Analysis method for free surface tolerance

An analysis method and tolerance technology, applied in the field of free-form surface tolerance analysis, can solve the problems of free-form surface machining accuracy and test verification that cannot be verified

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

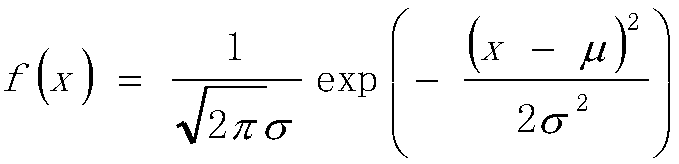

[0021] The analysis method described in this paper involves three types of data, including: the formula coefficient of the free-form surface, the formula coefficient of the surface tolerance of the free-form surface, and the PV value of the surface tolerance of the free-form surface.

[0022] The purpose of the analysis method described in this paper is to convert the formula and coefficient value of free-form surface tolerance commonly used by designers into the PV value of free-form surface tolerance commonly used by processors, so as to facilitate actual processing and verification.

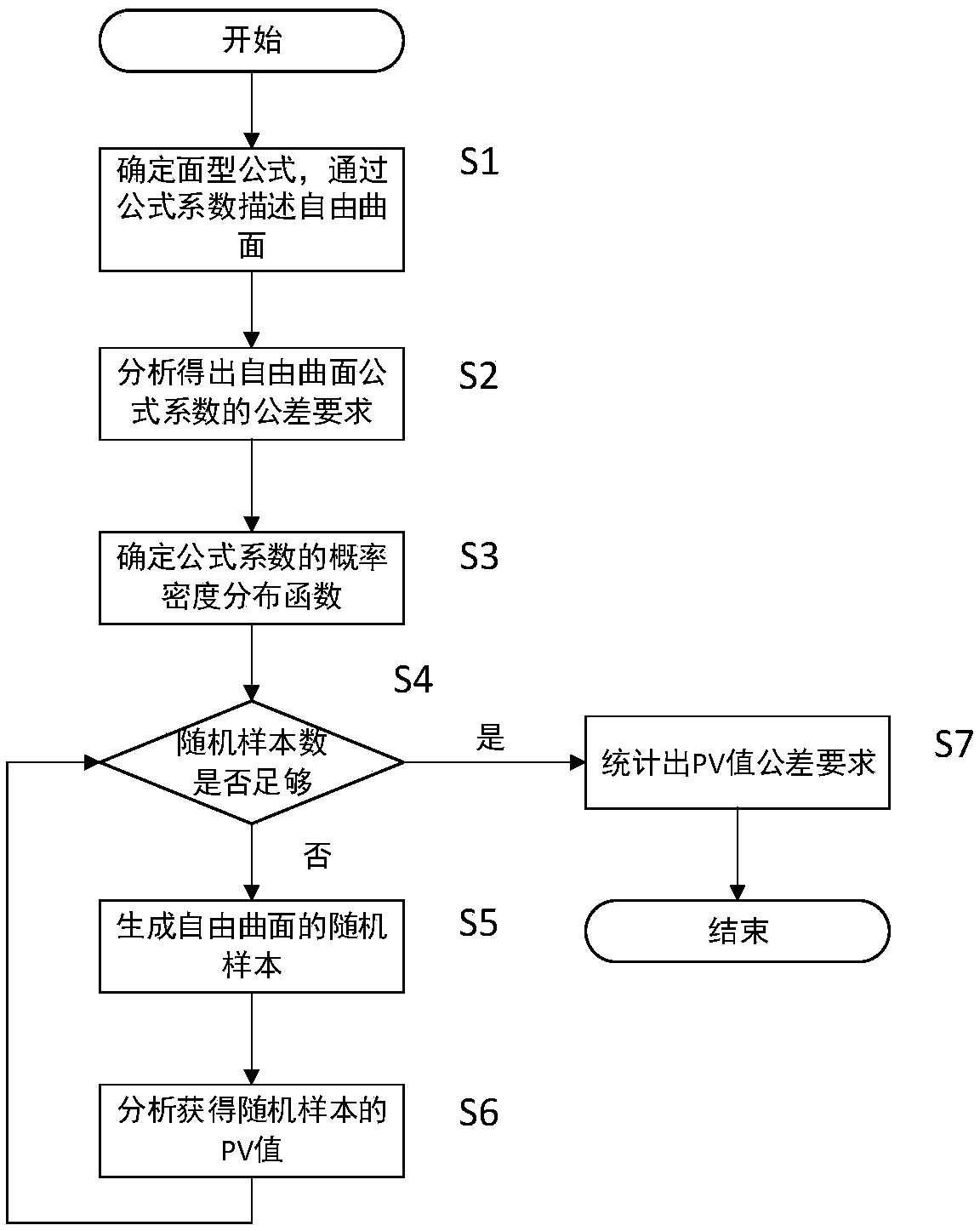

[0023] The analysis method of the free-form surface tolerance of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. see figure 1 :

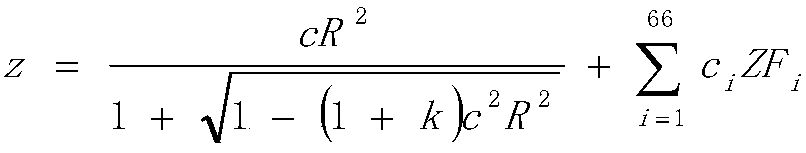

[0024] First, optical designers describe and optimize free-form surfaces (S1) according to specific surface formulas according to their design habits and experience. Taking the Zernike...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com