Gas sensitive element by taking single-walled carbon nanotube/phthalocyanine composite material as ammonia-sensitive material and preparation method thereof

A single-walled carbon nanotube and composite material technology, which is applied in the field of gas sensing elements and their preparation, can solve the problems of poor reversibility and high resistance value, and achieve the effects of fast response, excellent comprehensive performance and improved gas sensing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0016] Specific Embodiment 1: In this embodiment, a gas sensor with single-wall carbon nanotube / phthalocyanine composite material as ammonia-sensitive material is composed of interdigital electrodes and single-wall carbon nanotube / phthalocyanine composite material; The phthalocyanine in the single-wall carbon nanotube / phthalocyanine composite material is a pentyloxy metal phthalocyanine.

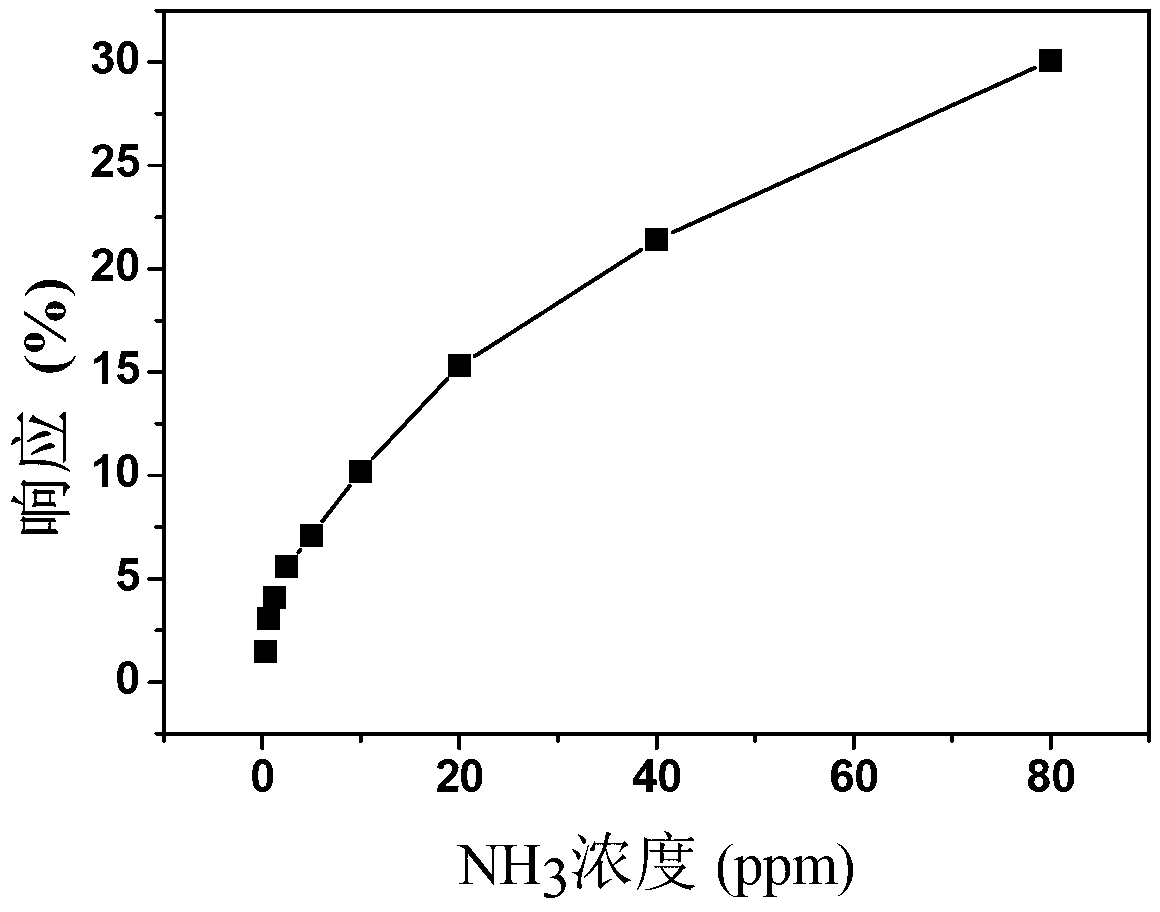

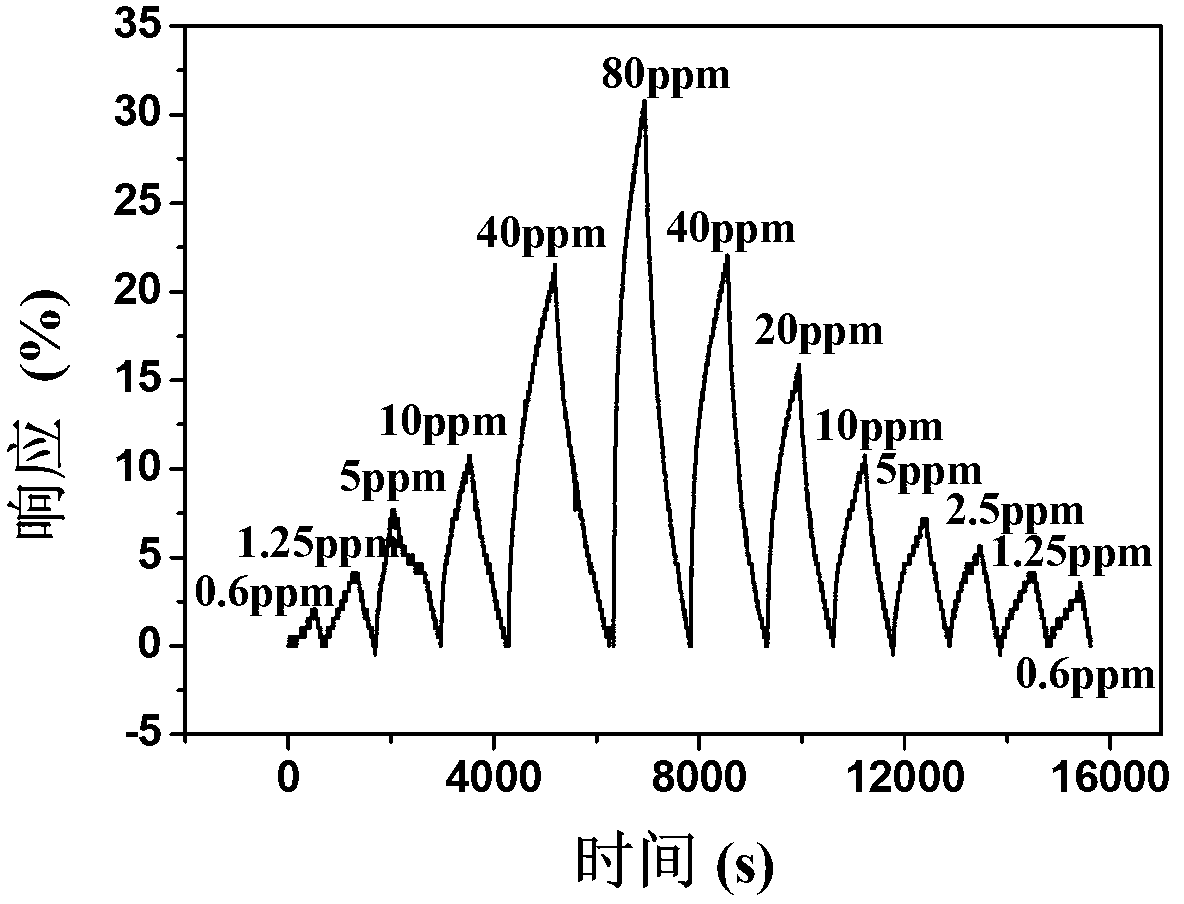

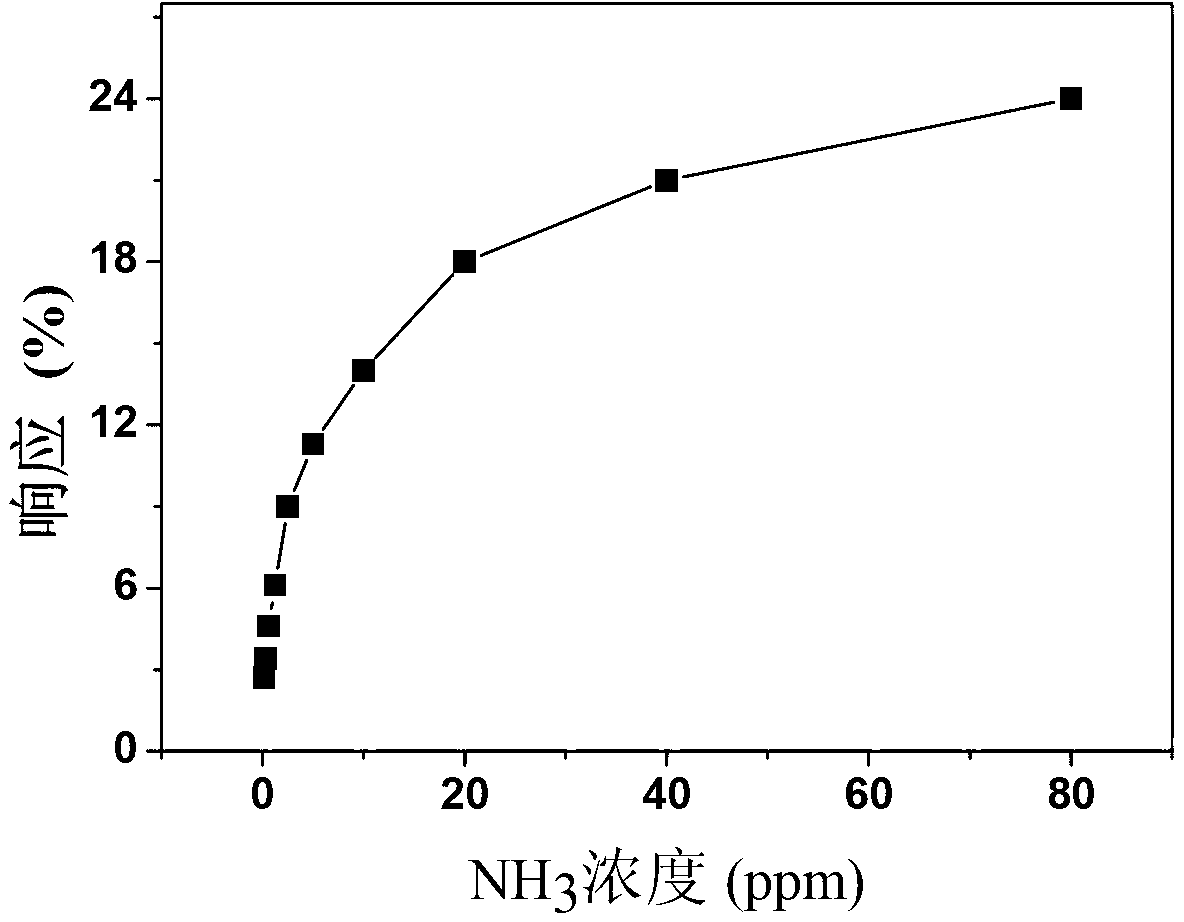

[0017] The gas sensor using the single-walled carbon nanotube / phthalocyanine composite material as the ammonia-sensitive material described in this embodiment mode is at room temperature, and at room temperature, 0.6ppm~80ppmNH 3 It has a good response in the concentration range, and the low concentration of NH in the range of 0.6ppm to 40ppm 3 range NH 3 There is a good linear relationship between concentration and response, and 600ppb NH can be detected 3 .

[0018] The gas sensor using the single-walled carbon nanotube / phthalocyanine composite material as the ammonia-sensitive material...

specific Embodiment approach 2

[0019] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the structural formula of the pentyloxy metal phthalocyanine is or in M in is Cu, Pb, Ni, Co or Zn; Wherein M in is Cu, Pb, Ni, Co or Zn; Wherein M in is Cu, Ni, Co or Zn. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Specific embodiment three: In this embodiment, a method for preparing a gas sensor using a single-walled carbon nanotube / phthalocyanine composite material as an ammonia-sensitive material is carried out according to the following steps:

[0021]1. Preparation of carboxylated single-walled carbon nanotubes: Add single-walled carbon nanotubes into an aqueous solution of nitric acid with a concentration of 2mol / L-3mol / L, reflux reaction at a temperature of 80°C-90°C for 36h-48h, and obtain filtered Cake, disperse the filter cake in a hydrochloric acid aqueous solution with a concentration of 0.5mol / L-2mol / L, vibrate ultrasonically for 10min-30min, filter to obtain purified single-walled carbon nanotubes, and then place the obtained purified single-walled carbon nanotubes in mixed acid Heat treatment to obtain the reacted solution, add deionized water to the reacted solution for dilution, and then filter with 0.20 μm polytetrafluoroethylene filter membrane to obtain the crud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com