A liquid level controller for vacuum calibrating tank for pipe production

A liquid level controller and vacuum shaping technology, applied in liquid level control, non-electric variable control, control/regulation system, etc., can solve the problem of high-efficiency and continuous production of pipes, low control accuracy, and inconvenient observation and later maintenance. and other problems, to achieve the effect of improving monitoring accuracy, efficient completion, and convenient observation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

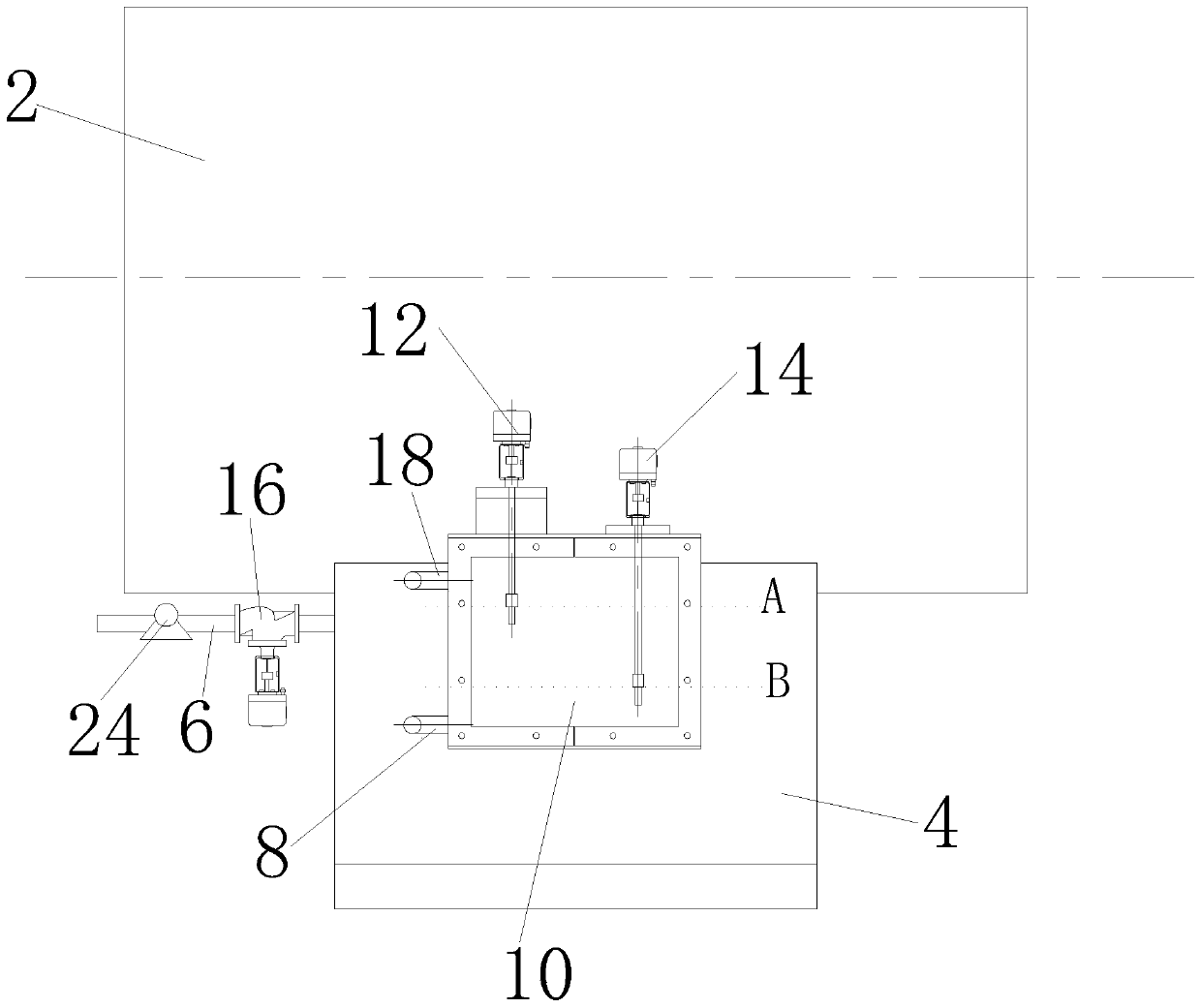

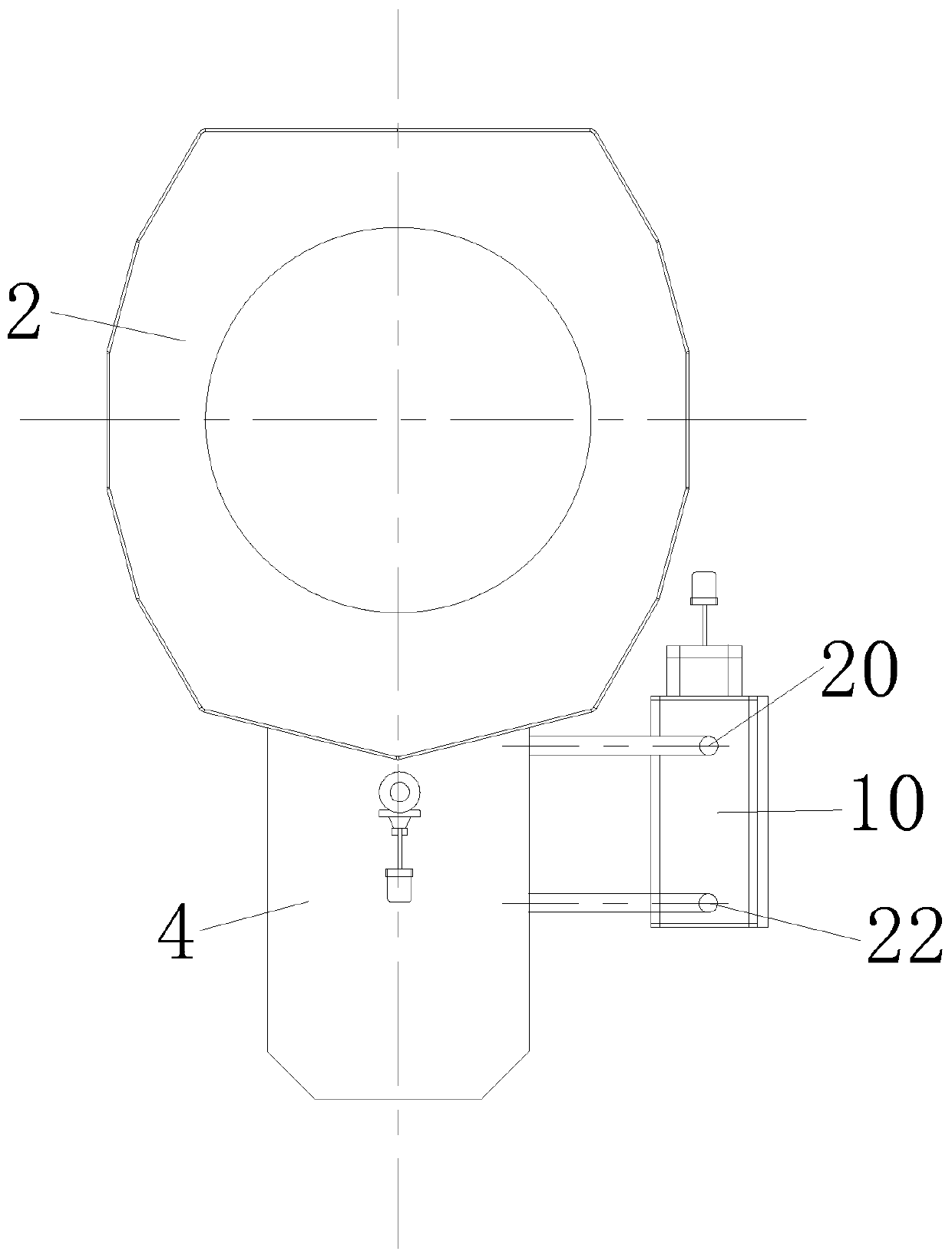

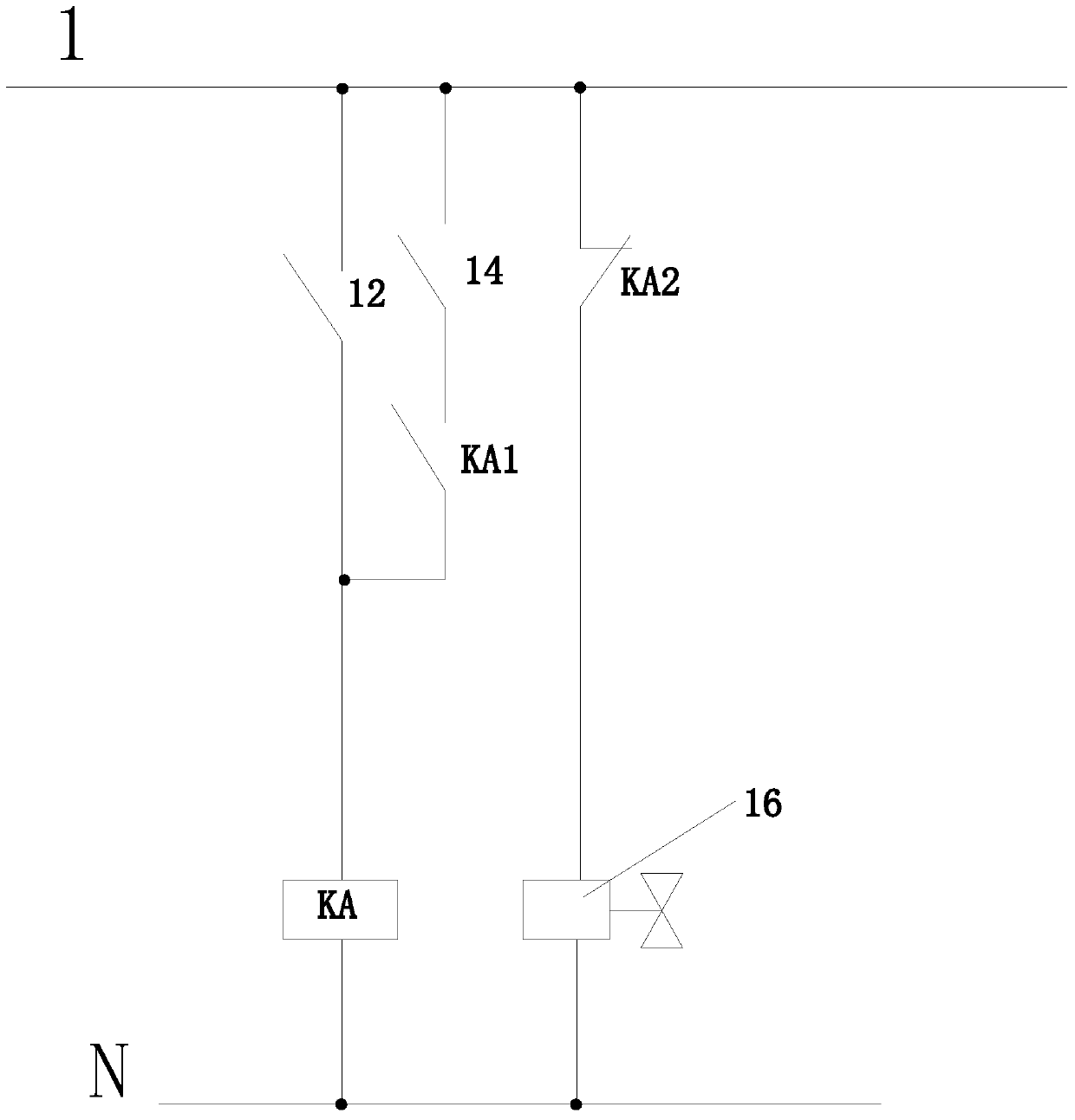

[0020] Such as figure 1 , 2 As shown, this embodiment discloses a vacuum calibrating tank liquid level controller for pipe production, including a vacuum calibrating tank 2, a water tank 4 and a liquid level control box 10 connected in sequence, wherein the control liquid level control box 10 Identical with the air pressure in the water tank 4, a water inlet pipe 6 is connected with the water tank 4 for supplying new water in the water tank 4, and the water inlet pipe 6 is provided with a pipeline electromagnetic valve 16, and the water tank 4 is provided with a There are upper limit liquid level A and lower limit liquid level B. The upper limit liquid level A and the lower limit liquid level B can be set according to the needs of actual processing and production. There is no limit here. In general production, it is a combination of continuous production and resource conservation. Consider, usually the upper limit liquid level A is set as 75% of the highest liquid level of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com