Micro instrument terminal based on module joint and used for minimally invasive surgery robot

A surgical robot and minimally invasive surgery technology, applied in the field of minimally invasive surgical robot medical equipment, can solve the problems of reducing the reliability and safety of surgical instruments, the layout of degrees of freedom is not flexible enough, and increasing design costs, etc., to achieve easy assembly , large clamping force, and the effect of increasing the size of the wire rope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

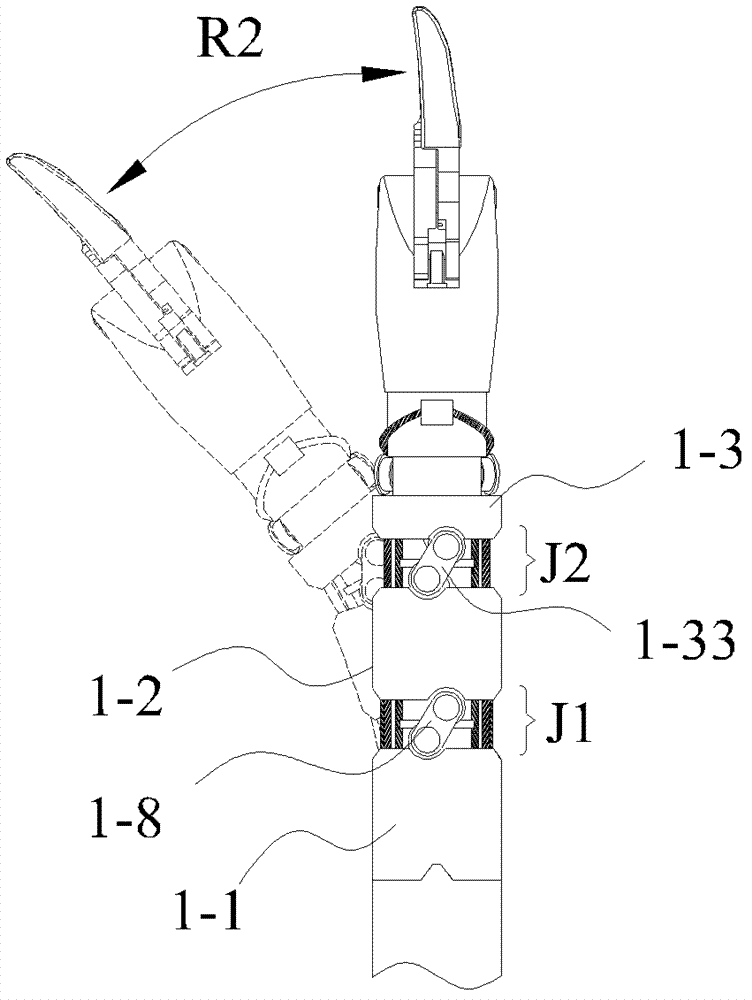

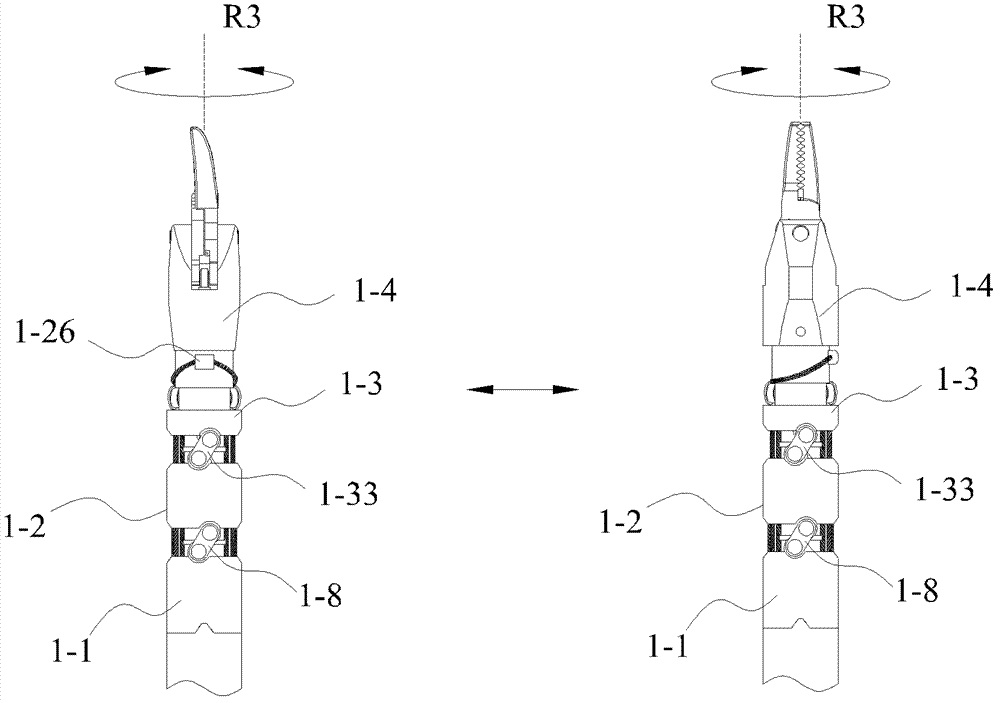

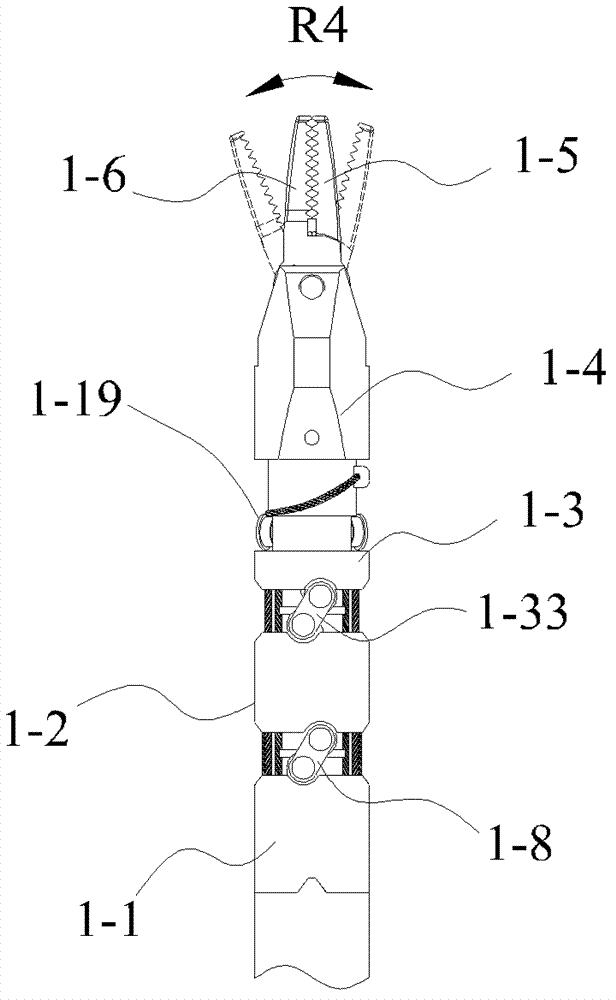

[0026]A micro-instrument terminal for a minimally invasive surgical robot based on a modular joint of the present invention includes a module bottom part 1-1, and a module top part 1-2 and a rotating connection shaft 1 are sequentially arranged above the module bottom part -3, upper arc grooves 1-20 are respectively opened on the top surfaces of the module bottom part 1-1 and the module top part 1-2, and lower arc grooves are respectively opened on the bottom surface of the module top part and the bottom surface of the rotating connecting shaft Arc groove 1-18, on the module bottom part 1-1, top part 1-2 and rotating connecting shaft 1-3 on the left and right sides of each upper arc groove 1-20 and lower arc groove 1-18 The left and right connecting seats with connecting holes 1-22 are arranged respectively, and the axis of each upper and lower arc groove 1-20 is parallel to the axes of the connecting holes 1-22 on the left and right connecting seats on both sides thereof. Off...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com