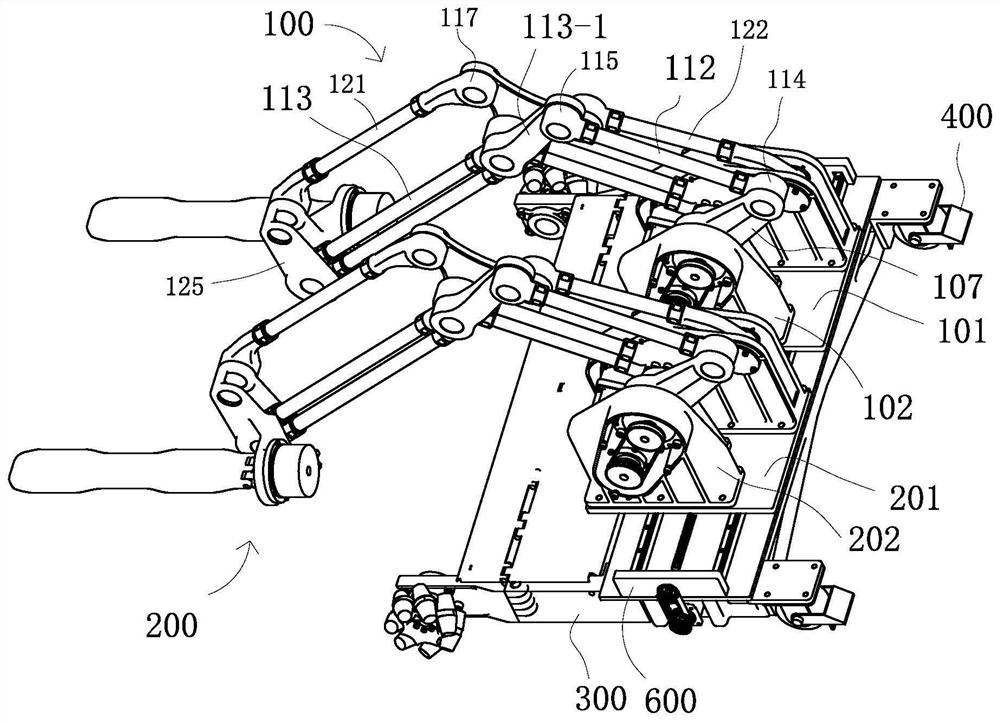

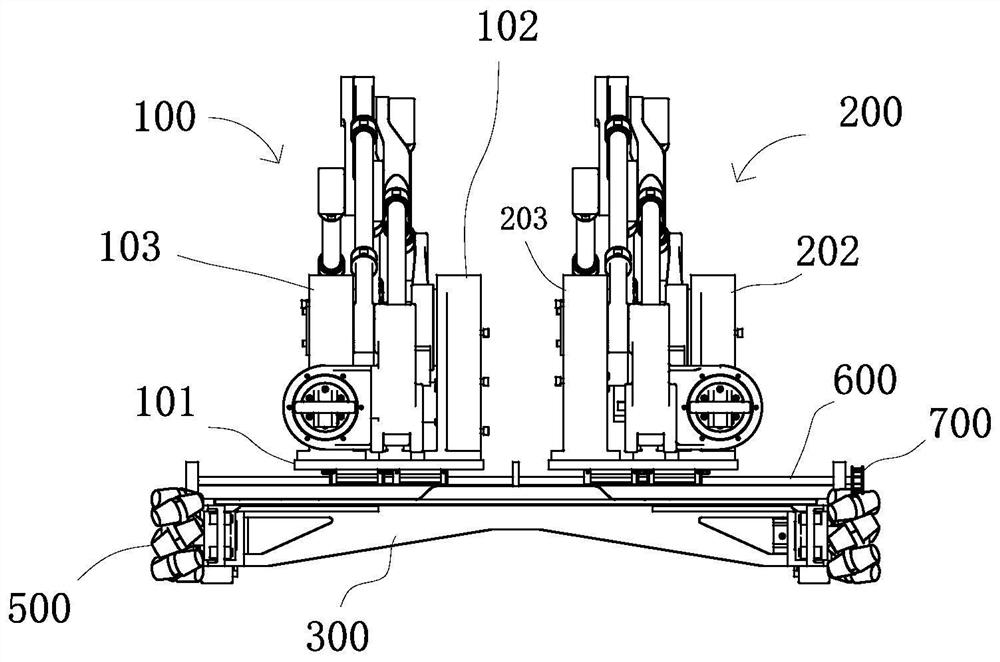

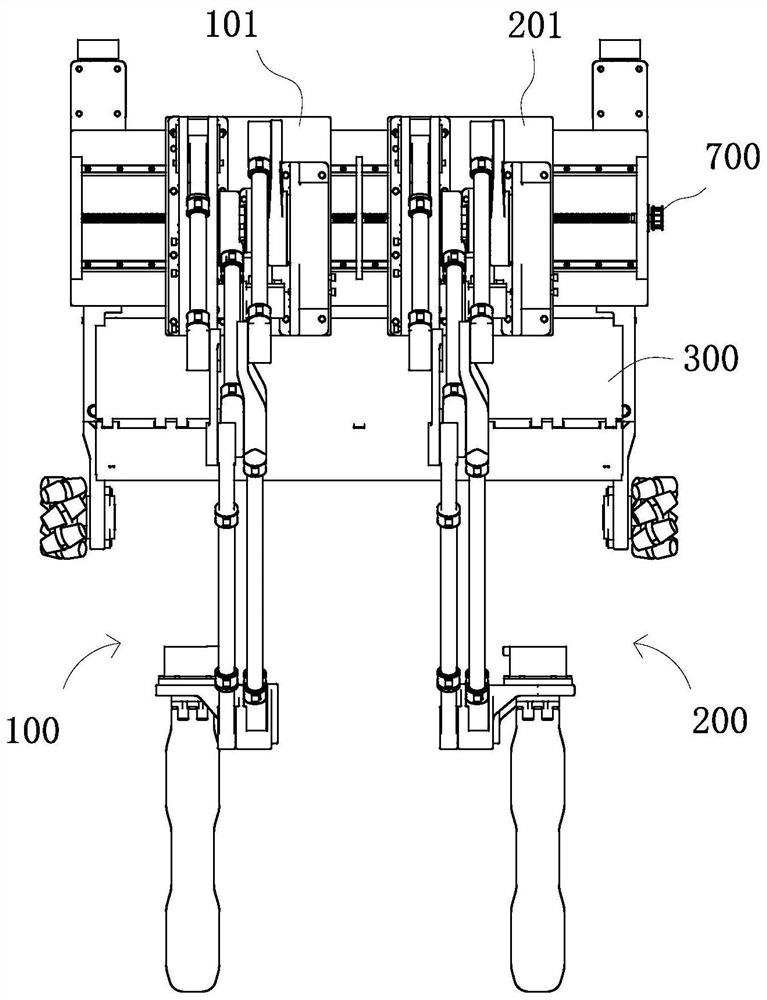

Transferring robot

ActiveCN108724213AReduce manufacturing costIncrease load capacityManipulatorMedical equipmentAgricultural engineering

The invention relates to a transferring robot. The transferring robot solves the existing technical problems that when people with mobility inconvenience are transferred and carried by manual work, the burden on nursing staff is increased, and the safety is low. The transferring robot comprises a left mechanical arm, a right mechanical arm and a chassis, wherein the left mechanical arm is providedwith a left bearing pallet, and the right mechanical arm is provided with a right bearing pallet. The transferring robot is widely used in the technical field of medical equipment.

Owner:HARBIN INST OF TECH AT WEIHAI

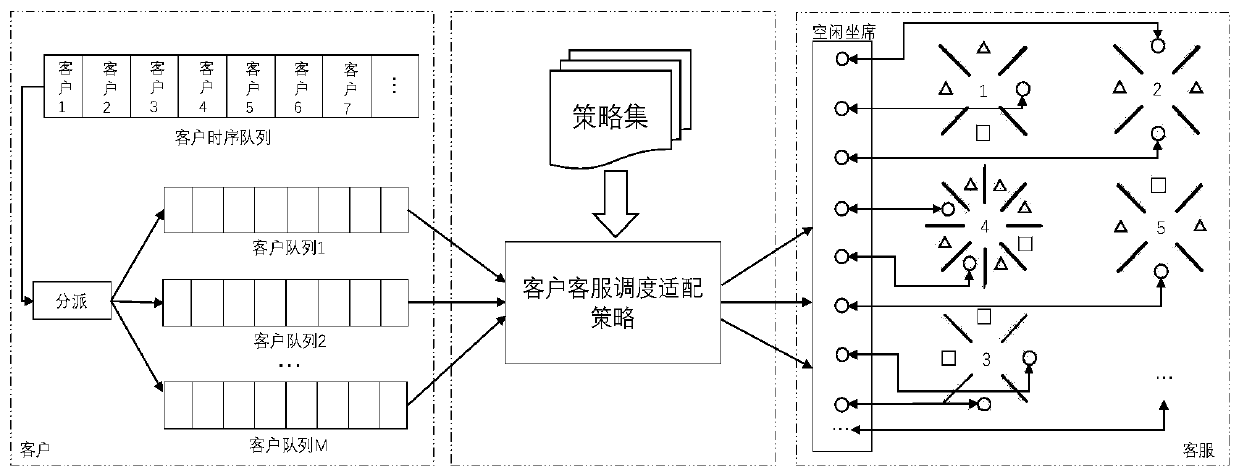

Intelligent scheduling method of online customer service system

ActiveCN111163238AReasonable designLower average wait timeAutomatic exchangesCustomer delightOperations research

The invention discloses an intelligent scheduling method of an online customer service system, which comprises the steps of constructing a multi-priority customer queue according to customer characteristics, and establishing a corresponding relationship between a scheduling strategy and a system state. The scheduling process comprises the steps of firstly, assigning customers in a time sequence queue of the customer service system to corresponding characteristic sub-queues in multiple queues according to the customer characteristics; extracting the head customer of each sub-queue, and selecting the scheduled customer according to the priority of the sub-queues and the waiting time of the customers; judging the state of the online customer service system, and selecting a proper scheduling strategy according to the system state; and finally, selecting a customer service agent to be allocated to the customer according to the selected scheduling strategy. According to the invention, the average waiting time of customers can be reduced, the reasonable distribution of customer service agents is realized, and the load balance among the customer service agents is realized, so that the service quality and the working efficiency of the online customer service system are improved, and the customer satisfaction is improved.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ELECTRIC POWER RES INST +3

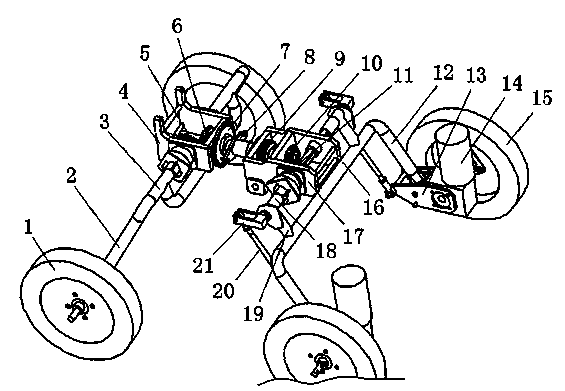

Controllable mechanism type metamorphic wheeled mobile welding robot

ActiveCN104552243ALarge working spaceHigh Motion RedundancyProgramme-controlled manipulatorWelding/cutting auxillary devicesClosed loopMulti degree of freedom

The invention provides a controllable mechanism type metamorphic wheeled mobile welding robot, which comprises a metamorphic executing mechanism sub-chain, a serial executing mechanism main chain and a moveable platform, wherein the metamorphic executing mechanism sub-chain is provided with parallel closed-loop sub-chains, the serial executing mechanism main chain is used for controlling the plane movement of a tail executer, and the space movement of the movable platform is realized by the movement of a robot body and the movable platform; the metamorphic movement is realized by the metamorphic executing mechanism sub-chain with the parallel closed-loop sub-chains and the serial executing mechanism main chain through a closed-loop sub-chain. The controllable mechanism type metamorphic wheeled mobile welding robot has the advantages that the controlling is realized by the metamorphic synthesis movement, the controllable, adjustable and output flexible functions are realized, and the features of multifunctional phase change, multi-topological structure and multi-degree-of-freedom change are realized; the movement inertia of the tail executer is small, the dynamic property is good, the reliability is high, the movement and operation functions are realized, and the robot can be applied to multiple occasions.

Owner:GUANGXI UNIV

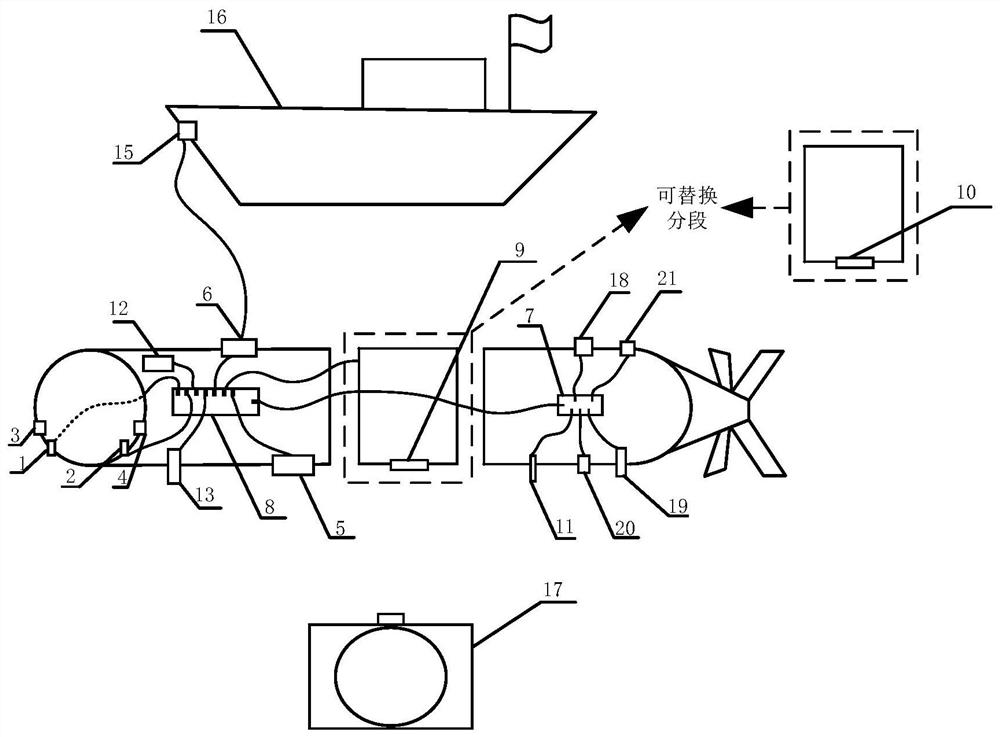

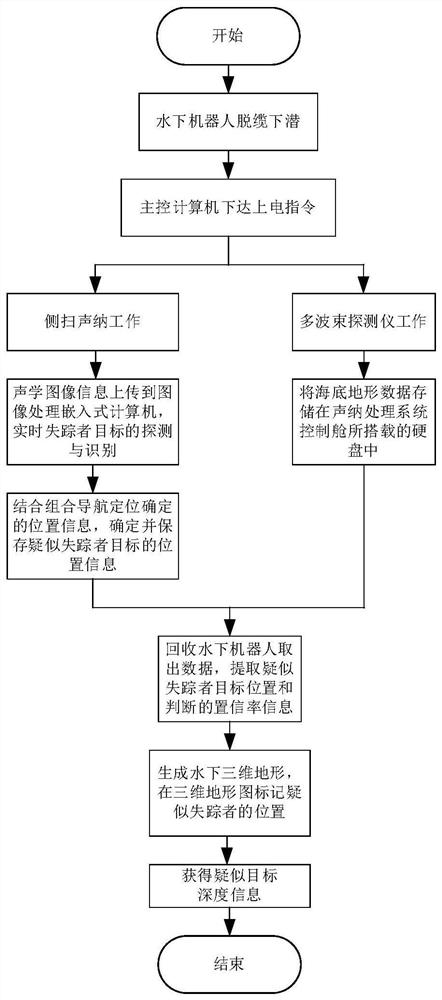

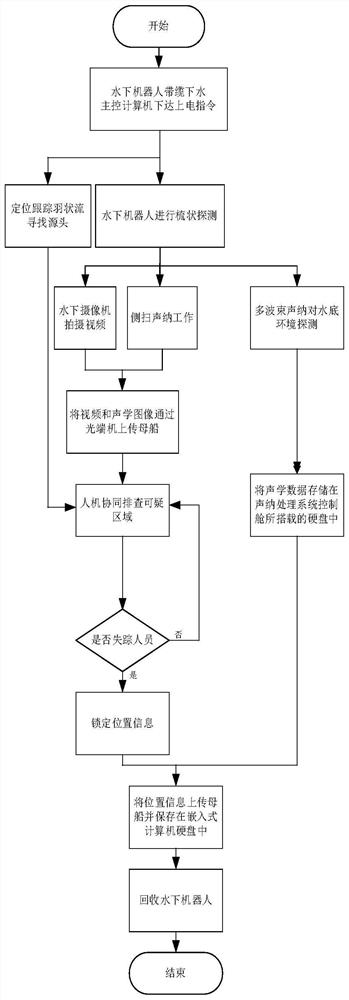

System and method for searching and positioning missing person by underwater robot

PendingCN111638523AFlexible to completeAccurately doneOptical transmission adaptationsClosed circuit television systemsEngineeringHandling system

The invention provides a system and method for searching and positioning a missing person by an underwater robot, and the method comprises the steps of carrying out the large-range searching operationin a disaster region in a cableless operation mode through employing autonomous detection and a side-scan sonar and a processing system control cabin of the side-scan sonar, and obtaining the underwater position information of suspected missing persons with different confidence rates. In a cabling operation mode, fine search is carried out in each suspected area according to the target confidenceof the suspected missing person from high to low, personnel on the ship observe underwater optical and acoustic images uploaded to a mother ship in real time, and fine missing person search operationis carried out through man-machine cooperative judgment. The invention is an efficient and multi-method matched detection means, the underwater condition can be detected under the severe and complexwater body condition, so people in distress can be positioned in time through the means of area investigation, man-machine cooperation, chemical reagent sniffing tracking and the like, and a foundation is laid for further rescue.

Owner:HARBIN ENG UNIV

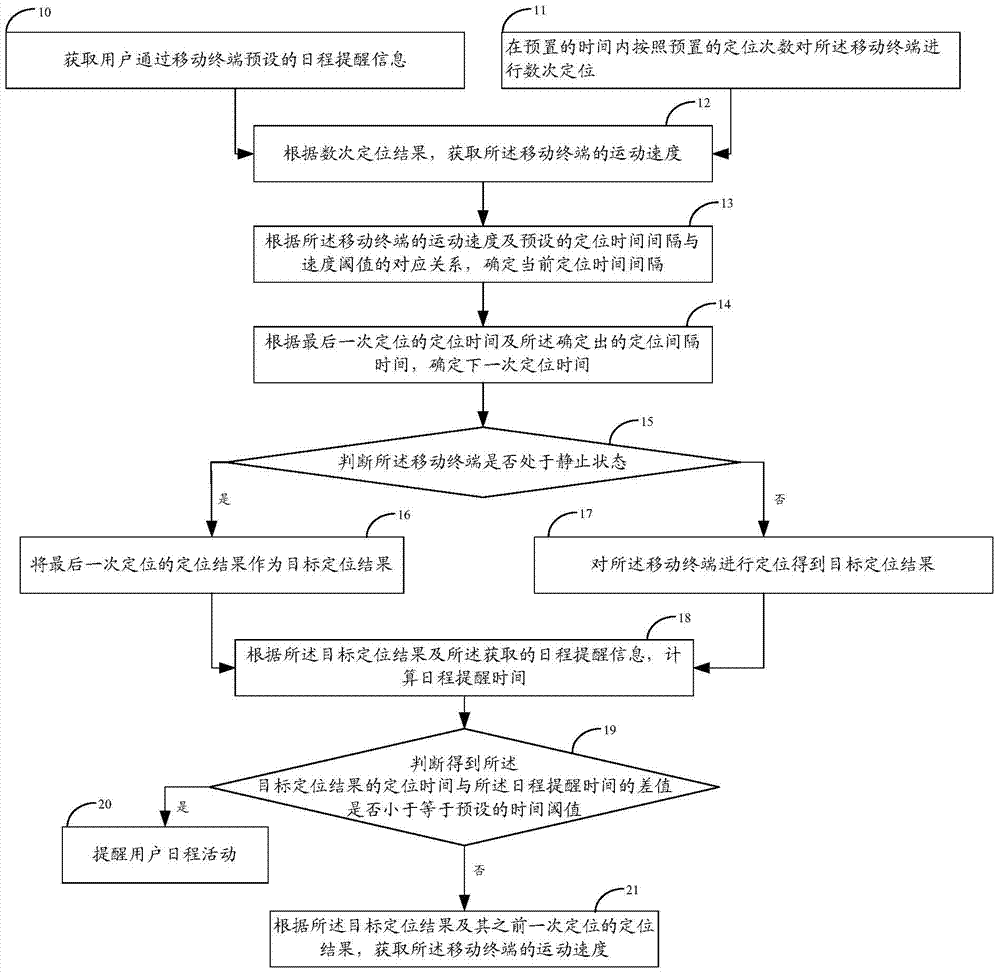

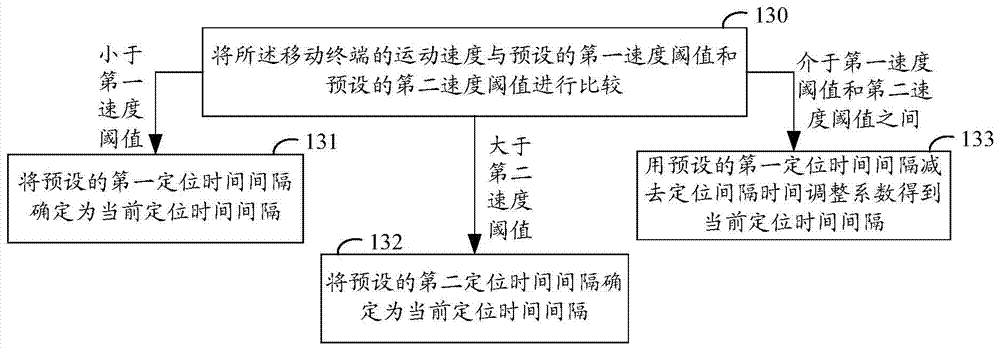

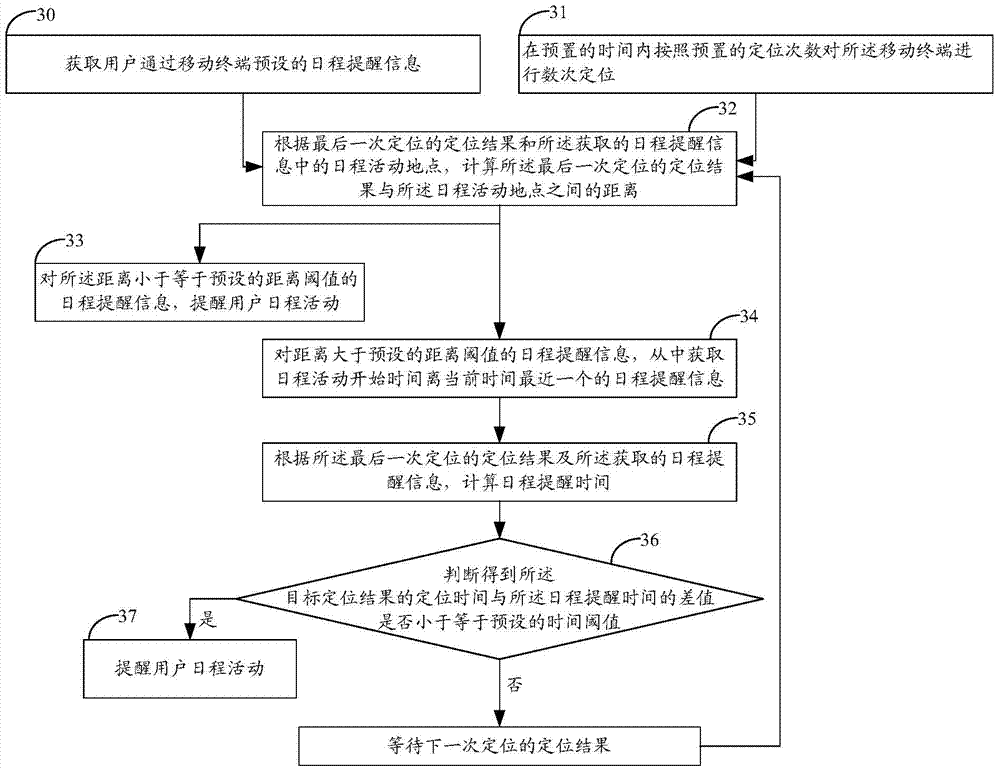

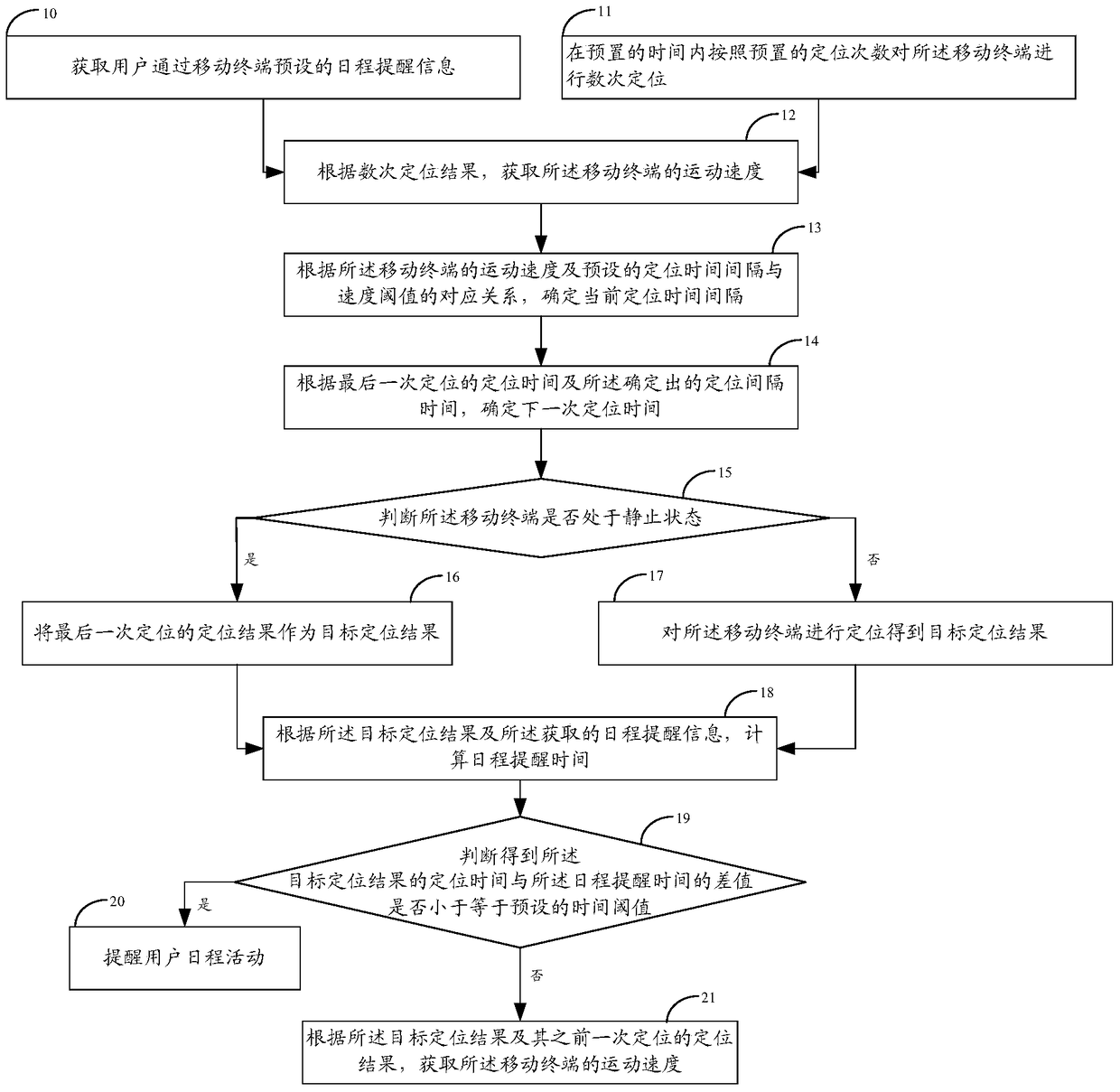

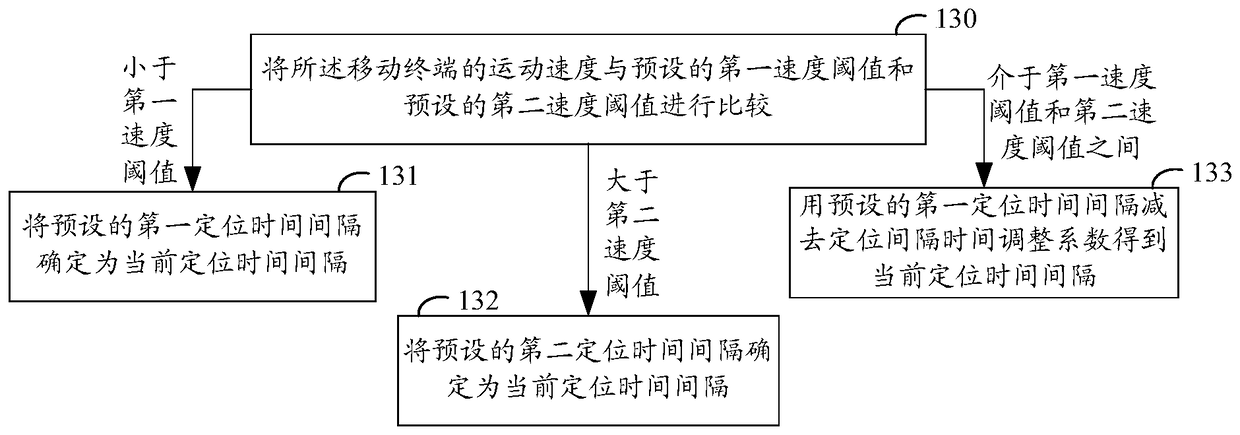

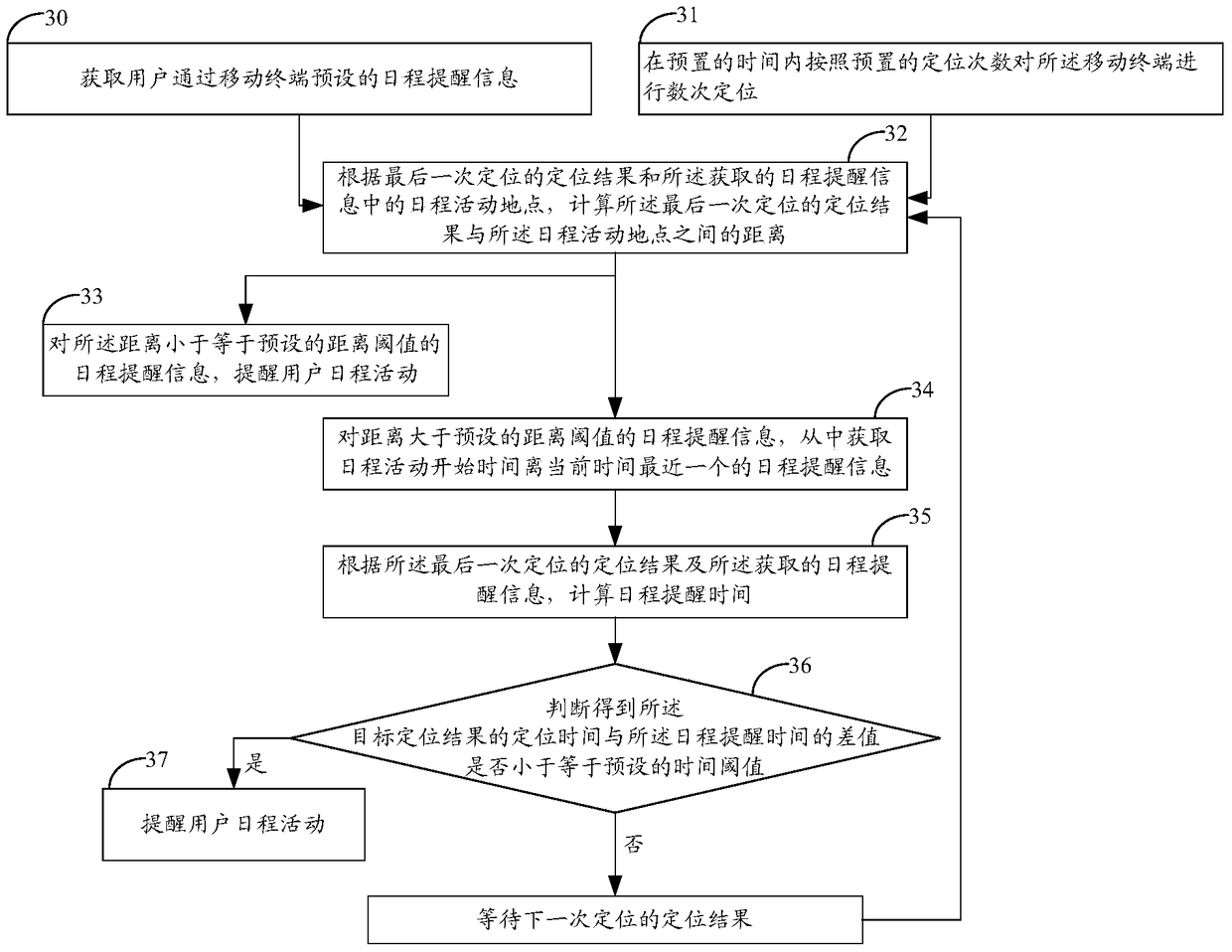

Schedule reminding method and mobile terminal

ActiveCN104717607APracticalGuaranteed real-timeCommmunication supplementary servicesSubstation equipmentReal-time computingComputer terminal

Owner:ALIBABA (CHINA) CO LTD

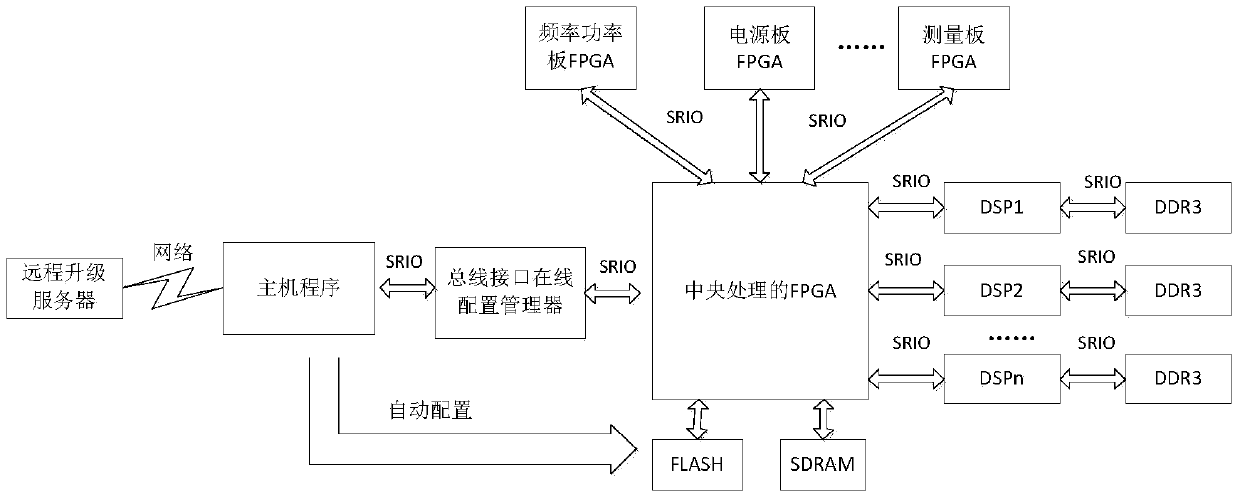

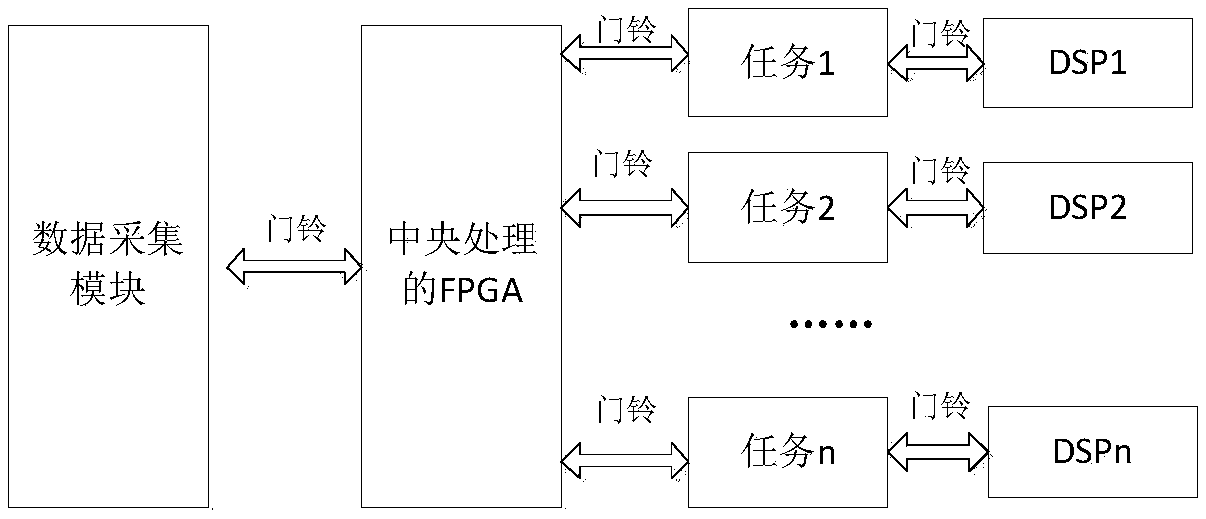

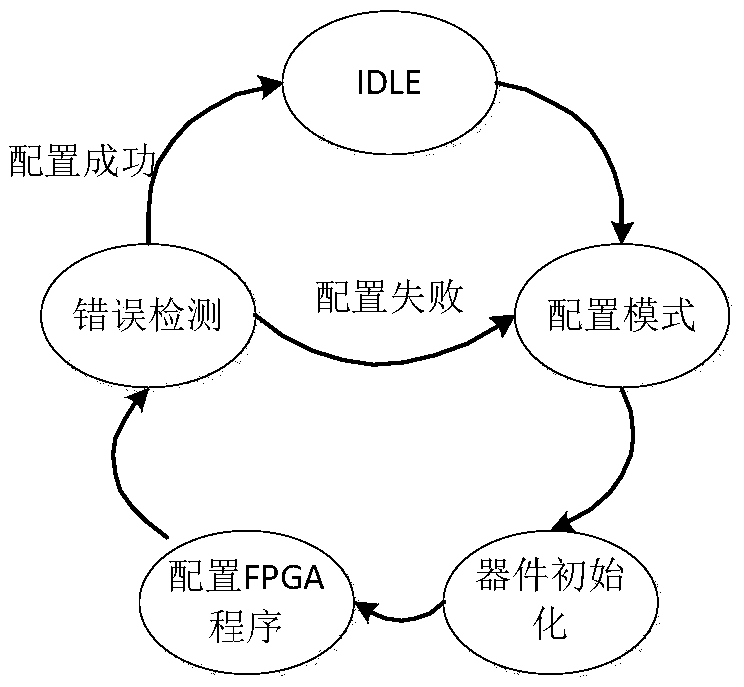

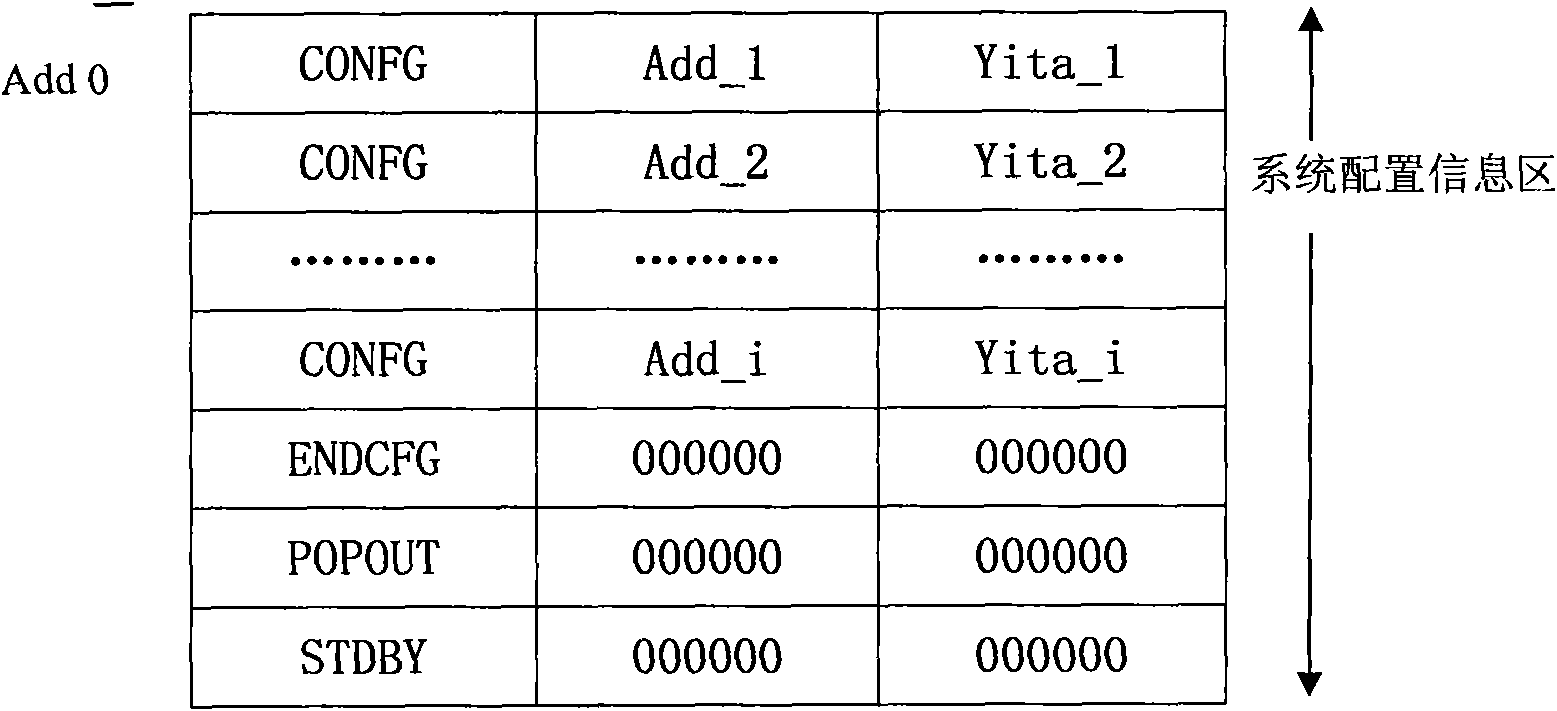

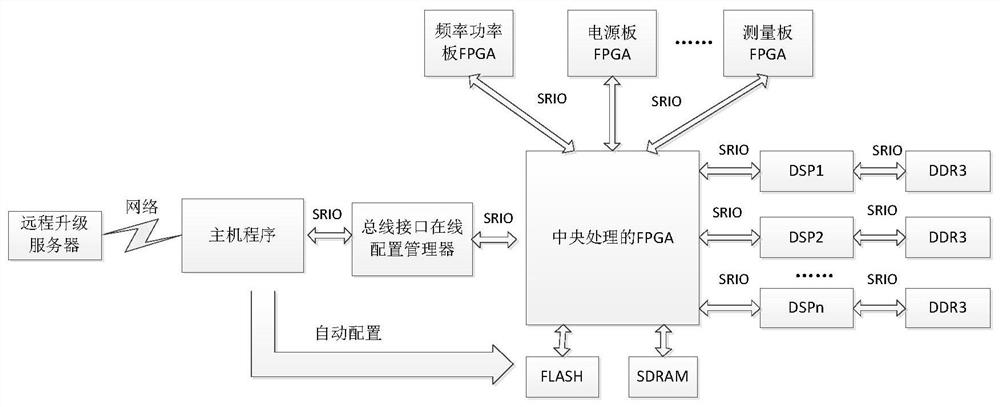

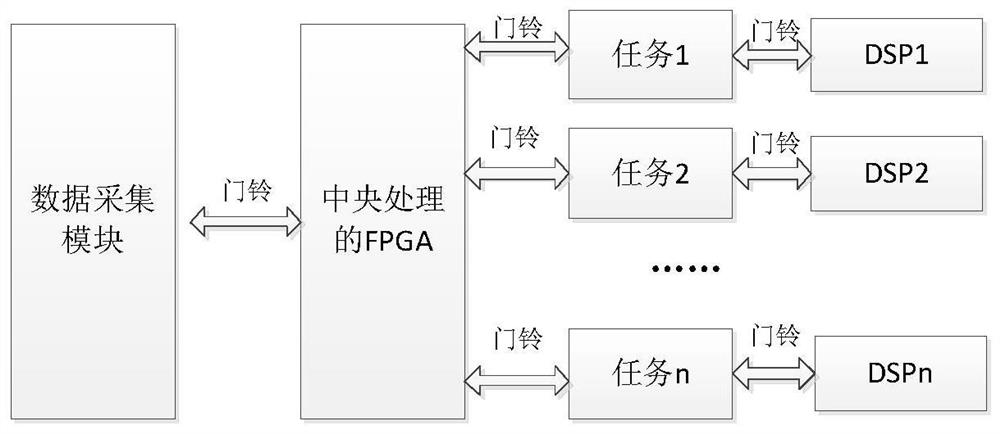

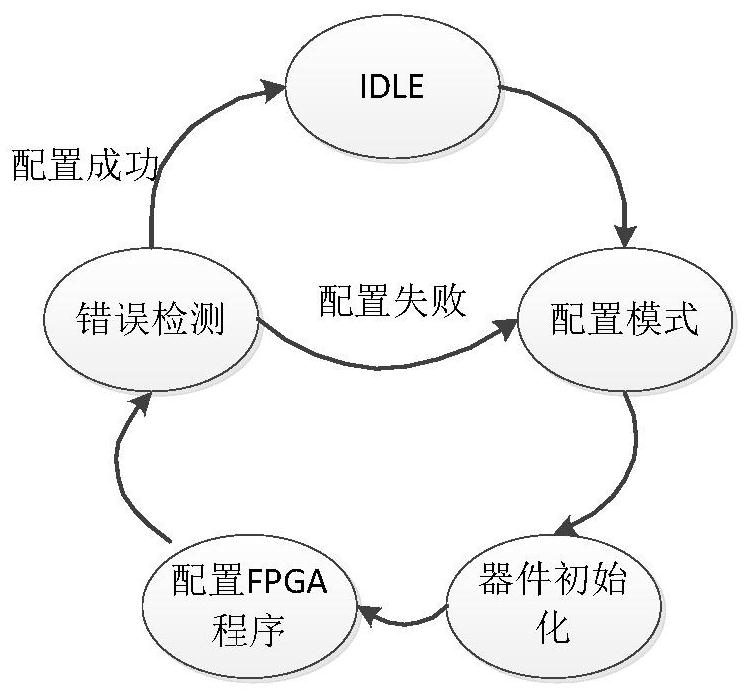

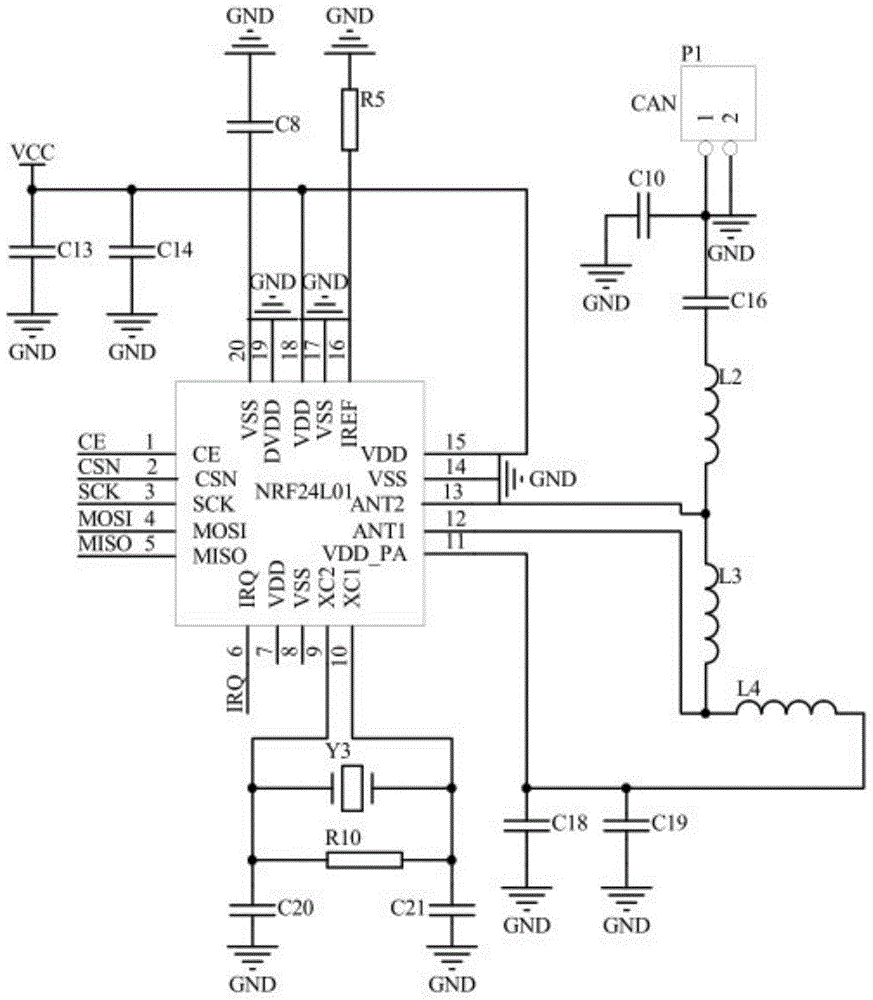

An automatic configuration device and method of a multi-mode and multi-function testing instrument

ActiveCN109542481AFunction switching is simpleSync configurationProgram loading/initiatingSoftware deploymentAuto-configurationFunctional testing

The invention discloses an automatic configuration device and method of a multi-mode and multi-function testing instrument, and belongs to the technical field of testing. The device comprises a remoteupgrading server, a host program module, a bus interface online configuration manager, a central processing FPGA, a DSP, a DDR3 memory, a frequency power board FPGA, a power board FPGA and a measurement board FPGA. The invention adopts a more reconfigurable hardware platform structure, primarily DSP clusters, FPGA-centric FPGA combination based on CPU, This combined structure can flexibly implement various algorithms, And flexibility can also be ensured, not only can be convenient to configure applications, but also can be real-time automatic configuration of multiple FPGA and multiple DSP programs, configuration process more flexible and efficient, to solve the configuration of the process of a large amount of data, data transmission speed, synchronization between the states.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

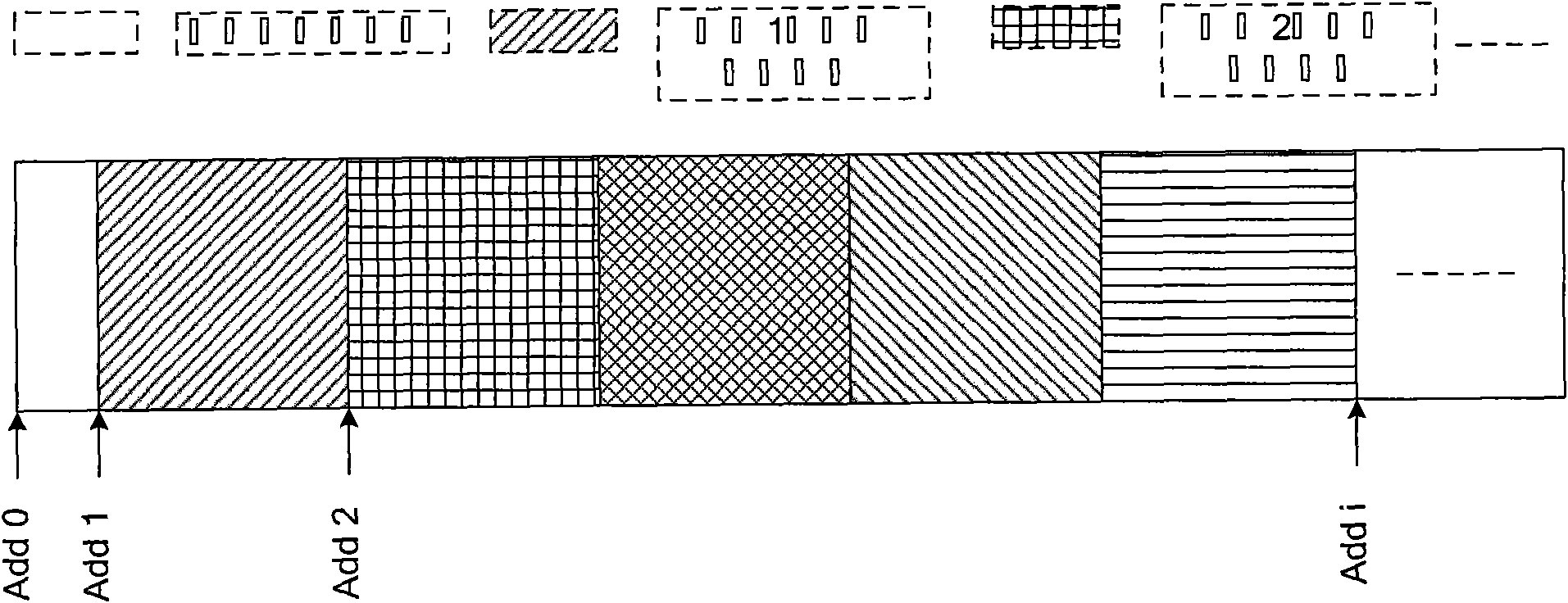

Phase-change-material-based thermal bar code system and reading method thereof

InactiveCN106250960AStrong combination of multiplicityHigh sensitivityRecord carriers used with machinesSensing by electromagnetic radiationRoom temperaturePhase change

The invention, which belongs to the technical field of bar code coding, discloses a phase-change-material-based thermal bar code system and a reading method thereof. The system comprises a marked object and a tracer agent for the marked object; and the tracer agent is made from more than one kind of phase-change material, wherein each kind of phase-change material has different phase change temperatures. In addition, according to the reading method, after the temperature of a thermal bar code system increases at a V0 temperature rising rate and reaches a preset temperature value, the system is cooled at a V0 cooling rate and the temperature of the system reaches a room temperature value; a thermal detection device reads number and position information of an endothermic peak and an exothermic peak of the tracer agent in the thermal bar code system is read during the temperature rising and cooling processes; according to the information, the type of the tracer agent is determined; and the information and the data in the database are compared to obtain identity information of a marked object. The thermal bar code system has a wide application range; and the reading method has advantages of high simpleness, high accuracy and quick operation.

Owner:苏明 +1

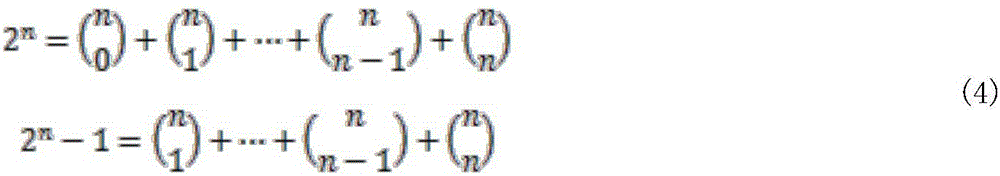

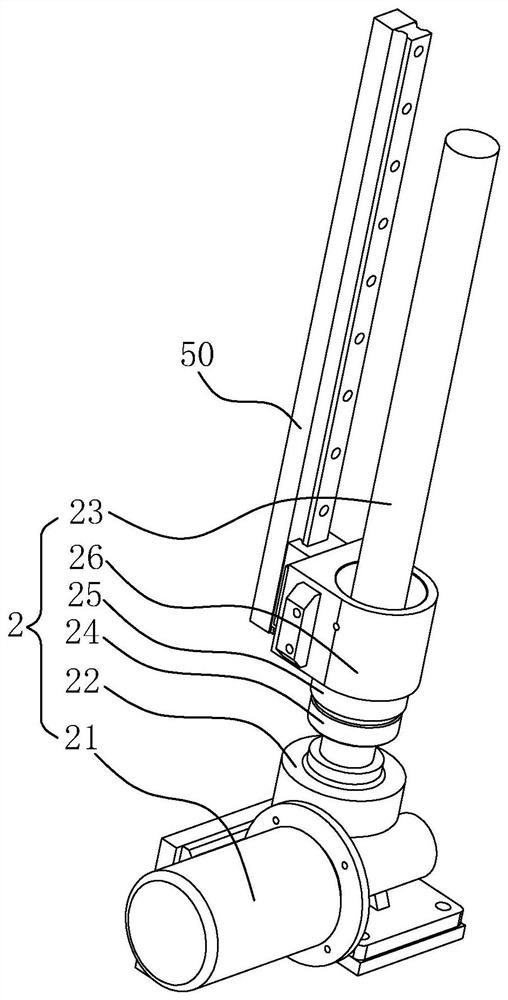

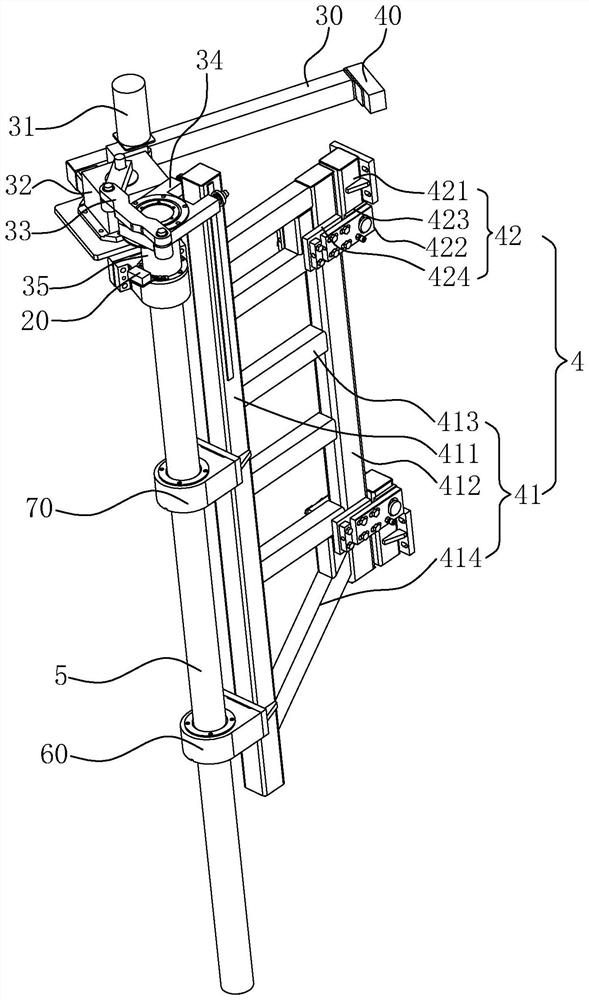

Auxiliary furnace chamber lifting and rotating device for single crystal furnace

PendingCN111850678AImprove stabilityGuaranteed safe operationPolycrystalline material growthBy pulling from meltEngineeringSingle crystal

The invention relates to the field of single crystal furnaces, and especially discloses an auxiliary furnace chamber lifting and rotating device for a single crystal furnace. The auxiliary furnace chamber lifting and rotating device is arranged on one side of a main furnace chamber and is connected with an auxiliary furnace chamber, and comprises a supporting frame, a lifting mechanism, a rotatingmechanism and a connecting mechanism connected with the auxiliary furnace chamber. The supporting frame is connected with a main furnace chamber rack; a main shaft is arranged on the supporting frame; the lifting mechanism is arranged on the supporting frame and movably connected with the main shaft, the rotating mechanism is arranged at the top of the supporting frame and connected with the mainshaft, one end of the connecting mechanism is connected with the lifting mechanism, the other end of the connecting mechanism is connected with the rotating mechanism, and the connecting mechanism isarranged on the side face of the main shaft and fixedly connected with the main shaft. The single crystal furnace has the effects that the operation stability of the single crystal furnace is improved, and the long-term safe and reliable operation of the single crystal furnace in the production process is ensured.

Owner:BEIJING NORTH HUACHUANG VACUUM TECH CO LTD

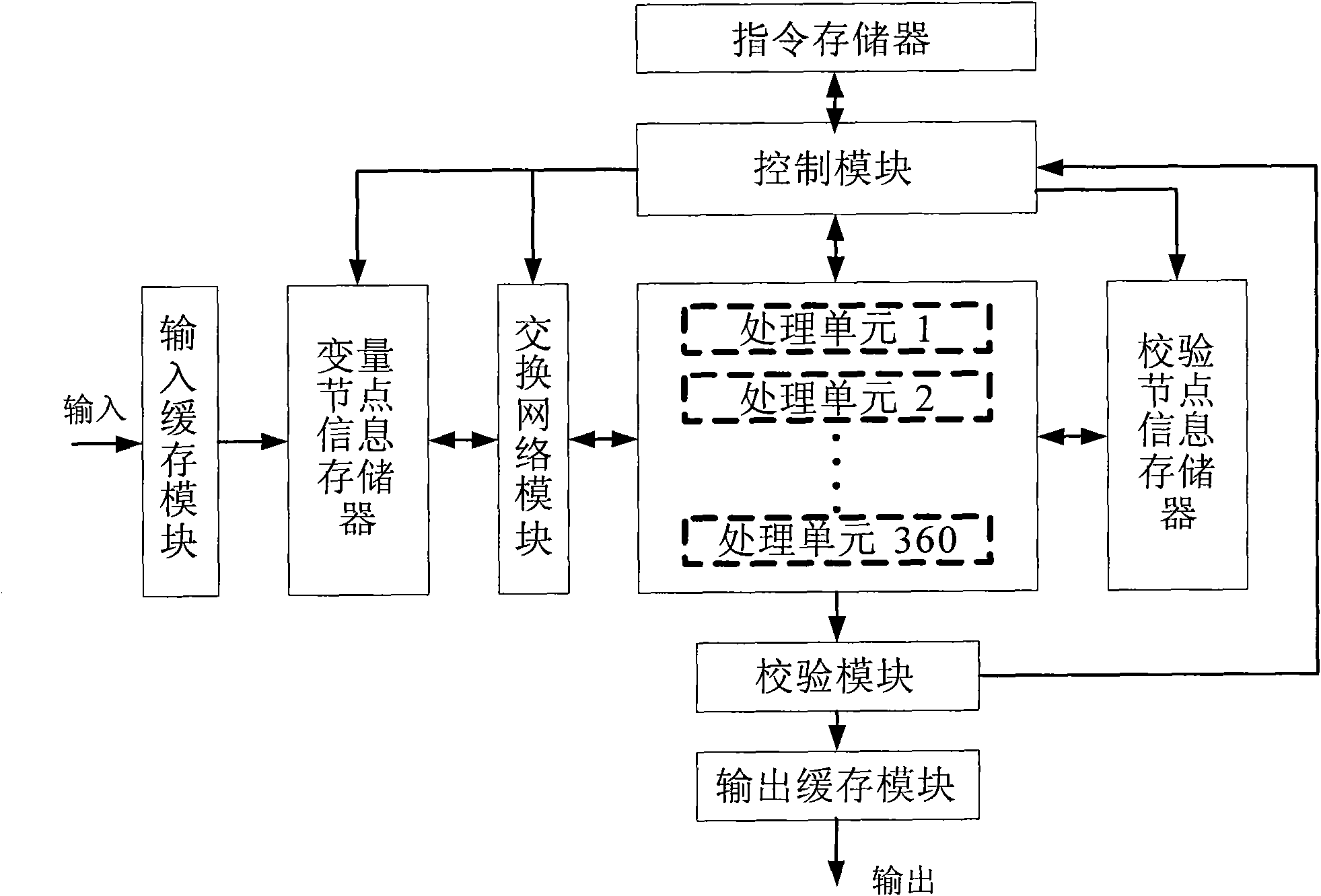

LDPC code decoder

InactiveCN101594151AEasy to operateIncrease flexibilityError correction/detection using multiple parity bitsHardware structureInstruction memory

The invention relates to an LDPC code decoder supporting arbitrary various code rates, which comprises an input buffer module, a control module, an arithmetic processor module, an intermediate memory, a microinstruction memory, a switched network module, a verification module, an output buffer module and an Internet, and adopts a partially parallel structure. Based on a microinstruction control mode, the decoder stores different code rate information into the microinstruction memory to separate the code rates and a hardware structure, thereby realizing support for arbitrary various code rates without increasing hardware cost; the connecting wires of the decoder are in a neat order, so the complexity of the connecting wires is reduced greatly; and the decoder can effectively reduce the design period of a digital communication system and improve design efficiency.

Owner:FUDAN UNIV

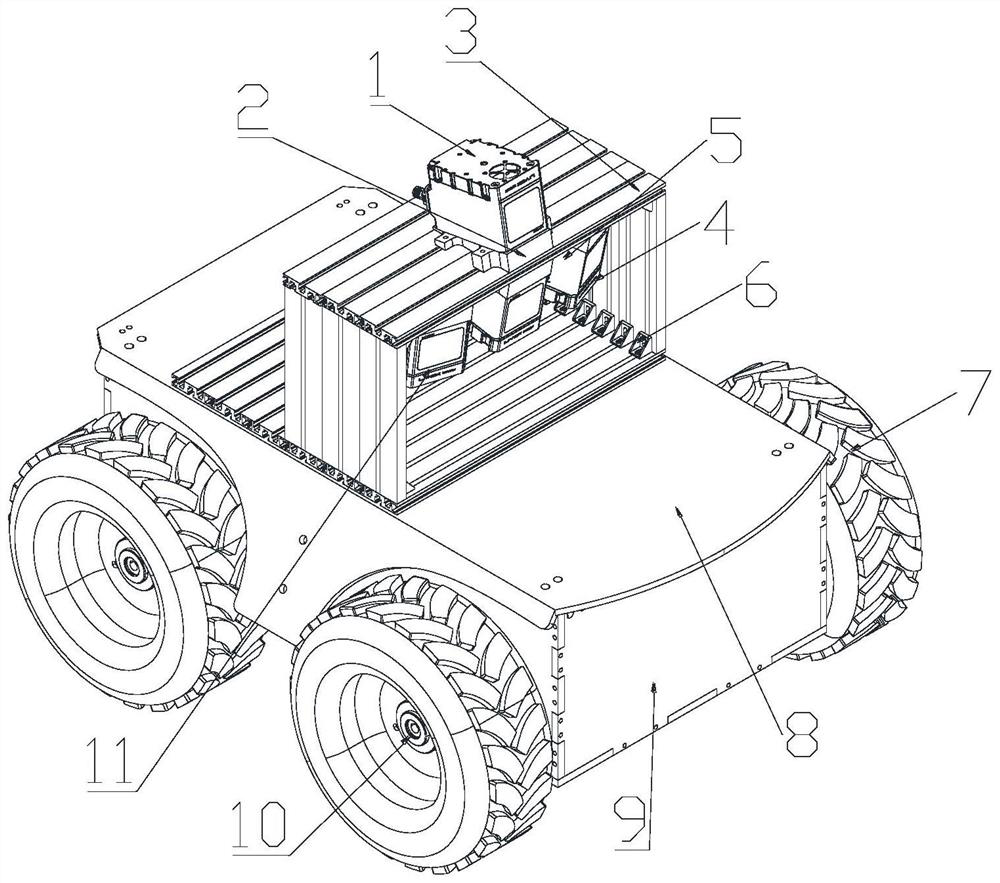

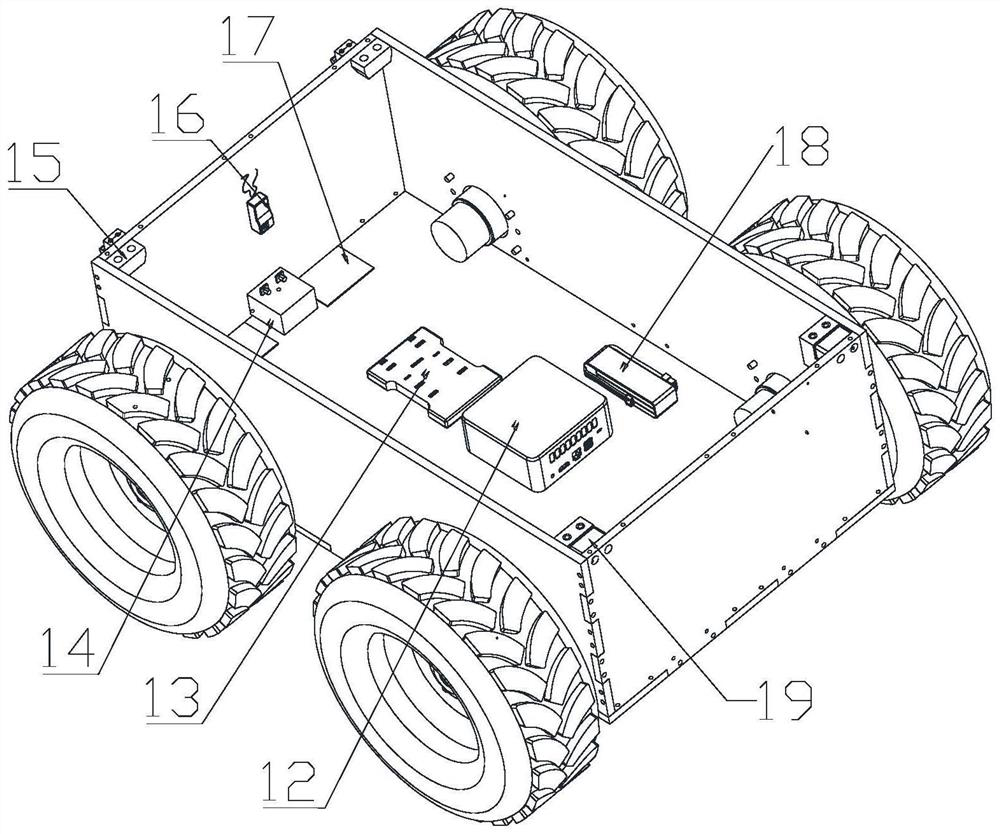

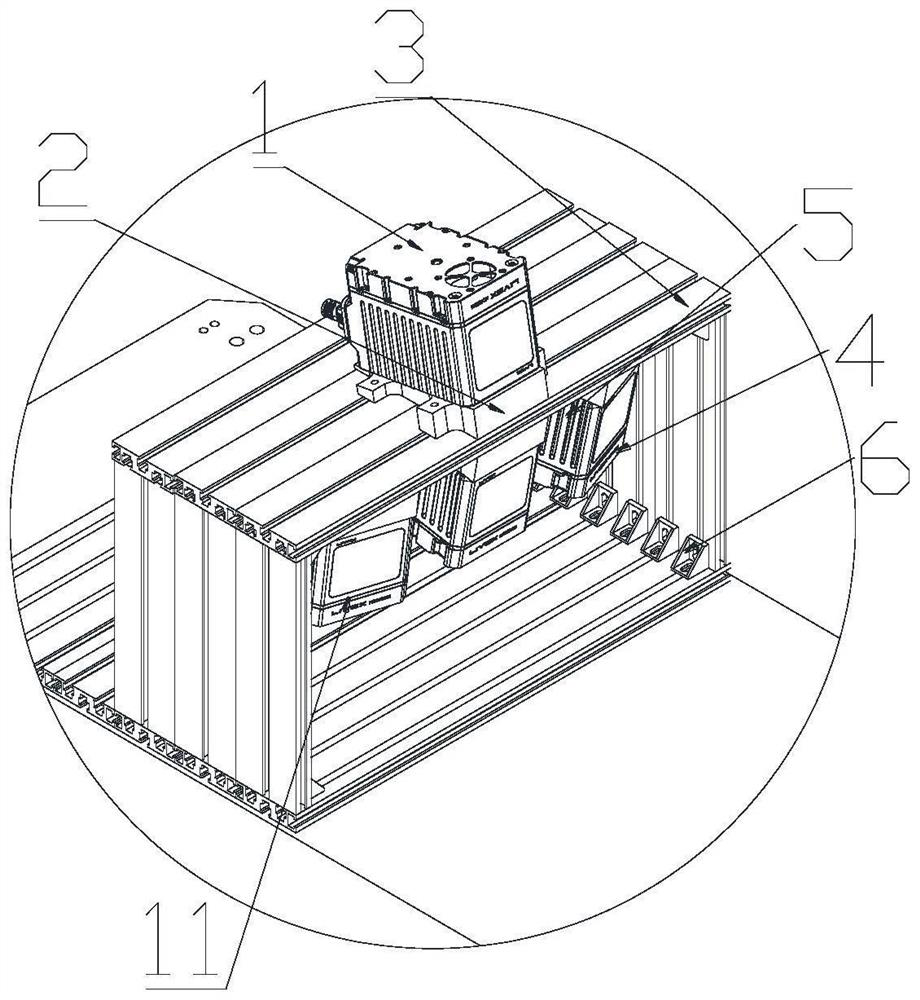

Mine autonomous three-dimensional surveying and mapping unmanned vehicle and surveying and mapping method

PendingCN113581320AAccurately doneEnsure safetyDetails involving processing stepsVehicle componentsPoint cloudEngineering

The invention relates to a mine autonomous three-dimensional surveying and mapping unmanned vehicle and a surveying and mapping method. The method comprises the steps: enabling a laser radar on the unmanned vehicle to collect the point cloud data of a current environment in real time during the advancing process of the unmanned vehicle in the mine, and transmitting the corresponding point cloud data to a host frame by frame; enabling the host to screen out high-value data points, and acquiring a plane feature point set and an edge feature point set according to the high-value data points; performing iterative pose optimization calculation to obtain the pose of the unmanned vehicle corresponding to the current frame, and creating a three-dimensional map of the current frame; and according to the three-dimensional map, planning an advancing route of the unmanned vehicle in real time, and according to the advancing route, controlling the unmanned vehicle to advance through a controller. The surveying and mapping task in the mine can be autonomously completed, and the efficiency and the precision are high.

Owner:福建飞虎无人机有限公司

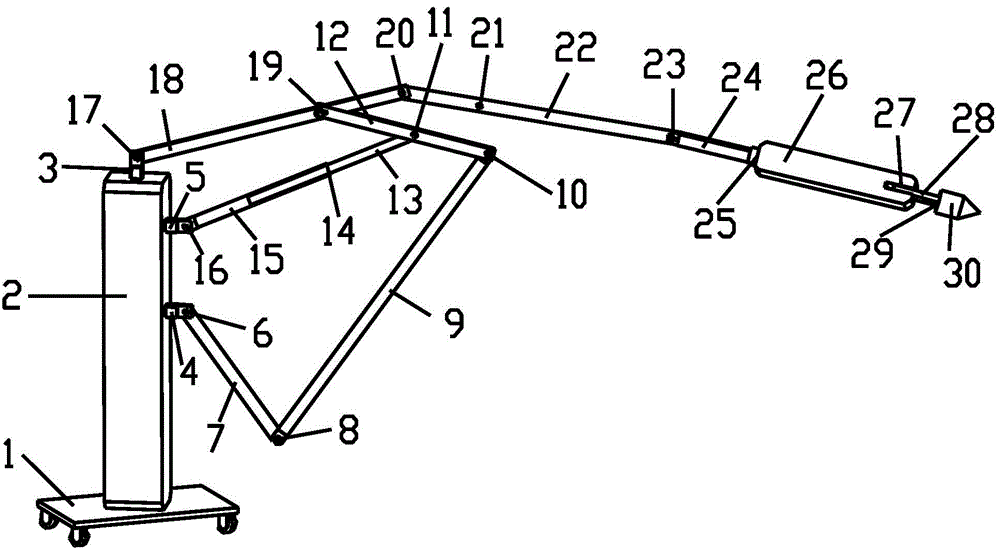

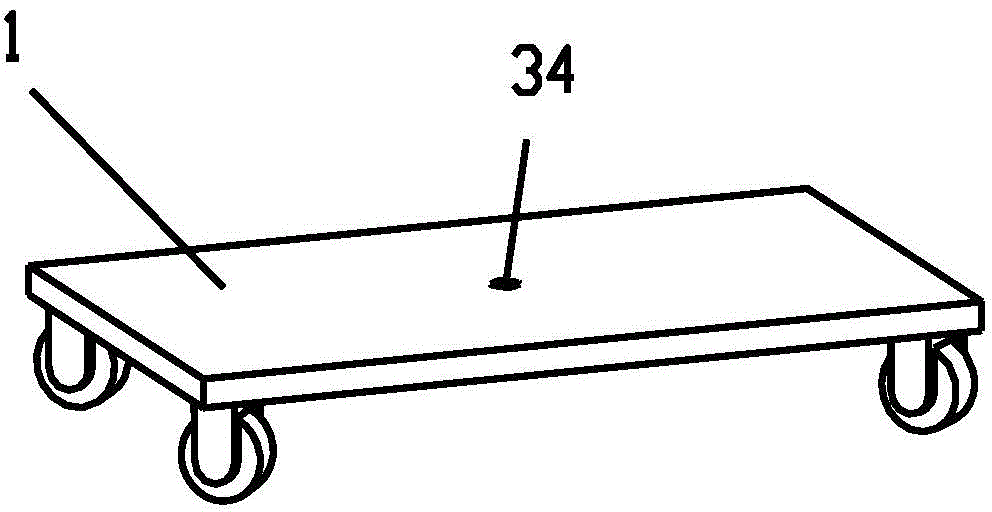

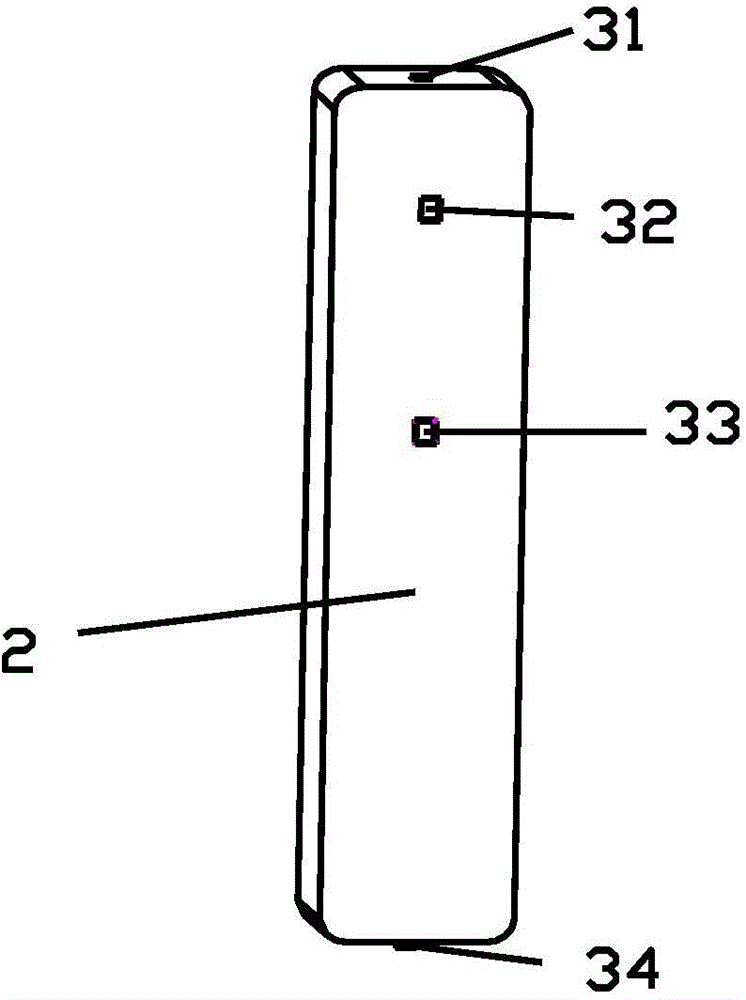

Hydraulic flexible robot joint and robot

PendingCN110614628AFlexible to completeEasy to completeProgramme-controlled manipulatorJointsManipulatorHydraulic cylinder

The invention belongs to the field of robots and particularly relates to a hydraulic flexible robot joint and a robot. The hydraulic flexible robot joint is composed of a power mechanism, a hydraulicallocation part and multiple sets of execution units. Each set of execution unit comprises organic arrangement of an execution mechanism of series-connected hydraulic cylinders which is composed of multiple hydraulic cylinder bodies. The flexible robot joint which can be prolonged or shortened optionally as required is provided. Each work is flexibly completed through the robot which is connectedwith a manipulator through a servo motor in front of the flexible robot joint.

Owner:陕西蓝智机器人有限公司

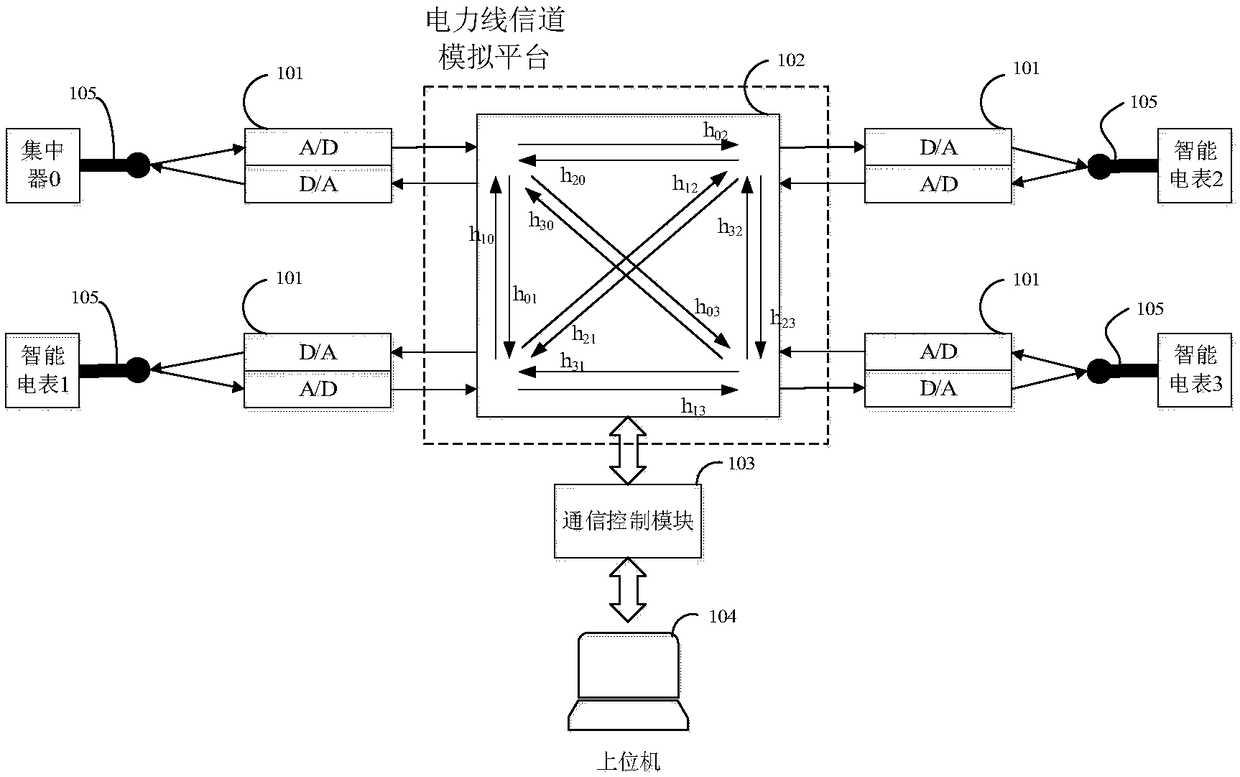

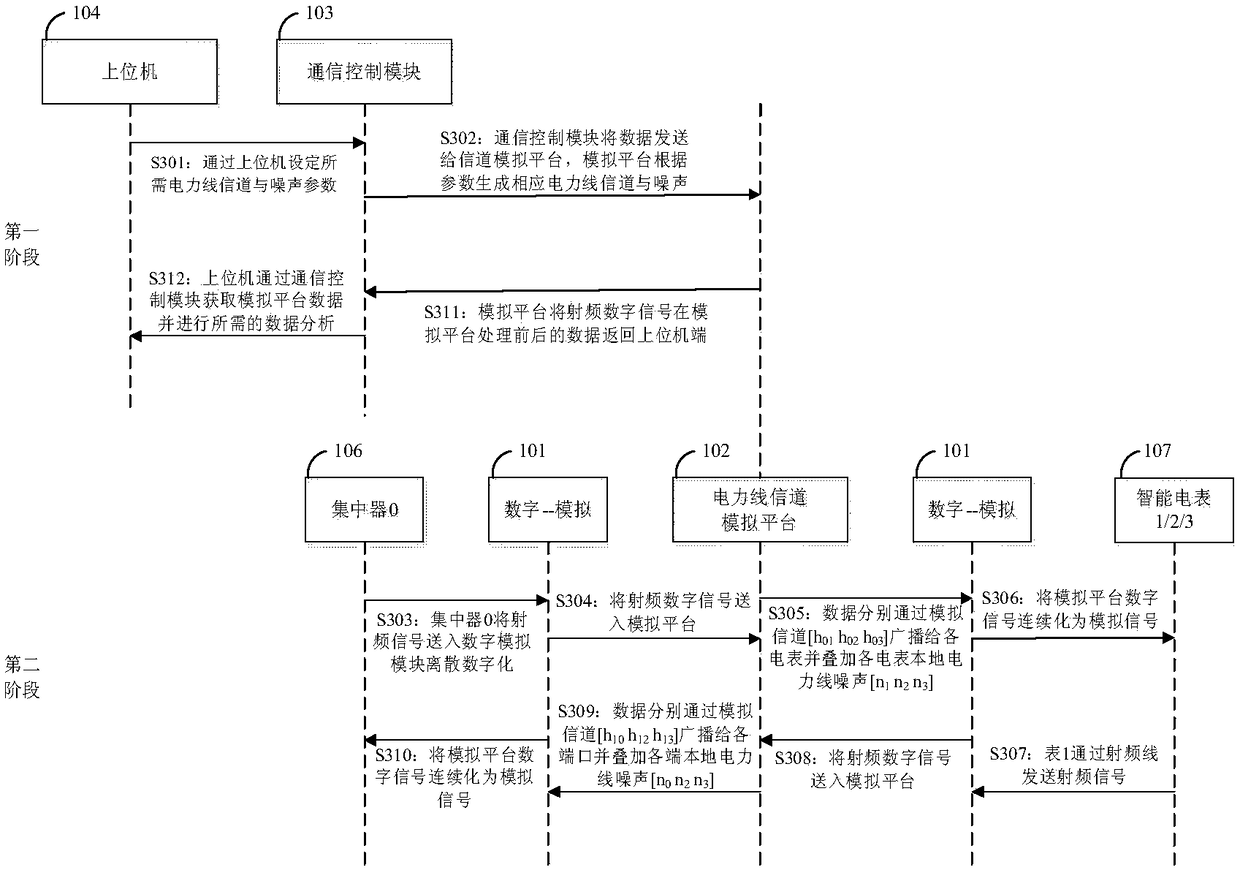

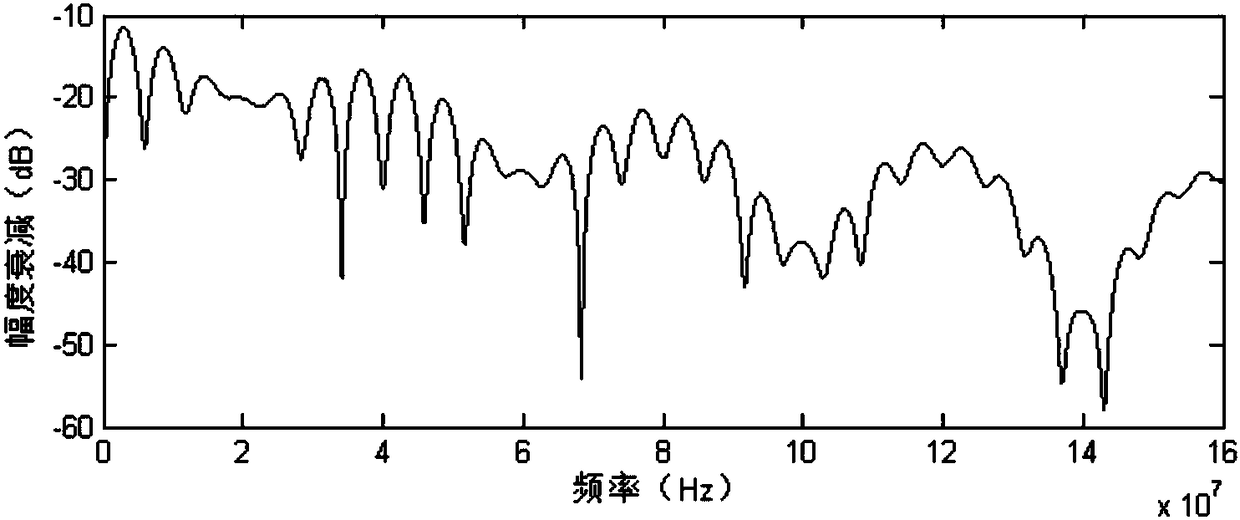

A digital power line channel simulation device and simulation method based on multi-port

ActiveCN106374975BEasy to completeAccurately doneElectric signal transmission systemsPower distribution line transmissionCarrier signalEngineering

The invention requests to protect a multiport-based digitalized power line channel simulation device and method. The device comprises a radio frequency line for forming a physical transmission medium for the uplink and downlink transmission of a radio frequency signal; a digital-analog signal conversion module for digitalizing a radio frequency analog signal of a power line carrier module or analogizing a digital signal output by a simulation platform; the power line channel simulation platform for constructing digitalized models of power line channels and noise between a concentrator and each ammeter or between different ammeters; a communication control module for realizing the communication of the power line simulation platform and an upper computer and the control of the communication; and the upper computer for realizing the configuration of the channel and noise parameters in the power line channel simulation platform and the monitoring of signal data. Through the adoption of the device and method provided by the invention, the working efficiency is further improved, and the problems of strong electromagnetic interference between the traditional simulation device cables, multiport noise devices and multi-impedance devices are solved at the same time; and a channel support is provided for forming a traceable and unified carrier module communication performance test standard.

Owner:王毅

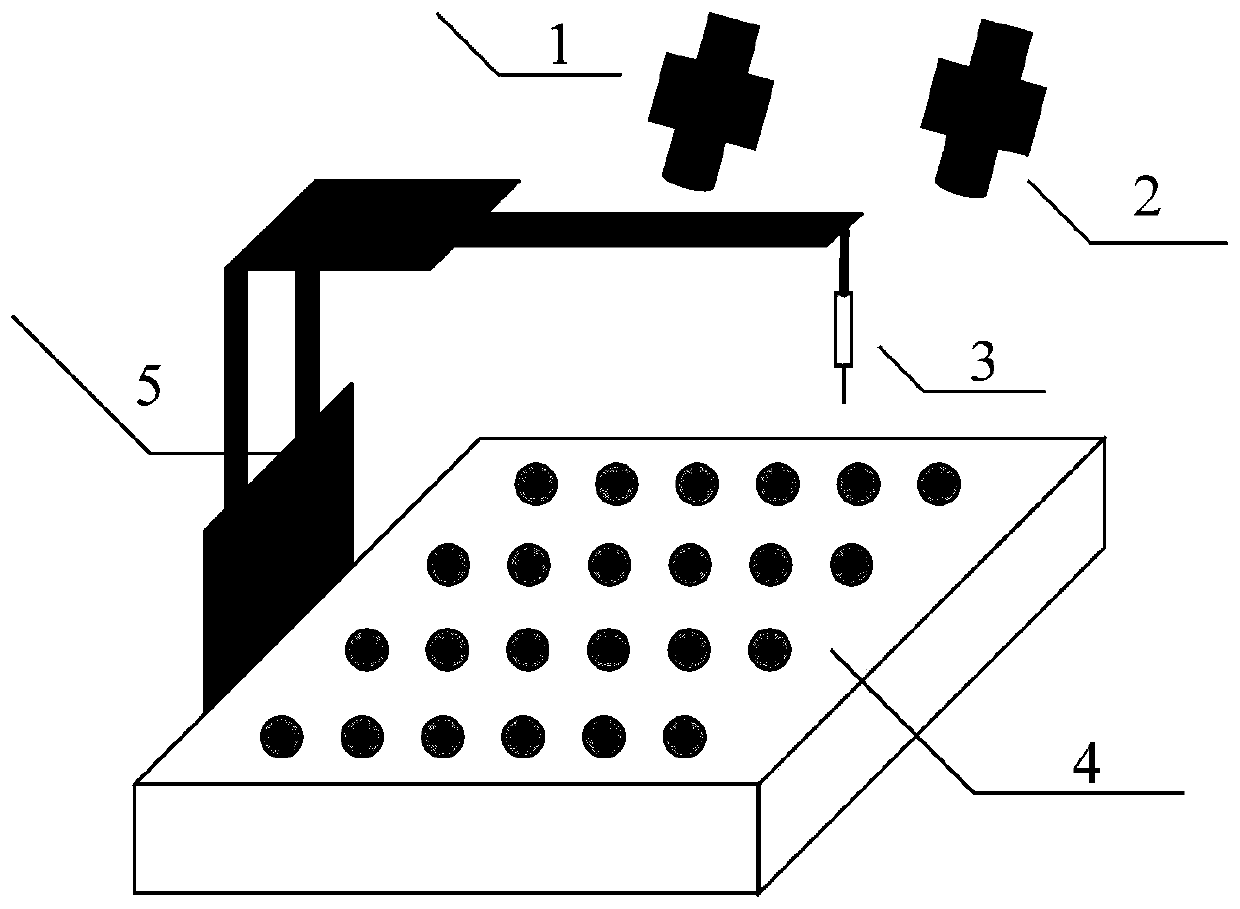

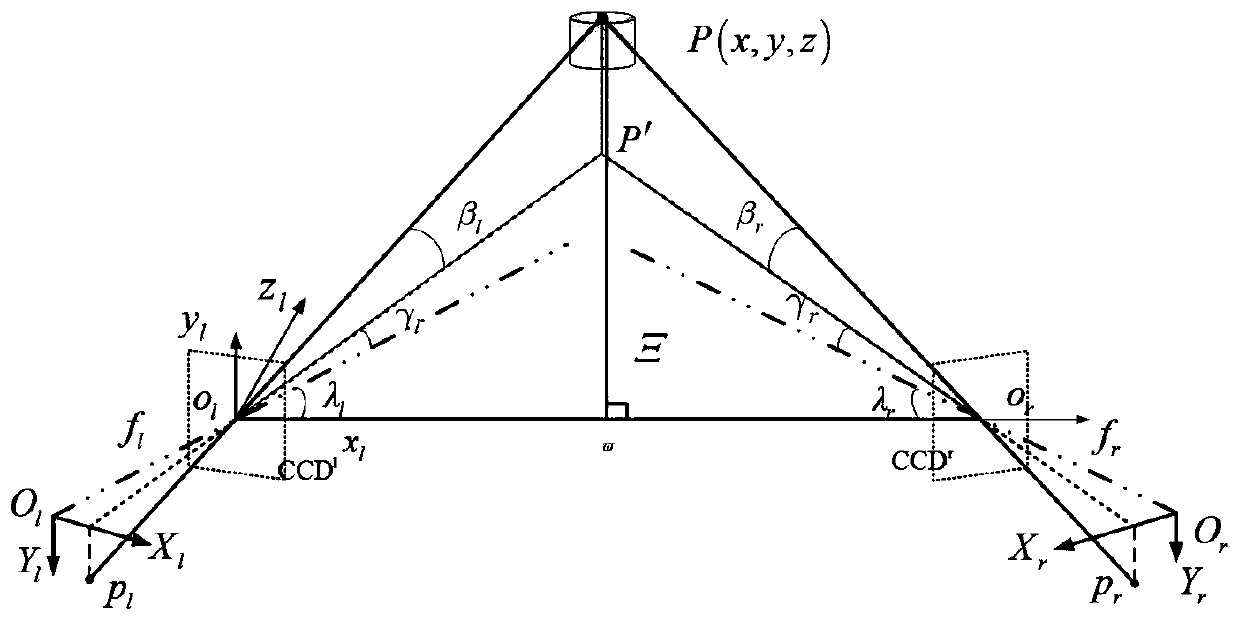

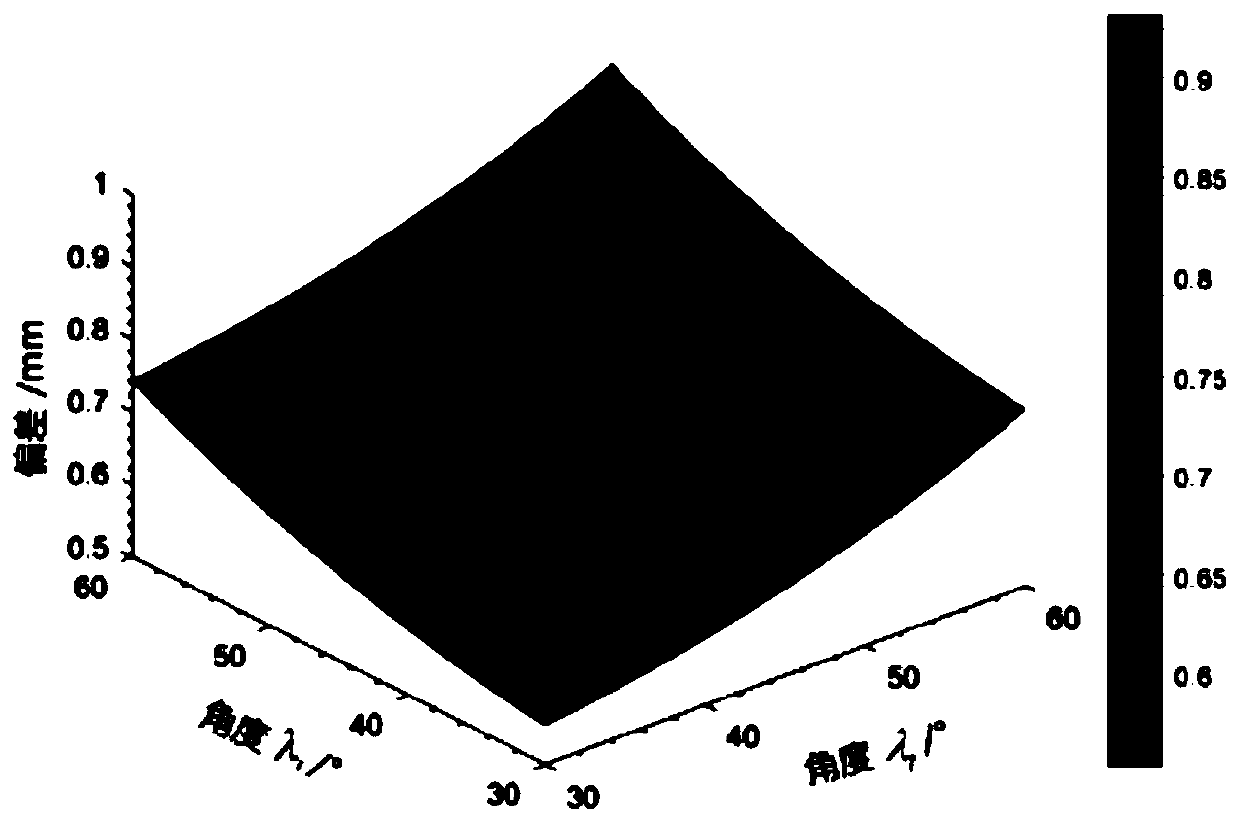

Bi-linear CCD-based dilutor spatial vision positioning deviation correction method

ActiveCN110332924AAccurately doneFinish quicklyPicture taking arrangementsPicture interpretationSpatial visionExecution unit

The invention discloses a bi-linear CCD-based dilutor spatial vision positioning deviation correction method. In view of the problems existing in the current dilutor, in order to improve the dilutor liquid dispensing accuracy and the efficiency, enhance the stability and the output value of the product in actual use and reduce or even eliminate instrument damages and accidents caused by positioning errors, a bi-linear CCD measurement mode is adopted to position a sample bottle on a dilutor platform. Through the method, high-precision positioning on the spatial position distribution of all sample bottles on a dilutor table by the linear CCD with common performance can be realized, and the position distribution information of the sample bottles is transmitted to a motion control unit of thedilutor, and thus, the system can accurately, quickly and flexibly complete a corresponding dilution task. The rapid effect achieved in the invention is embodied in the positioning system, the globalspatial distribution of the sample bottles is provided, and an execution unit can accelerate to directly reach the position of a task bottle rather than the traditional uniform progression while detection.

Owner:哈尔滨博觉科技有限公司

A wheeled mobile palletizing robot with controllable mechanism

ActiveCN104476539BFlexible to completeVersatile stage changeProgramme-controlled manipulatorClosed loopMulti degree of freedom

Owner:GUANGXI UNIV

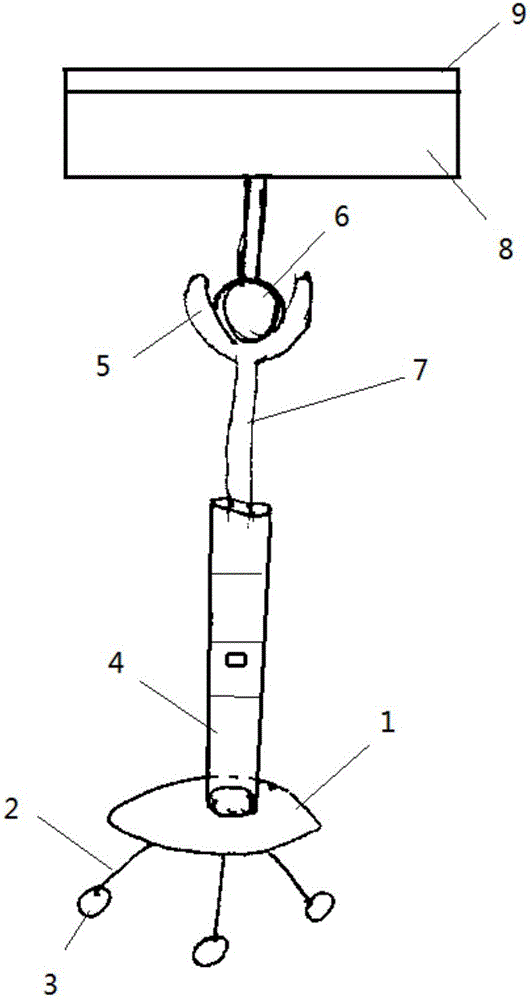

Elbow rest for ultrasonography doctor in examination and utilization method of elbow rest

InactiveCN106725603ASimple structureEasy to operateInfrasonic diagnosticsSonic diagnosticsEngineeringCushion

The invention discloses an elbow rest for an ultrasonography doctor in examination and a utilization method of the elbow rest. The elbow rest comprises a base, moving rollers are mounted at ends of connection rods which are arranged at the bottom of the base, a regulation supporting rod is arranged on the upper portion of the base, an elbow supporting seat is arranged in a U-shaped support which is arranged at the top end of the regulation supporting rod, and a rotating rod provided with an elbow cushion layer is arranged on a rotating rod which is connected to the elbow supporting seat. The elbow rest has advantages of simple structure, ingenious design and simplicity in operation and is capable of freely moving on the ground and sliding near and far according to requirements of the doctor, and the elbow rest is adjustable in height according to heights of examination beds so as to adapt to the elbow of the doctor, and rotating movements of the elbow can be completed flexibly.

Owner:AFFILIATED HOSPITAL OF ZUNYI MEDICAL COLLEGE

A schedule reminder method and mobile terminal

ActiveCN104717607BGuaranteed real-timeGuaranteed accuracyCommmunication supplementary servicesSubstation equipmentComputer terminalReal-time computing

Owner:ALIBABA (CHINA) CO LTD

A device and method for automatic configuration of a multi-mode and multi-function test instrument

ActiveCN109542481BFunction switching is simpleSync configurationProgram loading/initiatingExecution paradigmsComputer architectureAuto-configuration

The invention discloses an automatic configuration device and method for a multi-mode and multi-functional testing instrument, which belongs to the technical field of testing, and includes a remote upgrade server, a host program module, a bus interface online configuration manager, centrally processed FPGA, DSP, DDR3 memory, frequency Power board FPGA, power board FPGA and measurement board FPGA. The present invention adopts a more "reconfigurable" hardware platform architecture, which mainly includes a DSP cluster and an FPGA combination based on a central processing FPGA as the center. This combination structure can flexibly complete various algorithms, and the flexibility can also be guaranteed, not only The application program can be configured conveniently, and multiple FPGAs and multiple DSP programs can be automatically configured in real time. The configuration process is more flexible and efficient, and solves the problem of large amount of configuration data, data transmission speed, and synchronization between states during the configuration process.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

Quadcopter-Based Air Quality Detector

ActiveCN104149982BExpand the detection rangeFlexible to completeAircraft componentsPosition/course control in three dimensionsMicrocontrollerAutomatic control

An air quality detector based on a quadcopter comprises the quadcopter and control systems. The quadcopter mainly comprises a mechanical arm, a main engine body, a containing platform, a machine body cavity, a propeller, a foot stand, a camera pan-tilt and the like, the control systems comprise an onboard control system and a ground control system, the onboard control system comprises a posture measuring unit, an application measuring unit and an onboard microcontroller, and the ground control system comprises a manual control unit and an automatic driving control center. The quadcopter stable in flying and good in controllability is adopted to be carried with a camera and the detector, the quadcopter can be controlled by a ground remote control unit, meanwhile, automatic control can be achieved, the detecting range can be expanded, multi-index detection on air quality is carried out at different heights and different positions of the low altitude, the indexes are transmitted to the ground to be received, and the air quality detector has the advantages of being small in size, light, low in cost, low in requirement for the flying airspace, safe, reliable, flexible and efficient.

Owner:SHAANXI UNIV OF SCI & TECH

A metamorphic wheeled mobile welding robot with controllable mechanism

ActiveCN104552243BLarge working spaceHigh Motion RedundancyProgramme-controlled manipulatorWelding/cutting auxillary devicesClosed loopMulti degree of freedom

Owner:GUANGXI UNIV

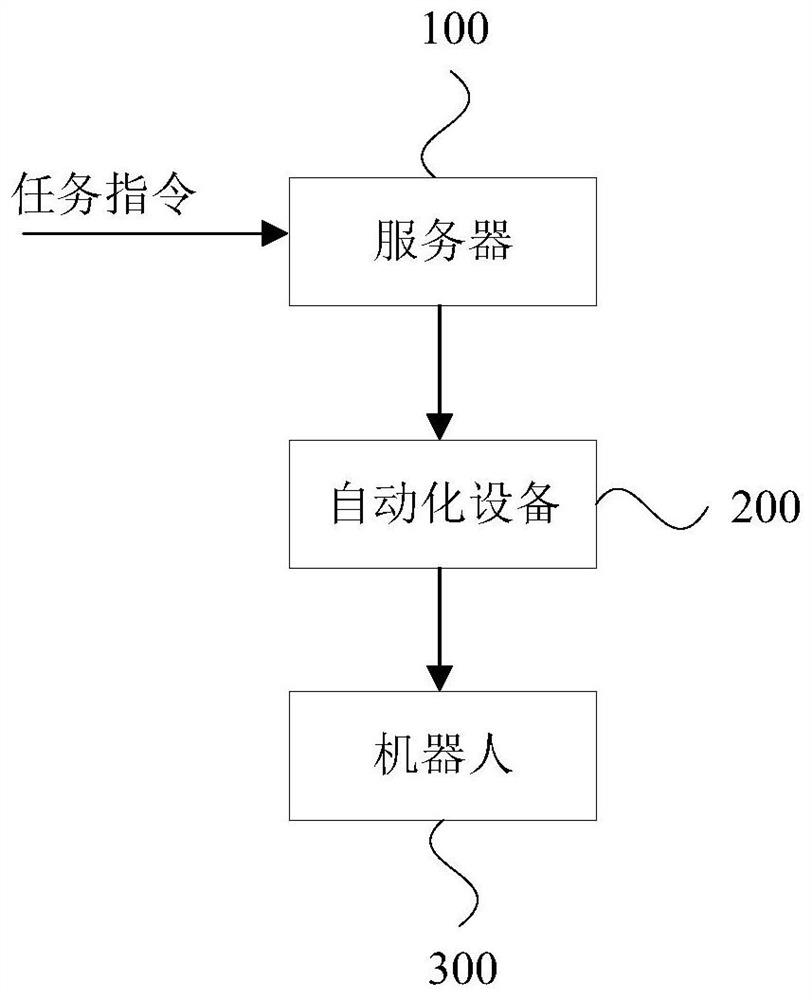

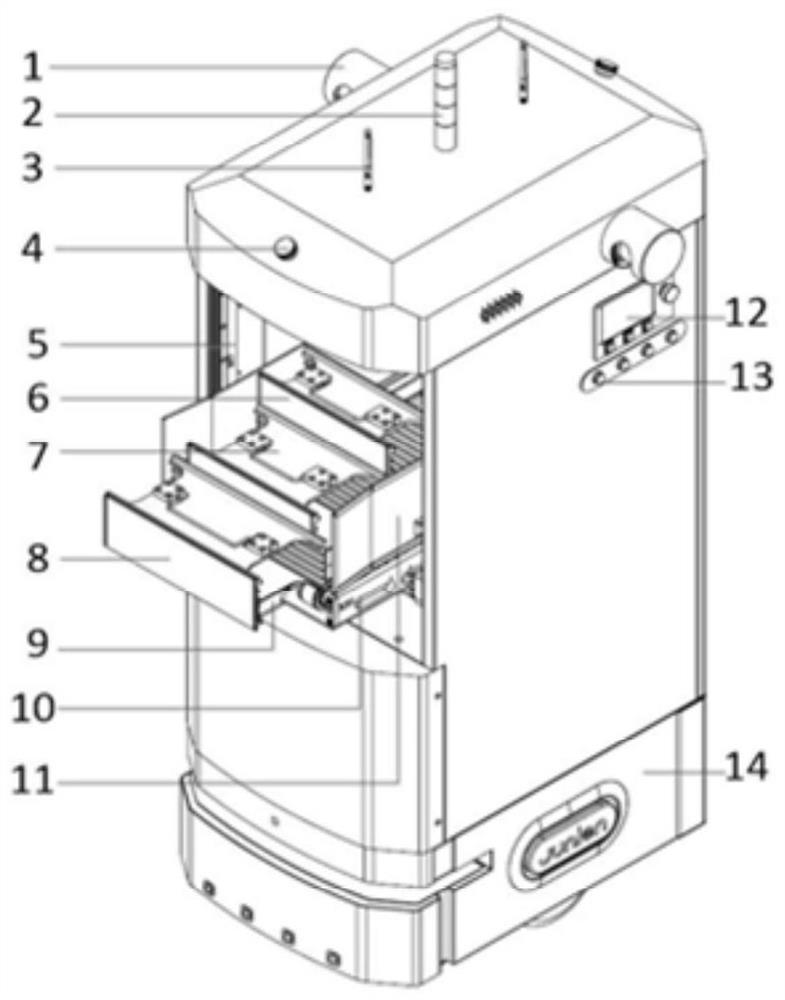

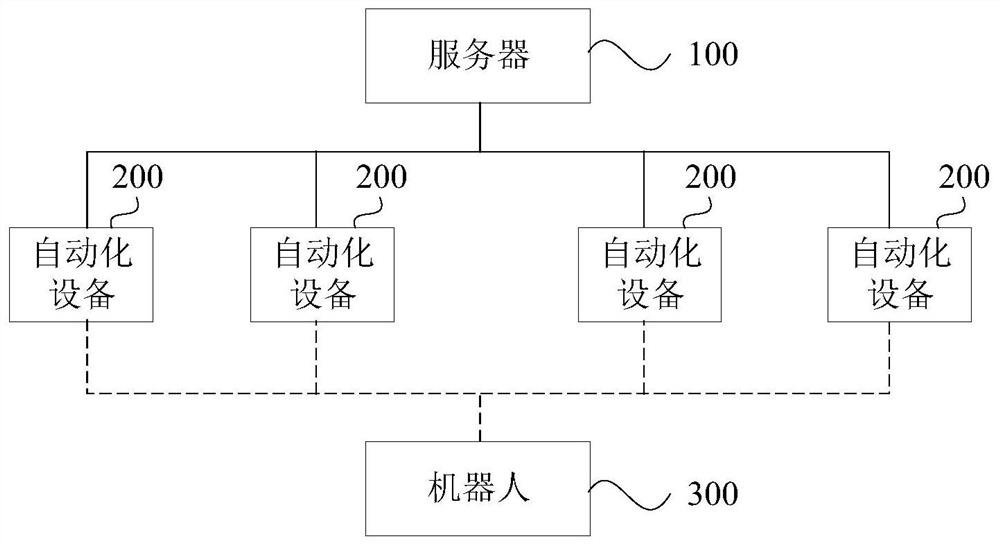

Macroscopic deployment robot system and method for dust-free workshop

ActiveCN113219979AComplete efficientlyAccurately donePosition/course control in two dimensionsRobotic systemsMacroscopic scale

The embodiment of the invention discloses a macroscopic deployment robot system and method for a dust-free workshop. The macroscopic deployment robot system for the dust-free workshop comprises a server used for receiving a task instruction; automation equipment which comprises a first infrared device, wherein the automation equipment is in communication connection with the server and receives the task instruction; a robot which comprises a laser scanner and a second infrared device, wherein the laser scanner is matched with the reflector to determine absolute coordinates of the robot, wherein the first infrared device and the second infrared device transmit task instructions through infrared communication; the robot comprises a robot end charging interface; a charging pile which is in communication connection with the server and receives the task instruction, wherein the communication end of the charging pile end charging interface is electrically connected with the communication end of the robot end charging interface; and the robot receives the task instruction through the charging pile. Compared with the prior art, the embodiment of the invention adopts a new navigation mode to replace the existing magnetic stripe navigation mode, and realizes the macroscopic deployment of the robot in the dust-free workshop.

Owner:LUXSHARE ELECTRONICS TECH (KUNSHAN) LTD

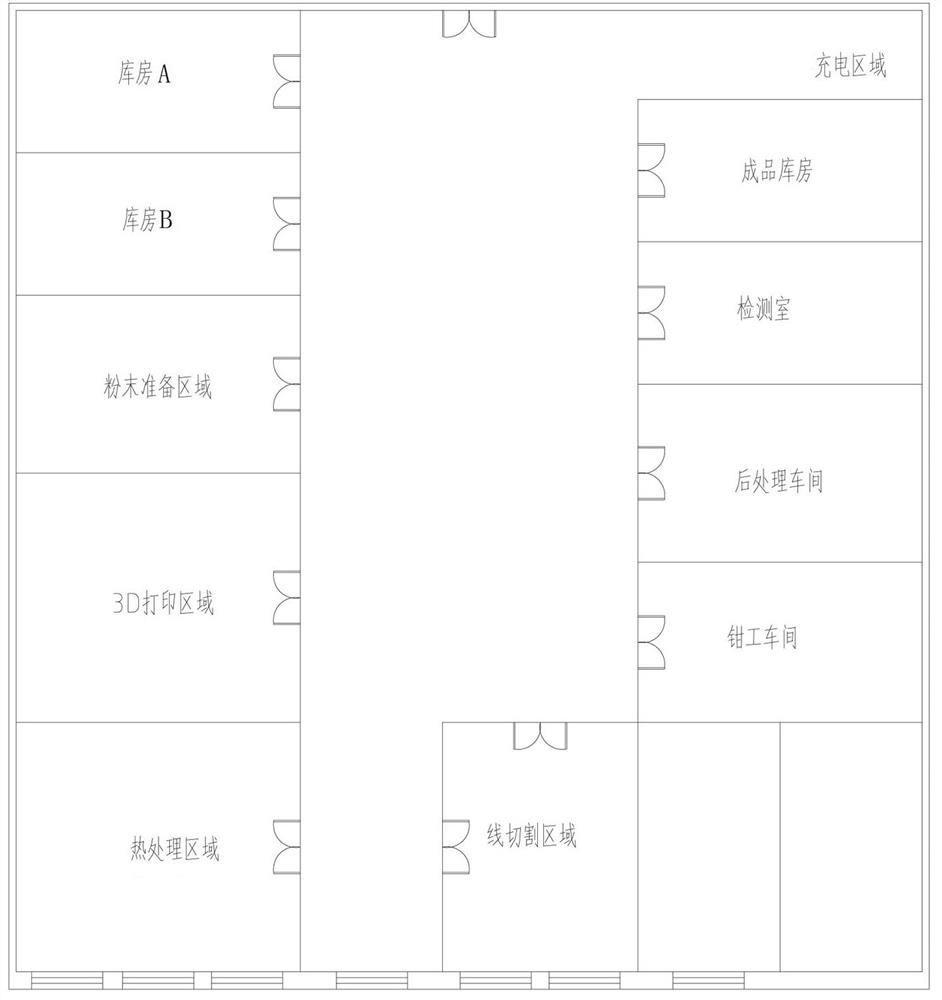

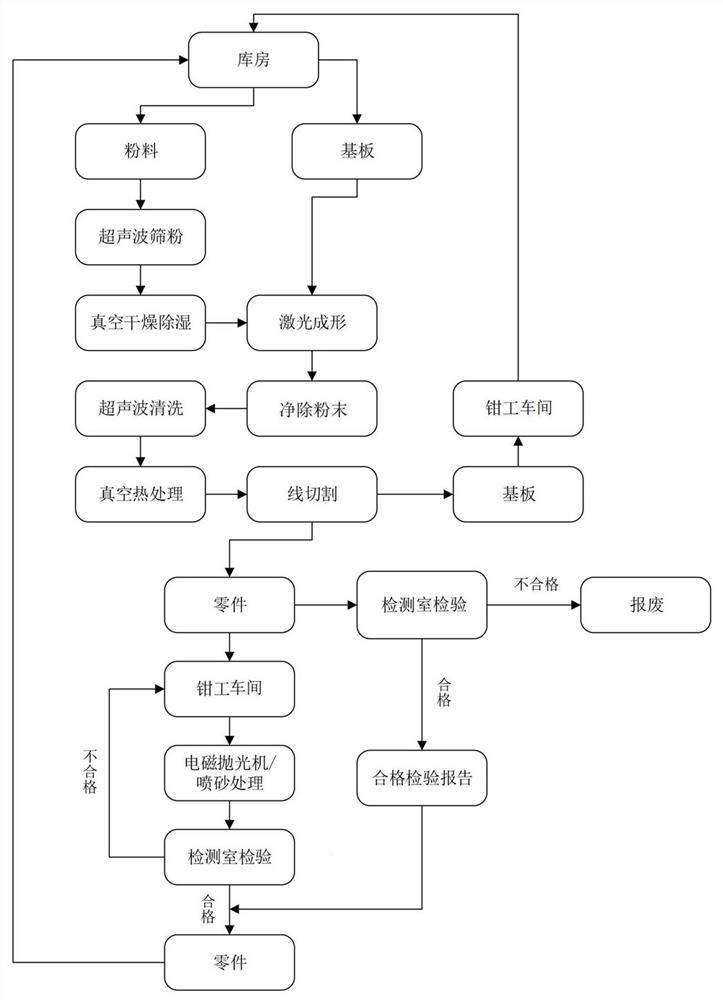

3D printing workshop based on additive manufacturing industry internet platform

PendingCN114801162AImprove transmission efficiencyComplete efficientlyAdditive manufacturing apparatus3D object support structuresLogistics managementSand blasting

According to the 3D printing workshop based on the additive manufacturing industry internet platform, an AGV conveys powder to a powder preparation area, treated powder and a substrate are conveyed to a 3D printing area to produce parts, the parts are conveyed to a heat treatment area to be subjected to heat treatment, the parts subjected to heat treatment are conveyed to a linear cutting area to be cut and separated, and the AGV conveys the parts and the substrate separately; and the parts are conveyed to a bench worker workshop to be treated, subjected to ultrasonic cleaning, polishing or sand blasting treatment in a post-treatment workshop and conveyed to a detection room to be detected, and qualified parts are conveyed to a finished product warehouse to be registered and put in storage. The AGV trolley is used for completing material carrying, the carrying route is adjusted along with the production technological process, manpower is saved, logistics management is improved, the material conveying efficiency is improved, and safety is improved; the AGV trolley transmits the information to the Internet platform, so that the working state of the trolley can be mastered conveniently, the information feedback time is shortened, the equipment utilization rate and the production efficiency are improved, the cost is reduced, and the benefit is improved.

Owner:山东变量空间科技有限公司

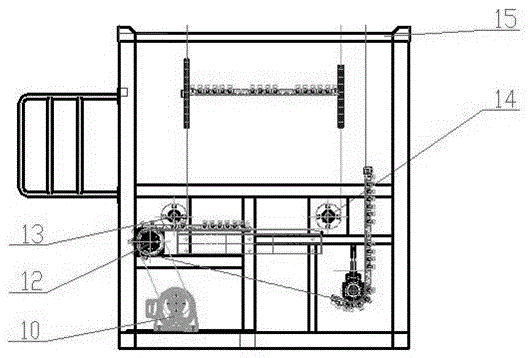

Mechatronic continuous hoist

InactiveCN103693370BConsecutive completionReliable completionConveyorsControl devices for conveyorsTop driveCarton

Owner:DALIAN JIALIN EQUIP MFG

A moving robot

ActiveCN108724213BReduce manufacturing costIncrease load capacityManipulatorPhysical medicine and rehabilitationMedical equipment

The invention relates to a transferring robot. The transferring robot solves the existing technical problems that when people with mobility inconvenience are transferred and carried by manual work, the burden on nursing staff is increased, and the safety is low. The transferring robot comprises a left mechanical arm, a right mechanical arm and a chassis, wherein the left mechanical arm is providedwith a left bearing pallet, and the right mechanical arm is provided with a right bearing pallet. The transferring robot is widely used in the technical field of medical equipment.

Owner:HARBIN INST OF TECH AT WEIHAI

Micro instrument terminal based on module joint and used for minimally invasive surgery robot

ActiveCN102488554BFlexible to completeThe total length of the closed-loop transmission remains unchangedDiagnosticsSurgical robotsEngineeringSacroiliac joint

The invention discloses a micro instrument terminal based on module joints and used for a minimally invasive surgery robot. The micro instrument terminal comprises a rotary module of a first four-bar mechanism consisting of a module top end part, a module bottom end part, a lower support and first left and right connection pieces, and a rotary module of a second four-bar mechanism consisting of amodule top end part, a rotary connection shaft, an upper support and second left and right connection pieces; two ends of a first steel wire rope are connected with the top surfaces of the module topend parts, and the other two ends of the first steel wire rope are sequentially connected with a first rotary actuating device through the module bottom end part; two ends of a second steel wire ropeare connected with a rotary connecting shaft, and the other two ends of the second steel wire rope are sequentially connected with the first rotary actuating device through the module top end parts and the module bottom end part; and the upper part of the rotary connecting shaft is inserted into the central hole of a rotary rod and is in clearance and running fit with the rotary rod, and the rotary rod is connected with a surgery apparatus. Complex surgery can be more flexibly completed by adopting the device.

Owner:SHANDONG WEIGAO SURGICAL ROBOT CO LTD

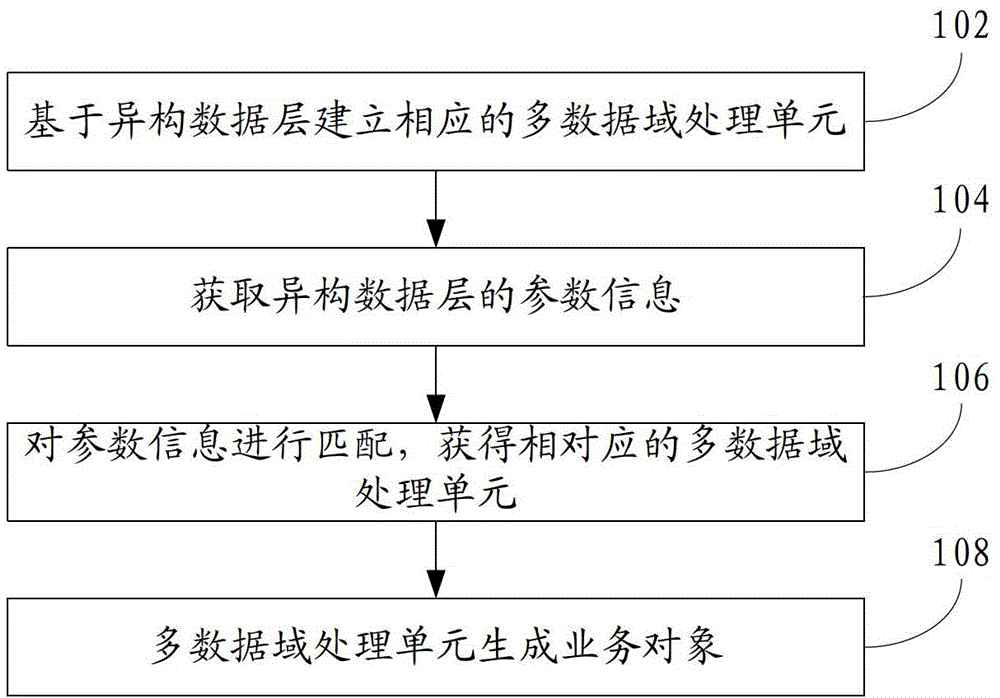

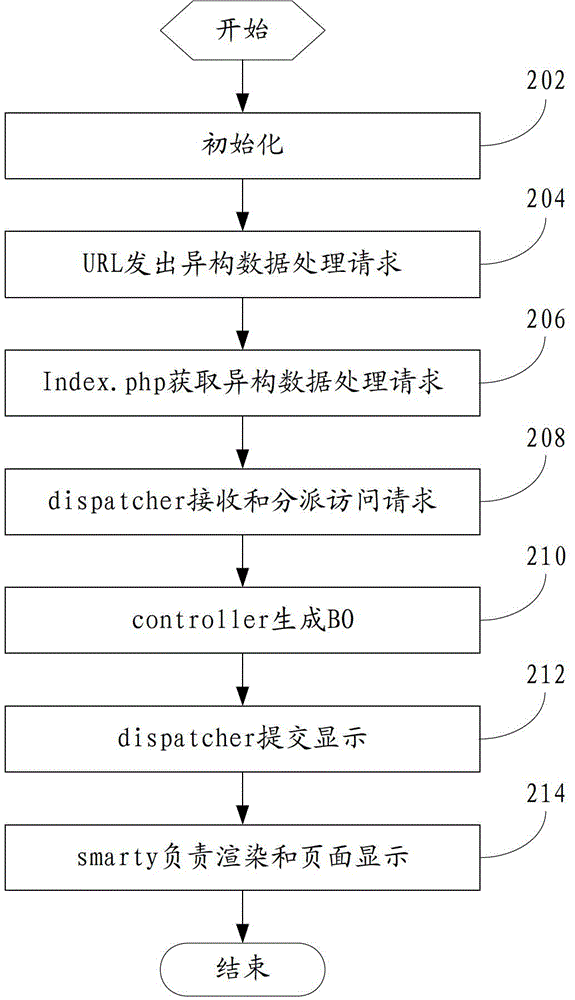

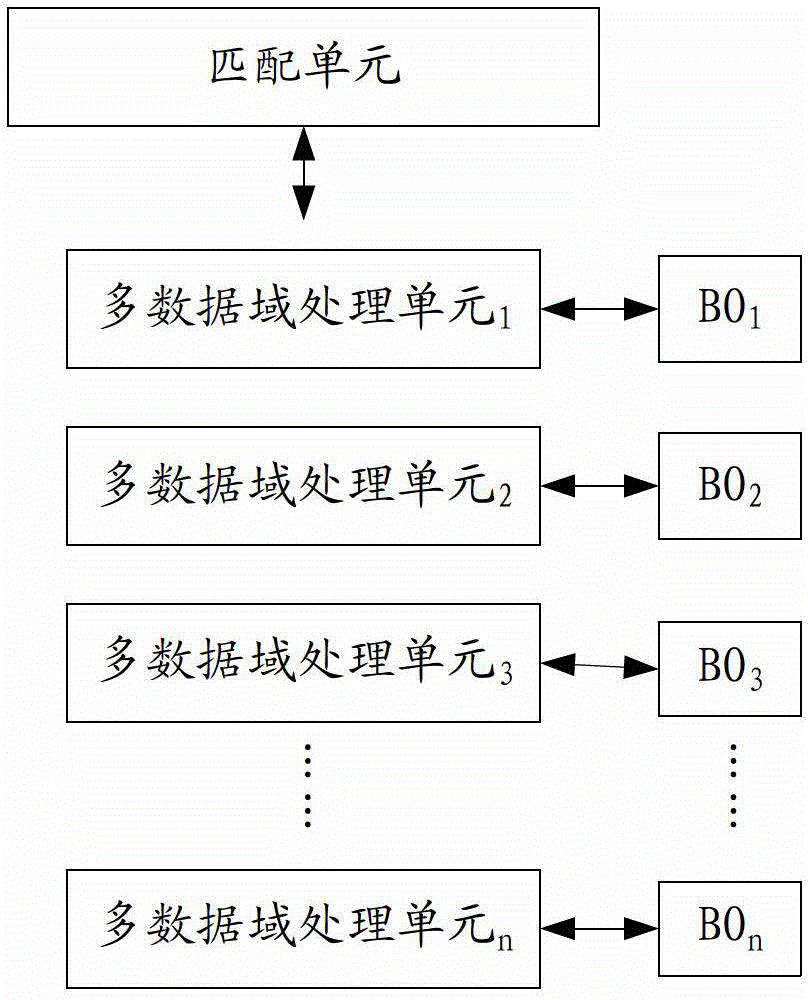

A heterogeneous data processing method and device

ActiveCN102855280BHandle scene simplificationFlexible to completeSpecial data processing applicationsData operationsData field

The invention discloses a heterogeneous data processing method and a device. The method includes that a plurality of corresponding data field processing units are established on the basis of heterogeneous data layers; parameter information of the heterogeneous data layers is acquired; the parameter information is matched to obtain a plurality of corresponding data field processing units; and the plurality of data field processing units generate service objects, and the service objects comprise data operation objects. The invention further discloses a heterogeneous data processing device. According to the heterogeneous data processing method and the device, parameters of the heterogeneous data layers are matched, and the plurality of corresponding data field processing units are found to generate the service objects, so that processing scenes of the heterogeneous data layers are simplified, processing details of a plurality of data fields can be avoided during data layer development stages, developers can finish development work as flexibly and conveniently as develop applications of single data layers and are not interfered by trivial details brought by a plurality of field scenes, and development efficiencies are guaranteed.

Owner:BEIJING ERENEBEN INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com