Integrated optimization method for process of milling free-form surface hardened steel mold using ball end

An optimization method, ball-end milling technology, applied in simulators, instruments, control/adjustment systems, etc., can solve the problems of complex analysis of ball-end milling process and uneven distribution of machining errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

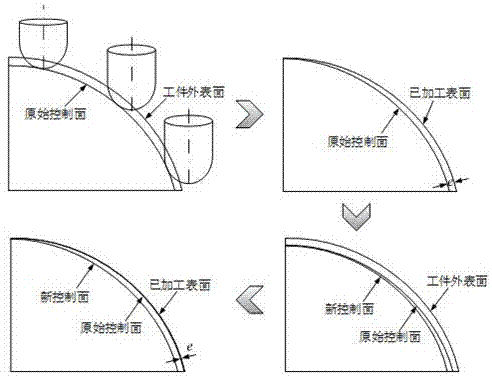

[0047] The free-form surface spherical head milling hardened steel mold process integration optimization method of the present invention comprises the following steps:

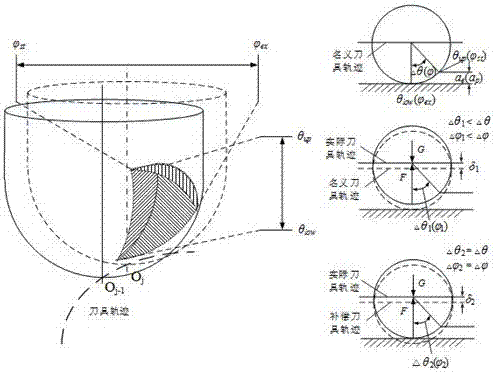

[0048] The first step is to establish a tool-making error track compensation method consistent with the tool contact area for areas with excessive curvature;

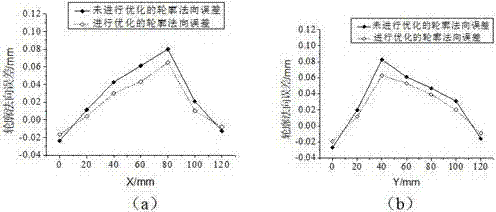

[0049] The tool contact area accurately reflects the machining state of the tool, and controls the radial cutting angle of the tool during cutting along the compensated tool path φ st and cut-out angle φ ex , the upper and lower boundaries of the axial tangential antenna θ up and θ low , are consistent with the nominal tool path during cutting, so as to ensure that the machining shape and normal contour error meet the requirements, such as figure 1 Shown; △ θ ( φ ) is the axial contact angle (radial contact angle) when cutting along the nominal tool path; δ 1 is the offset between the actual tool path and the nominal tool path caused by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com