Three-primary colours dye and method for detecting two fibers blending ratio of linen to cotton

A technology of cotton and linen fibers and three primary colors, which is used in the preparation of organic dyes, test samples, and color/spectral properties measurement, etc., can solve the problems of long time, large errors, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1, a kind of trichromatic dyestuff that detects the blending ratio of cotton and linen blend

[0022] The raw material is directly selected as date red GB, the strength is 100%, and the No. 3 Dyestuff Chemical Factory in Tianjin;

[0023] Cationic bright yellow O, strength 100%, Shaoxing Green Chemical Co., Ltd.;

[0024] Disperse blue 2BLN, 100% strength, Zhejiang Runtu Co., Ltd.;

[0025] Penetrant JFC, Jiangsu Haian Petrochemical Plant.

[0026] Weigh 3 g of direct bougainvillea GB, cationic bright yellow O, and disperse blue 2BLN dyes, 9 g in total, and put them into a 1000 mL beaker, add 90 g of penetrant JFC and 90 g of soft water at 40 °C to make the dyes wet and remove them with a glass rod. Stir well, slowly add soft water at room temperature while stirring to fully dissolve and disperse the mixed dye, add soft water at room temperature until the total weight of the liquid is 900 g. The liquid is the three-primary-color dye liquid for detecting th...

Embodiment 2

[0027] Embodiment 2, the method for detecting the fiber blending ratio of cotton and linen blends using three primary color dyeing methods

[0028] Take by weighing 2 g of the three primary color dye solutions of Example 1, put them into a dyeing cup, add soft water to dilute until the total weight is 200 g, stir well to become a dyeing medium; weigh 2 g of the cotton-linen fiber blend to be determined, and immerse in the dyeing medium, Stir with a glass rod for 1 min; put the dyeing cup containing the dyeing medium and the cotton and linen blend to be tested into the HBC-12 swinging room temperature dyeing sample machine (Ronggui Huibao Dyeing and Finishing Machinery Factory, Shunde District, Foshan City), and use 3 The temperature was raised to 95 °C at a rate of °C / min, and the dyeing was maintained at 95 °C for 5 min; after dyeing, the dyed cotton-linen fiber blend was taken out, washed with cold running water for 2 min, and dried in an oven at 40 °C; -Rite 8200 deskto...

Embodiment 3

[0035] Embodiment 3, the method for detecting the fiber blending ratio of cotton / ramie blended fabrics using three primary color dyeing methods

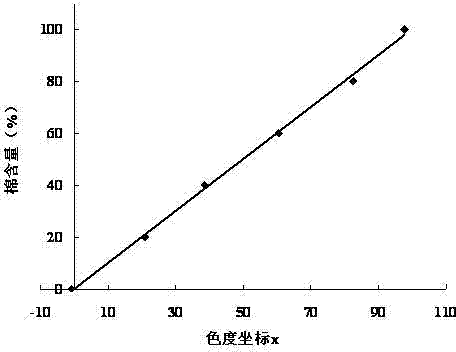

[0036] Desized, scoured and bleached cotton / ramie blends from the market (21 s ×21 s , blending ratio 45 / 55), washed with soft water containing 1g / L penetrant JFC at 50 °C for 30 min, rinsed with cold running water, and dried below 100 °C; weighed 2 g of the treated fabric, according to Example 2 Dyeing, washing and drying described in the "Method of detecting the fiber blending ratio of cotton and linen blends by three primary color dyeing methods"; measuring the dried cotton and linen fibers with an X-Rite 8200 desktop reflection spectrophotometer (X-Rite, USA) Color Tristimulus Values of Blended Fabrics X, Y and Z ;Substitute the chromaticity coordinates x Calculation formula to find the chromaticity coordinates of the dyed matter x = 0.382, substituted into the cotton fiber content linear regression equation C(%) = 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com