Method for curve surface grinding with cylindrical grinding wheel at virtual ball cutter radius

A cylindrical and grinding wheel technology, applied in the field of precision grinding of free-form surfaces, can solve the problems of low machining accuracy, fast tool wear, and low machining efficiency, and achieve the effects of high machining precision, small surface roughness, and brief algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and examples, but the protection scope of the present invention is not limited to the scope shown in the examples.

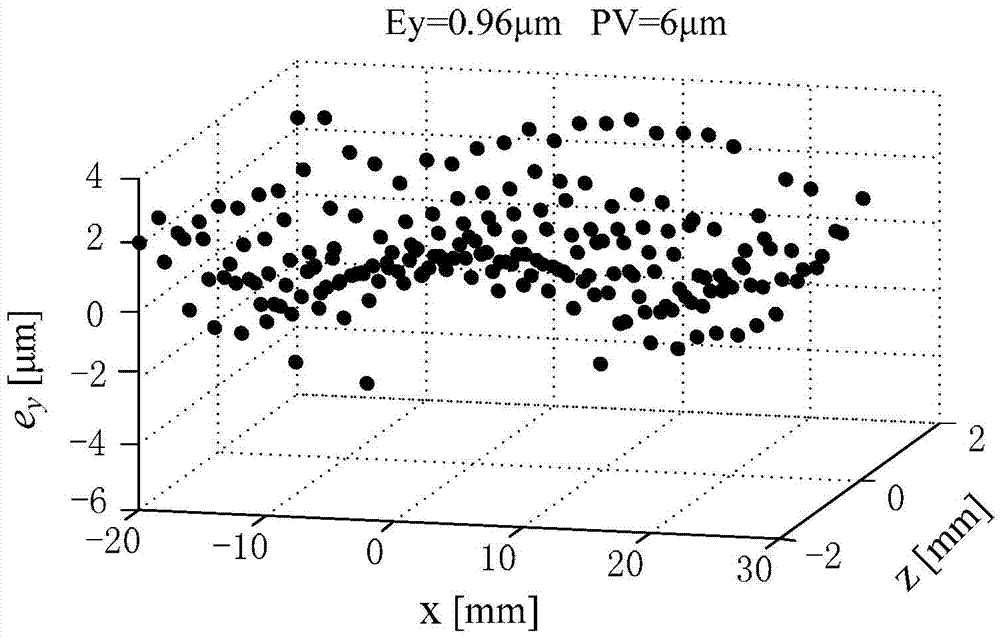

[0034] Such as Figure 1 to Figure 6 Described, a kind of cylindrical emery wheel curved surface grinding method of virtual ball cutter radius, comprises steps:

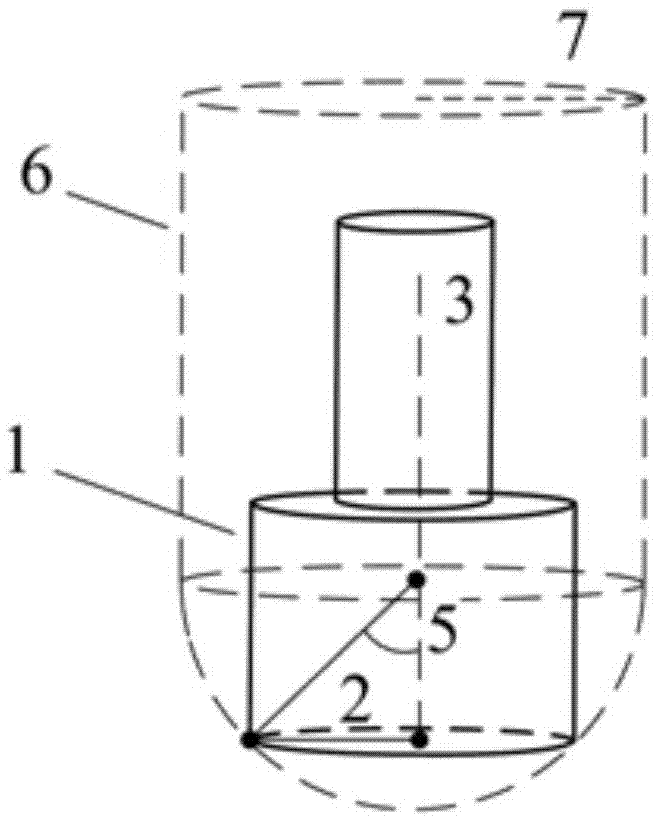

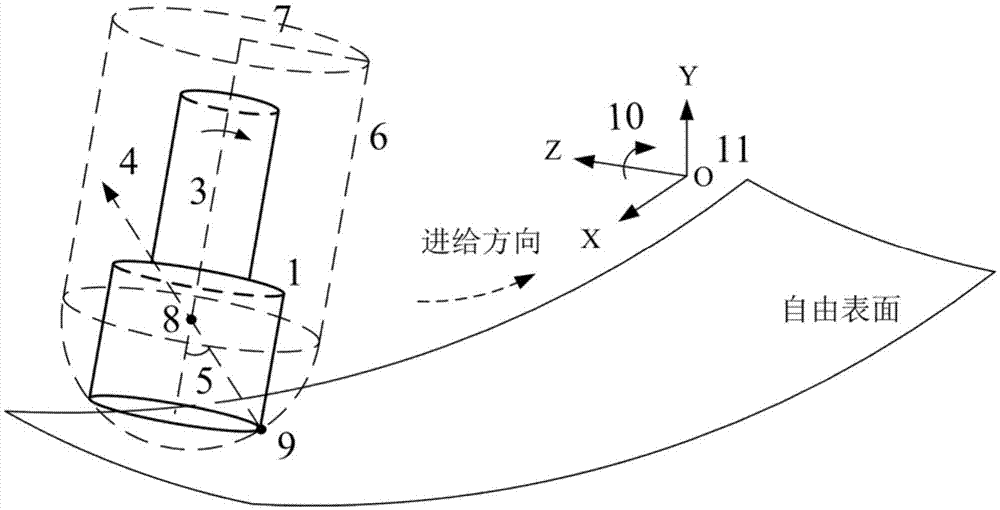

[0035] Step 1, designing the attitude angle of the cylindrical grinding wheel, designing the inclination angle of the axis of the cylindrical grinding wheel on the surface tangent point normal vector 4 through the virtual ball cutter model;

[0036] Step 2. Plan the tool trajectory, determine the tool trajectory according to the surface tangent point normal vector 4 and the virtual ball cutter model 6, and ensure the inclination angle set in step 1 through a rotation axis of the machine tool.

[0037] Step 3. Grinding the workpiece according to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com