Electric lifting travelling mechanism

A walking mechanism and lifting type technology, applied in the field of electric walking mechanism, can solve the problems of difficult crop management, high labor intensity, small adjustment range, etc., and achieve the effect of simple structure, high degree of automation, and large height adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings, but the content of the present invention is not limited thereto.

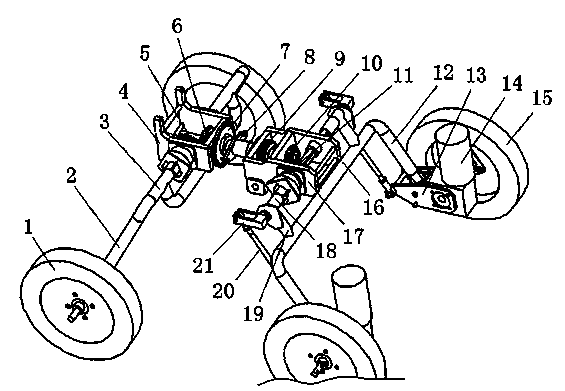

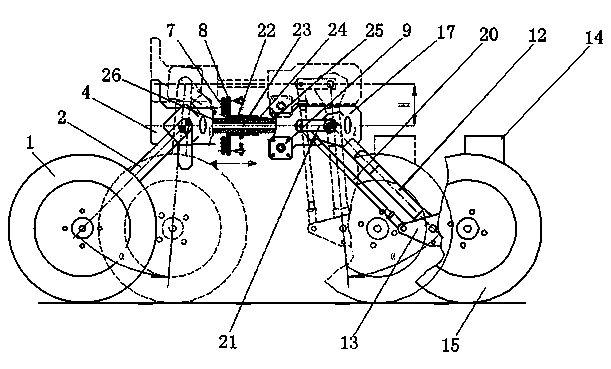

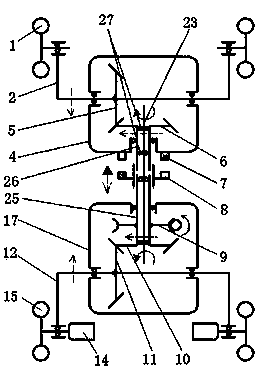

[0024] Such as figure 1 , figure 2 , image 3 , the lifting type electric running mechanism provided by the present invention comprises two front wheels 1 and two rear wheels 15, wherein the two rear wheels are driving wheels 15, and the two front wheels 1 are respectively fixed on two vertical rods of the front gantry 2 lower ends, two rear wheels 15 are respectively fixed on the lower ends of the two vertical rods 12 of the rear gantry, the front gantry is connected with the front axle sleeve 26 through the front right angle steering piece, and the rear door shape is connected with the rear axle sleeve 25 through the rear right angle steering piece Connected, the rear axle sleeve 25 is provided with the main transmission part, the front and rear axle sleeves 26, 25 are connected through the clutch as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com