Patents

Literature

169results about How to "Reduce the error value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

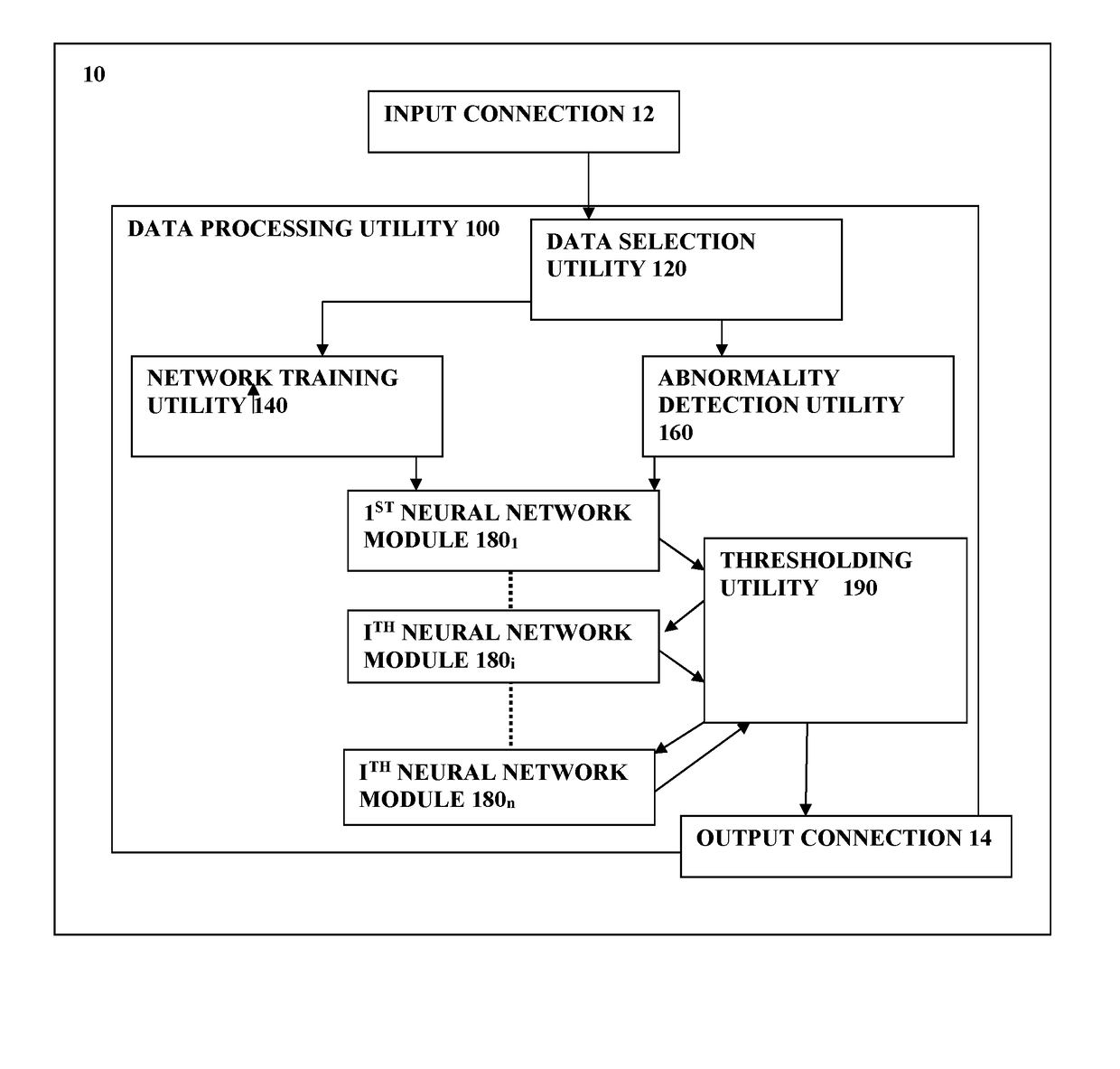

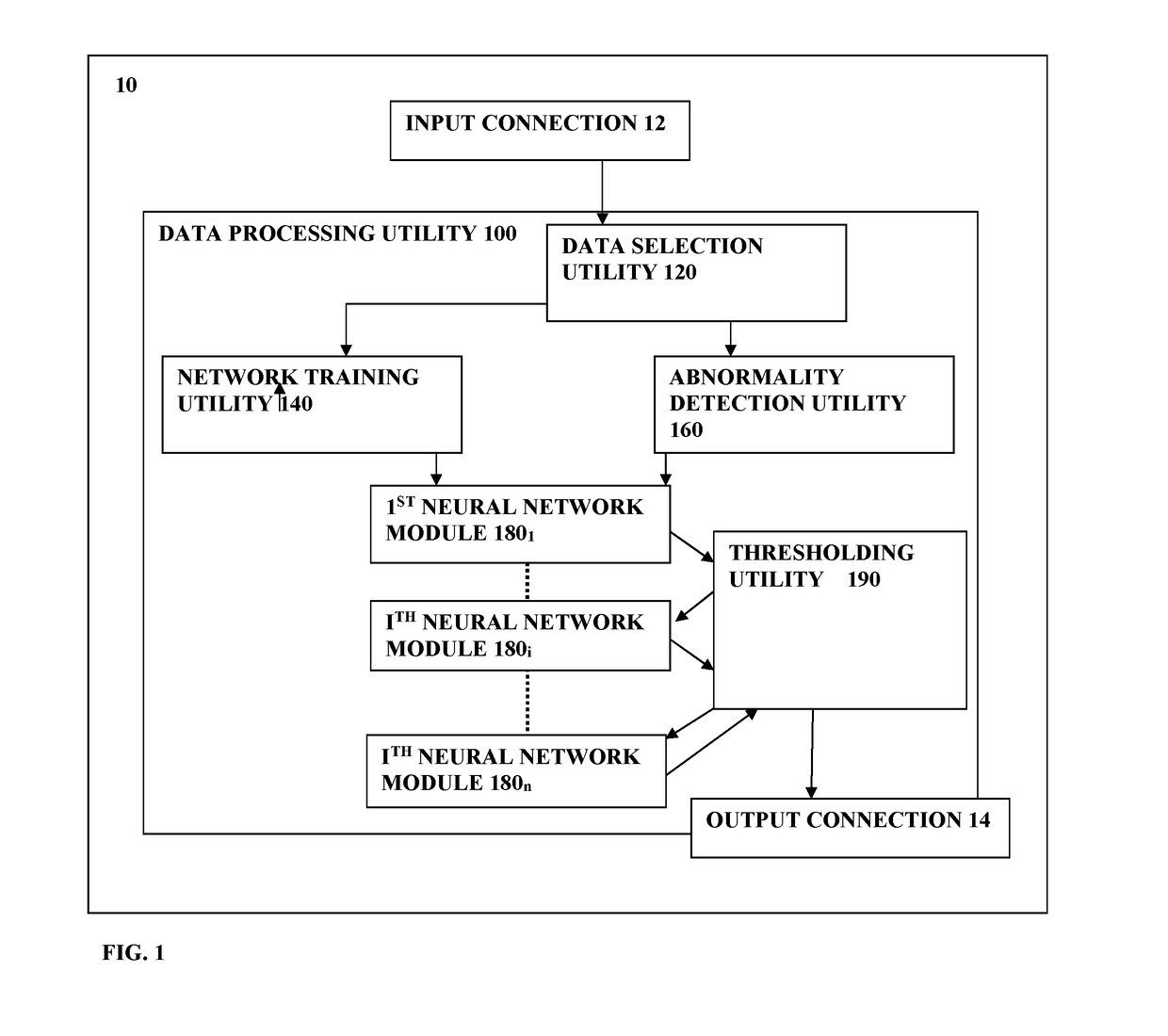

System and method for abnormality detection

ActiveUS20160139977A1Accurately determineReduce the error valueCharacter and pattern recognitionNon-redundant fault processingComputer moduleMachine learning

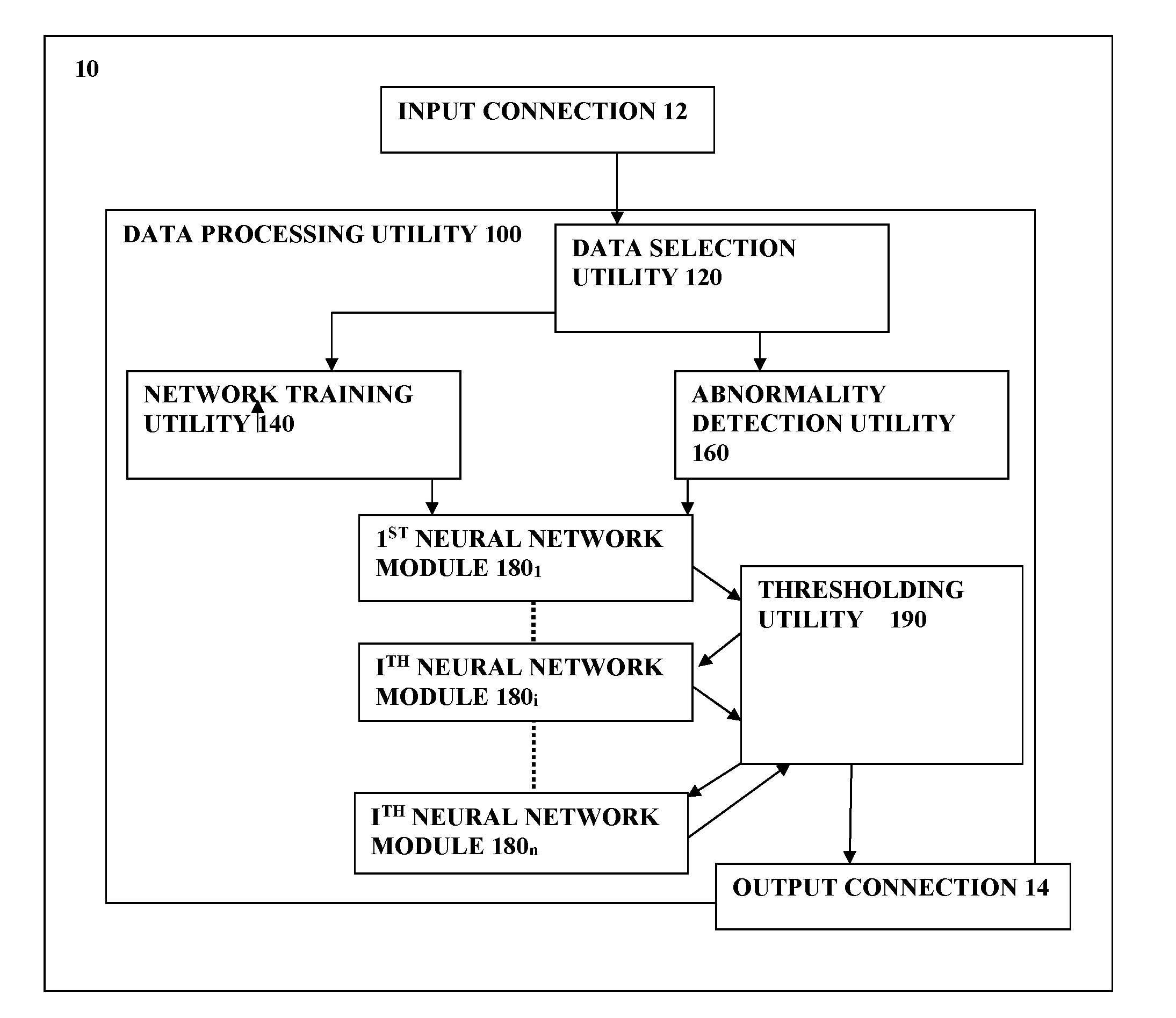

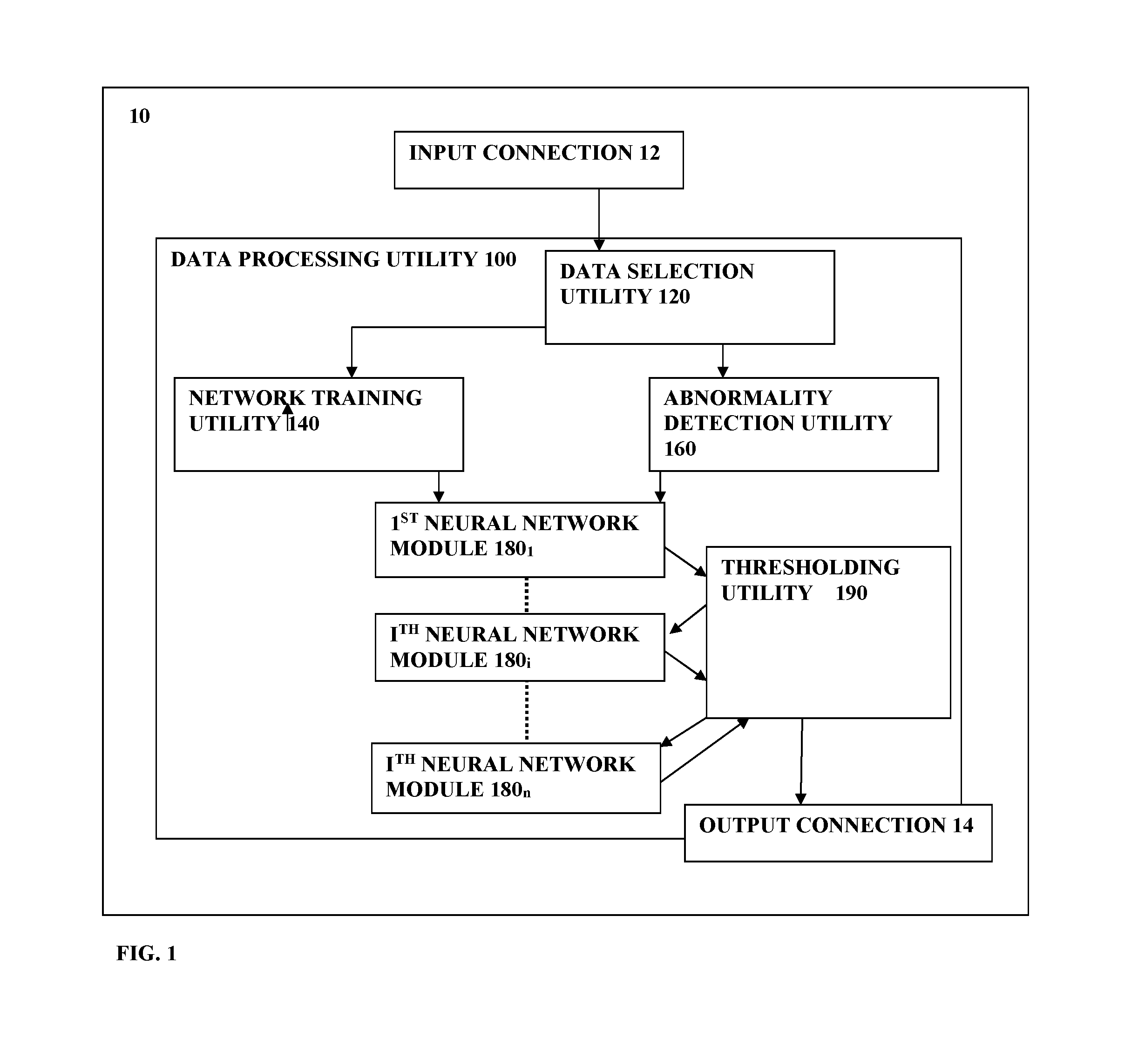

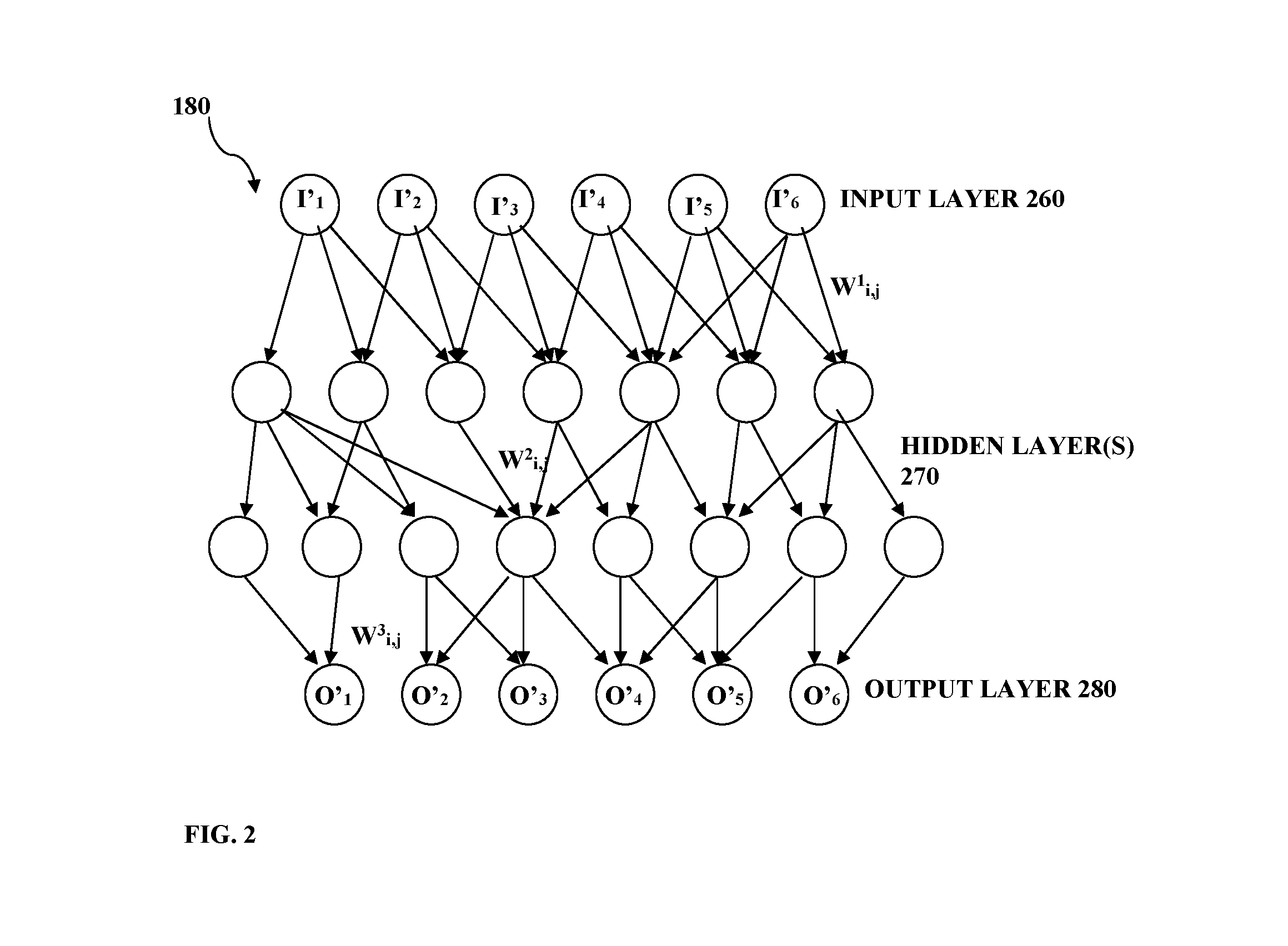

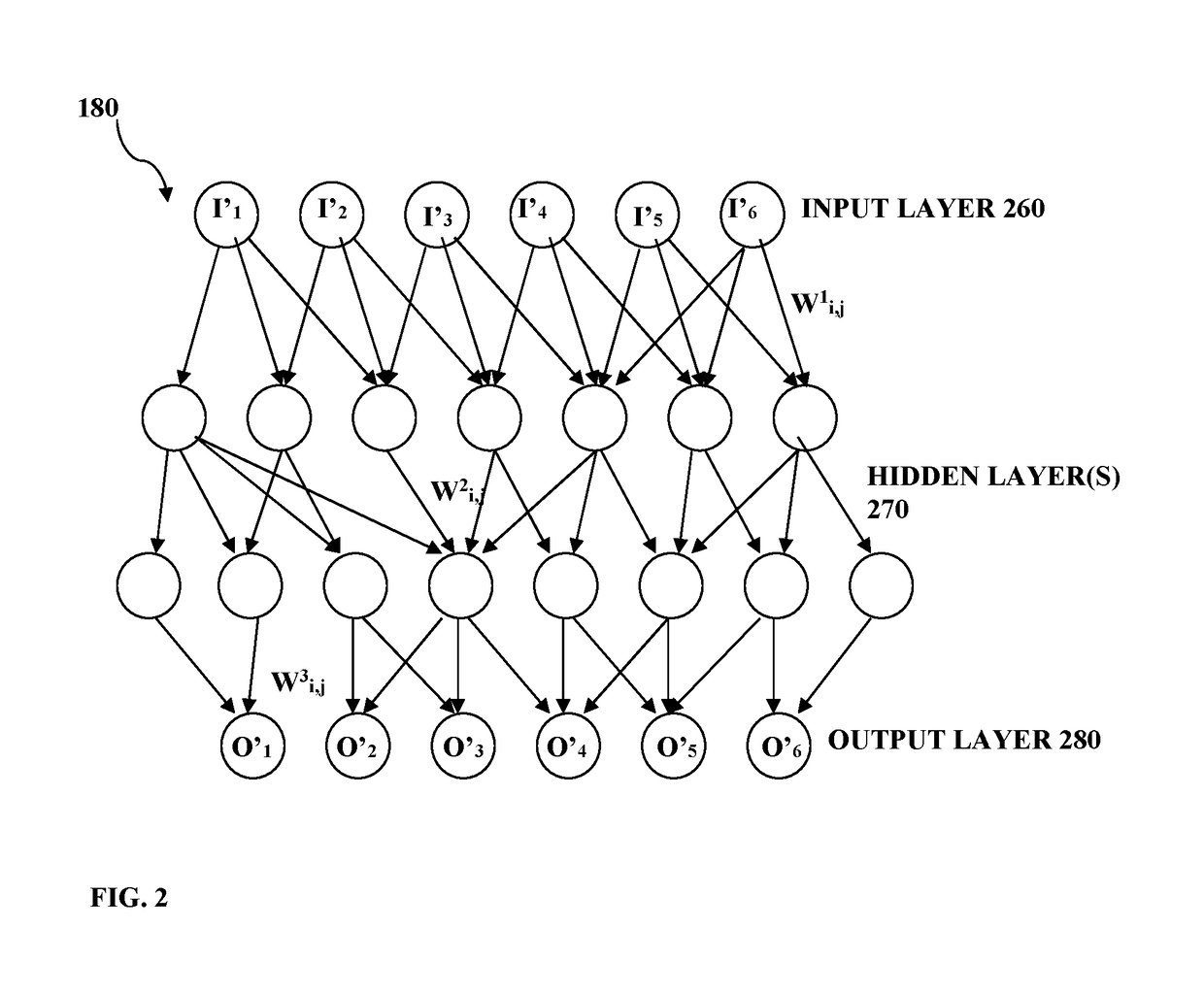

A system and method for use in data analysis are provided. The system comprises a data processing utility configured to receive and process input data, comprising: plurality of neural network modules capable for operating in a training mode and in a data processing mode in accordance with the training; a network training utility configured for operating the neural network modules in the training mode utilizing selected set of training data pieces for sequentially training of the neural network modules in a cascade order to reduce an error value with respect to the selected set of the training data pieces for each successive neural network module in the cascade; and an abnormality detection utility configured for sequentially operating said neural network modules for processing input data, and classifying said input data as abnormal upon identifying that all the neural network modules provide error values being above corresponding abnormality detection thresholds.

Owner:AGENT VIDEO INTELLIGENCE

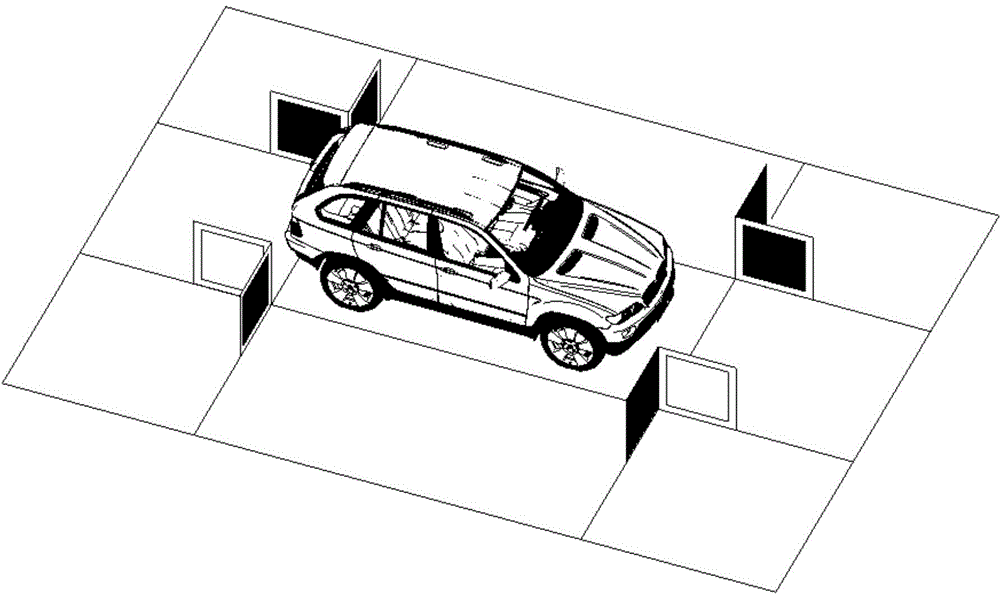

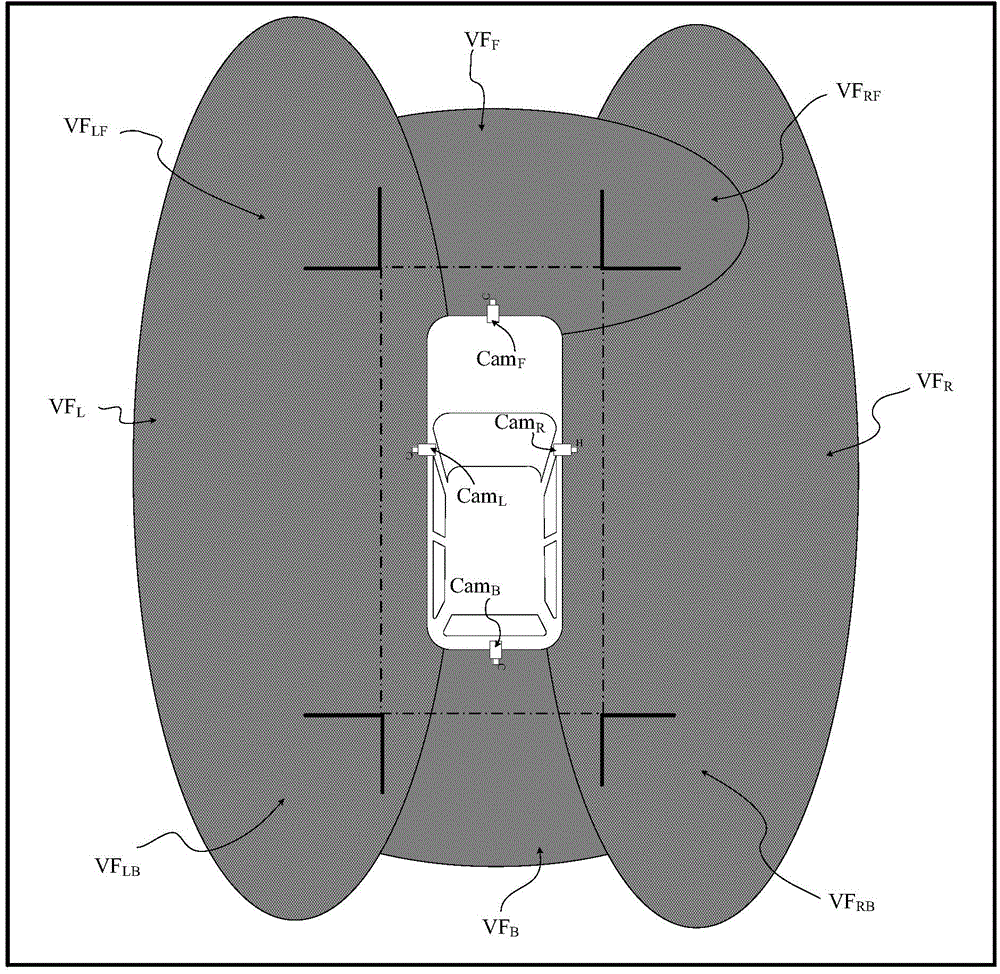

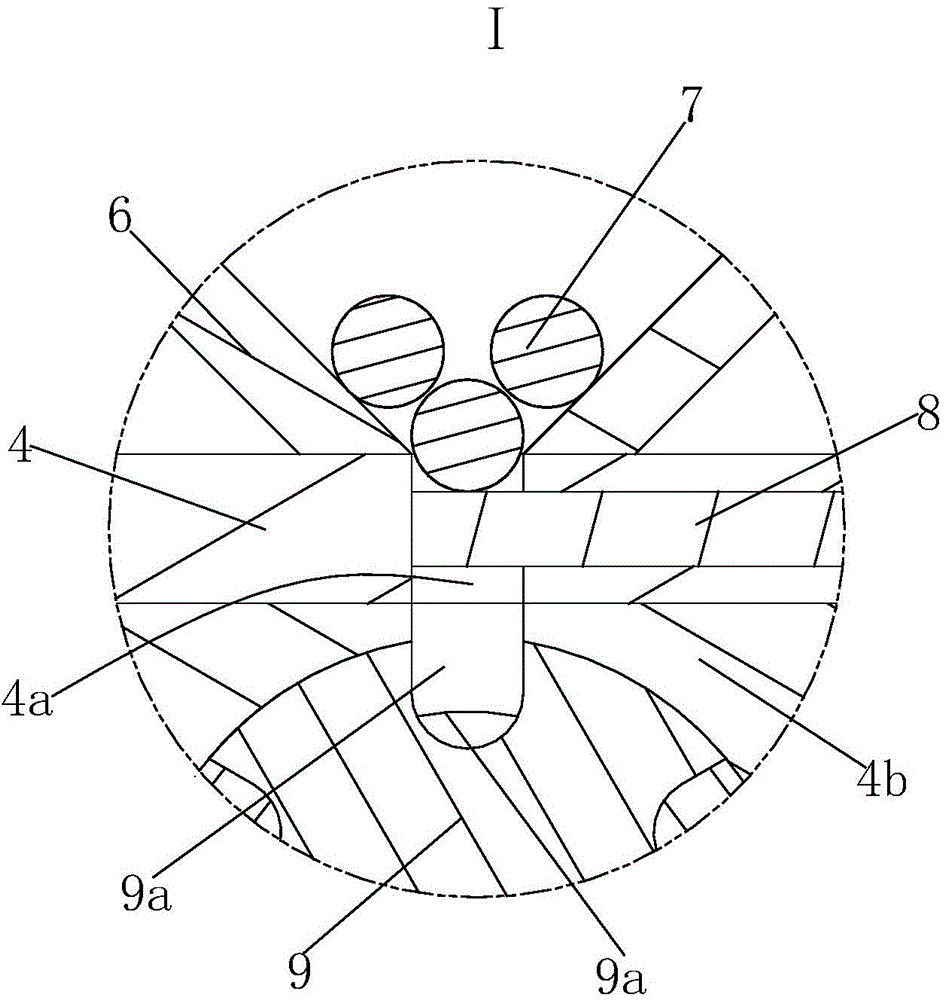

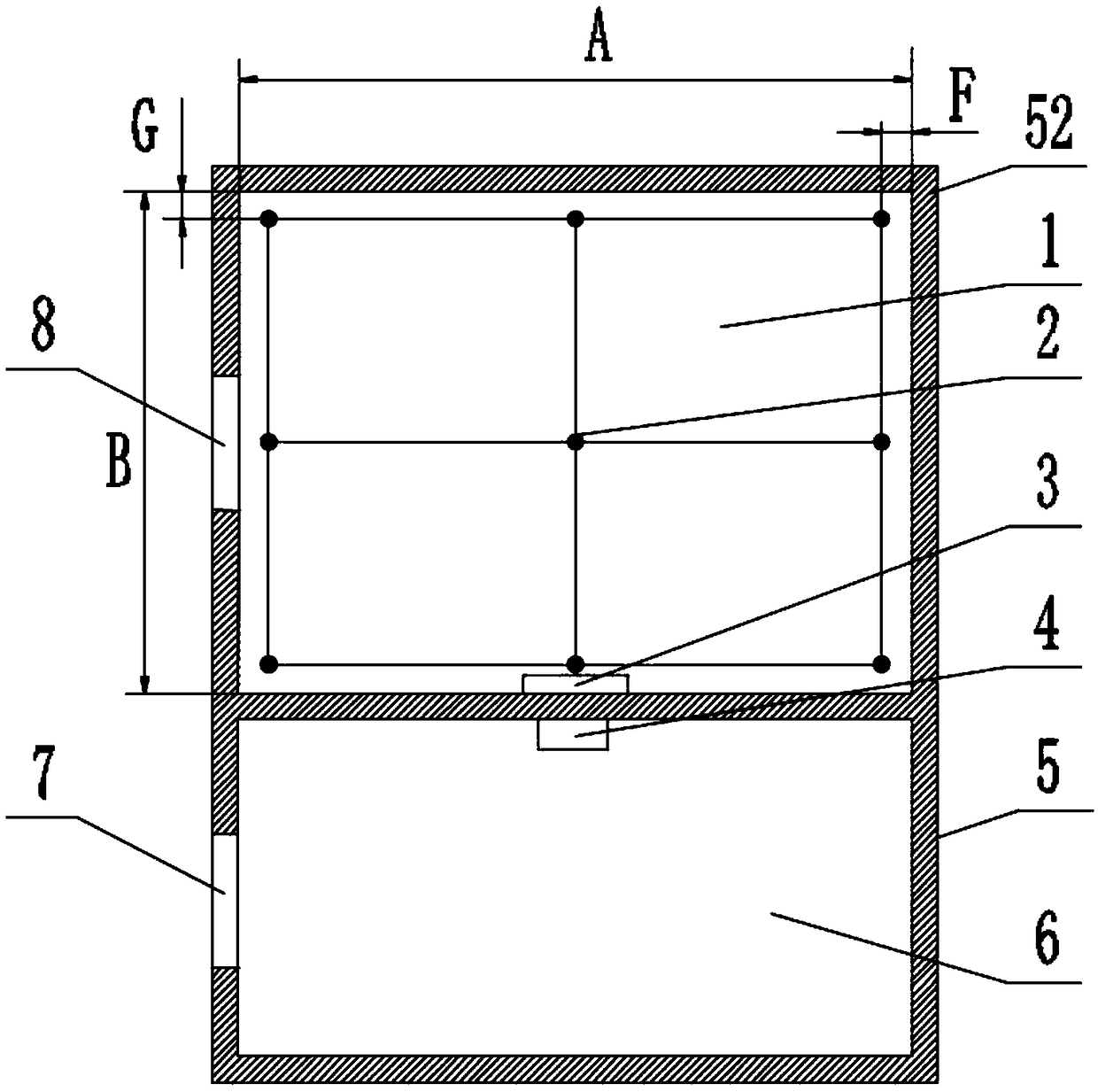

Parameter calibration method for cameras of vehicle-mounted all-round view system

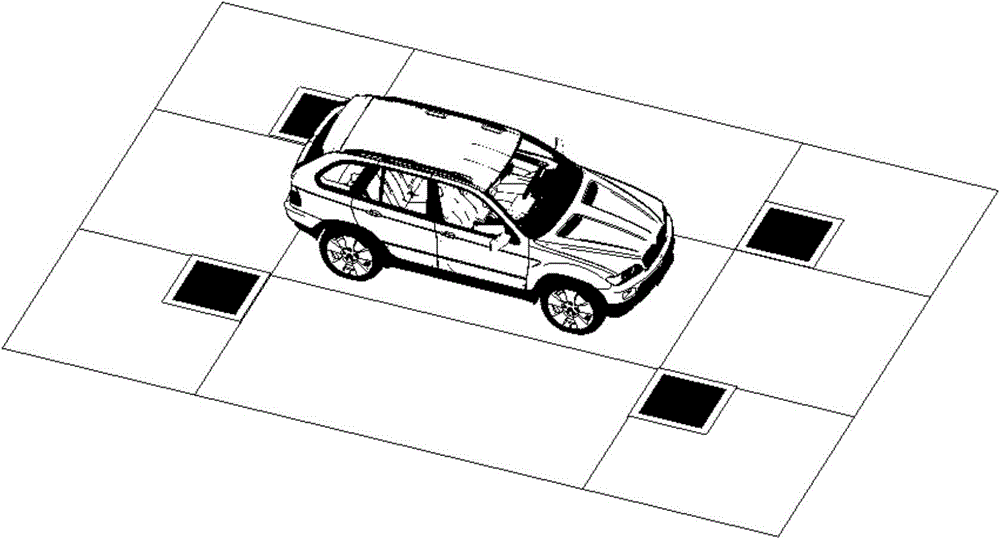

Provided is a parameter calibration method for cameras of a vehicle-mounted all-round view system. When internal parameters and external parameters of the cameras of the vehicle-mounted all-round view system are calibrated, a set of three-dimensional calibration markers are adopted and comprise a plurality of characteristic points which can be recognized easily from images and are provided with given three-dimensional coordinates; when a vehicle to be calibrated is parked in a calibration area, automatic image data collection is carried out through manual work or through external trigger signals, characteristic point extraction is carried out on the collected images, each camera is calibrated corresponding to the three-dimensional coordinate of each characteristic point, and errors of locating are lowered through the processes such as parameter optimization. According to the parameter calibration method for the cameras of the vehicle-mounted all-round view system, through the three-dimensional calibration markers, all areas of the cameras can be covered as much as possible, and the influence of camera distortion on the measuring errors in the calibration process is small; compared with a previous plane two-dimensional calibration board, a three-dimensional calibration board is accurate in selected characteristic point position, clear in imaging and low in error value, and image stitching precision is greatly improved.

Owner:宁波舜宇智行传感技术有限公司

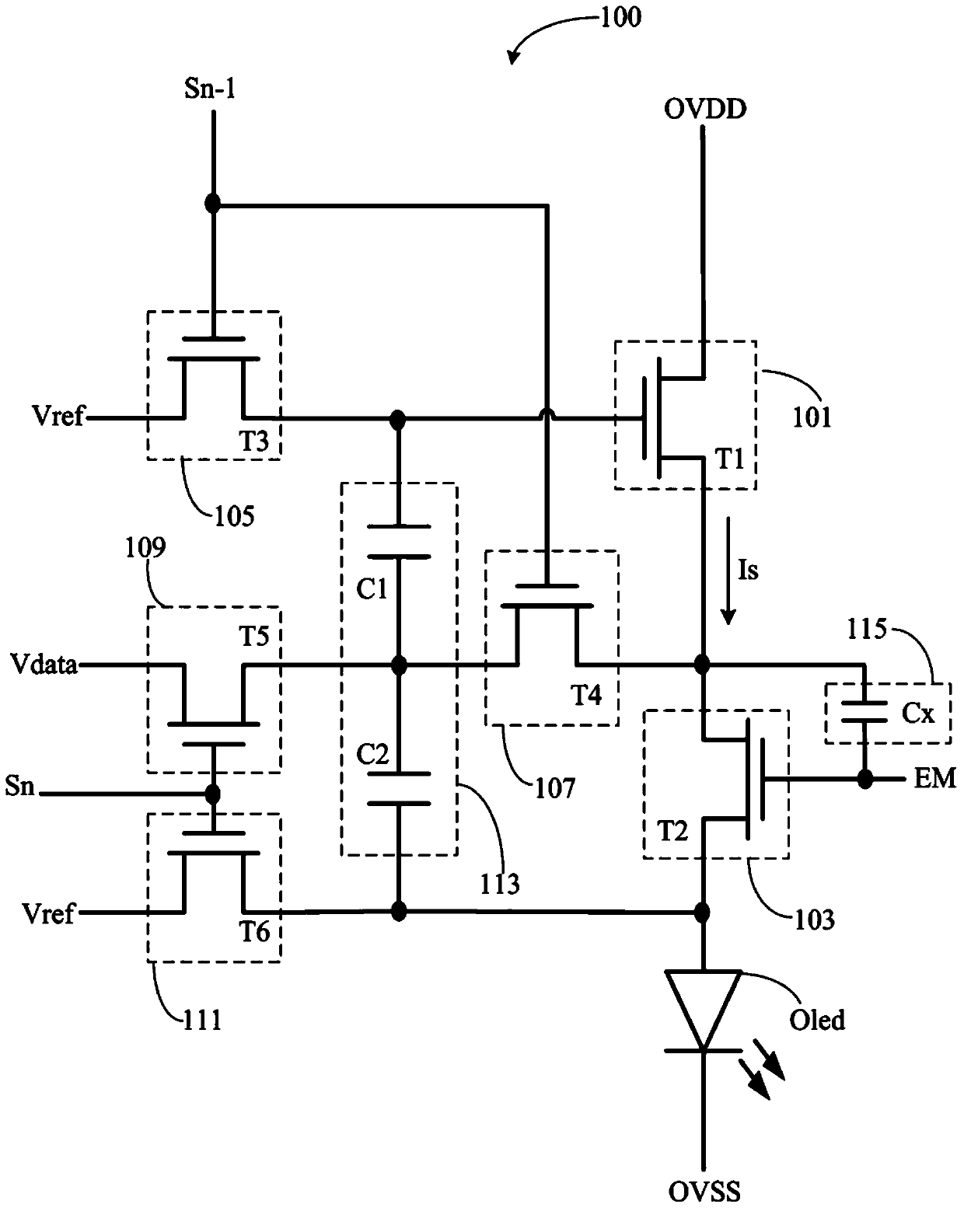

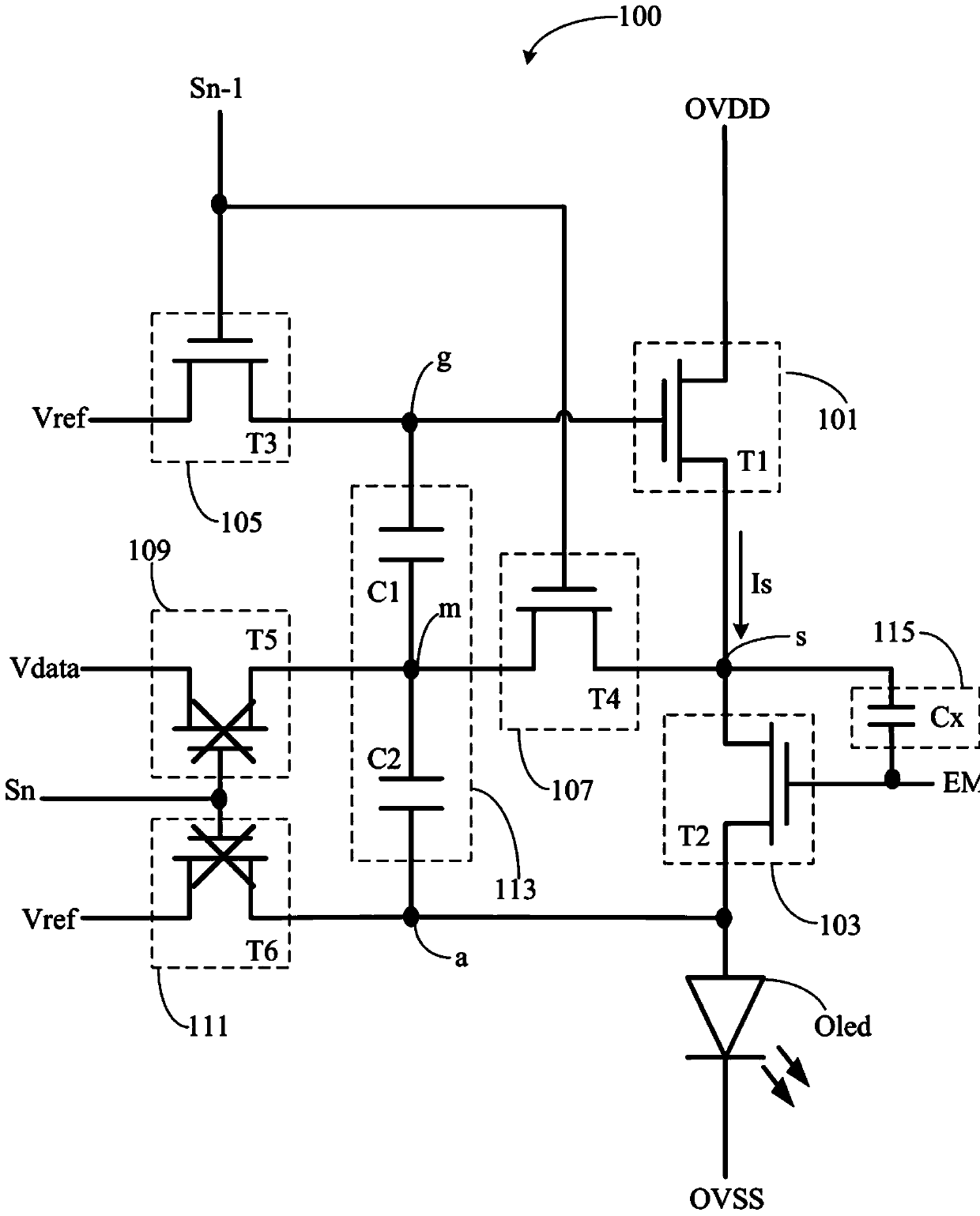

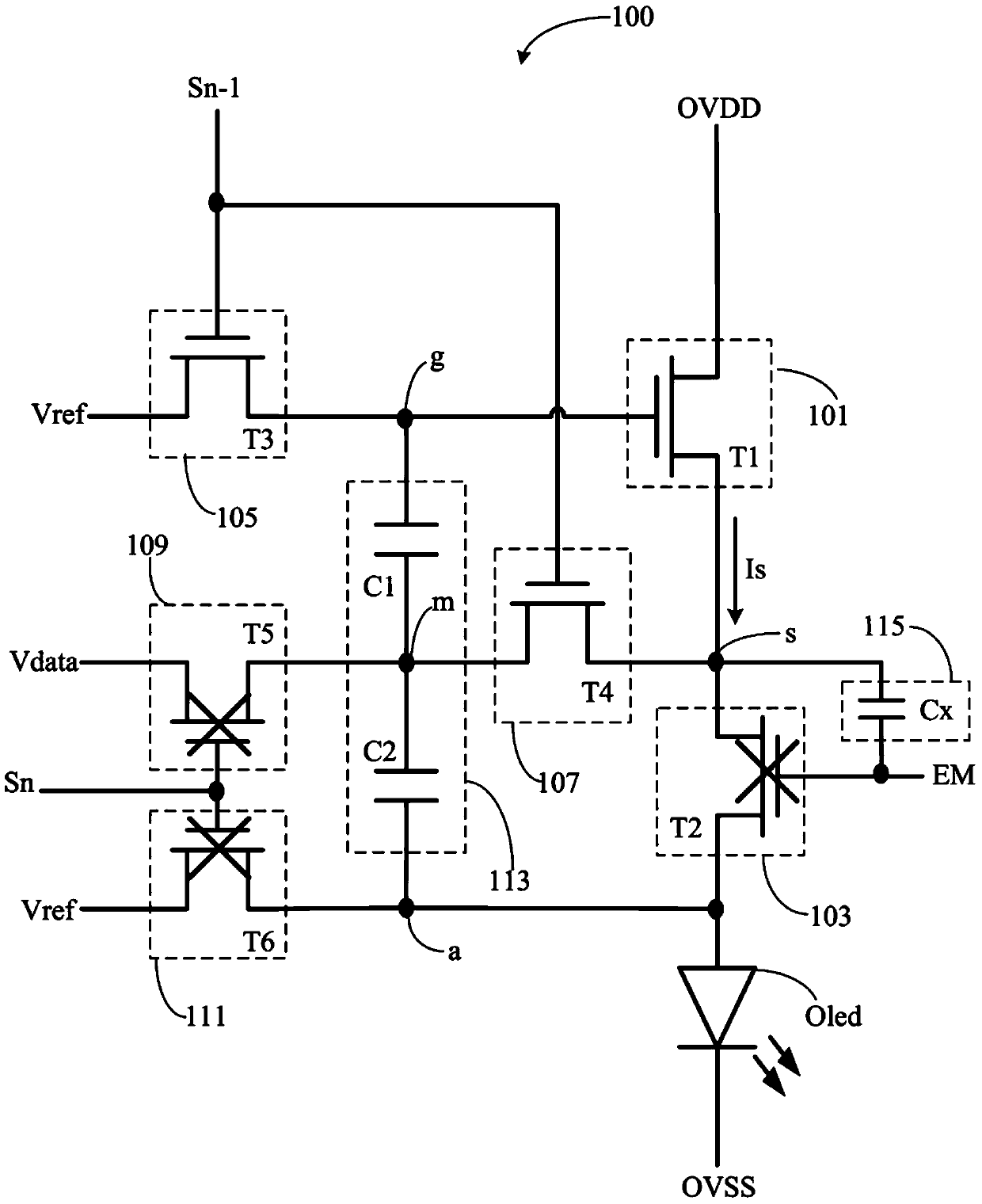

Organic light emitting diode circuit and driving method thereof

ActiveCN103778889ASuppress mutationReduce brightness unevennessStatic indicating devicesCapacitanceDriving current

The invention discloses an organic light emitting diode circuit and a driving method thereof. The organic light emitting diode circuit comprises a storage unit, a transistor, a coupling capacitor, a compensation unit, an input unit, a switching unit, and an organic light emitting diode. The transistor is used to drive a second end of the transistor by voltage stored by the storage unit, so as to generate driving current. The coupling capacitor changes potential of the second end of the transistor. The compensation unit makes potential of the second end of the transistor change according to a first scanning signal. The input unit transmits data voltage to the storage unit according to a second scanning signal. The switching unit is connected according to a lighting signal, so that the driving current is transmitted to the organic light emitting diode through the switching unit.

Owner:AU OPTRONICS CORP

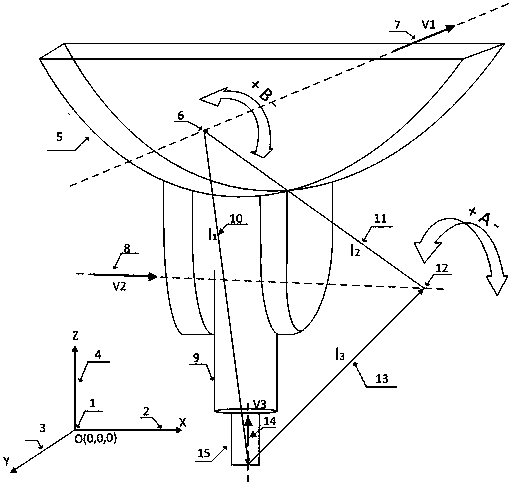

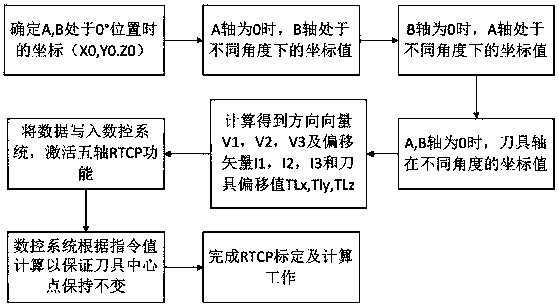

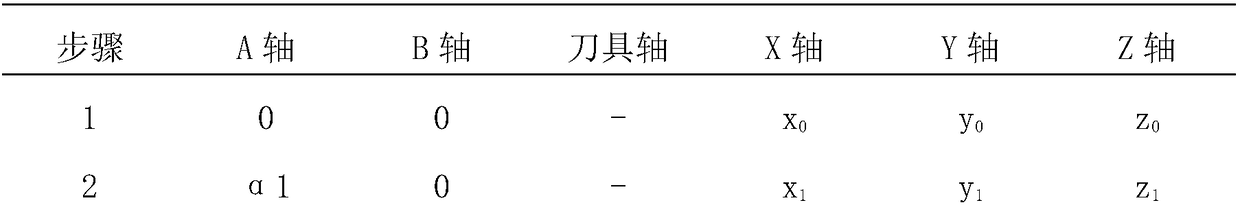

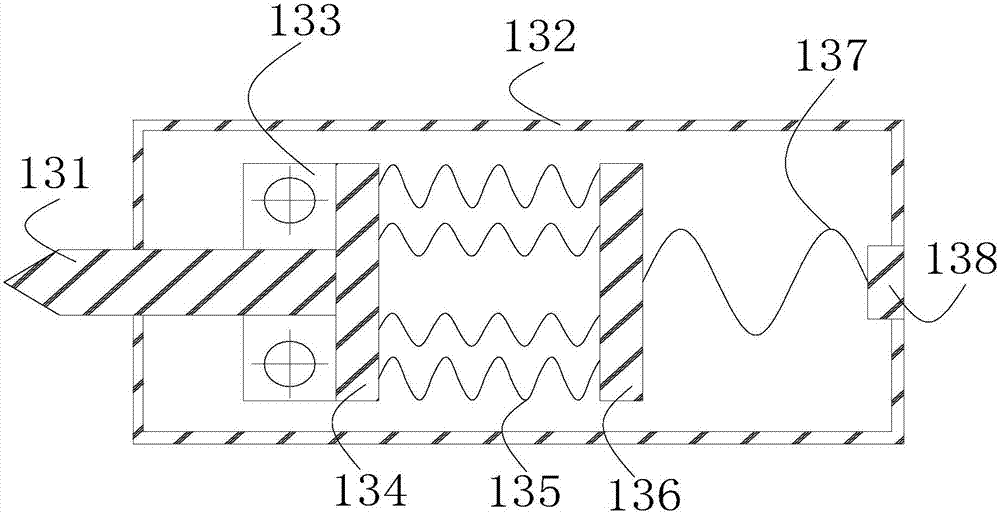

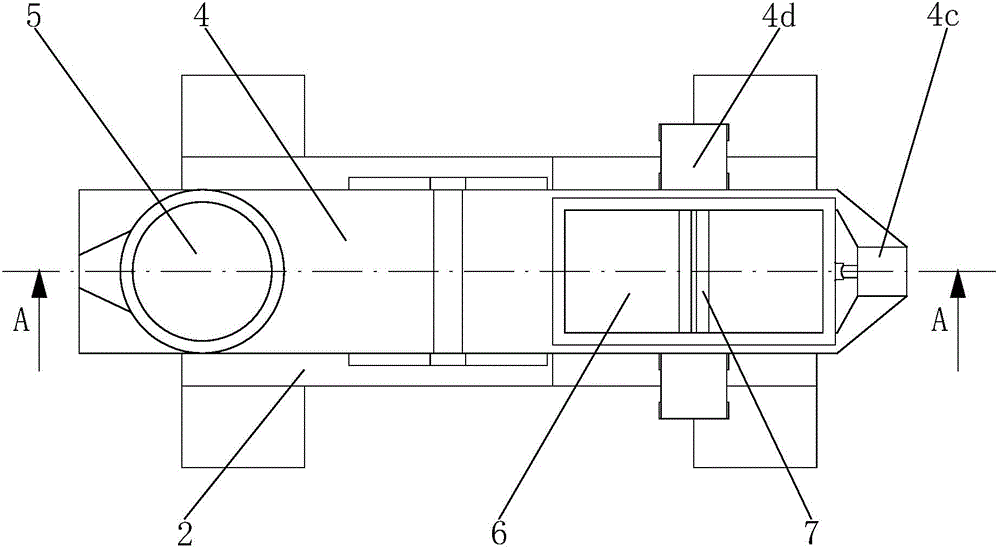

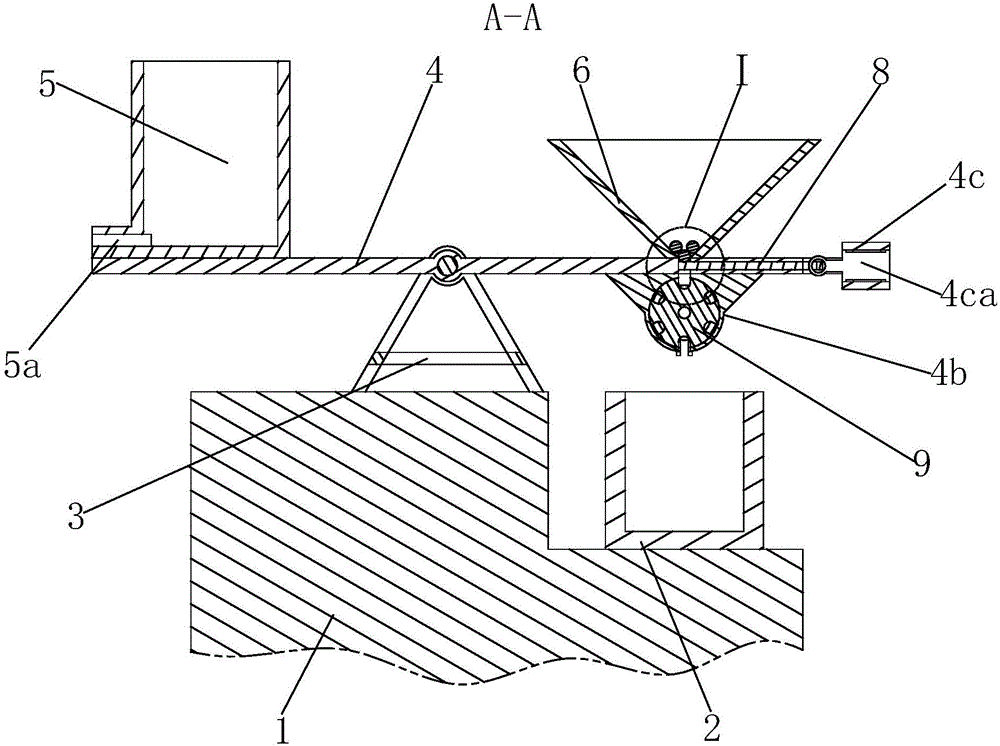

RTCP calibration and compensation method for five-axis NC machine tool of double-pendulum-head structure

ActiveCN108334030AHigh precisionReduce the error valueProgramme controlComputer controlEngineeringMachine tool

The invention discloses an RTCP calibration and compensation method for a five-axis NC machine tool of a double-pendulum-head structure. The method comprises the steps of recording the calibrated coordinate values of each rotating shaft at different angle positions, and calculating to obtain the offset vector of each rotating shaft and the vector data of each rotating shaft in the axis direction;writing the data into corresponding machine tool parameters of a numerical control system; and activating the five-axis linkage function of the numerical control system. In this way, the problems thatthe characteristic data of the five-axis machine tool cannot be directly acquired and the precision of a traditional method is low can be effectively solved. The accuracy of calibrated data is guaranteed, and the rapidity and the accuracy of the five-axis RTCP calibration are improved. As a result, the adjustment time is shortened, and the introduction of human errors is reduced.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

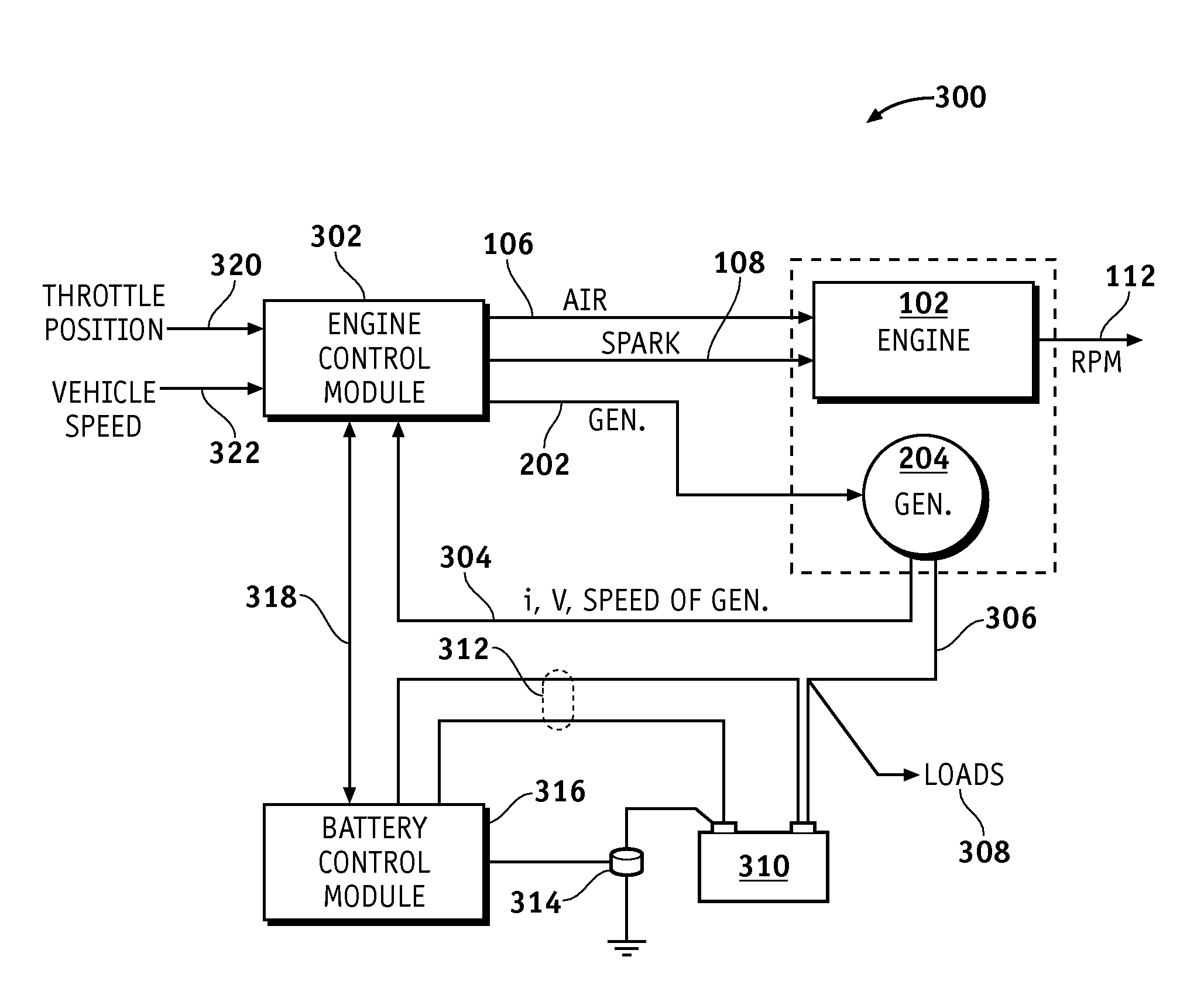

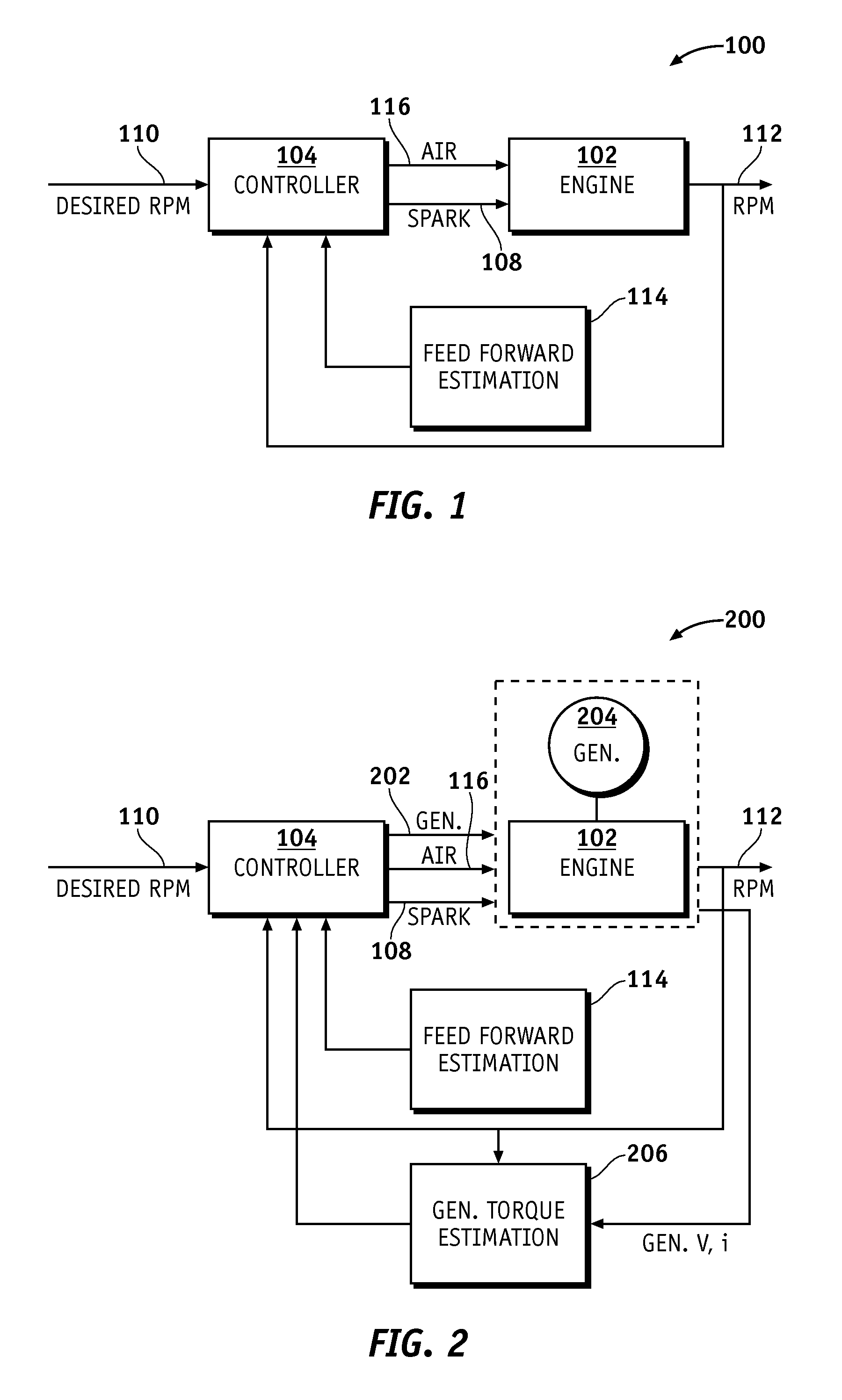

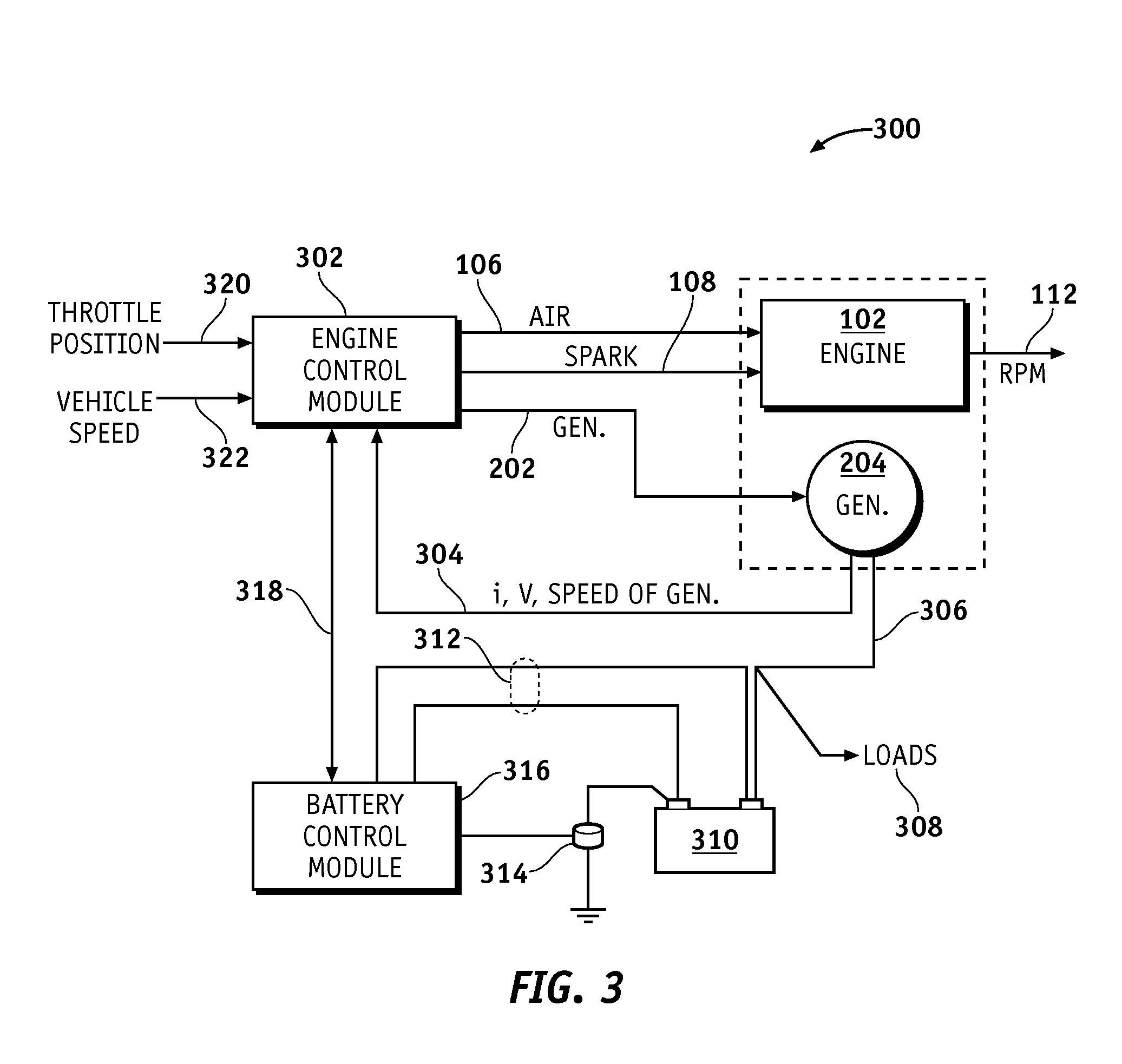

Methods and apparatus for an engine speed controller using generator torque load

ActiveUS7290525B1Reduce the error valueReduce the valueHybrid vehiclesElectrical controlControl systemCombined use

An engine control system for use in connection with vehicles and the like allows the engine speed to be modified using the torque load from the electrical generator. The engine is subject to a torque load from a generator coupled to the engine. The controller compares the desired speed to the actual speed of the engine to determine an error value, and the torque load of the generator is modified (increased / decreased) based on the error value such that the absolute value of the error value is reduced. The generator control is combined with and arbitrated with respect to traditional spark control methods, thus reducing the need for spark timing that is substantially retarded from the mean best timing (MBT) setting. The electrical generator can operate in either voltage control mode or field duty cycle control mode, depending upon various conditions.

Owner:GM GLOBAL TECH OPERATIONS LLC

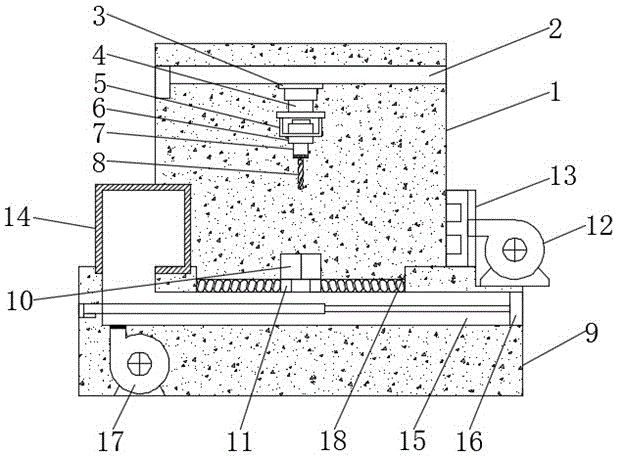

Drilling machine facilitating scrap collection

InactiveCN106514421AEasy to collectReduce precisionMaintainance and safety accessoriesBoring/drilling machinesFixed frameWorkload

The invention discloses a drilling machine facilitating scrap collection. The drilling machine comprises a support and a base. A linear motor is arranged on a top plate of the support. The bottom end of the linear motor is provided with a moving plate. The bottom end of the moving plate is provided with a telescopic rod. The bottom end of the telescopic rod is provided with a fixed frame. The middle portion of the bottom end of the fixed frame is connected with a pneumatic drilling machine in a sleeving mode. According to drilling machine facilitating scrap collection, wind generated by a draught fan is distributed through a flow distribution pipe to blow machined metal products; a suction fan operates to suck wind on a collection frame; wind flows to blow scraps generated after machining into the collection frame, and the scraps fall into a collection cavity; the electric telescopic rod operates to drive a cleaning plate to clean the scraps out of the collection cavity. Accordingly, scrap collection is facilitated, and the workload of workers is reduced. Heat generated during metal product machining is reduced. The cleanliness of the machine is guaranteed. The service life of the machine is prolonged. The machining precision of metal products is guaranteed.

Owner:WUXI CAIYUN MACHINERY & EQUIP

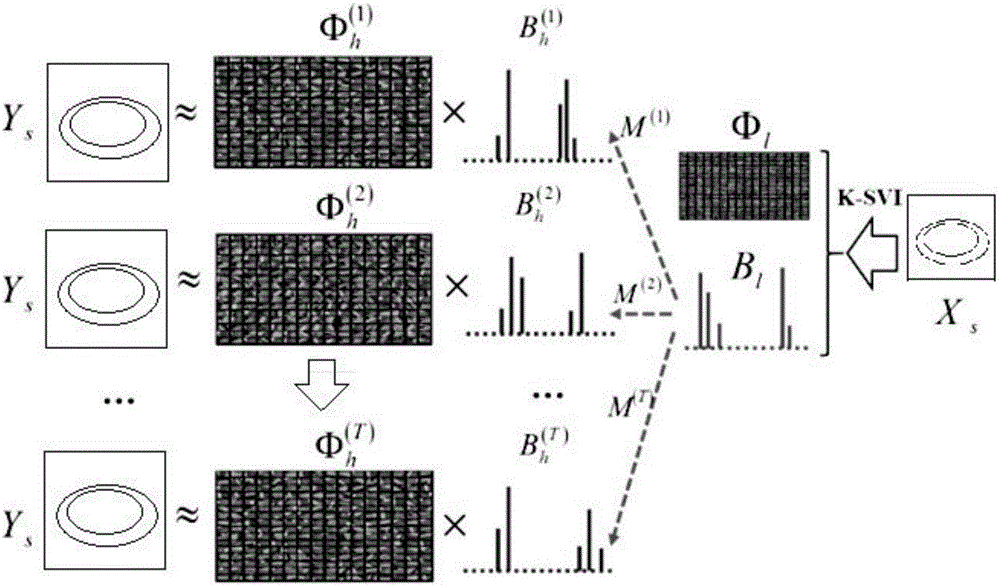

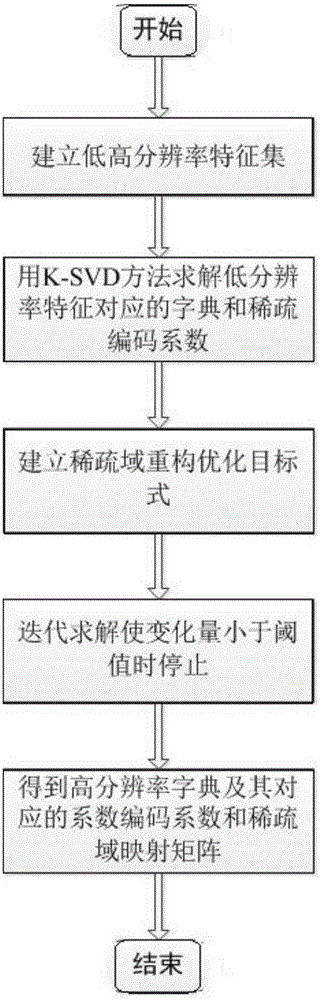

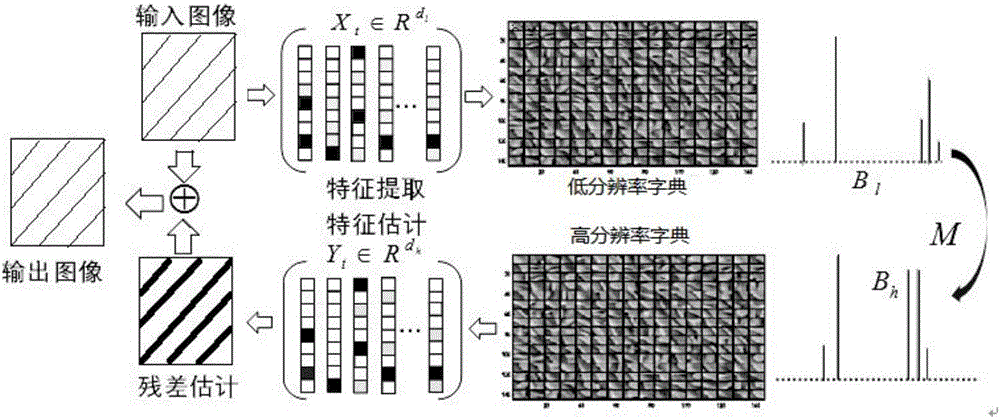

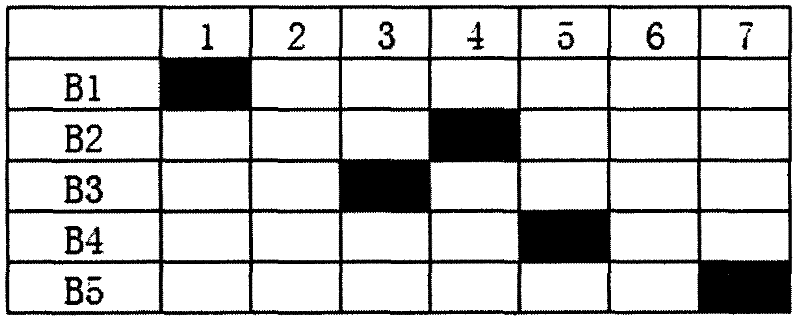

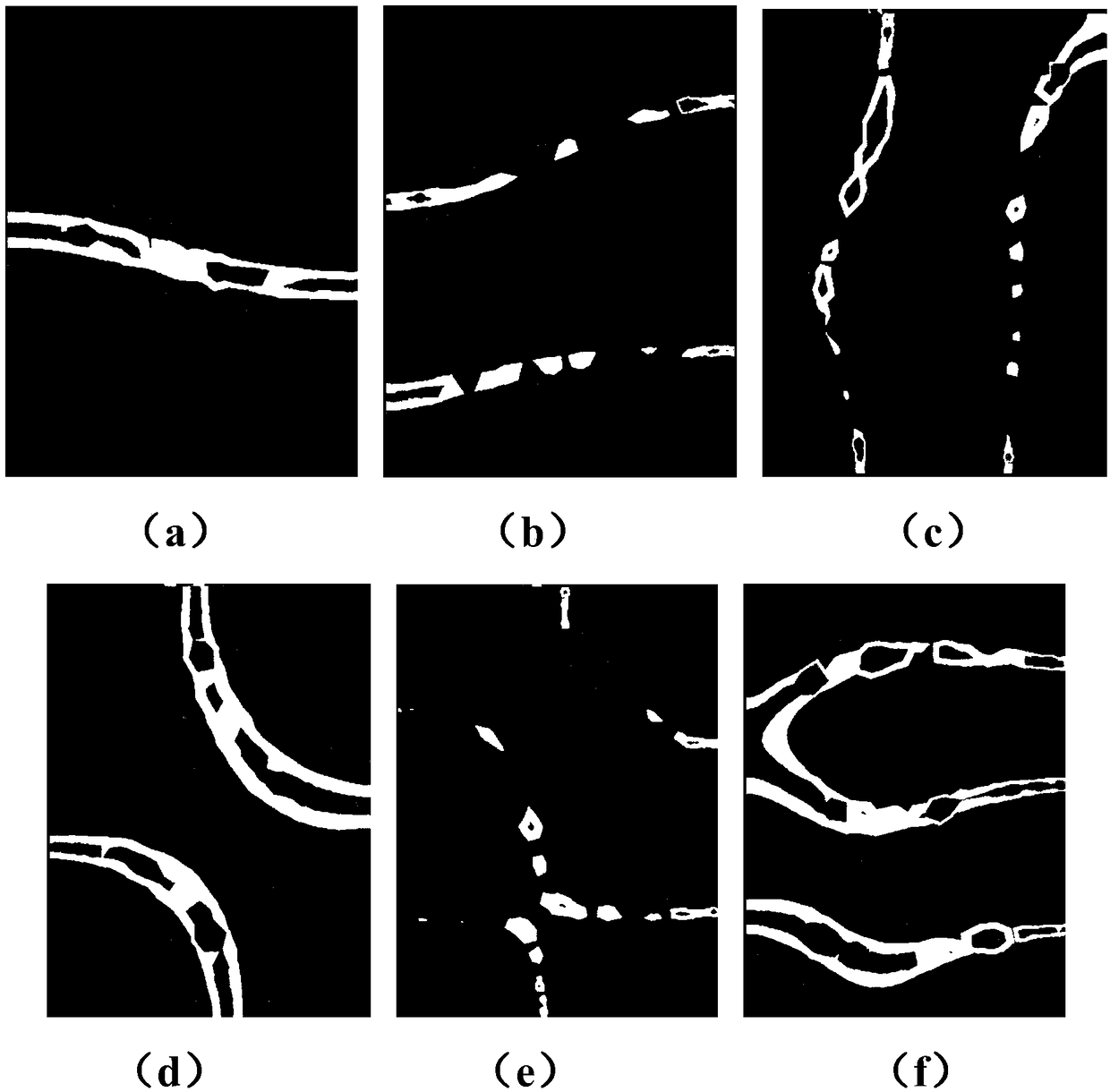

Sparse domain reconstruction-based single-frame image super-resolution reconstruction method and device

InactiveCN106780342AImprove accuracyReduce the error valueImage enhancementImage analysisGraphicsImage resolution

The invention relates to a sparse domain reconstruction-based single-frame image super-resolution reconstruction method and a sparse domain reconstruction-based single-frame image super-resolution reconstruction device. The technical problem that a proper interpolation function cannot be selected according to the priori knowledge of an image to acquire a high-quality reconstructed image in the prior art is mainly solved. A first normal form of instance mapping learning is adopted, mapping M from a low-resolution characteristic B1 on a sparse domain to a high-resolution characteristic Bh on the sparse domain and mapping from the high-resolution characteristic Bh on the sparse domain to the high-resolution characteristic YS are subjected to combined training, and mapping error and reconstruction error are halved to a mapping operator M, a reconstructed high-resolution dictionary phi h and a reconstructed high-resolution sparse coefficient Bh, so the problem that the reconstruction quality is influenced by a larger error of one specific item is solved well, and the method and the device can be applied to graphic processing.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

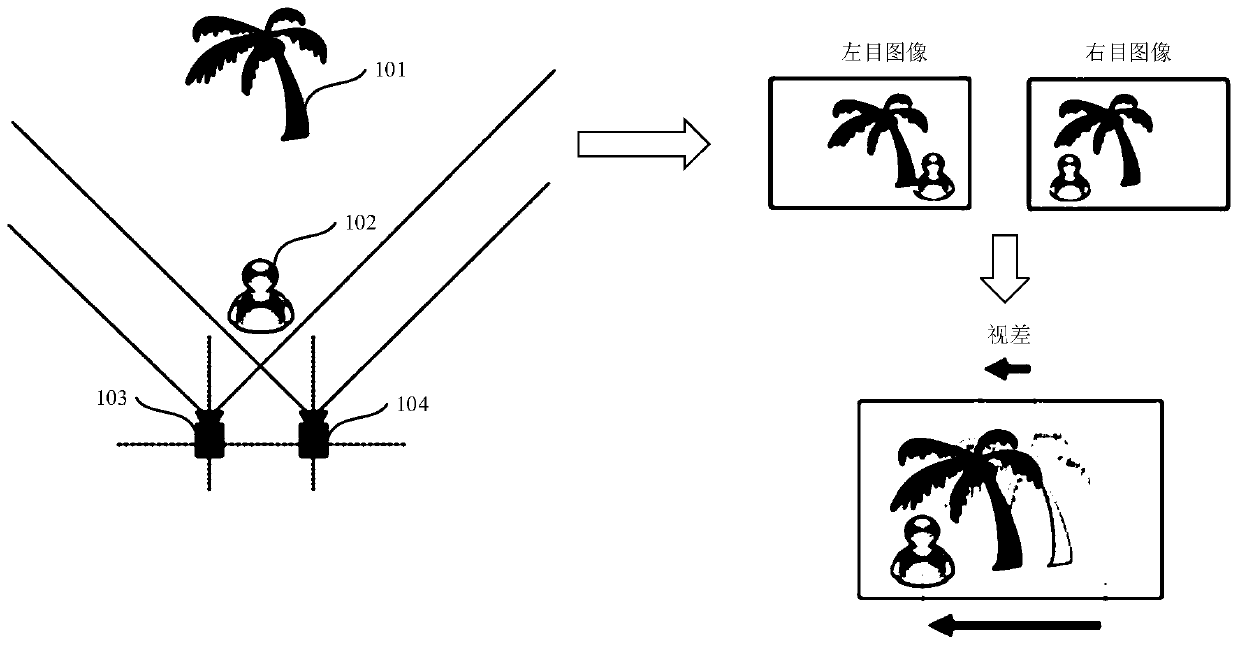

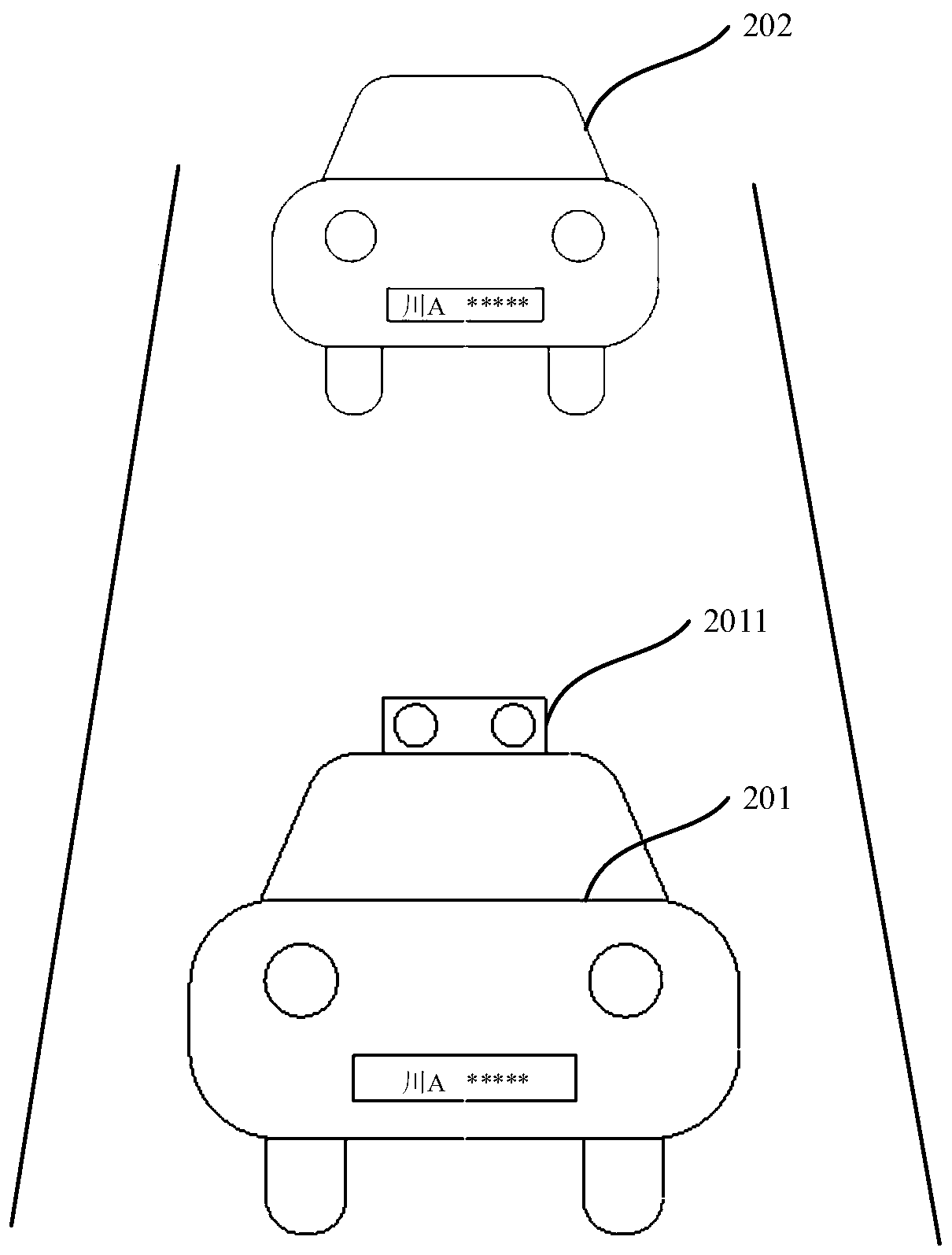

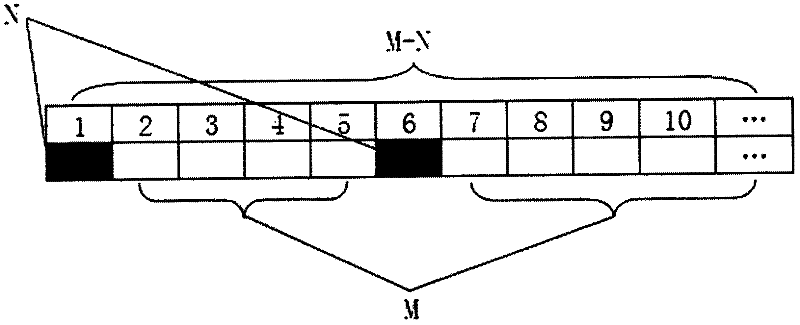

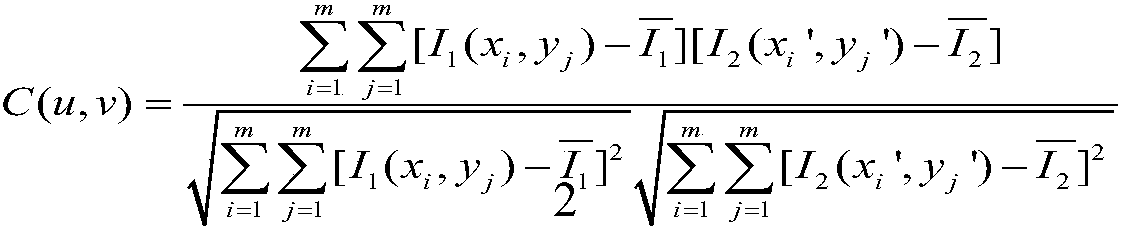

Parallax image acquisition method, device and apparatus and control system

PendingCN109919993AReduce the error valueImprove accuracyImage enhancementImage analysisParallaxImaging processing

The invention discloses a parallax image acquisition method, device and apparatus and a control system, belonging to the technical field of image processing, and is used for improving the accuracy ofdisparity prediction. The method comprises the steps of performing feature extraction on a left eye image and a right eye image of a shot object layer by layer through M cascaded feature extraction layers to obtain a left eye image feature set and a right eye image feature set of each layer; wherein M is a positive integer greater than or equal to 2; constructing an initial disparity map based onthe left-eye feature map set and the right-eye feature map set extracted by the Mth feature extraction layer; and from the first layer, iteratively updating the disparity map through the left-eye feature map set and the right-eye feature map set extracted by each feature extraction layer in sequence until a final disparity map is obtained based on the disparity map subjected to the first-layer iteration updating.

Owner:TENCENT TECH (SHENZHEN) CO LTD

System and method for abnormality detection

ActiveUS9852019B2Accurately determineReduce the error valueCharacter and pattern recognitionNon-redundant fault processingNerve networkAnomaly detection

Owner:AGENT VIDEO INTELLIGENCE

Speech adversarial sample generation method

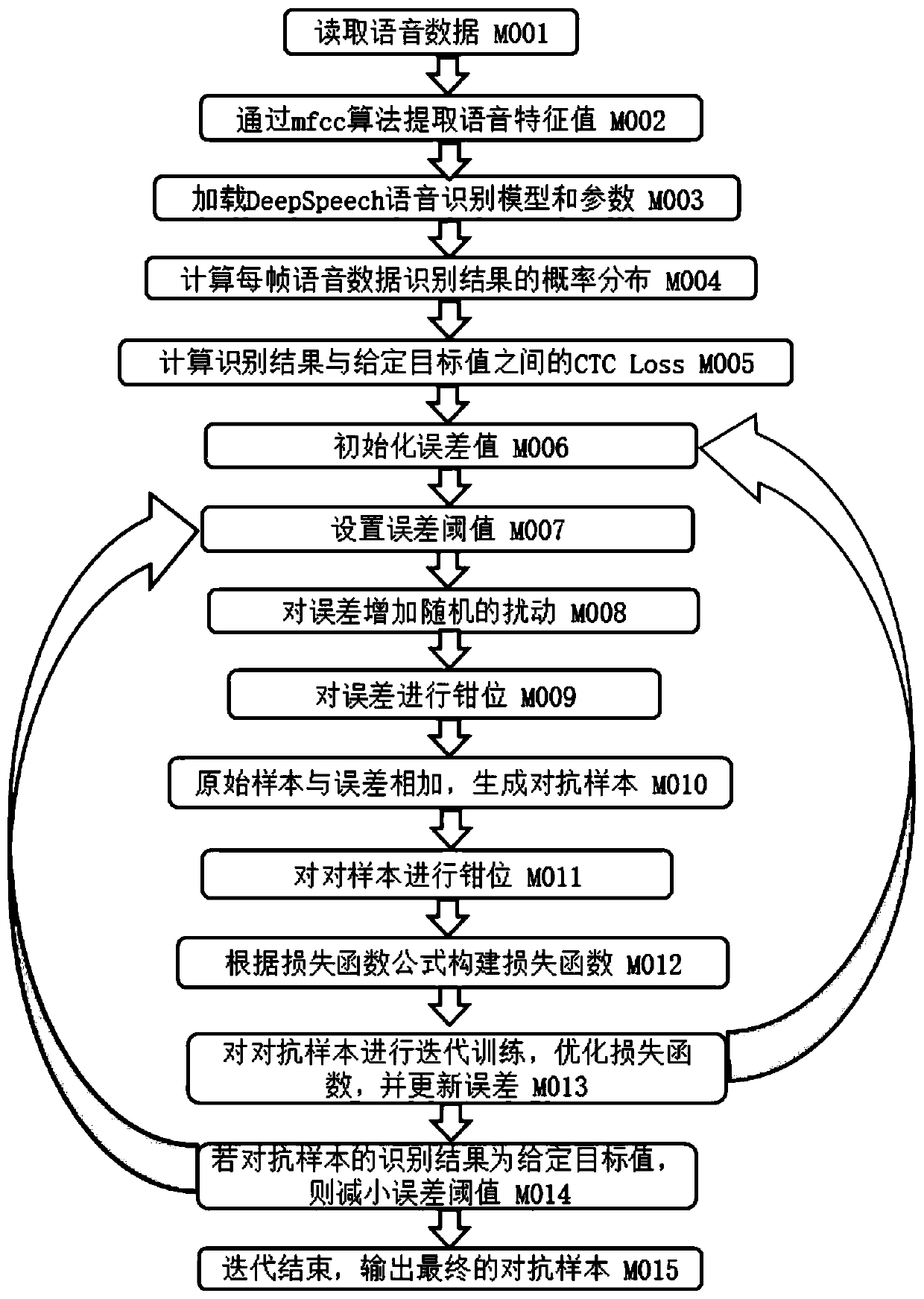

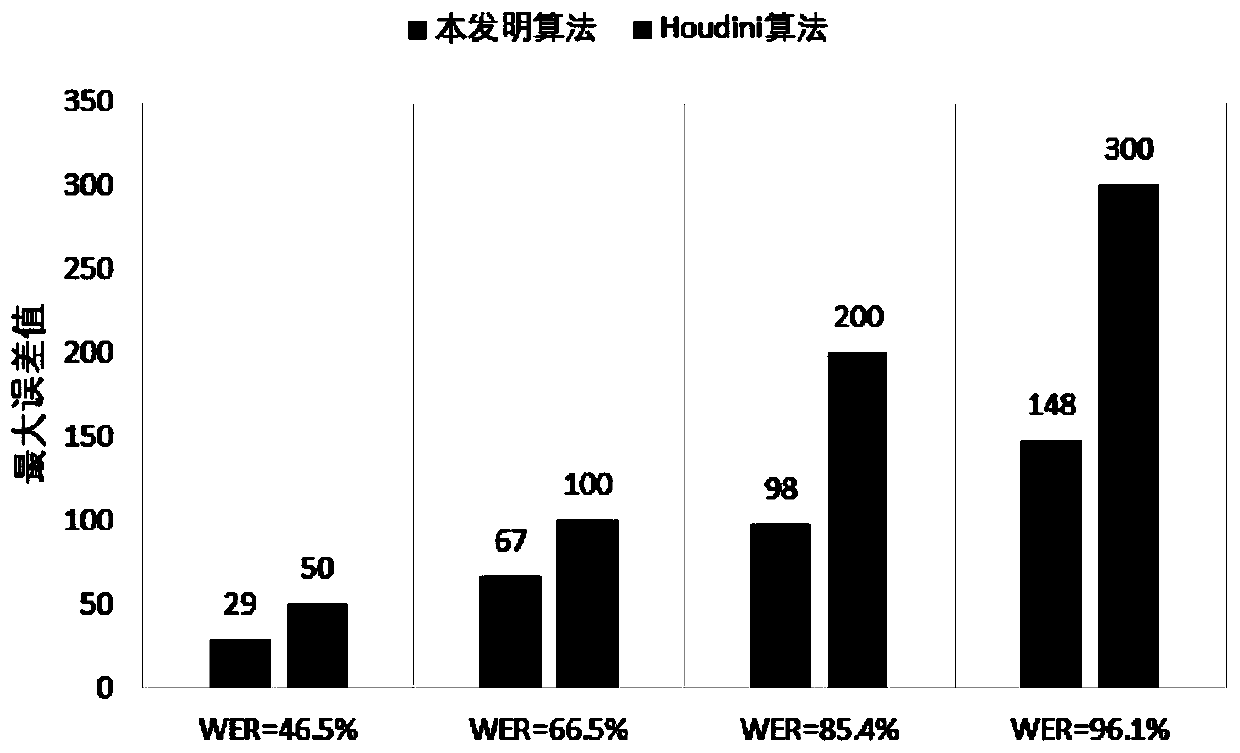

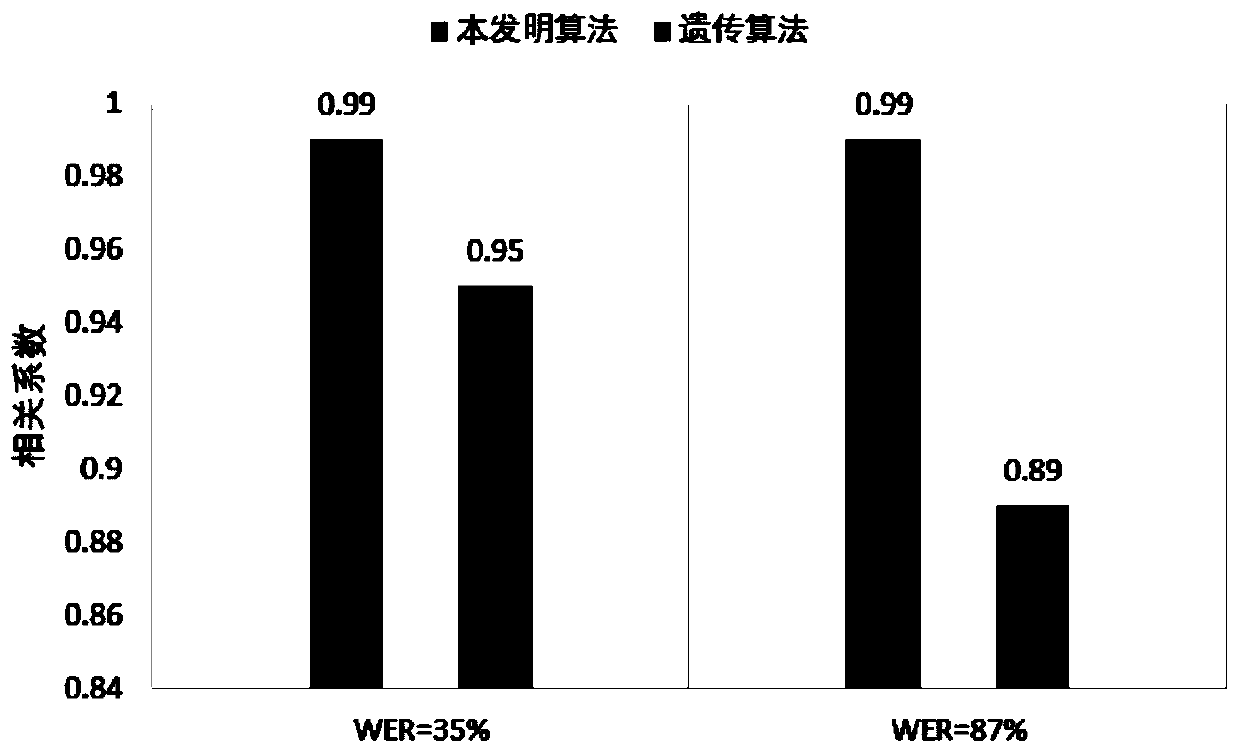

ActiveCN110379418AImprove generalization abilityFast convergenceSpeech recognitionNeural architecturesAlgorithmNetwork model

The invention discloses a speech adversarial sample generation method, which comprises the steps of reading input speech data, performing preprocessing operation on the input speech data, and extracting a speech feature value of the input speech data; loading a deep neural network model and parameters of the DeepSpeech speech recognition system; meanwhile, the extracted speech characteristic valueis input into a DeepSpeech speech system; calculating probability distribution of a recognition result of each frame of input speech data, initializing an error value and an error threshold value according to CTC Loss between the result and a given target value, and performing clamping operation on the error value and the generated adversarial sample; constructing a loss function of a speech adversarial sample generation algorithm, iterating for multiple times, and updating an error value; and if the identification result of the generated adversarial sample is a given target value, reducing an error threshold to update a threshold error, continuing iteration until iteration is finished, and outputting a result. The similarity between the adversarial sample generated by the algorithm and the original sample is higher.

Owner:XI AN JIAOTONG UNIV

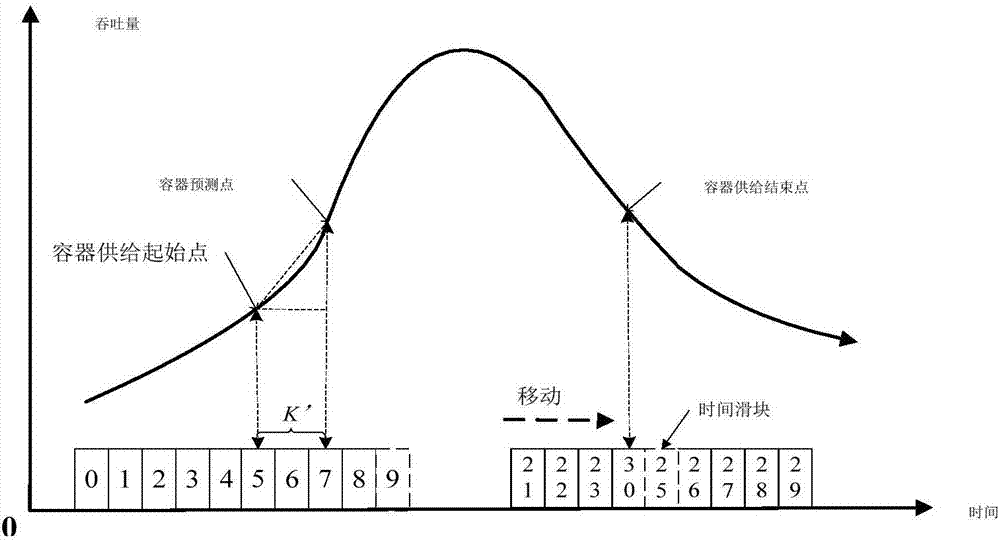

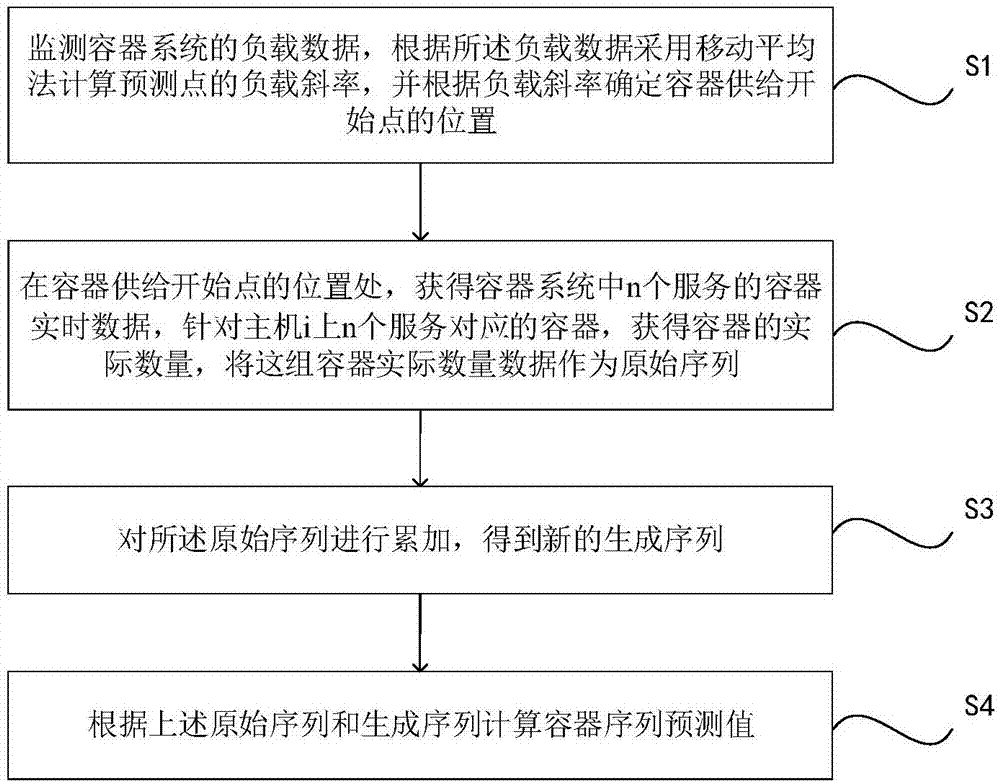

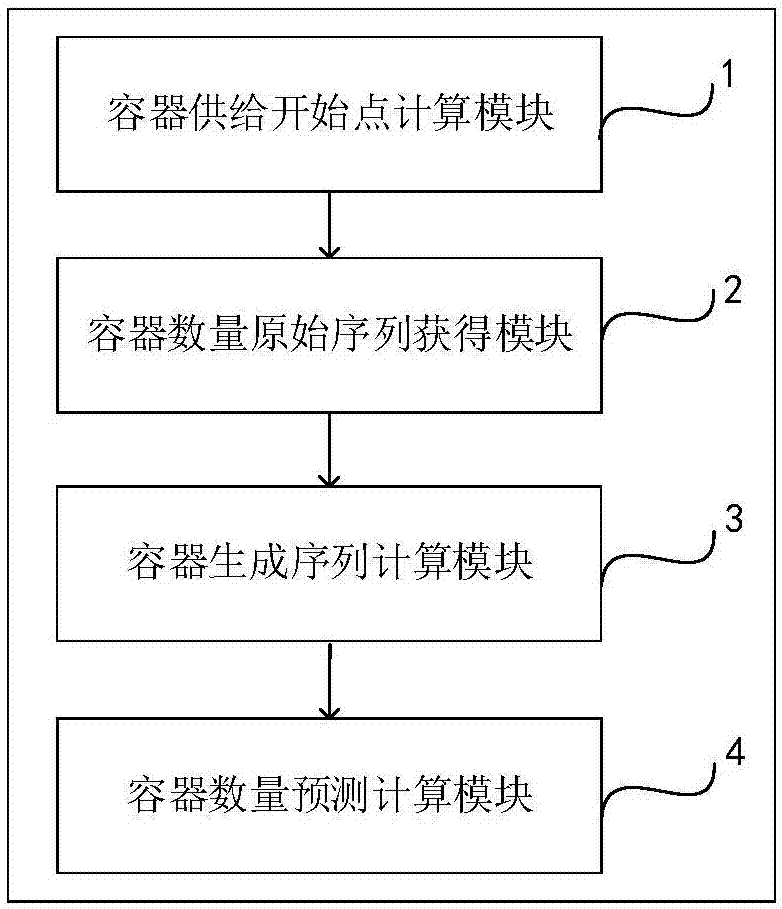

Sudden changed load oriented container cloud elastic supplying container number predication method and system thereof

ActiveCN107404409AQuality improvementImprove efficiencyData switching networksMoving averageReal-time data

The invention discloses a sudden changed load oriented container cloud elastic supplying container number predication method and a system thereof. The method comprises the steps of monitoring load data of a container system, calculating a load gradient of a predication point according to the load data by means of a moving average method, determining the position of a container supplying starting point according to the load gradient; at the position of the container supplying starting point, acquiring container real-time data of n services in the container system, acquiring the actual number of the container for aiming at the containers which correspond with n services on a host machine I, and using the actual number data of the containers as an original sequence; accumulating the original sequence for obtaining a new generated sequence; and calculating a container sequence predication value according to the original sequence and the generated sequence. According to the method of the invention, the container supplying time point and the container supplying number are predicated according to the current system load, thereby predicating the container resource in advance, effectively handling an emergent load, and reducing influence of resource adjustment to service response.

Owner:GUANGXI UNIV

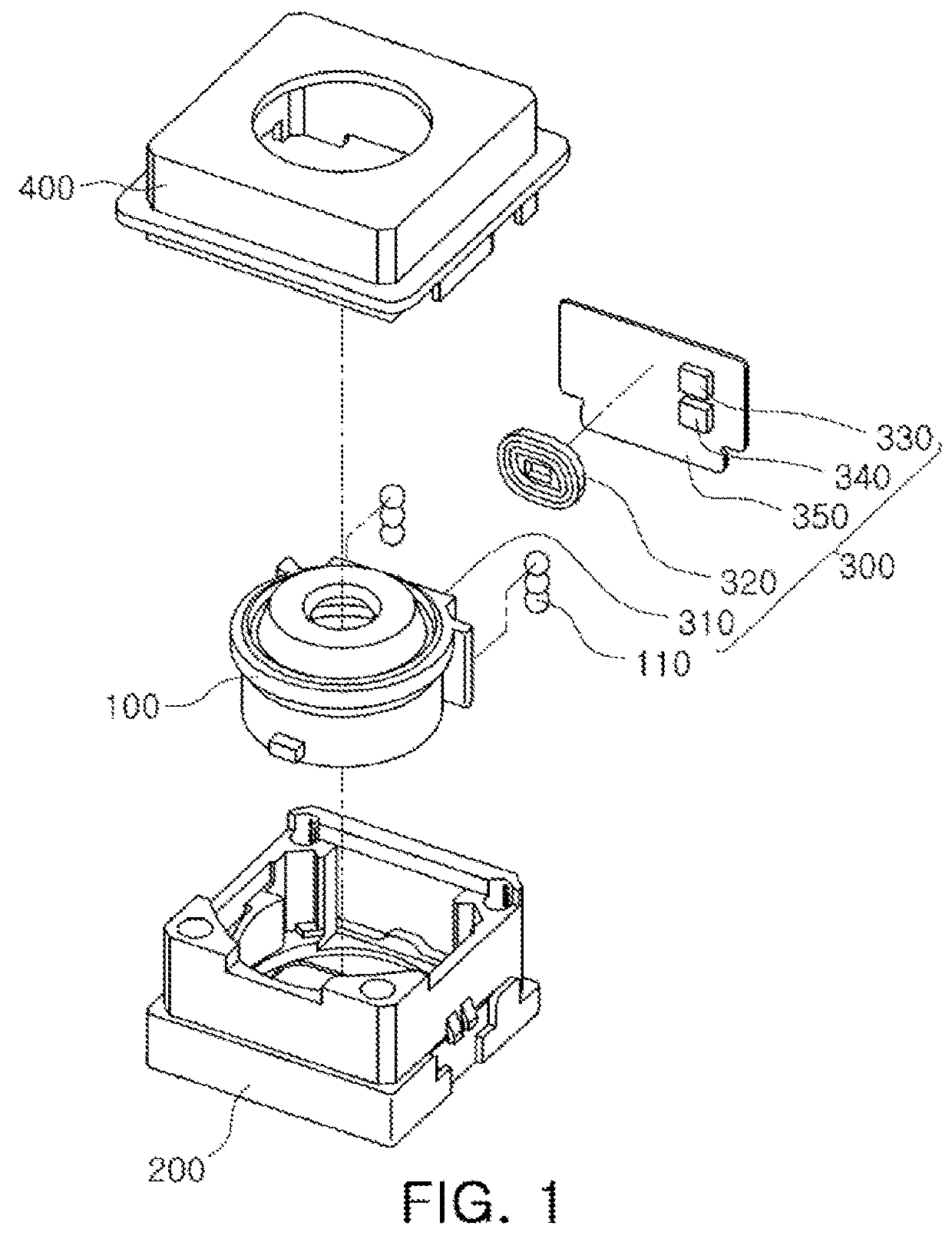

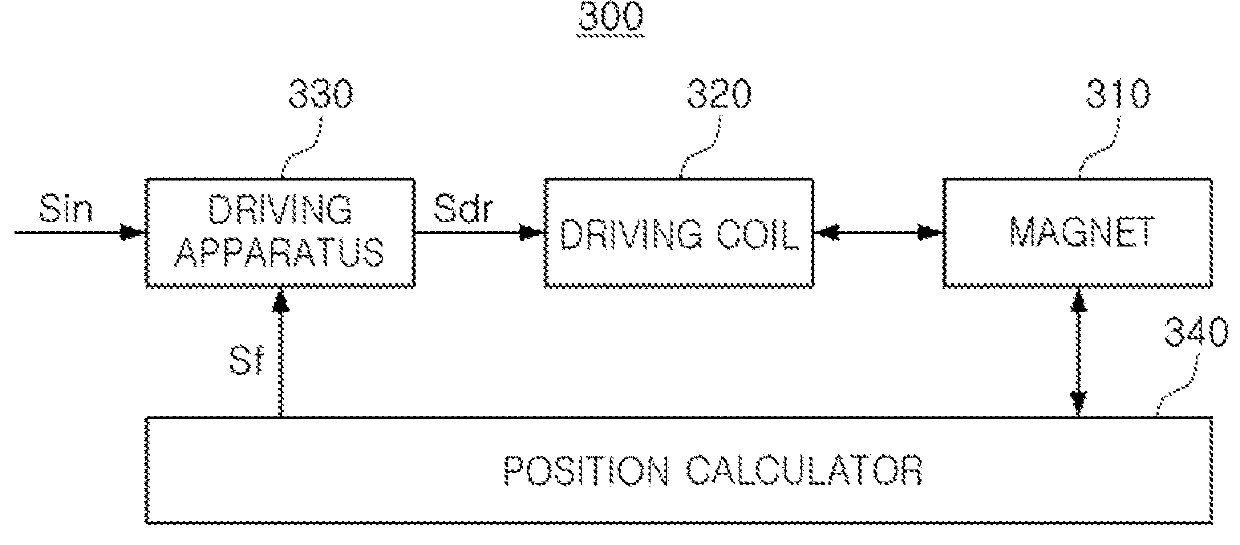

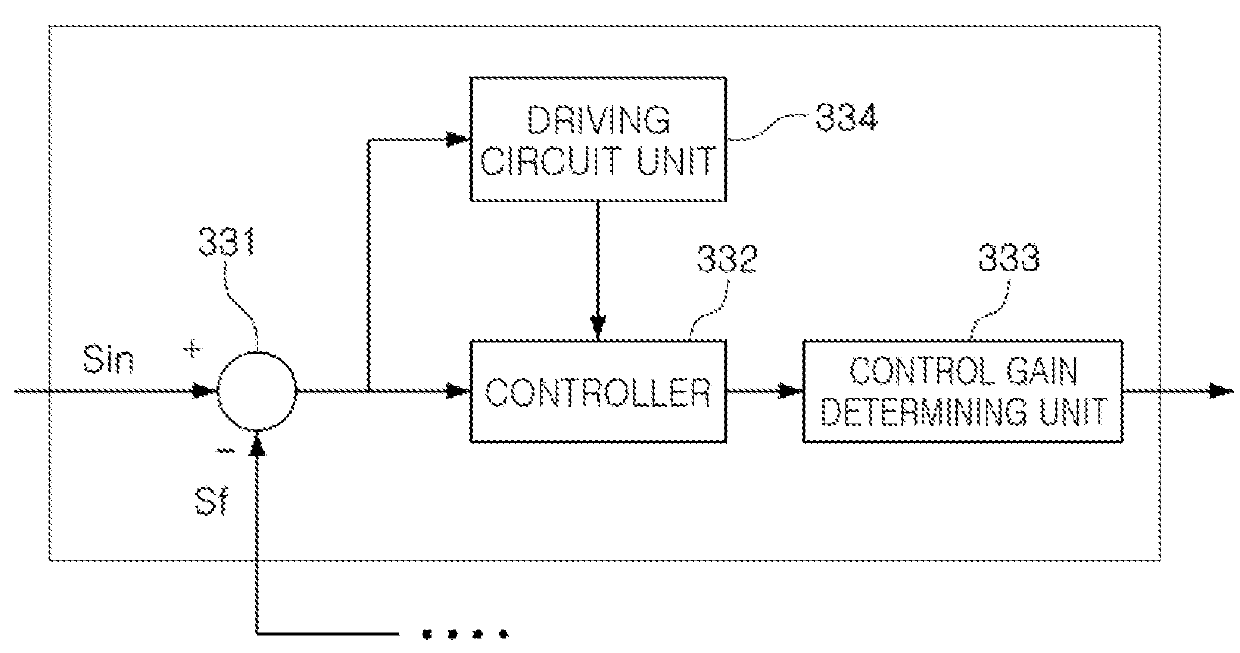

Actuator and driving apparatus of camera module

ActiveUS20180278853A1Reduce control gainReduce the error valueTelevision system detailsPrintersMagnetCalculator

An actuator of a camera module including a magnet, a driving coil facing the magnet, a driving apparatus including a driving circuit configured to apply a driving signal to the driving coil to move the magnet, and a position calculator configured to generate a feedback signal based on a current position of the magnet, wherein the driving apparatus is further configured to calculate an error value by comparing an input signal with the feedback signal, and to determine a control gain of a control signal provided to the driving circuit according to the error value, and wherein the control gain is reduced in response to an increase in the error value, and the control gain is increased in response to a decrease in the error value.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

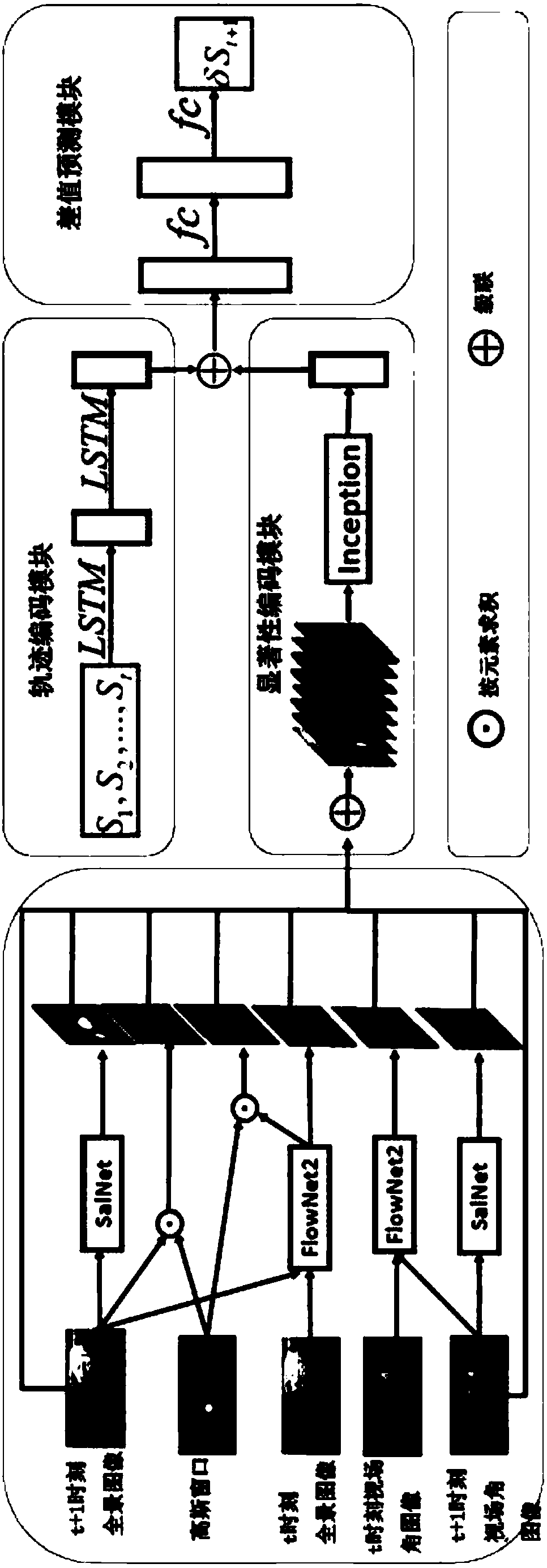

Prediction method of user fixation point in 360-DEG panoramic VR video

InactiveCN108462868AReduce the error valueTake advantage ofNeural architecturesSelective content distributionArtificial neural networkPrediction methods

The invention relates to a prediction method of a user fixation point in a 360-DEG panoramic VR video. The method comprises the following steps: acquiring a sample set about a video frame and a fixation point location when a past user watches a specific video; establishing an artificial neural network which comprises a track coding module, a significance coding module and a difference prediction module; inputting the sample set into the artificial neural network to train, thereby obtaining a fixation point prediction location with the minimum Euclidean distance with the actual fixation point location of the user. Through the prediction method disclosed by the invention, the 360-DEG space environment is actively explored, the possible fixation point of the future user can be predicted by using the past fixation point, the error value is small, and a video maker can utilize the fixation point more sufficiently.

Owner:PLEX VR DIGITAL TECH CO LTD

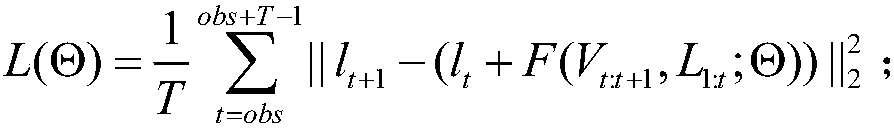

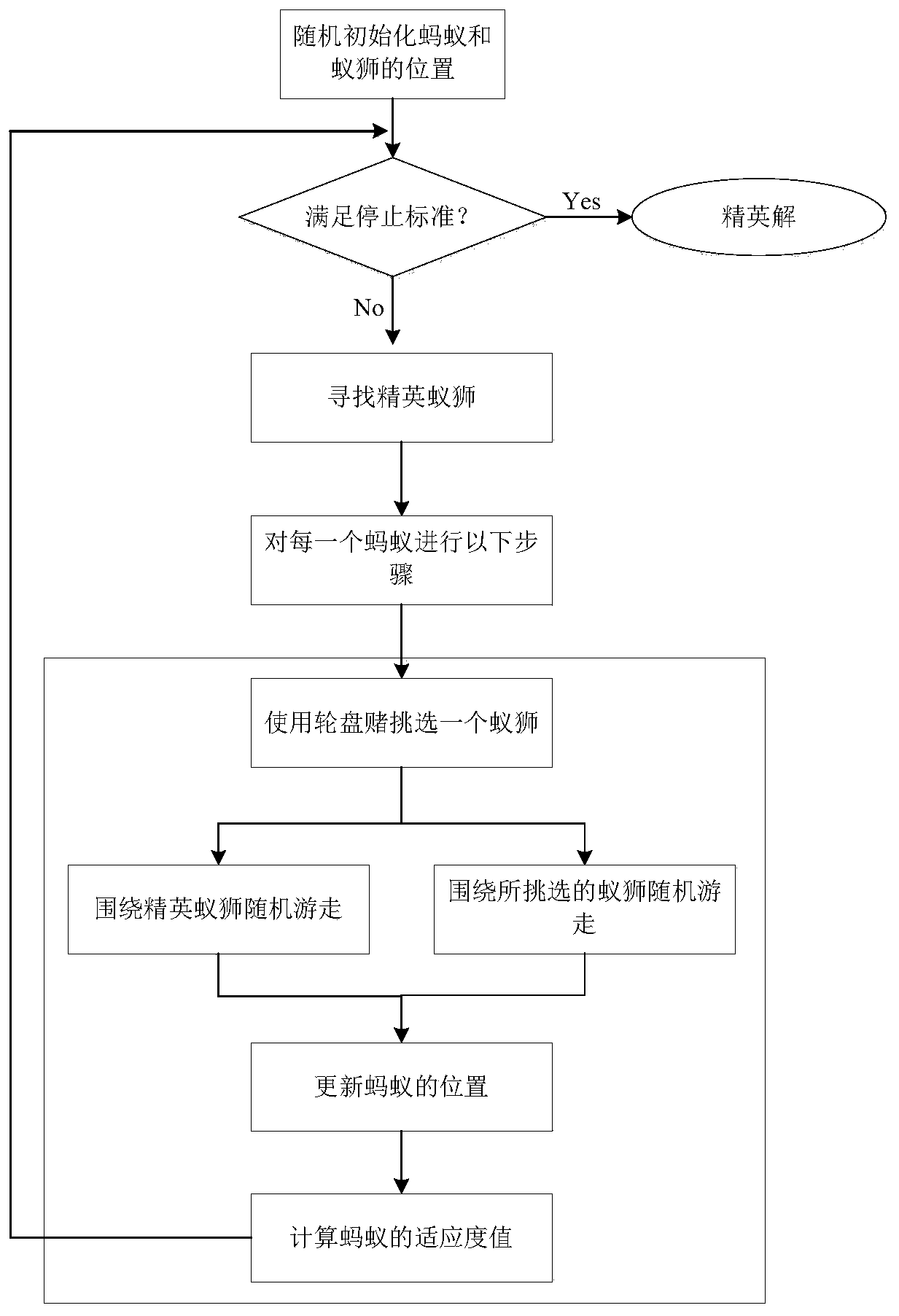

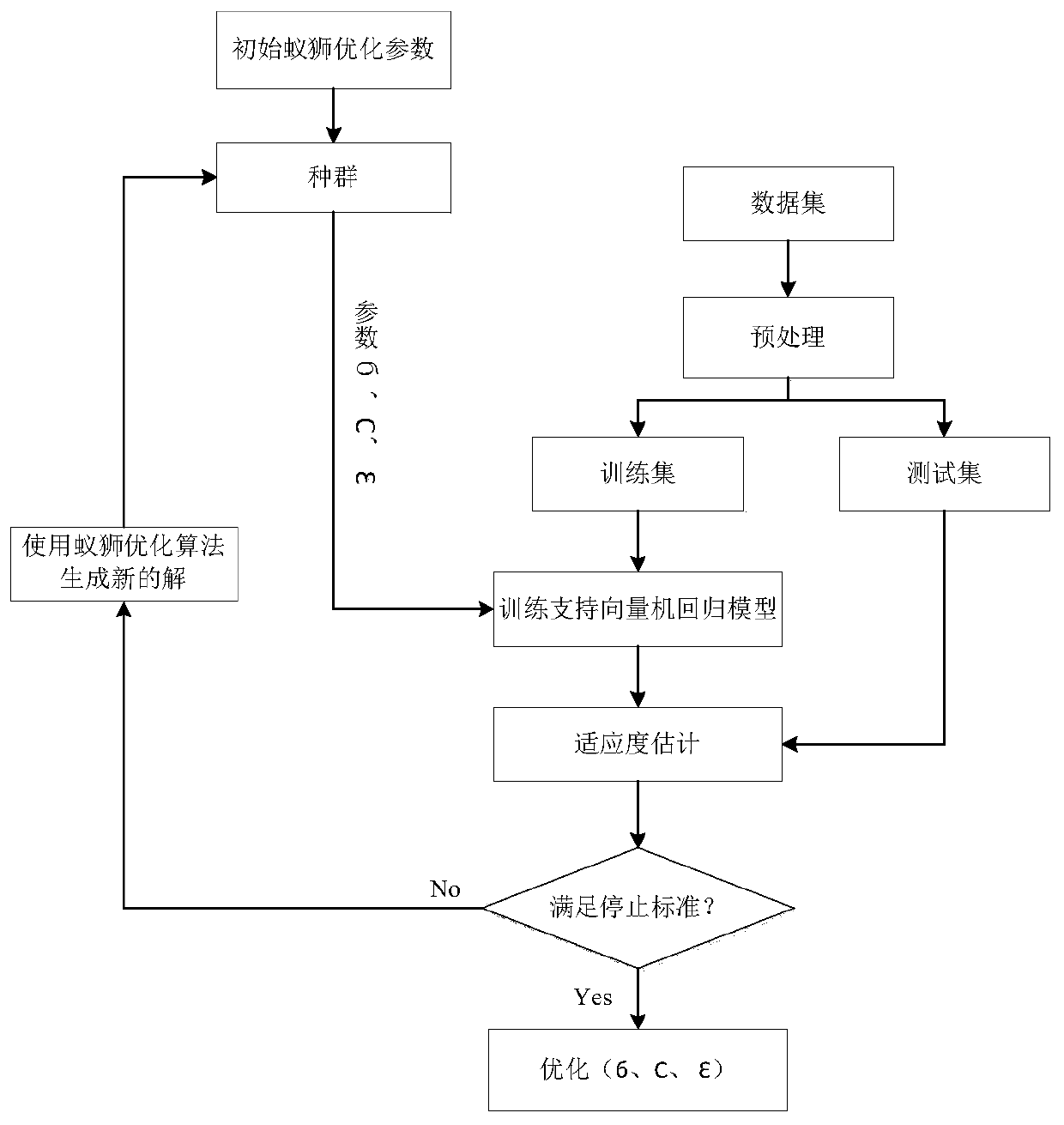

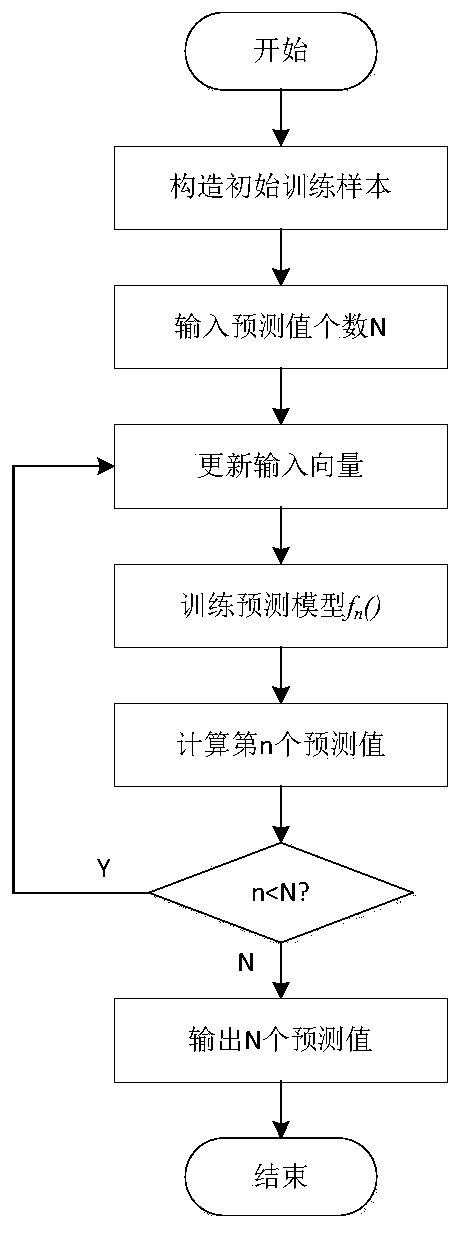

A support vector machine fault prediction method based on adaptive ant lion optimization

PendingCN109767036AReduce cumulative errorReduce the error valueForecastingCharacter and pattern recognitionSupport vector machineSelf adaptive

The invention discloses a support vector machine fault prediction method based on adaptive ant lion optimization. The method comprises the following steps of step 1, preprocessing is carried out; step2, ant lion parameters are initialized; step 3, a support vector machine regression model is trained; step 4, fitness is calculated according to a test set; and step 5, a life curve is predicted by using a single-step loop iteration method. According to the method, the historical data in a period of time when degradation of a monitoring circuit occurs serve as training samples, the number of thesamples is limited, at the moment, when a traditional multi-step prediction method is adopted for predicting characteristic parameter values, a plurality of prediction values at the future moment areestimated at the same time, and prediction errors are gradually increased along with increase of the prediction distance. According to the method, a new predicted value is used for replacing an initial value at an earlier moment in each cycle to serve as a training sample, the sample is updated in real time, the accumulative errors are reduced, and the error value of each prediction is reduced tothe minimum, so that the alculation results are more accurate.

Owner:BEIHANG UNIV

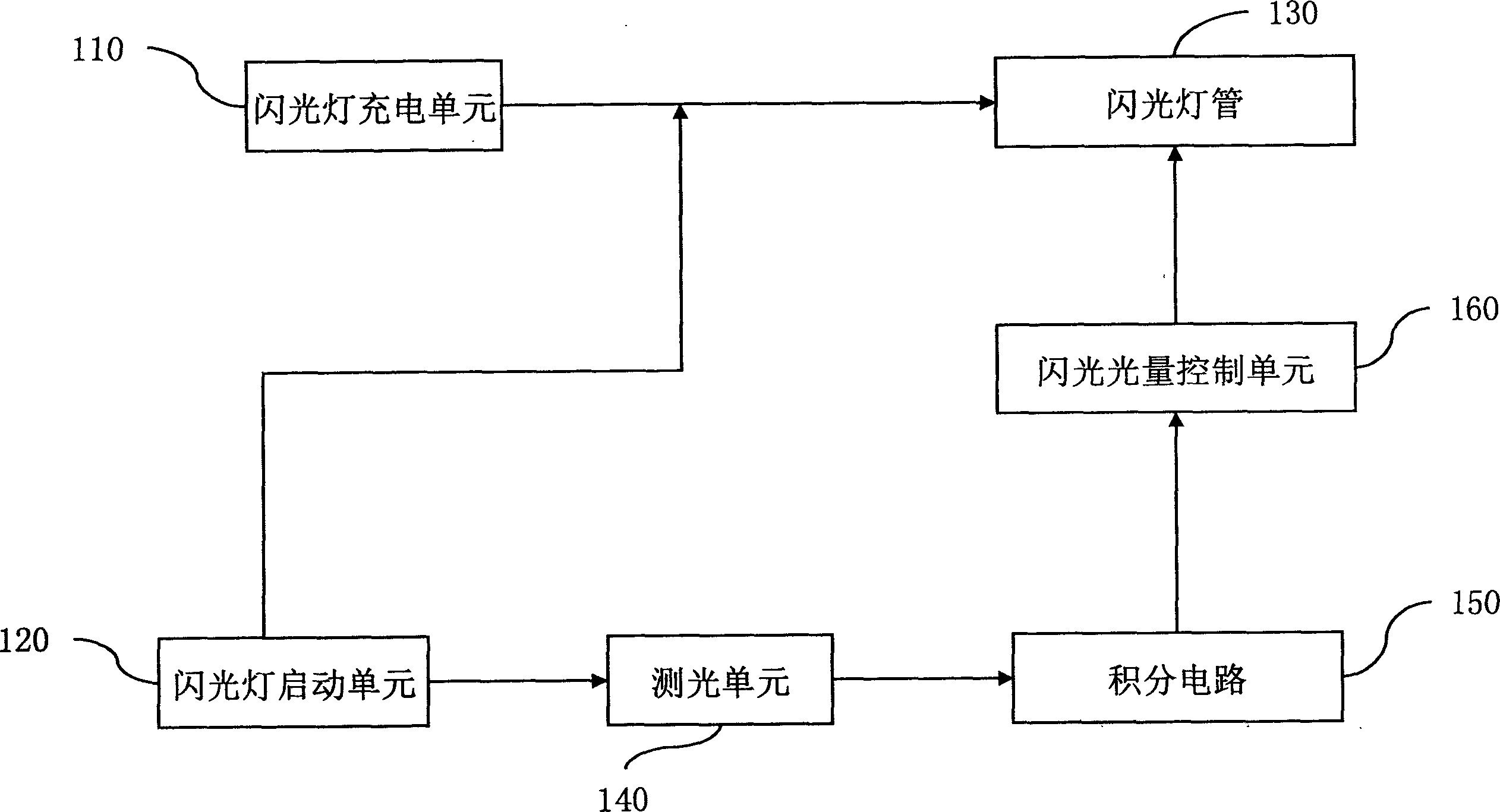

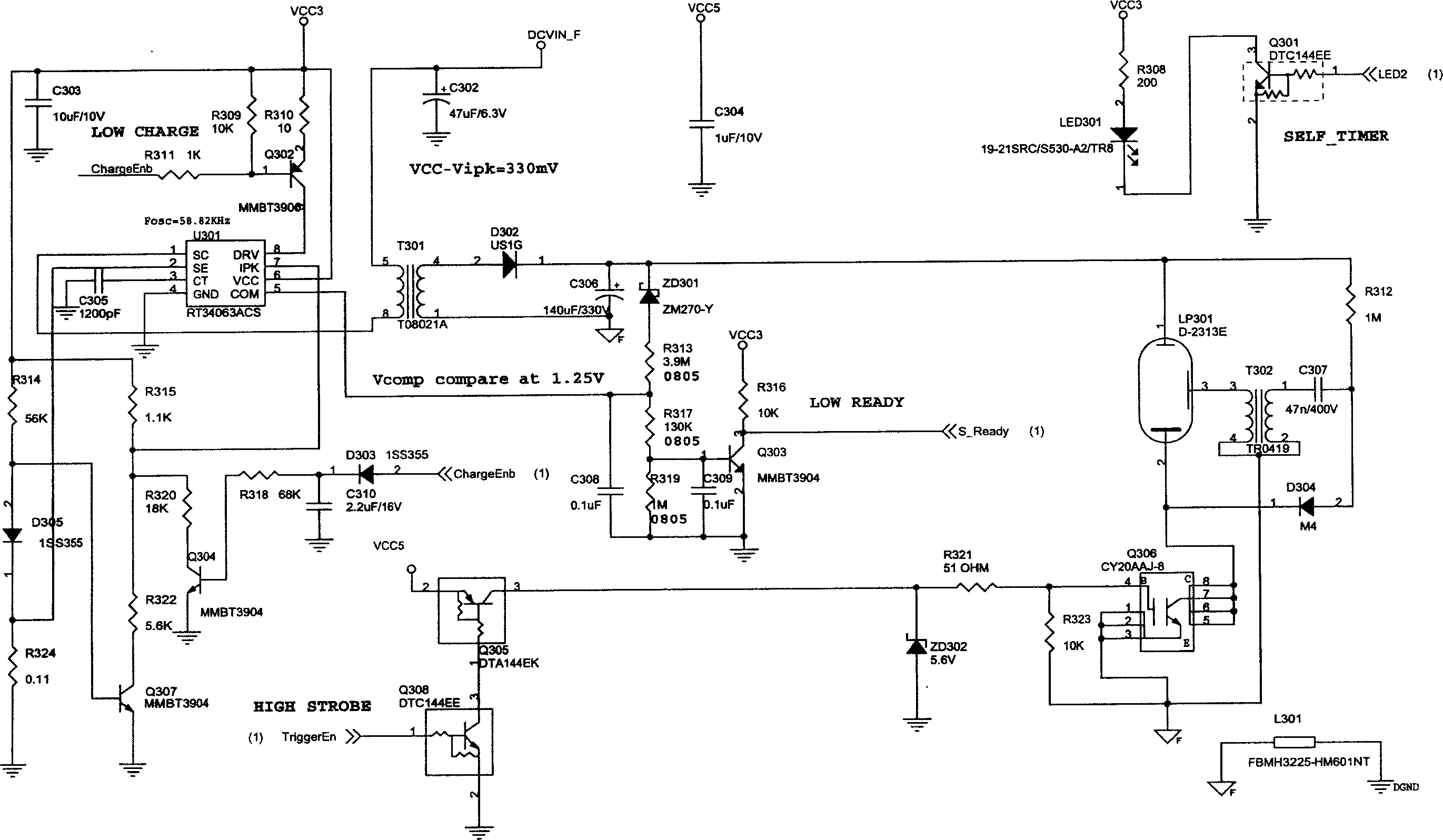

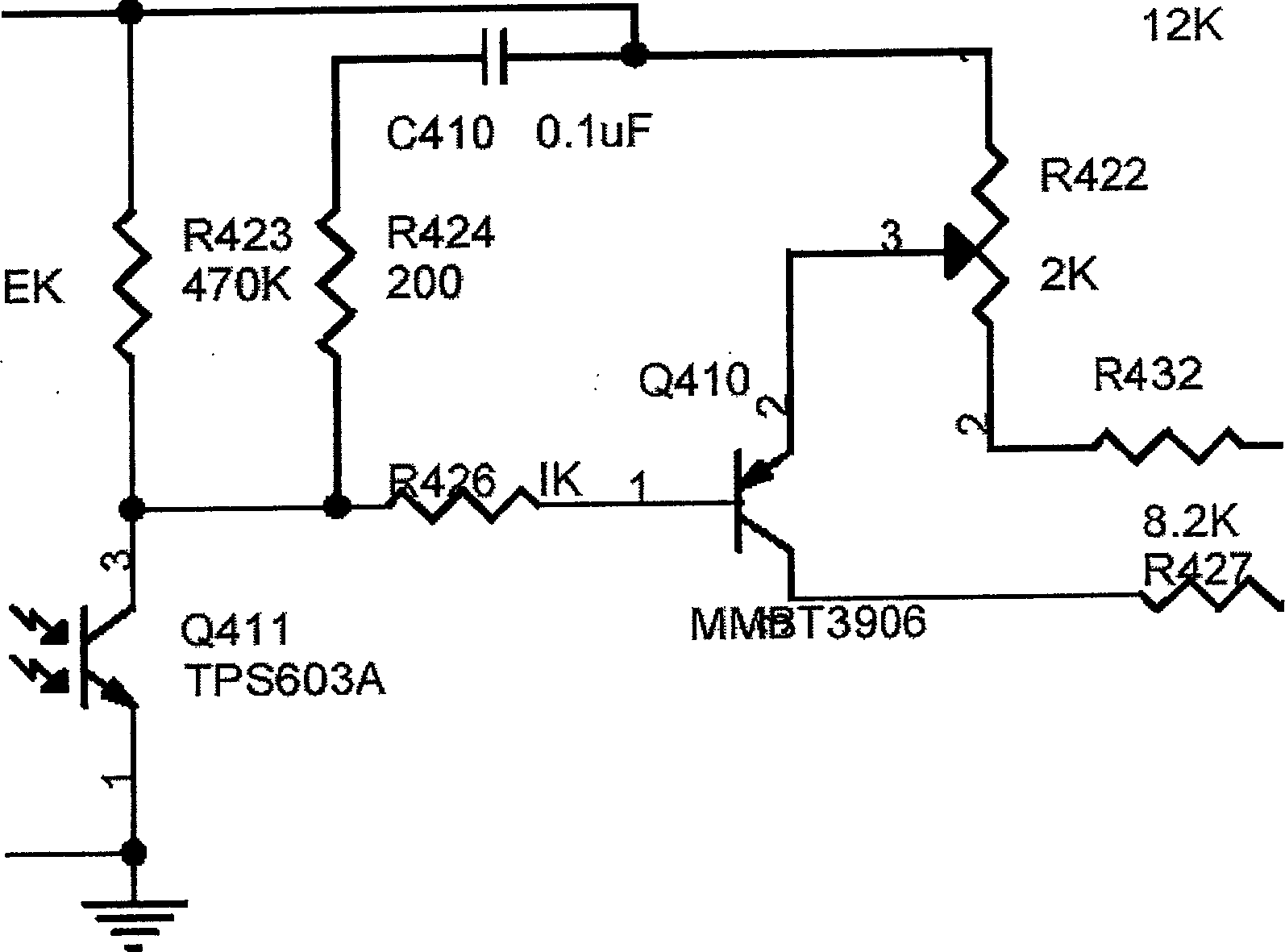

Automatic regulating flash light circuit

InactiveCN1606398AReduce the error valueImprove stabilityElectrical apparatusElectric lighting sourcesCapacitanceElectricity

A light automatic adjusting flash lamp circuit includes a flash lamp charge unit, a flash start unit, a flash lamp tube, a light test unit, an integrating circuit and a flash light volume control unit, among which, the flash lamp charge unit is used to control the charging action of a master capacitor, the flash start unit starts the lamp to illuminate the shot object, the light test receives the reflecting light of the shot object and converts the energy into electric signals, the integrating circuit receives said electric signals and regulates resistance value of the integrating circuit, when its volume value reaches to the exposing standard, the control unit turns off the lamp.

Owner:INVENTEC MULTIMEDIA & TELECOM

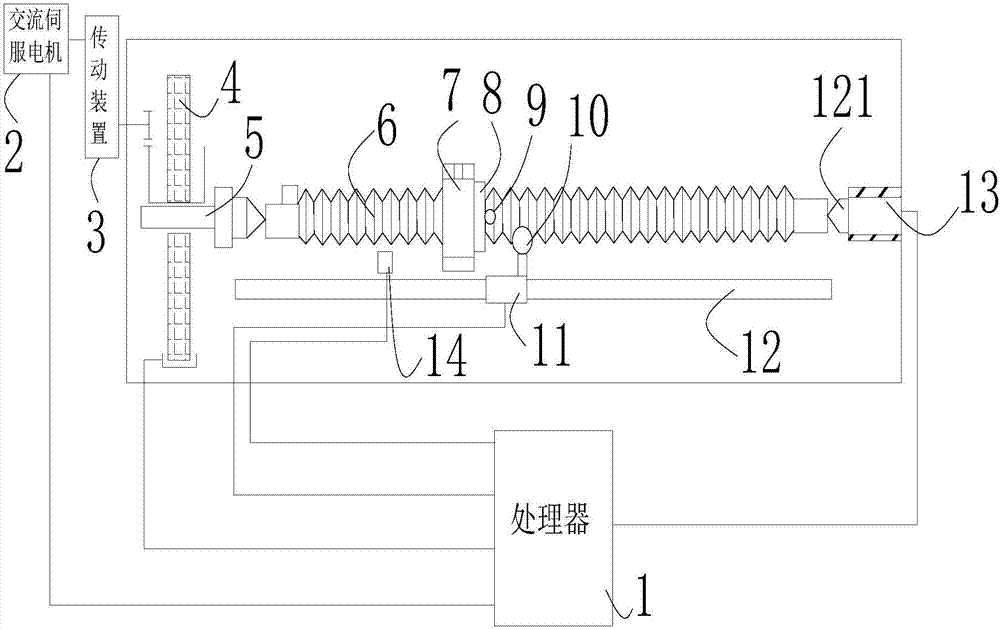

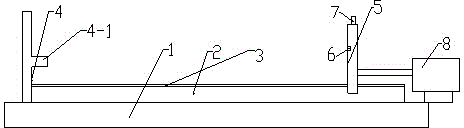

Ball screw auxiliary-stroke error detection system

PendingCN107063043ATo achieve the purpose of manufacturing precision testingReduce the error valueError compensation/eliminationAxial displacementGrating

A ball screw auxiliary-stroke error detection system comprises a main transmission shaft, a compensation follower, a circular magnetic grid and a grating ruler; one end of the compensation follower abuts against a ball screw pair, and the other end of the compensation follower is fixedly disposed; the circular magnetic grid and the main transmission shaft are coaxially disposed and fixedly connected; the grating ruler and the ball screw pair are disposed in parallel, and the grating ruler comprises a grating reading head and a measuring head which is connected with the grating reading head and abuts against and cooperates with screw threads of the ball screw pair; and axial displacement information and angle displacement information of the ball screw pair can be measured respectively through the grating reading head and the circular magnetic grid, and then the purpose of manufacturing precision detection for the ball screw pair is achieved. Compensation monitoring can be performed on a length change of the ball screw pair through the compensation follower. After environment temperature of the ball screw pair changes, a processor can receive a change signal sent from the compensation follower and perform processing, an actual length of the ball screw pair is restored, and then an error value brought by a temperature change is reduced to a maximum degree.

Owner:BEIJING PIXI AUTOMATION TECH

Length detection device

InactiveCN104482834AReduce the error valueHigh precisionMechanical measuring arrangementsEngineeringTouch switch

The invention discloses a length detection device. The length detection device comprises a substrate, a guide rail, a detection measuring tool, a fixed plate, a movable plate, a touch switch, an alarm apparatus and an oil cylinder, wherein the guide rail is arranged on the substrate; the detection measuring tool is fixed on the upper plane of the guide rail through bolts; the fixed plate is tightly attached to the end face of one end of the guide rail; the movable plate is arranged above the guide rail and moves left and right along the axis of the guide rail; the touch switch is arranged in the middle of the inner side of the movable plate, and the touch switch and the plane of the inner side of the movable plate are in the same horizontal plane; the oil cylinder is fixed above an engine base and is connected with the movable plate; the alarm apparatus is arranged on the upper end face of the movable plate and is connected with the touch switch. In this way, the length detection device disclosed by the invention can guarantee that the error value of object length detection size and practical processing size is the minimum to reach a high-standard detection requirement; meanwhile, the length detection device can further detect products with different lengths, and is wide in application range, convenient to detect, high in precision and easy to operate.

Owner:SUZHOU LECC TESTING TECH

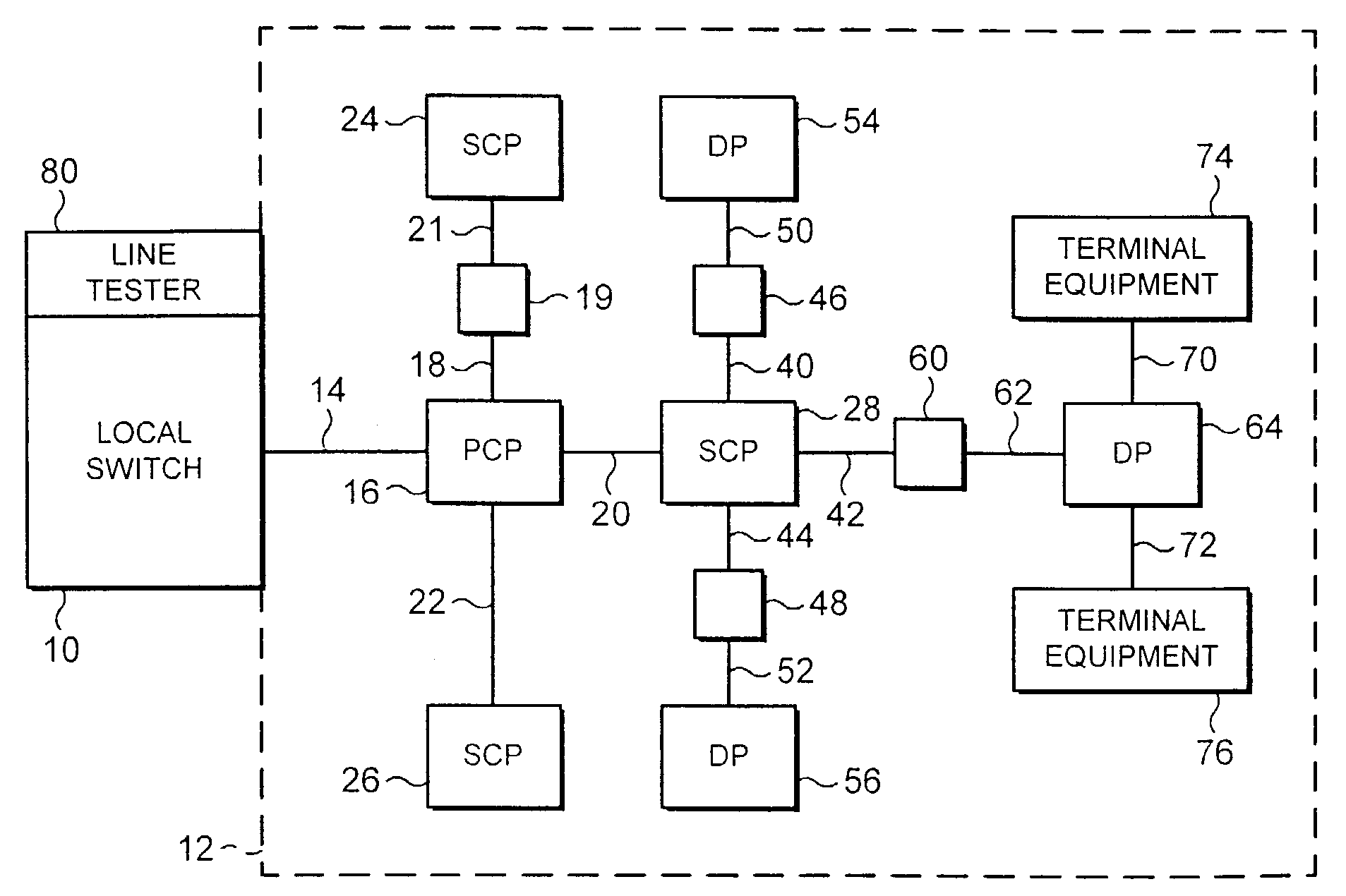

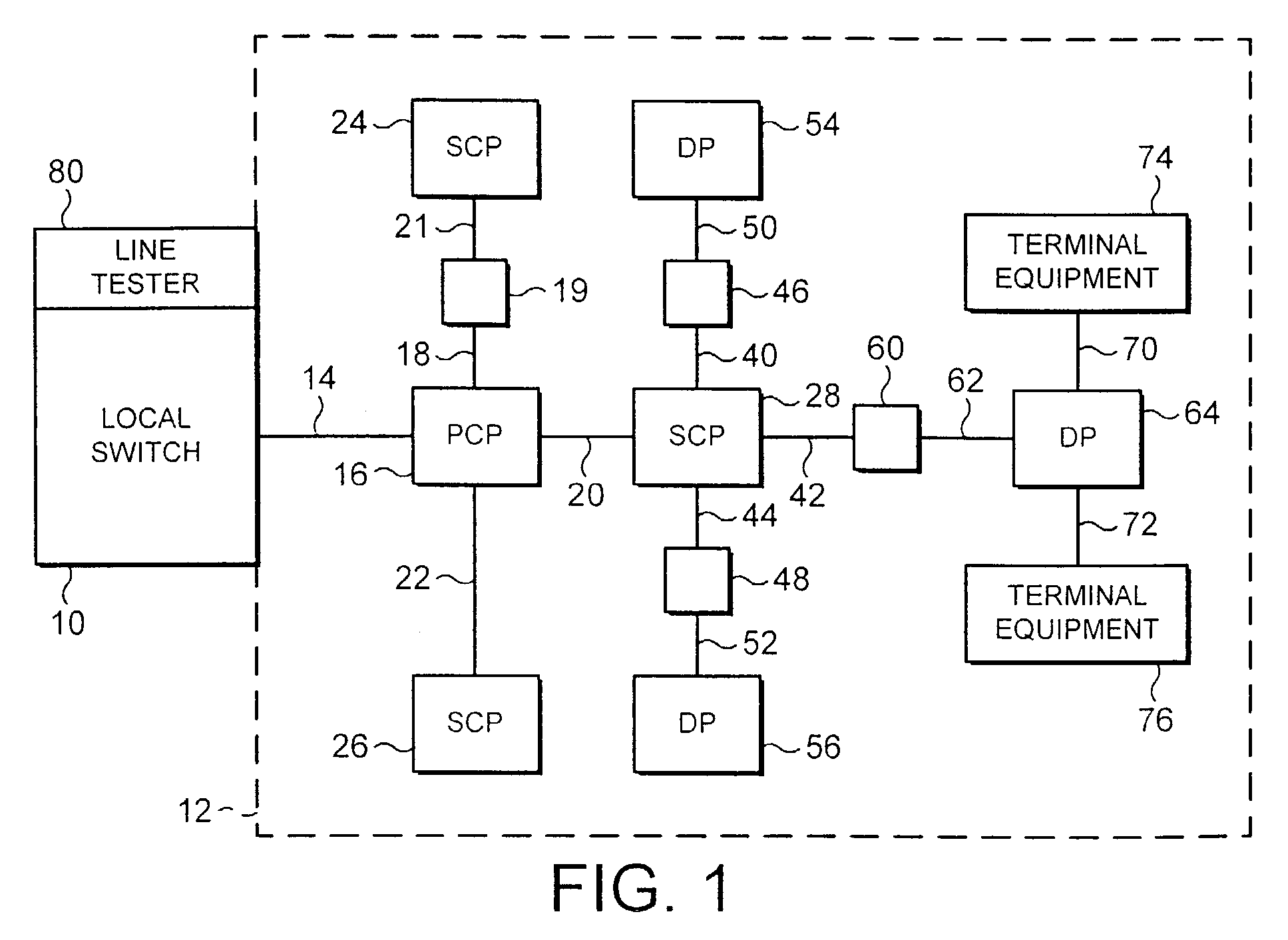

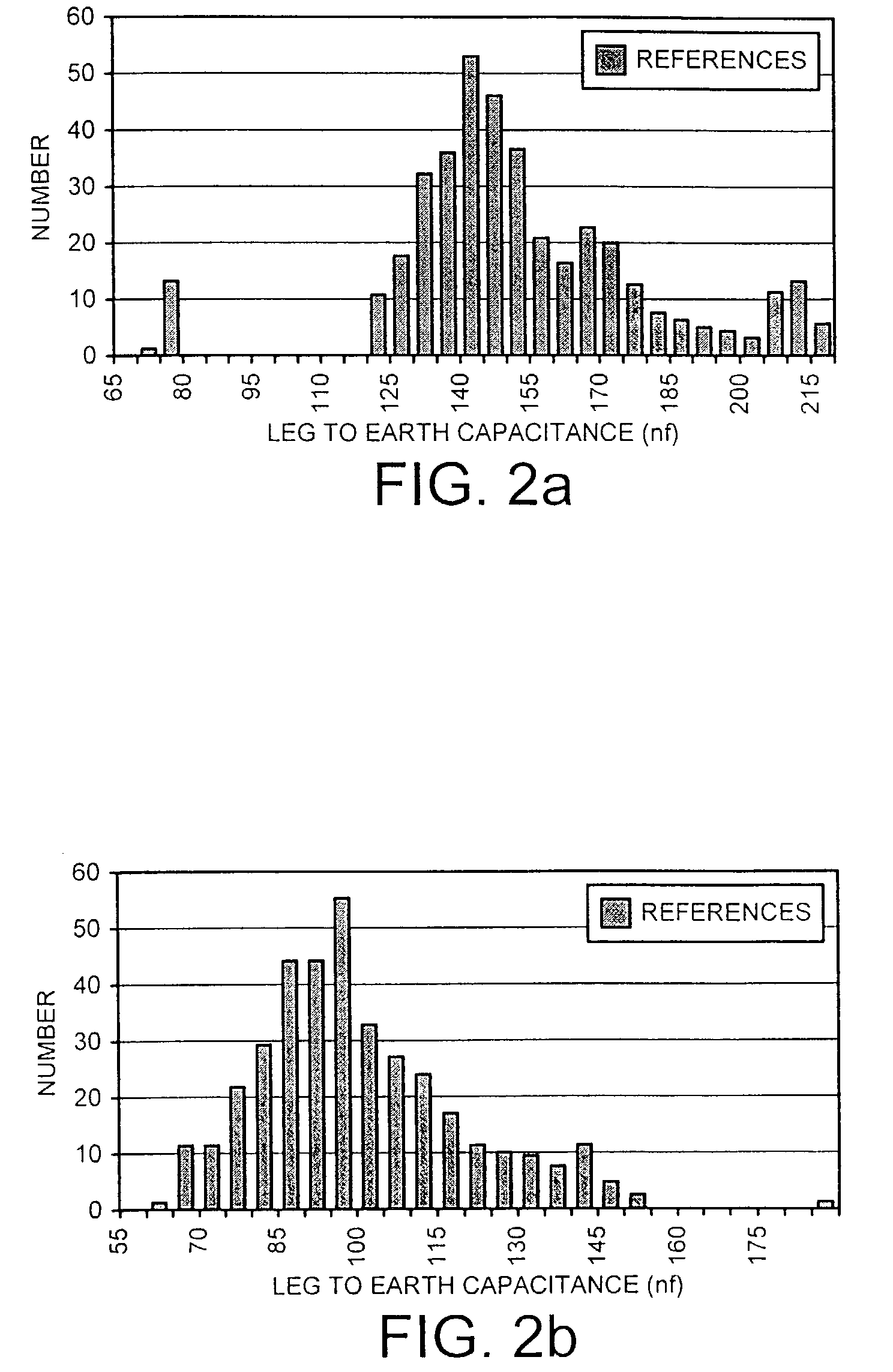

Fault location on a telecommunications network

InactiveUS7359330B2Simple calculationReduce the error valueError preventionFrequency-division multiplex detailsCall terminationCapacitance

A fault location system for a telecommunications network including a local exchange or switch, a node such as a primary connection point and a plurality of line terminations includes probability calculation to establish the location of a fault measured from the exchange. Historical non-faulty reference values of capacitance are compiled for each line passing through the node providing a measure of the distance of each line. A lowest valid capacitance value provides an estimate of the reference capacitance between the exchange and the node. A histogram is compiled of historic fault values and a new fault is compared against the histogram to establish the probability of it being a fault at the node or elsewhere. As a result the reference capacitance can be obtained without the need for an engineer at the node, and the likely location of a fault can be pinpointed with greater accuracy.

Owner:BRITISH TELECOMM PLC

Rationed pouring device for colloidal liquid special for oil paint barreling and covering assembly line

InactiveCN104670915AAccurate control of pouring volumeReduce the error valueBottle emptyingLoading/unloadingLacquerEngineering

The invention relates to a rationed pouring device for colloidal liquid special for an oil paint barreling and covering assembly line. The rationed pouring device mainly comprises a long warped plate. A mounting frame is hinged to the long warped plate, a paint barrel is arranged on the left portion of the upper end of the long warped plate, a tip nozzle is arranged on the lower left portion of the paint barrel, a counterweight bin is mounted on the right portion of the upper end of the long warped plate, round counterweight strips are stacked in the counterweight bin, a rectangular groove is formed in the long warped plate, a control sliding plate is arranged on the right end face of the rectangular groove, a counterweight air cylinder is connected to the right end of the control sliding plate, an air cylinder extension mounting frame is arranged at the right end of the long warped plate, a fixing clamp is communicated under the rectangular groove and sleeves a wheel rotating disc annularly, the wheel rotating disc is connected with a motor axially, side extension plates are arranged on the front end face and the rear end face of the right portion of the long warped plate respectively, weight storage bins are formed evenly in the periphery of the wheel rotating disc, a round-counterweight-strip stacking bin is arranged below the fixing clamp, and an elevated platform is arranged at the lower end of the stacking bin. The rationed pouring device has the advantages of accuracy in control of pouring quantity, reduced error values of oil paint barreling quantity, rapidness and convenience in control and use.

Owner:江苏智光创业投资有限公司

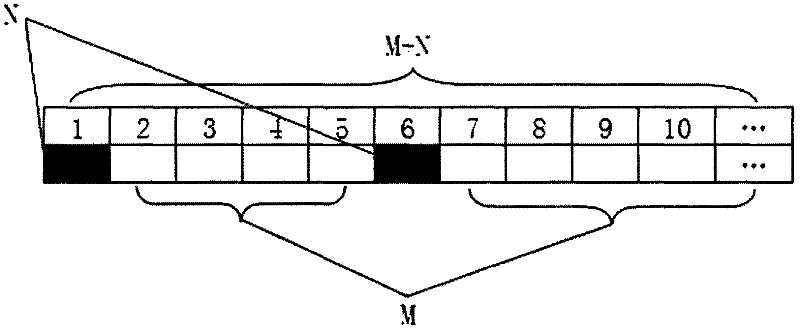

Energy saving data metering and calculating method

InactiveCN102520679AReal-time meteringEasy to controlTotal factory controlProgramme total factory controlProcess engineeringTiming/quantity

The invention discloses an energy saving data metering and calculating method. The method comprises the following steps: (1) taking (M+N) unit times as an energy saving period; (2) in the energy saving period, automatically and randomly selecting N unit times in advance to close an energy saving system with the system, and taking an energy consumption average value of the N unit times as energy consumption reference of unit time; (3) in other M unit times, starting the energy saving system, and taking an energy consumption average value of the M unit times as an energy consumption average value of the unit time when the energy saving system is started; (4) comparing the energy consumption average value of each unit time in the M unit times with the energy consumption reference to obtain average energy saving quantity of the unit time and average energy saving rate of the energy saving period when the energy saving system is started; (5) multiplying the average energy saving quantity of the unit time when the energy saving system is started by unit time quantity (which is M) of starting the energy saving system to obtain total energy saving quantity of the energy saving period.

Owner:朱建斌

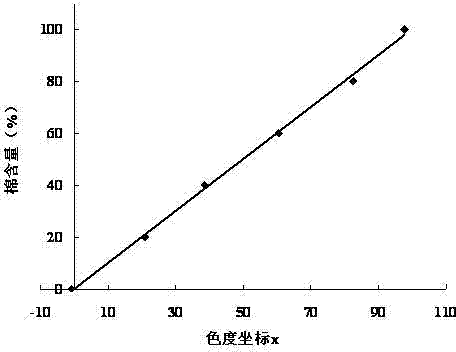

Three-primary colours dye and method for detecting two fibers blending ratio of linen to cotton

InactiveCN103076291AGood linear relationshipReduce intensityPreparing sample for investigationOrganic dyesPolymer scienceCotton fibre

The invention relates to a three-primary colours dye and a method for detecting two fibers blending ratio of linen to cotton, and relates to the method for detecting ratio of cotton fiber to linen fiber in a linen-cotton blending fabric, the method comprises the following steps: adding water in a mixture of direct date red GB to cationic bright yellow to disperse blue 2BLN of 1:1:1 according to weight ratio to prepare a three primary colors dye liquid, diluting the three primary colors dye liquid, immersing the linen-cotton fiber blending substrate to be measured and dyeing, using a reflective spectrophotometer to determine the tristimulus values of X, Y and Z of the dried dyed linen-cotton fiber blending substrate; and substituting the tristimulus values in a cotton fiber content linear regression equation to calculate the ratio of the cotton fiber to two fibers of linen and cotton. The three primary colors dye is the dye with high detection precision used for detecting by a dying method. The detection method is simple, the error for detecting two fibers blending ratio of linen to cotton is less than 3%, the speed is rapid, and the detection efficiency is high, and the examination work strength can be greatly reduced.

Owner:温演庆 +3

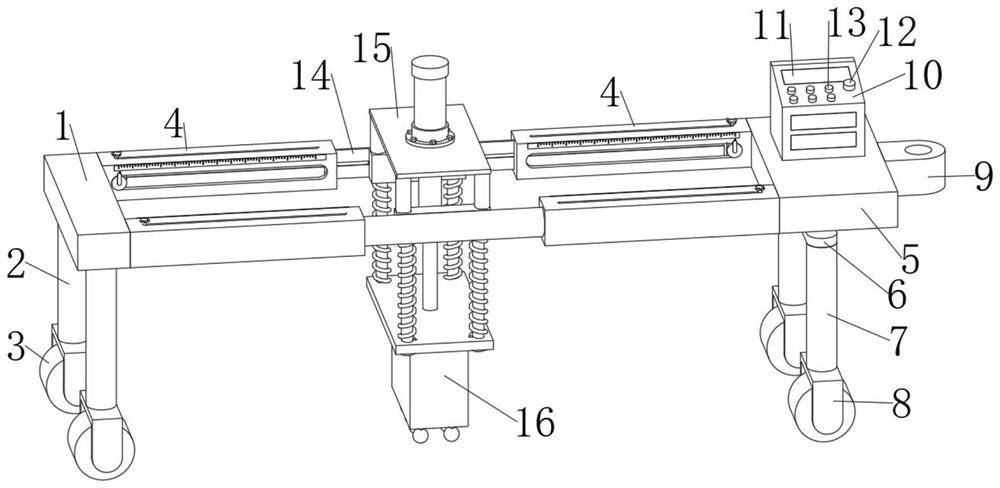

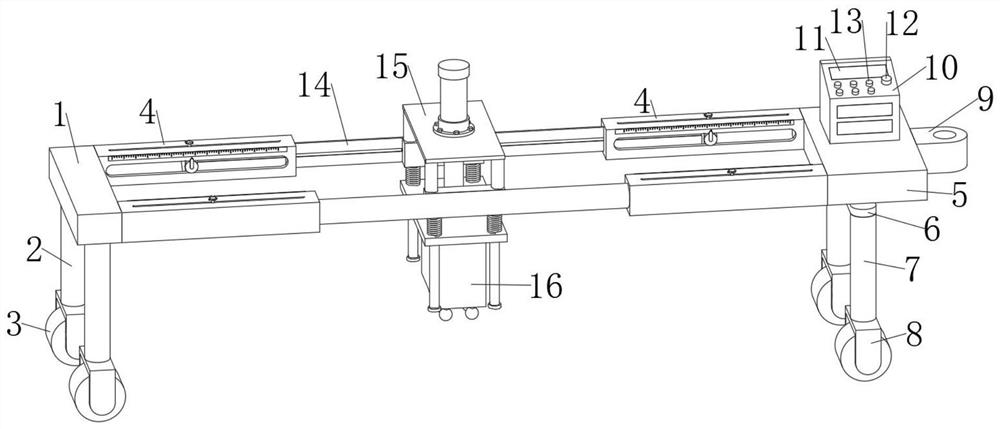

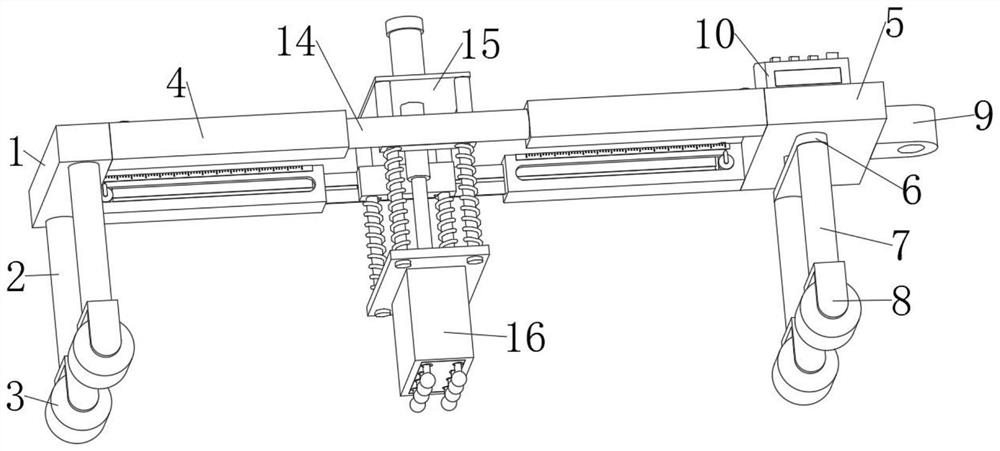

Flatness detection device for constructional engineering

PendingCN112683160APracticalEasy to knowElectric/magnetic roughness/irregularity measurementsStructural engineeringMechanical engineering

The invention discloses a flatness detection device for constructional engineering. The device comprises a left installation plate and a right installation plate, two first supporting columns which are symmetrical front and back are fixedly installed at the lower end of the left installation plate, first rolling wheels are fixedly installed at the lower ends of the two first supporting columns, and the right installation plate is located on the right side of the left installation plate; the lower end of the right installation plate is movably connected with a connecting plate through a bearing, two second supporting columns which are symmetrical front and back are fixedly mounted at the lower end of the connecting plate, second rolling wheels are fixedly mounted at the lower ends of the two second supporting columns, the second rolling wheels and the first rolling wheels are located on the same horizontal plane, and a traction ring is fixedly mounted at the right end of the right installation plate; and a console is fixedly mounted at the upper end of the right installation plate. According to the flatness detection device for constructional engineering, flatness detection can be conducted on the long-distance ground, a specific flatness deviation value can be obtained, the detection precision is high, the intelligent degree is high, operation is easy, use is convenient, and practicability is high.

Owner:LOUDI CITY WANBAO NEW DISTRICT DEV INVESTMENT CO LTD

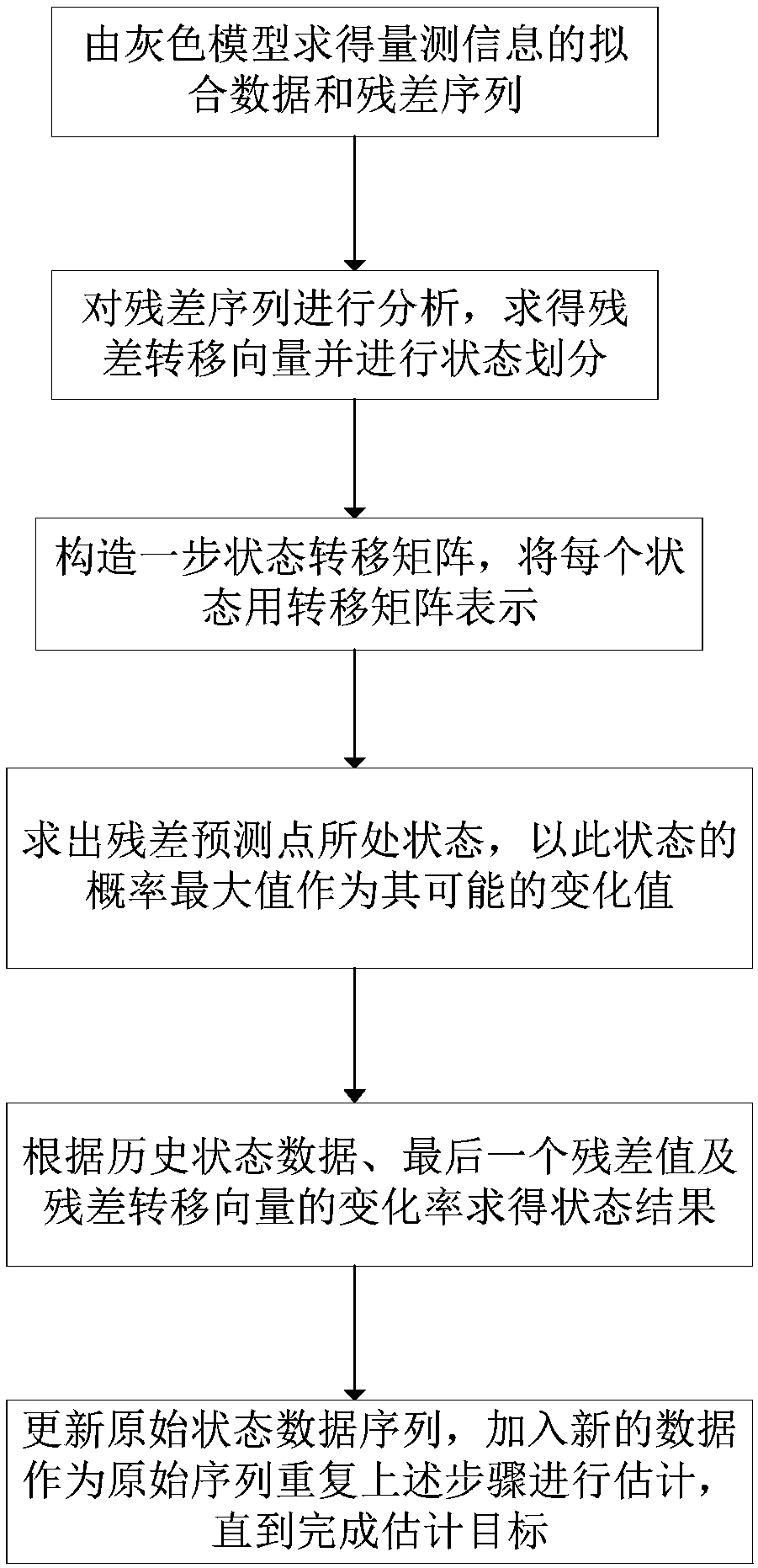

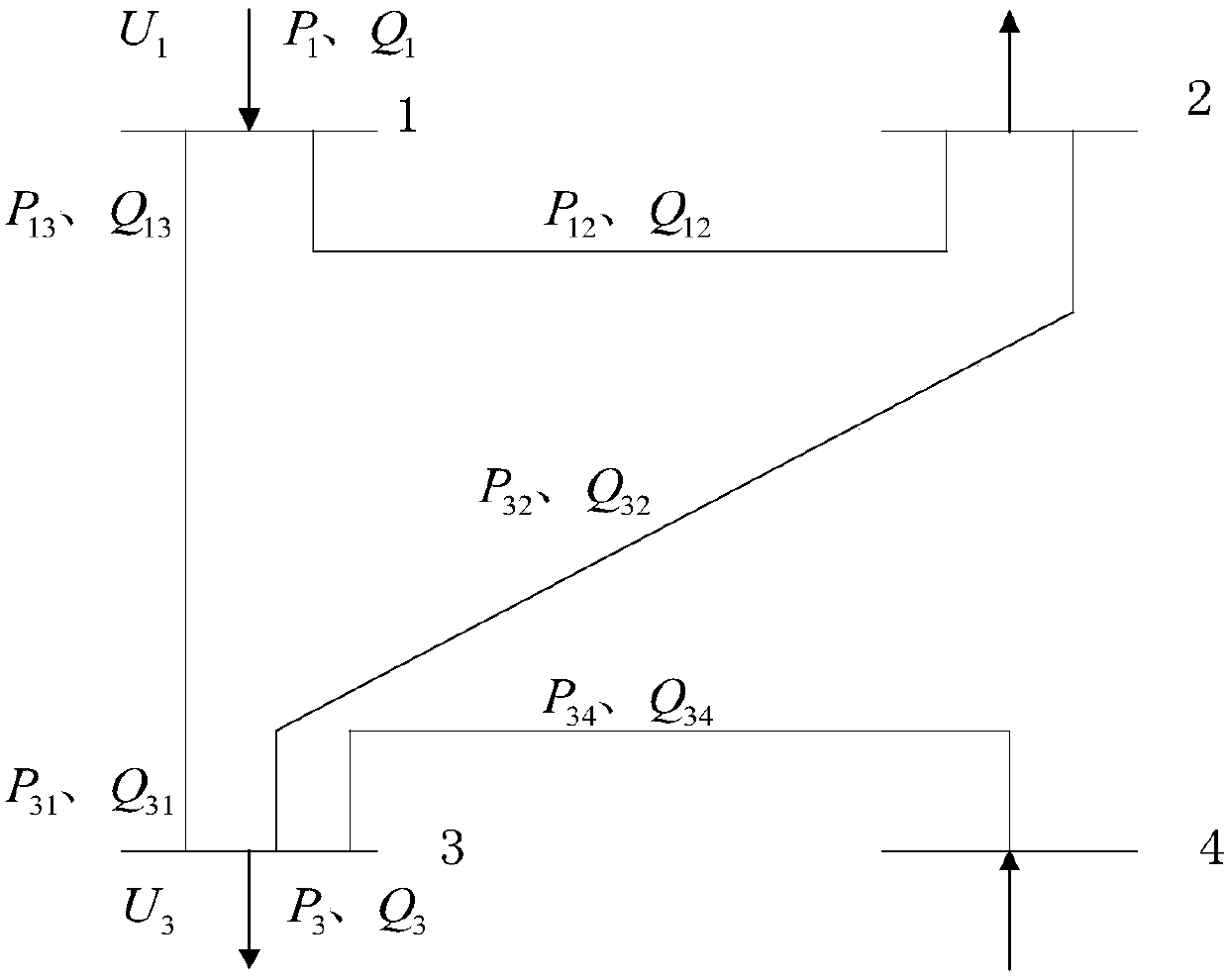

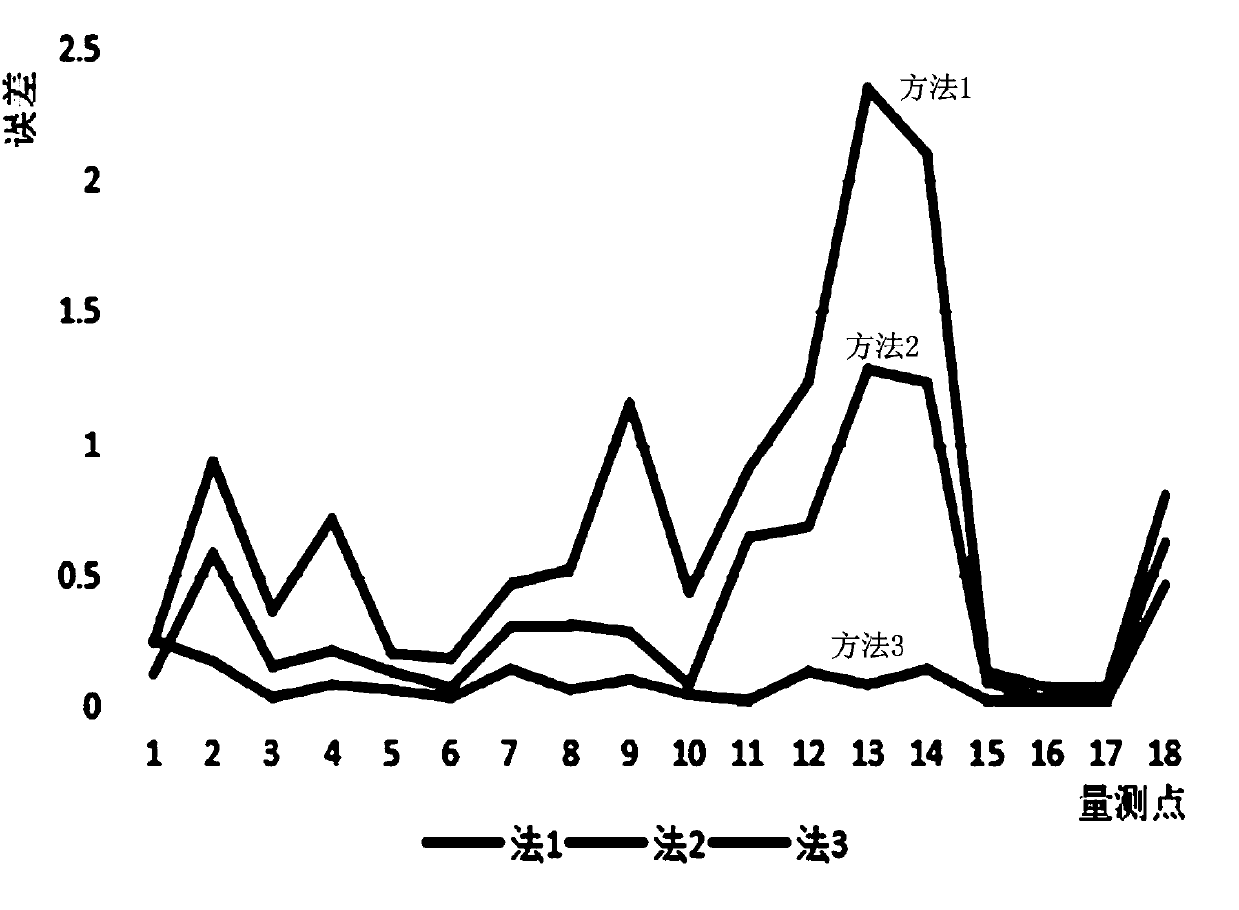

Gray-Markov chain-based distribution network state estimation method

InactiveCN107634516ACalculation speedIncreased use of memoryAc network circuit arrangementsPower flowEstimation methods

The invention relates to a gray-Markov chain-based distribution network state estimation method. According to the method of the invention, the power flow state of a power distribution network is regarded as a gray system; the fitting and prediction result of measurement information is obtained through adopting a gray model; a residual sequence between fitting data and actual data is calculated; the residual sequence is analyzed, so that a residual transfer vector is obtained, and a state transition probability matrix is constructed; and a state estimation result is obtained according to historical state data, the last residual value and the change rate of the residual transfer vector. According to the method of the invention, the gray theory and the Markov chain are combined, so that the gray-Markov chain-based distribution network state estimation method of the invention has high precision, high calculation speed, low memory consumption and high practical value.

Owner:CHINA THREE GORGES UNIV

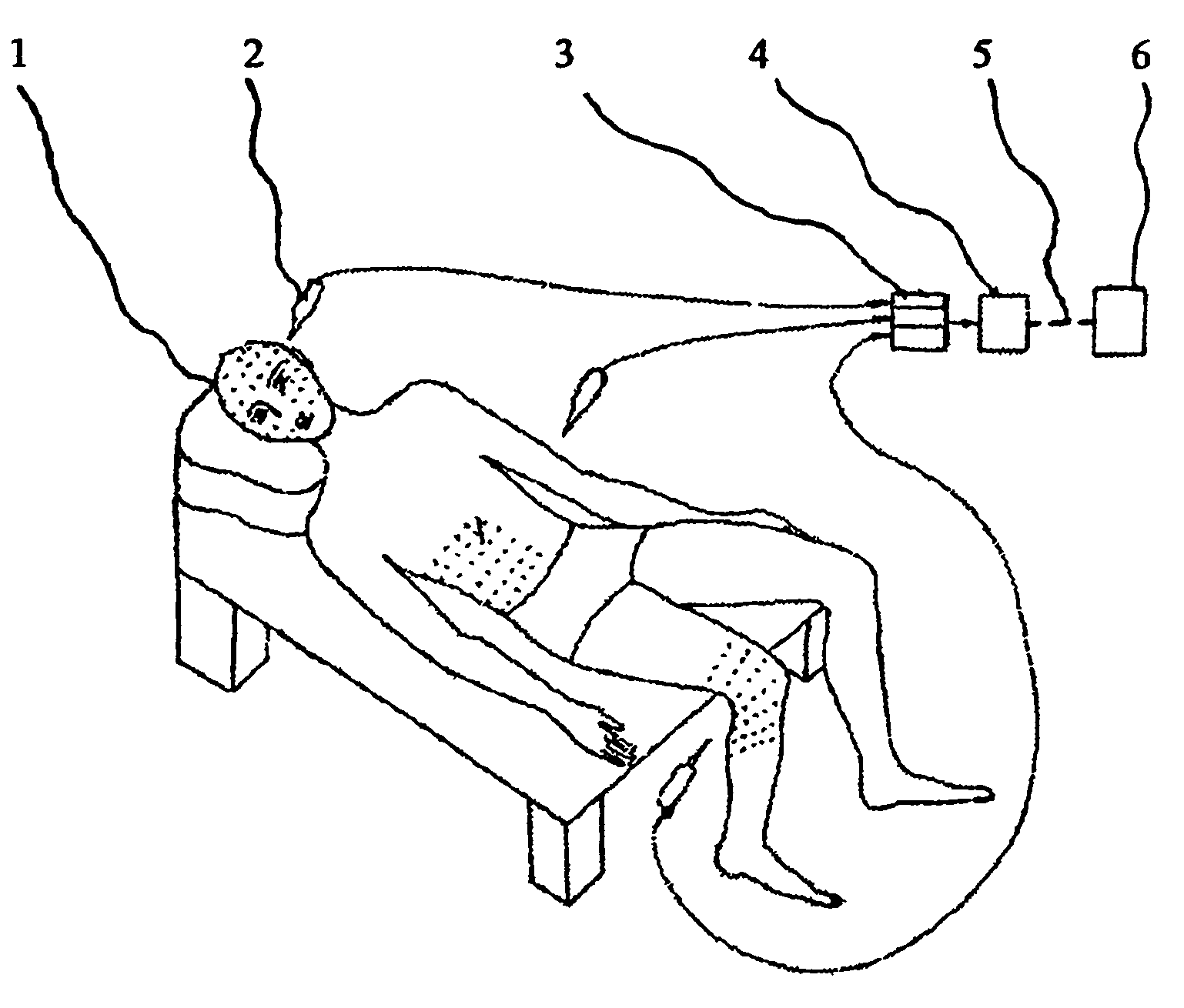

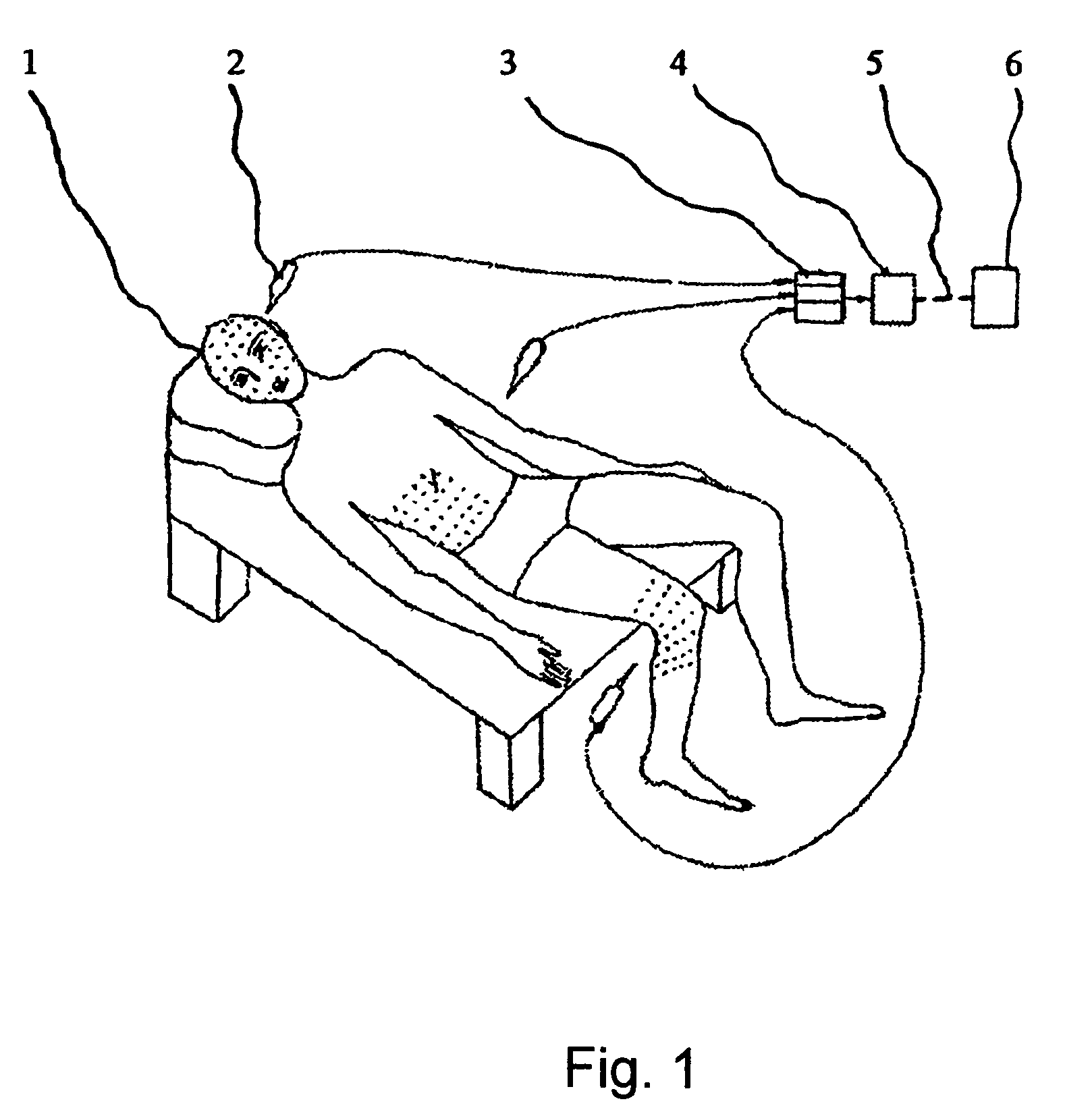

Method for thermal diagnosis of pathology of a bioobject and device for carrying out said method

InactiveUS7214194B2Increase in speed and reliabilityReduce the valueDiagnostic recording/measuringSensorsBiological bodyTemperature measurement

Owner:KLYUKIN LEMARK MIKHAILOVICH

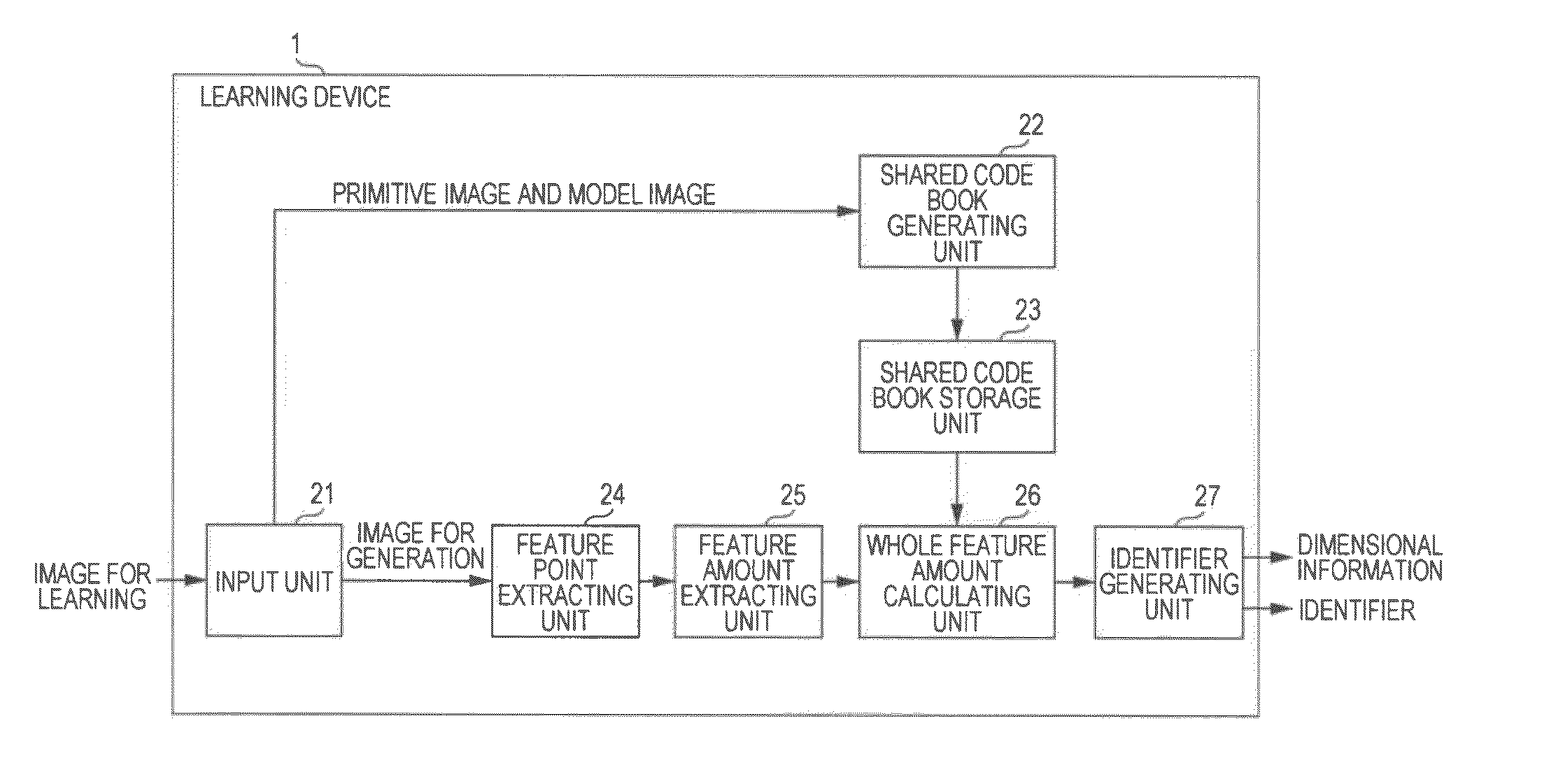

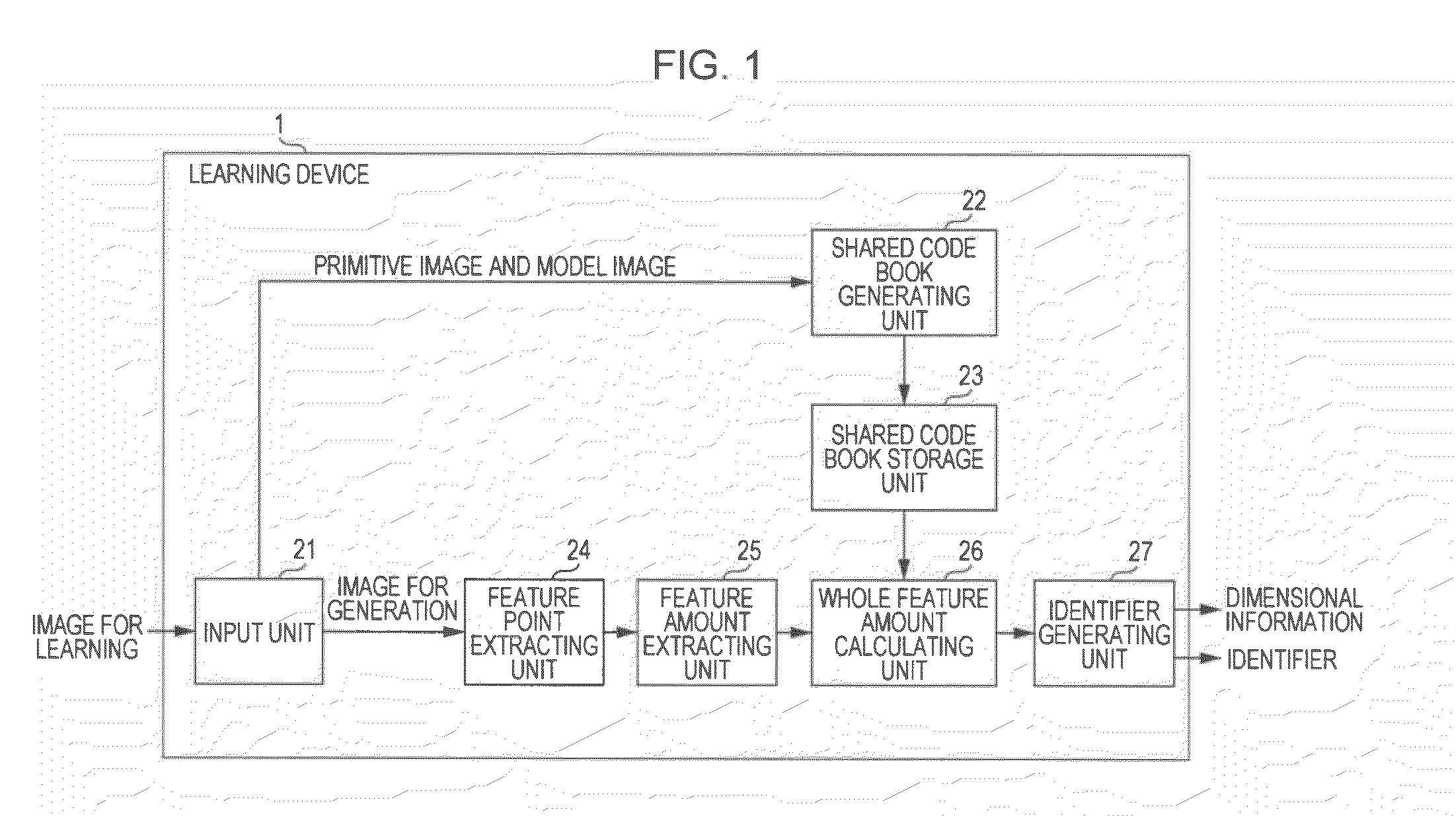

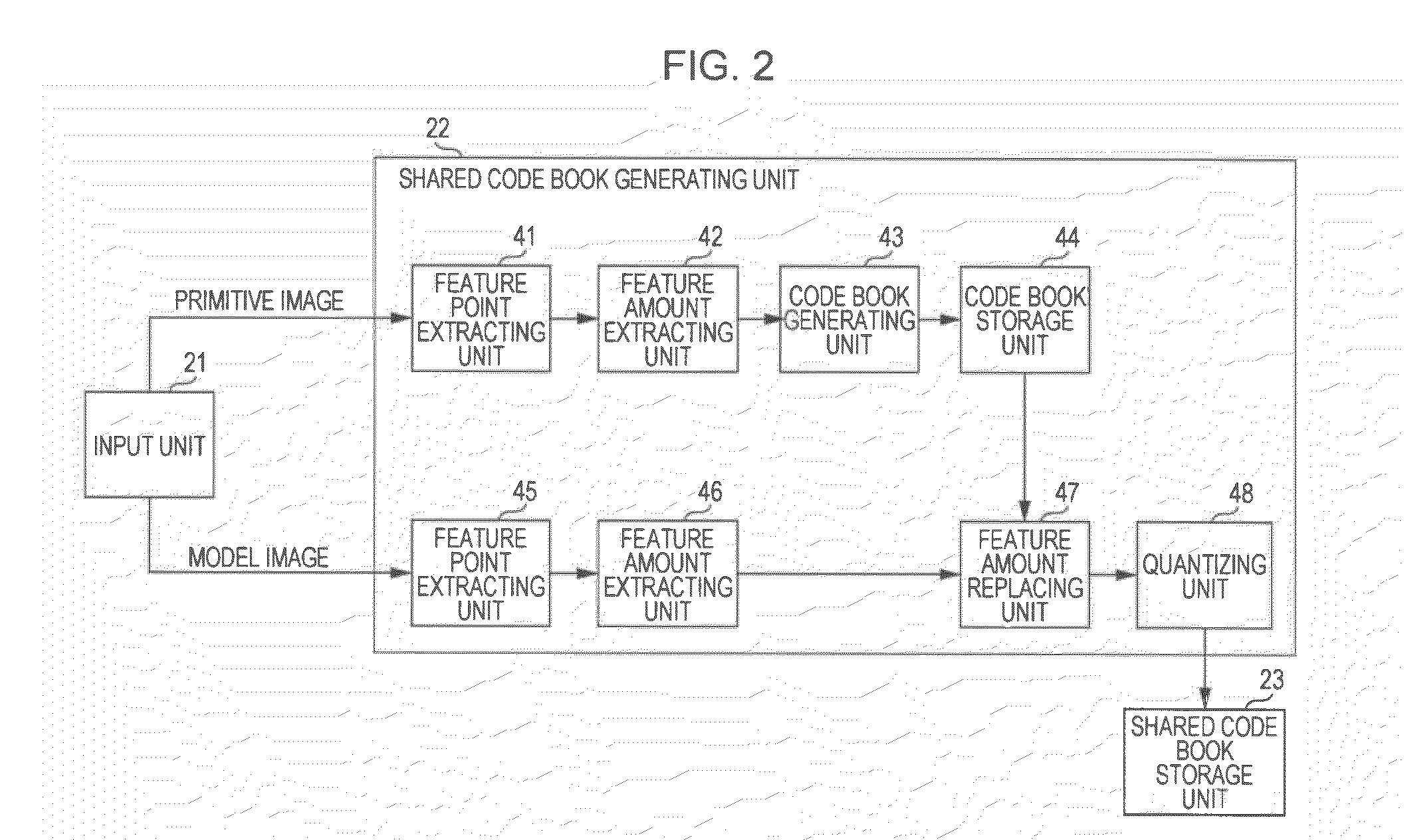

Learning device, learning method, identifying device, identifying method, and program

InactiveUS20110182515A1Suppressing increaseAccurate detectionCharacter and pattern recognitionPattern recognitionGenerating unit

A learning device includes: a feature point extracting unit for extracting a feature point from each of multiple generated images; a feature point feature amount extracting unit for extracting feature point feature amount representing the feature of the feature point from the generated image; a whole feature amount calculating unit for calculating the whole feature amount representing the feature of the whole generated image from the feature point feature amount of the generated image based on a shared code book including generated feature amount to be commonly used for generation of an identifier for identifying each of different identified objects; and an identifier generating unit for generating the identifier based on the whole feature amount of the generated image, and a correct answer label representing whether the generated image is the positive image or the negative image.

Owner:SONY CORP

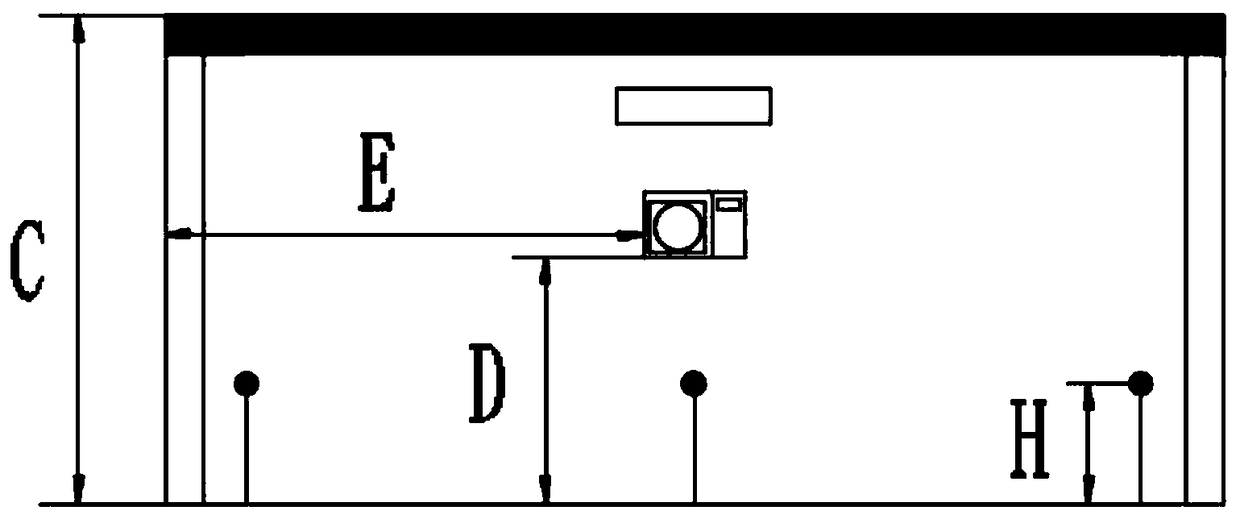

Air-conditioner noise test method

ActiveCN108955870AReflect the real situationThe test result is accurateSubsonic/sonic/ultrasonic wave measurementStructural/machines measurementOutdoor areaEngineering

The invention provides an air-conditioner noise test method. A noise lab for noise test is included, and divided into an indoor area and an outdoor area, an air-conditioner indoor set and an air-conditioner outdoor set are arranged and connected with the indoor area and the outdoor area of the noise lab respectively; and test recording devices are arranged in the indoor area of the noise lab uniformly in a multi-point laying manner. Via the method, noise conditions in the real condition of the air conditioner can be tested, a test result is accurate, and real conditions of the air-conditionernoise can be reflected effectively.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

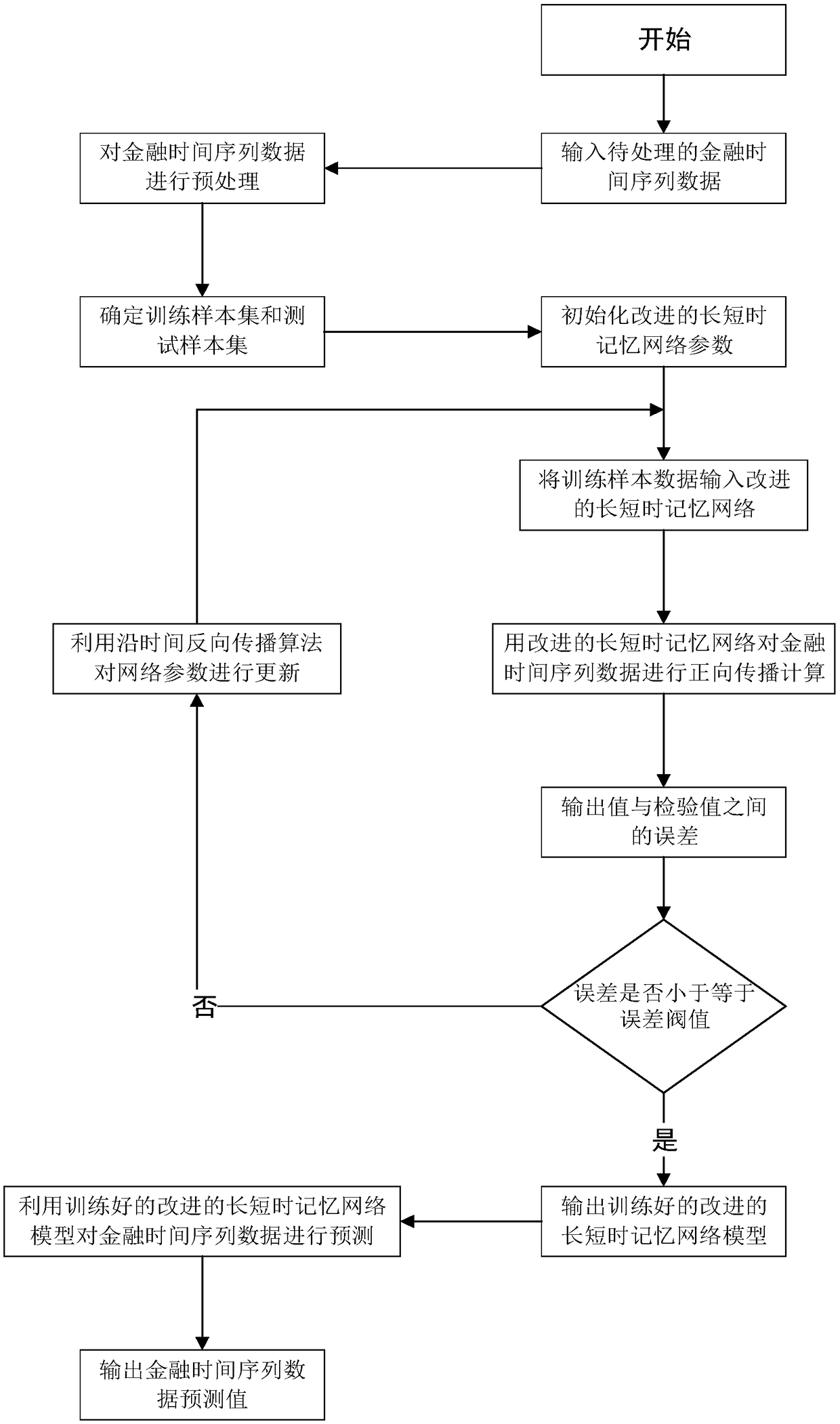

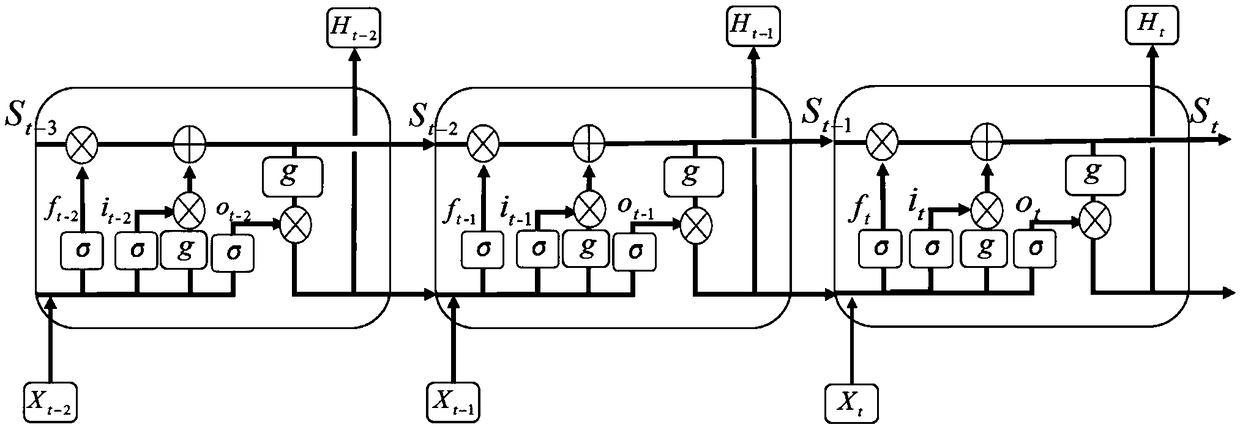

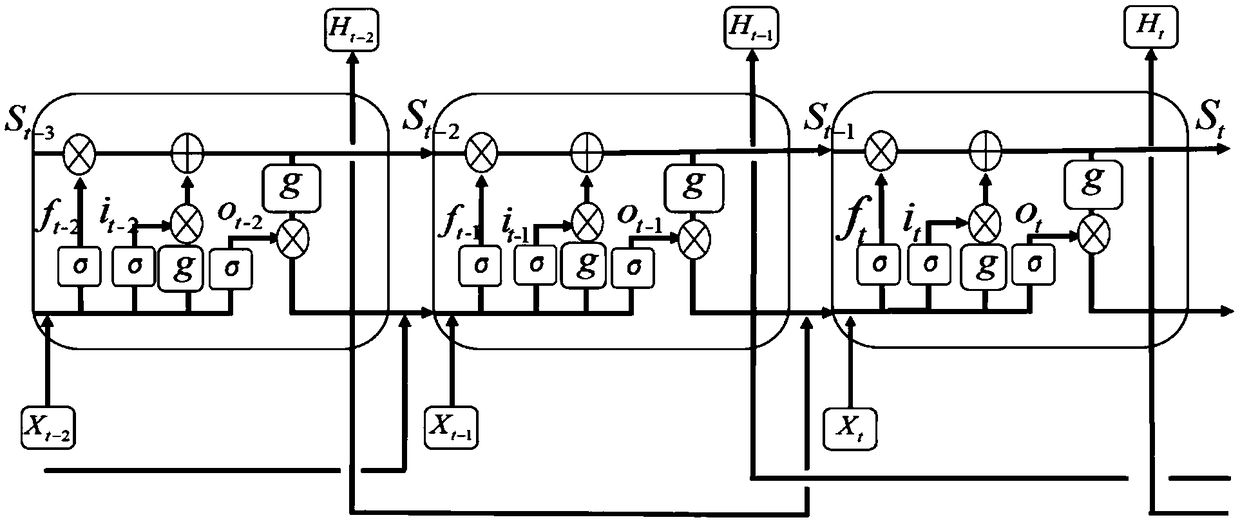

Financial data prediction method based on improved long-short term memory network

The invention discloses a financial data prediction method based on an improved long-short term memory network, and relates to the field of in-depth learning and financial data prediction. According to the method, when an input squeezing element, an input gate unit, a forgetting gate unit and an output gate unit are calculated, hidden layer information at more moments are added, a forward propagation algorithm and a back propagation along time algorithm are redesigned on this basis, and the improved long-short term memory network algorithm is used to predict the financial time series data, which improves the prediction accuracy of financial time series data and accelerates the convergence speed of the algorithms.

Owner:SOUTHWEST PETROLEUM UNIV

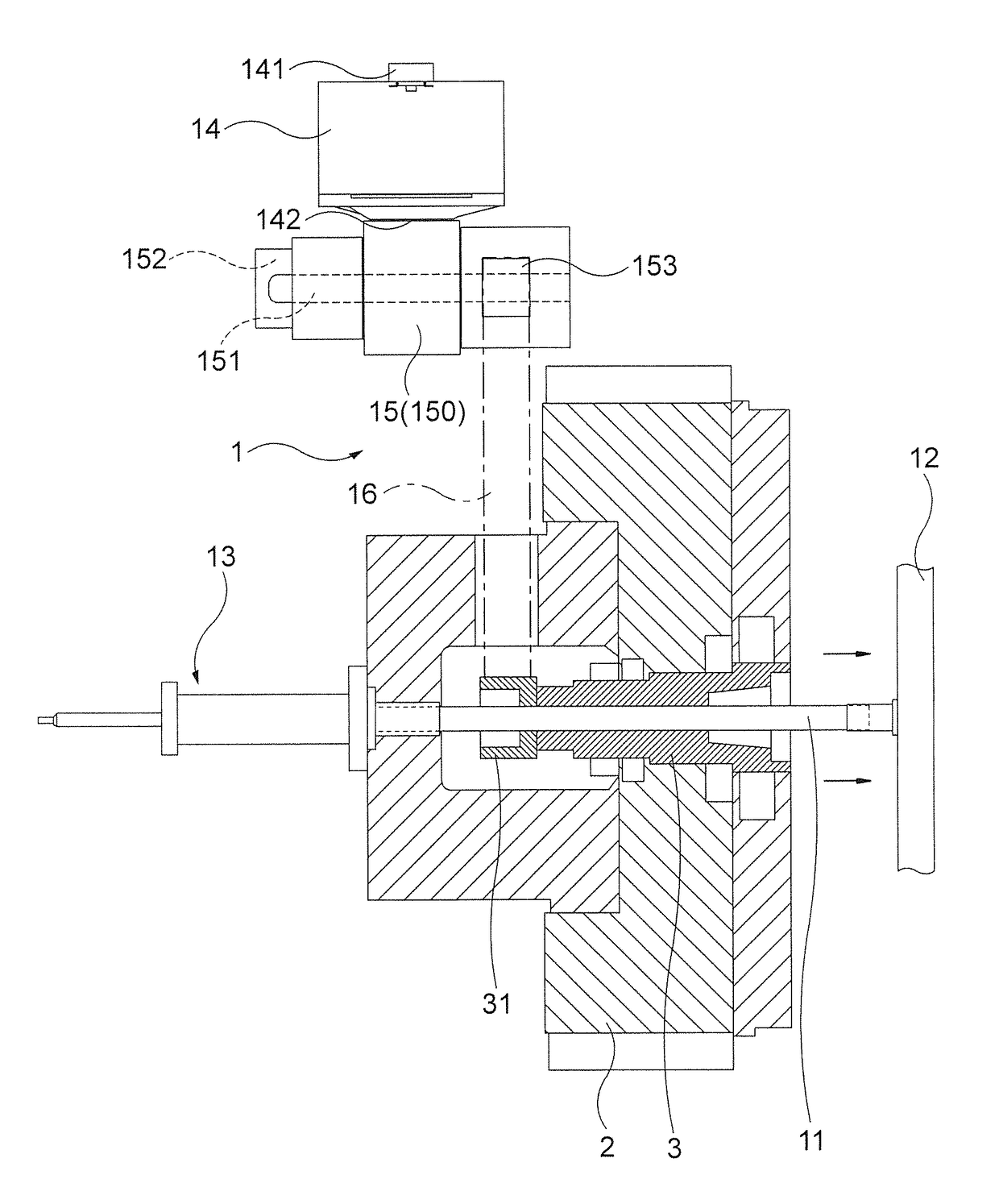

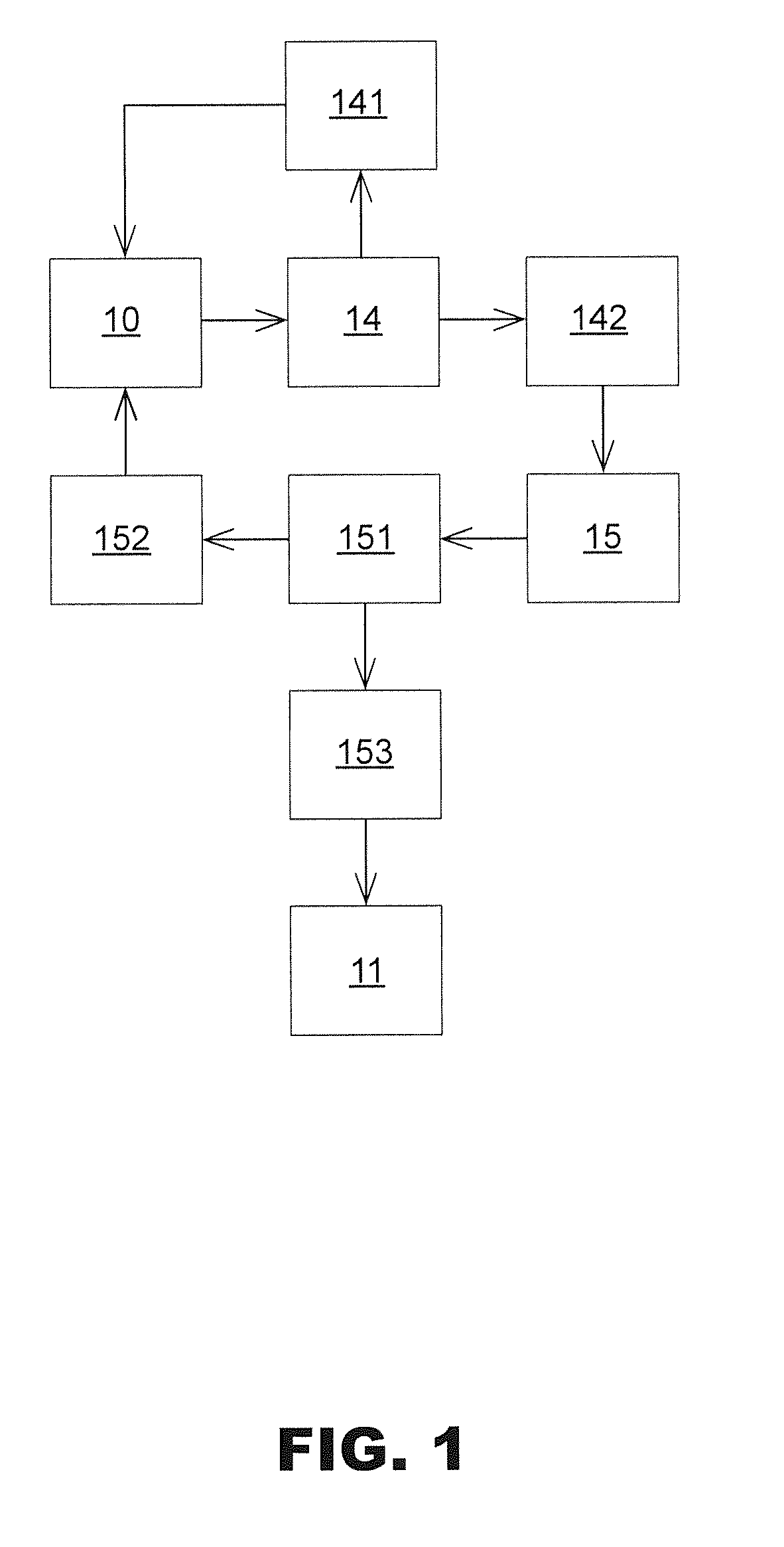

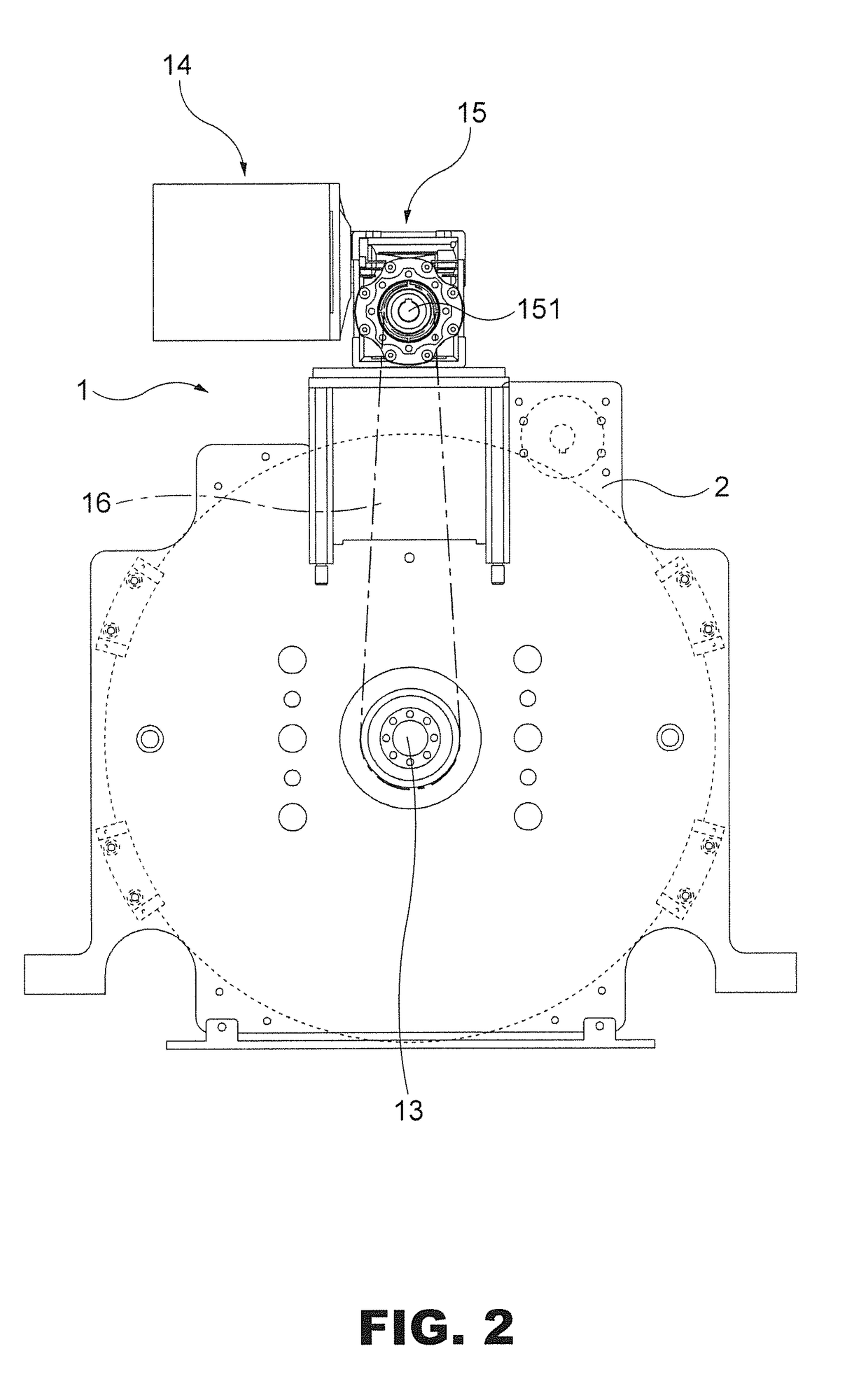

Rotary shaft type turntable positioning device of injection molding machine

A rotary-shaft type turntable positioning device of an injection molding machine includes a first encoder and a second encoder installed at a servomotor of a positioning device and a speed reducer respectively, so that after the injection molding machine finishes an injection molding, the servomotor is used to drive the driving shaft and link the output shaft to drive the driving wheel to rotate a rotary shaft, while rotating and positioning a turntable. During rotation, signals of the first encoder and the second encoder are sensed to adjust the position, so as to control the turntable to be rotated to a precise position.

Owner:HWA CHIN MACHINERY FACTORY

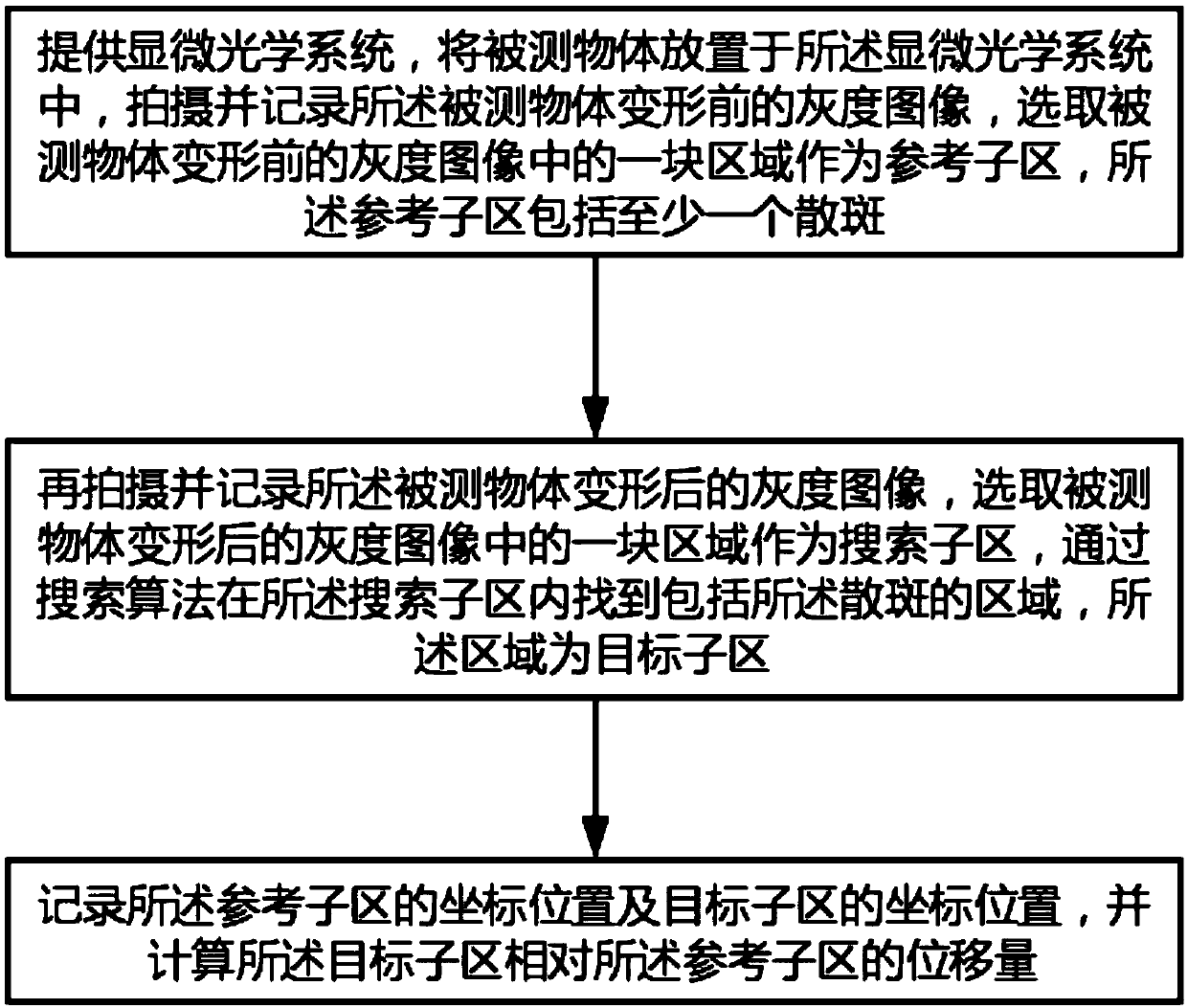

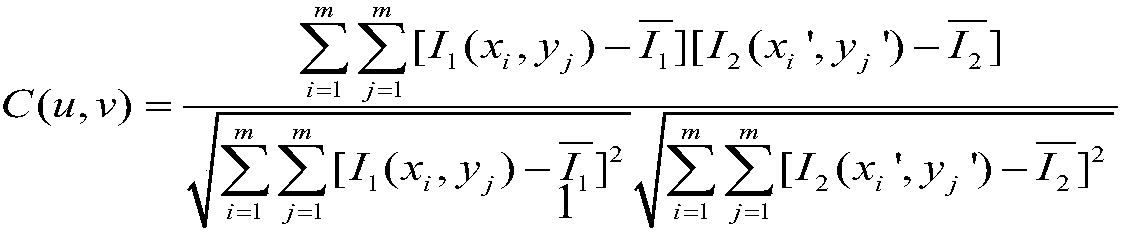

Young modulus measurement method based on microscopic optical digital speckle method

PendingCN108918271AReduce the error valueSimple stepsMaterial strength using tensile/compressive forcesUsing optical meansYoung's modulusA* search algorithm

The invention relates to a Young modulus measurement method based on a microscopic optical digital speckle method. The method comprises the following steps: designing a microscopic optical system, setting the amplification factor of the microscopic optical system as a specific value, placing an object to be measured in the microscopic optical system, shooting and recording a gray level image before the deformation of the object to be measured, and selecting an area in the gray level image before the deformation of the object to be measured as a reference subarea, wherein the reference subareacomprises at least one speckle; shooting and recording a gray level image after the deformation of the object to be measured, and selecting an area in the gray level image after the deformation of theobject to be measured as a search subarea, and finding the area comprising the speckle in the search subarea via a search algorithm; and recording a coordinate position of the reference subarea and the coordinate position of a target subarea, and calculating a displacement amount of the target subarea relative to the reference subarea. The method provided by the invention is high in measurement precision, simple in instruments and convenient to operate.

Owner:SUZHOU UNIV

Steel bar scanning and concrete protection layer thickness detection method

InactiveCN111854666AHigh precisionReduce the error valueUsing electrical meansElectrical/magnetic thickness measurementsClassical mechanicsDimensional modeling

The invention relates to the technical field of concrete structure detection and identification, and discloses a steel bar scanning and concrete protection layer thickness detection method, which comprises the following steps of S1, determining a detection region: obtaining the position of a region to be detected according to the detection requirement, and cleaning the position of the region to bedetected in advance; s2, building modeling: obtaining a building drawing, performing local three-dimensional modeling according to information in the building drawing, and making and displaying a building model of a to-be-detected area through three-dimensional software; s3, determining the position of the reinforcing steel bar: preheating and zeroing the reinforcing steel bar detector, and irregularly moving a probe of the reinforcing steel bar detector on the surface of the building to be detected until the instrument displays and receives a signal. The reinforcing steel bar scanning and concrete protection layer thickness detection method can solve the problem that when the diameter of the reinforcing steel bar and the thickness of the protection layer are detected at present, the detection result error is large.

Owner:广东雄炜建筑工程检测有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com