Heavy-load automated guided vehicle

A robot and transfer technology, applied in the field of robots, can solve the problems of limited working range, large starting torque, and low load of six-axis robots, and achieve the effects of reducing production costs, improving production efficiency, and realizing logistics automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

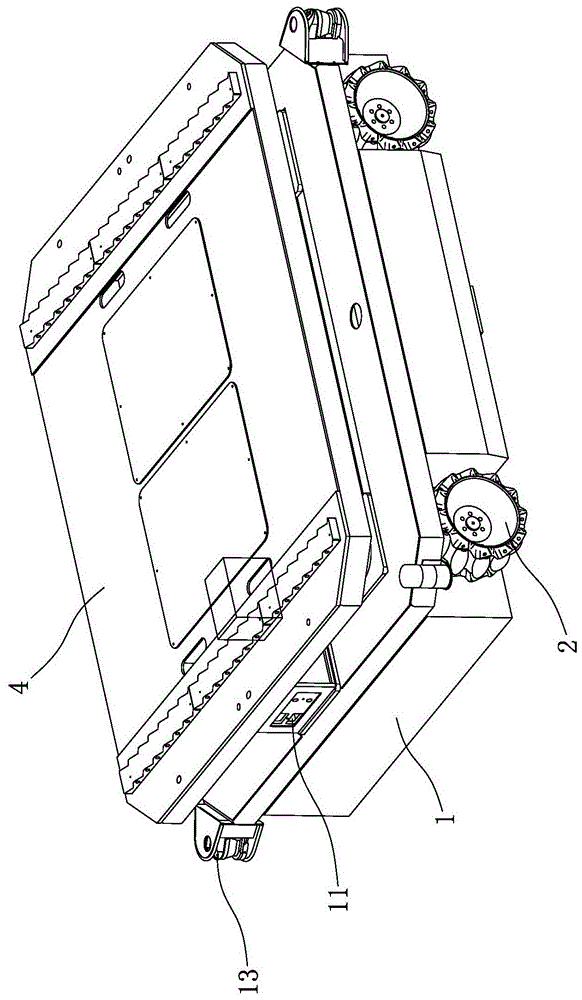

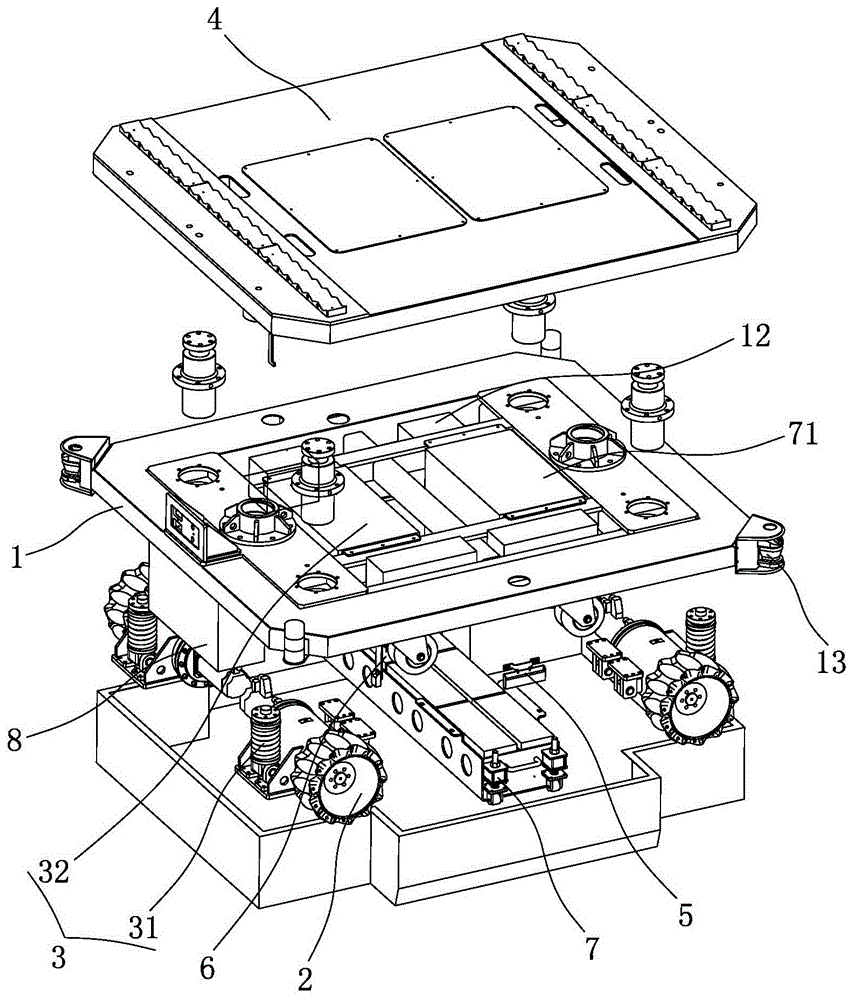

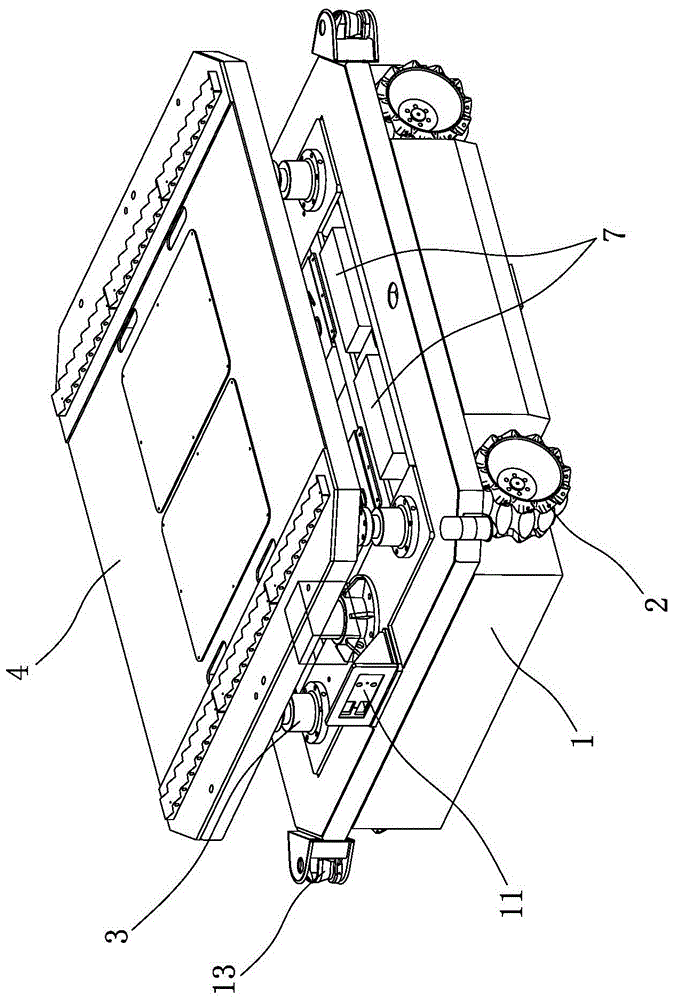

[0033] refer to Figure 1 to Figure 6 As shown, a heavy-duty transfer robot disclosed by the present invention includes a vehicle frame 1, a mecanum wheel drive mechanism 2, a lifting mechanism 3, a workbench 4, a magnetic navigation sensor 5, an RFID landmark sensor 6, a vehicle power supply 7 and PLC controller8.

[0034] The mecanum wheel driving mechanism 2 is installed on the bottom of the frame 1 to drive the frame 1 to walk in all directions. In this embodiment, four sets of floating mecanum wheel mechanisms 2 drive the heavy-duty transfer robot to move in all directions, which can realize Forward, backward, side shifting, rotating and other all-round walking can automatically transport materials to each station in the production line. In this embodiment, universal casters 9 are installed at the bottom of the vehicle frame 1, four se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com