Arc length parameter curve processing track generation method of free curved surface

A surface processing and parametric curve technology, which is applied in the field of arc length parameter trajectory generation of free-form surfaces, can solve problems such as difficult application in production practice, and achieve the effects of improving smoothness and machining accuracy, avoiding complex calculations, and reducing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0085] The numerical control machine tool used in this embodiment is a three-axis vertical milling machine, and the machine tool body includes a worktable and three linear motion axes of X, Y, and Z.

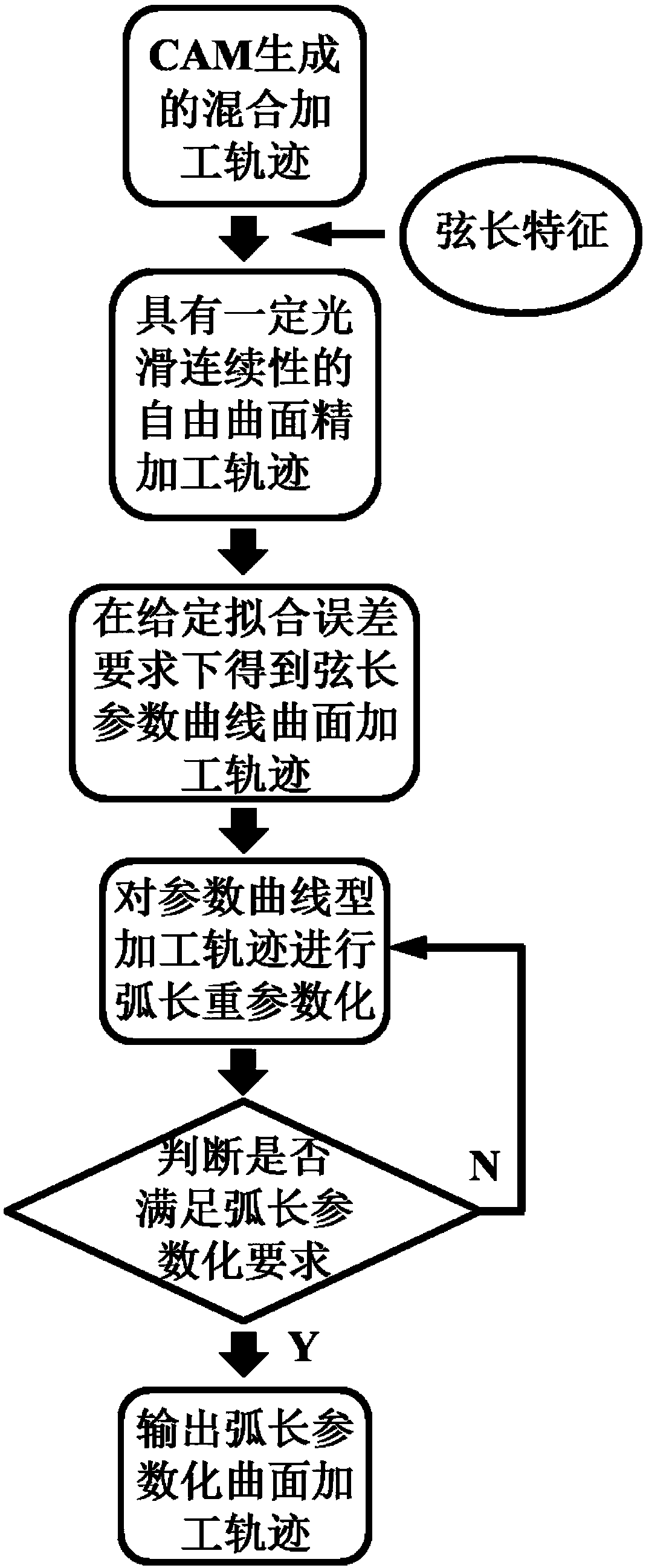

[0086] The specific operation steps for generating the arc length parameter curve processing track of the free-form surface are as follows:

[0087] (1) Smooth continuous feature free-form surface processing track extraction

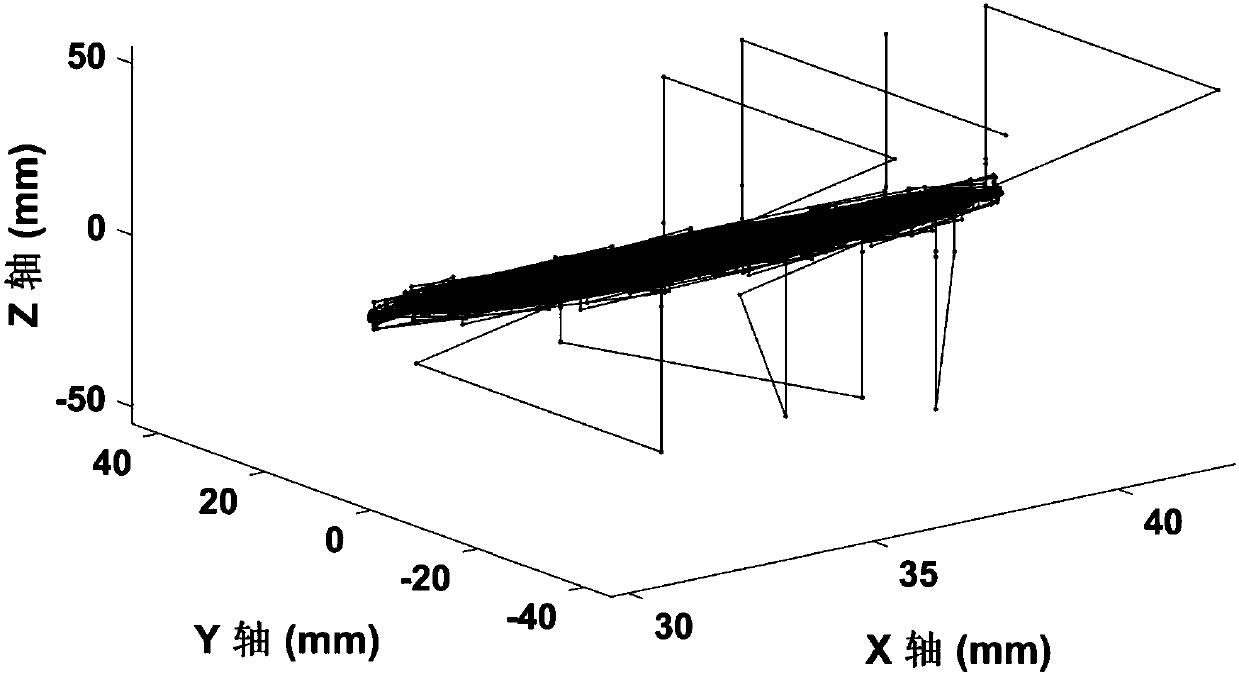

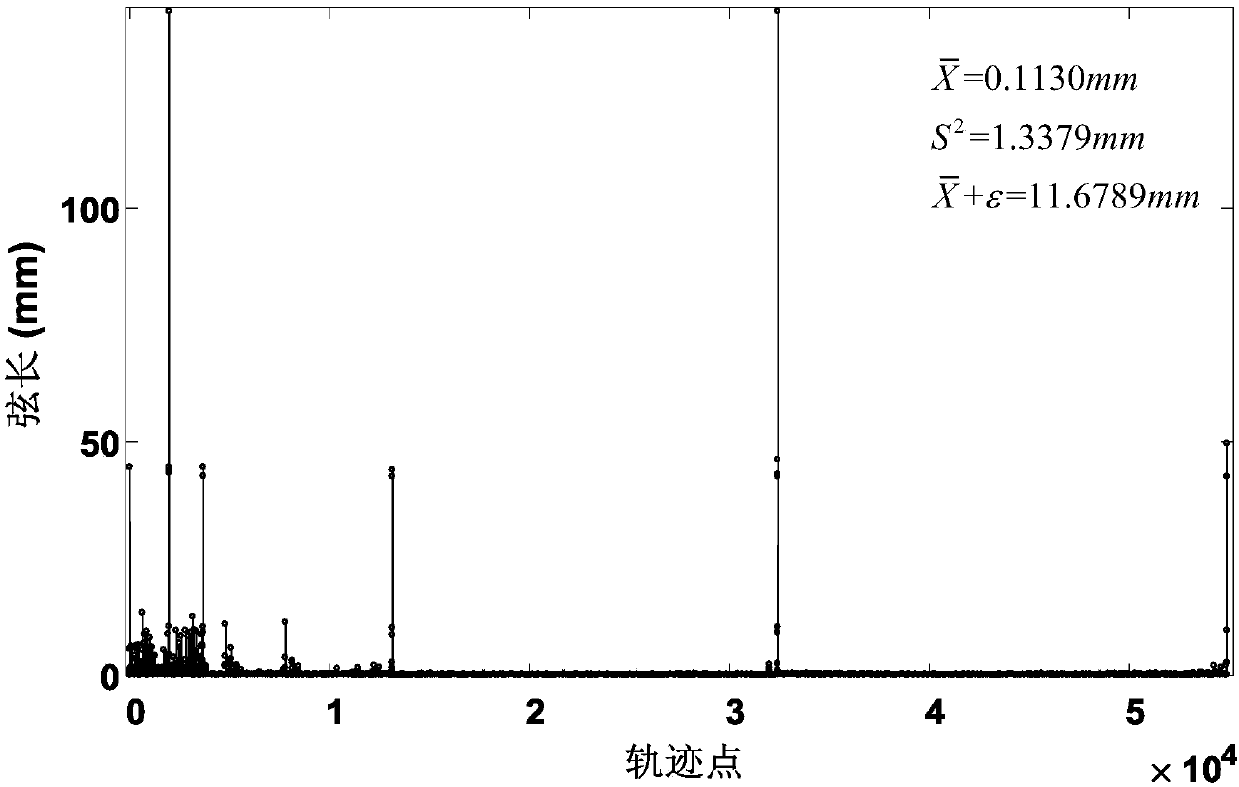

[0088] Such as figure 2 Shown is the small line segment processing trajectory of the denture generated by computer-aided manufacturing software (CAM) including rough machining, advance and retreat and finishing trajectories. First, the overall processing trajectory is performed according to the chord length characteristics between the adjacent track points of the discrete trajectory classification. Perform statistics on chord length samples to obtain the sample mean and sample variance of the overall trajectory chord length samples

[0089]

[0090]

[0091] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com