Quench hardening steel free curved surface test piece and milling process

A technology of hardened steel and curved surface, which is applied in the field of complex profile processing, can solve the problems of decreased dimensional accuracy of profile, large fluctuation of position error of curved surface processing surface, variable curvature of hardened steel profile, etc. Improved accuracy and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

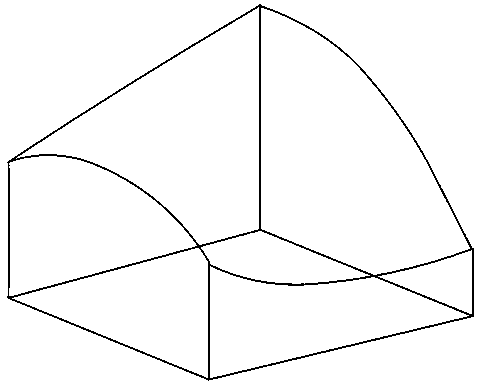

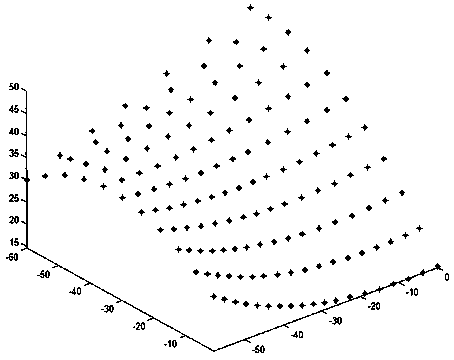

[0019] 1. Space free surface design

[0020] 1.1 Parametric equation of free-form surface in space

[0021] In differential geometry, a surface is usually expressed as a vector function form of two parameters u and v, that is, a surface S: r=r(u,v), then the principal curvature of a point on the surface along the line u is k 1 , the principal curvature along the v direction is k 2 , they have to multiply k 1 k 2 It is called the Gaussian curvature of the surface at this point, denoted as K, K=k 1 k 2 ; Their average becomes the average curvature of the surface at this point, denoted as H, H=(k 1 +k 2 ) / 2.

[0022] The first basic form of the surface is:

[0023]

[0024] where E=r u 2 , F=r u r v , G=r v 2 is the first basic quantity of the surface, then the unit normal vector:

[0025]

[0026] Surface second basis vector:

[0027]

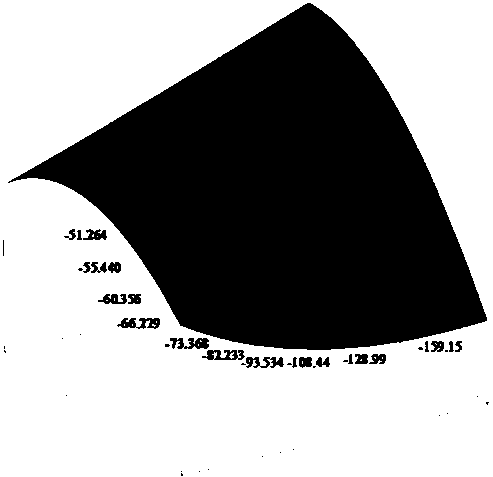

[0028] In the formula, L=n·r uu , M=n·r uv , N=n·r vv is the second basic quantity of the surface, then the principa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com