Metal liquid degassing and deslagging device

A metal liquid and storage device technology, applied in the field of impurity gas devices and devices for removing impurities in metal liquid, can solve the problems of unsatisfactory casting quality and internal microstructure, difficulty in forming a sedimentation process, and ineffective slag removal, etc. , to achieve the effect of low cost, avoiding high labor intensity, and compact and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

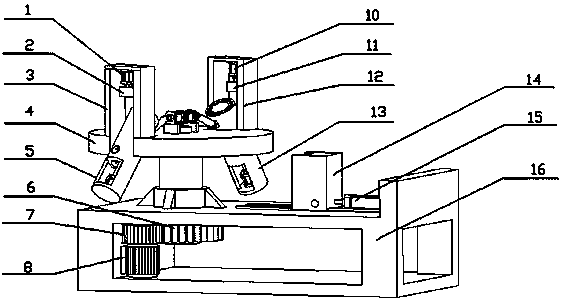

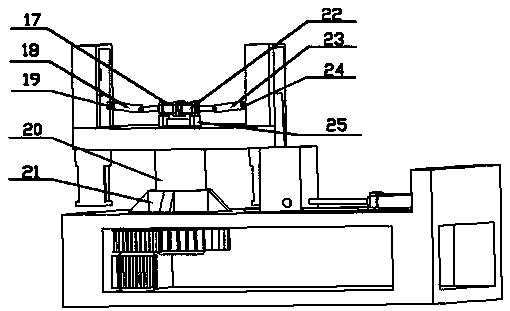

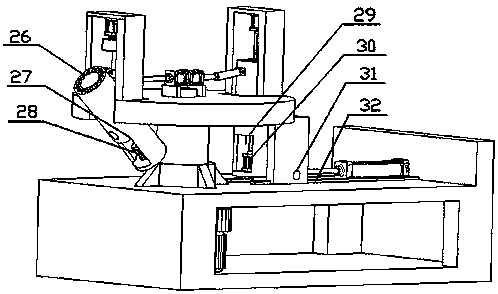

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0025] A metal liquid degassing and slag removal device described in this embodiment is as follows: Figure 1-Figure 5 As shown, it includes unloading unit, lock groove part, slurry storage device, rotating part, conveying part and base. The unloading unit is composed of hydraulic cylinder I1, hydraulic cylinder II10, plane piston I2, plane piston II11, unloading bracket I3, unloading bracket II12; unloading bracket I3 and unloading bracket II12 are respectively welded on the rotating parts The two opening positions of the turntable 4, the hydraulic cylinder I1 and the hydraulic cylinder II10 are vertically fixed on the inner side of the upper plate of the unloading support I3 and the unloading support II12 respectively, and the plane piston I2 and the plane piston II11 are respectively driven by the hydraulic cylinder I1 and the hydraulic cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com