Mechatronic continuous hoist

A hoist, electromechanical technology, applied in conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of affecting the service life of equipment, affecting the lifting efficiency, and heavy conveying platform, achieving simple structure, high conveying efficiency, The effect of a high degree of mechanical modularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

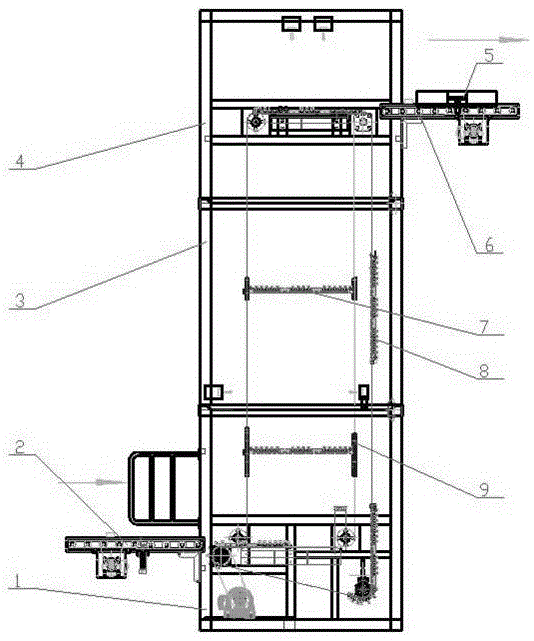

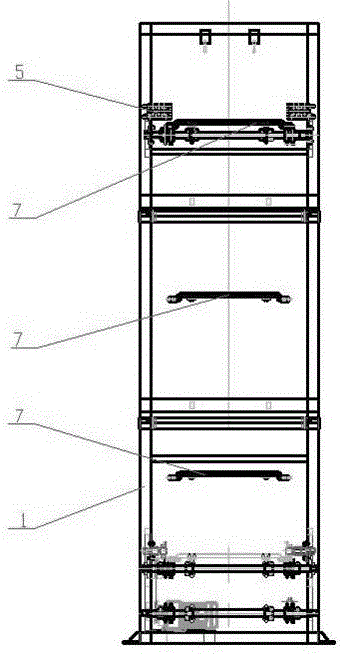

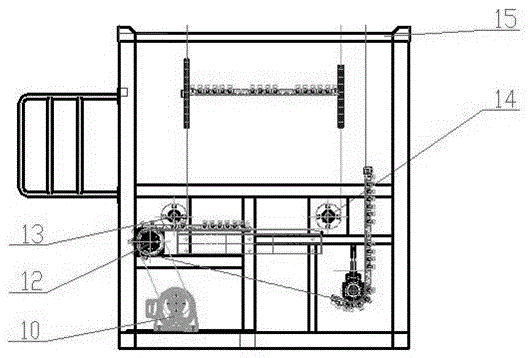

[0022] Such as Figure 1-Figure 10 As shown, the electromechanical integration continuous hoist includes a bottom driving unit 1, a feeding conveying unit 2, a top driven unit 4, a material sorting mechanism 5 and a discharging conveying unit 6, and the bottom driving unit 1 and the top driven unit A middle bracket part 3 is installed between the units 4, a feed conveying unit 2 is installed on the outside of the bottom driving unit 1, and a discharge conveying unit 6 is installed on the outside of the top driven unit 4. The discharge conveying A material arrangement mechanism 5 is installed on the unit 6, and a lifting tray part 7 is installed on the bottom active unit 1, the middle support part 3, and the top driven unit 4, and the bottom active unit 1, the middle support part 3, The inside of the top driven unit 4 is equipped with a left guide chain 8 and a right guide chain 9. The bottom active unit 1 includes a bottom frame body 15 and a pallet in place photoelectric dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com