Method for controlling machining track of numerically-controlled machine tool

A control method and technology of CNC machine tools, applied in the field of CNC machine tool machining track control and CNC machine tool adjustment processing effect control field, can solve the problems of increased data processing capacity of CNC machine tool system, increased system software and hardware requirements, and increased processing file length, etc. To achieve the effect of avoiding data processing volume, wide application range and avoiding increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

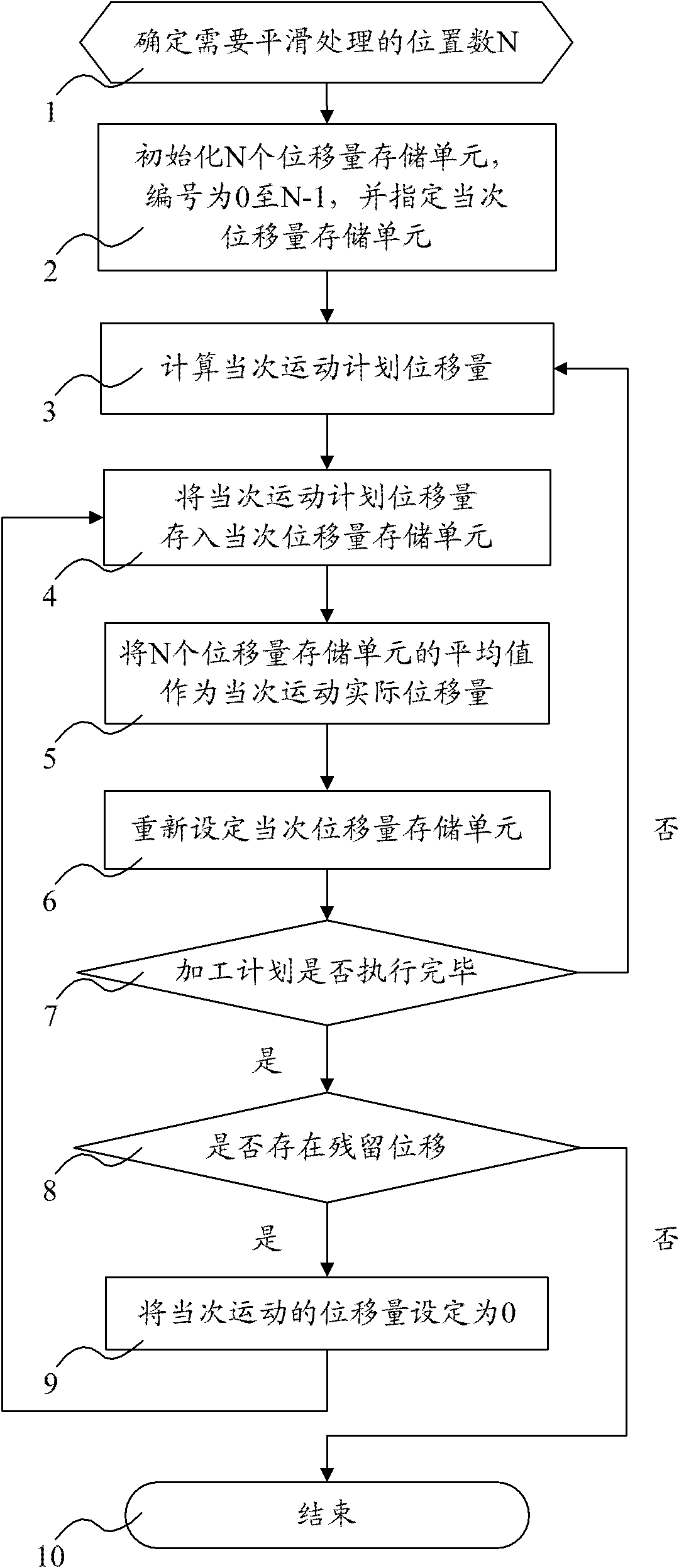

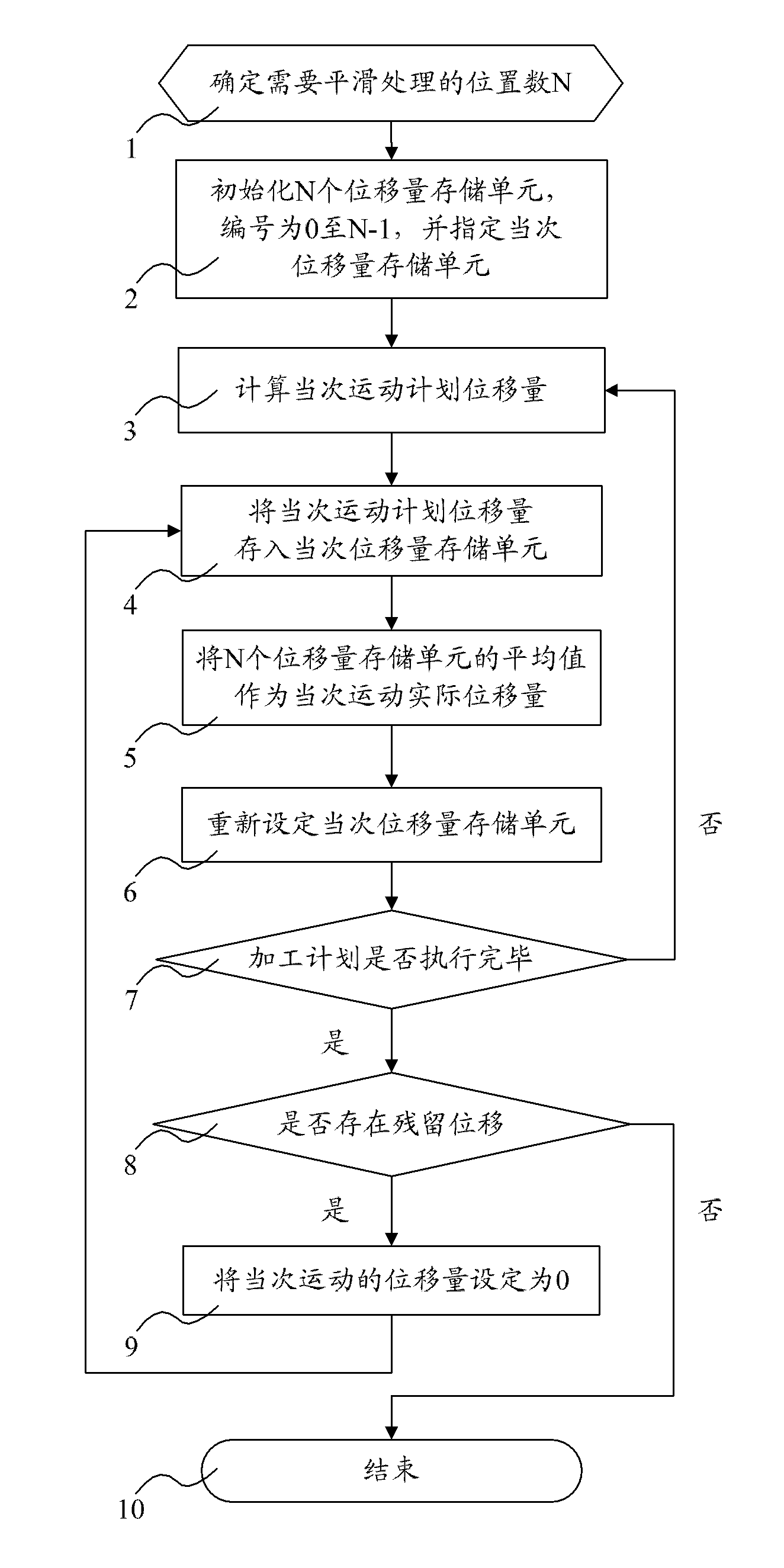

[0022] see figure 1 As shown, it is a flow chart of the steps of the CNC machine tool machining trajectory control method of the present invention.

[0023] In one embodiment of the present invention, this CNC machine tool processing track control method comprises the following steps:

[0024] (1) Determine the number N of positions that need to be smoothed according to the processing plan;

[0025] (2) Initialize N displacement storage units, number each displacement storage unit from 0 to N-1, and specify the numbering of the current displacement storage unit;

[0026] (3) Calculate the displacement of the current motion plan according to the processing plan;

[0027] (4) storing the displacement amount of the current motion plan into the displacement amount storage unit;

[0028] (5) The average value of N displacement storage units is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com