An automatic production line for semi-solid processing

An automatic production line, semi-solid technology, applied in the field of metal semi-solid processing, can solve the problems of difficult to guarantee product quality, low production efficiency, high labor intensity, etc., and achieve the effect of product quality assurance, convenient operation and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

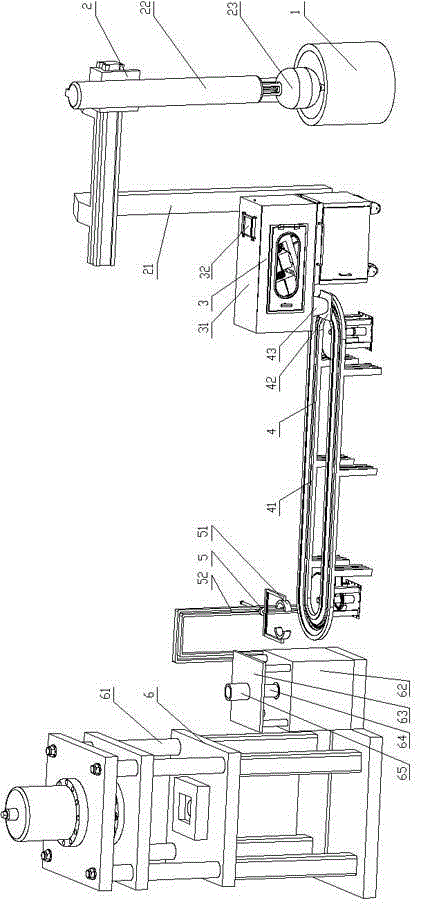

[0021] as attached figure 1 As shown, the semi-solid processing automatic production line of the present invention consists of a smelting furnace 1, a metal melt injection machine 2, a semi-solid slurry preparation device 3, a slurry delivery device 4, a manipulator device 5, and extrusion forming equipment 6 composition.

[0022] The melting furnace 1 is a resistance melting furnace, arranged at the starting station of the production line, and used for melting metal ingots.

[0023] The molten metal filling machine 2 is mainly composed of a frame 21 and a lifting and retrieving mechanism 22. The lifting and retrieving mechanism 22 is installed on the guide rail of the frame 21 and can move horizontally along the guide rail 21. The lower part is A closed tank body 23, the tank body 23 is equipped with a valve, by controlling the opening of the valve, the injection of molt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com