Rationed pouring device for colloidal liquid special for oil paint barreling and covering assembly line

A colloidal liquid and pouring device technology, which is applied in liquid handling, packaging, loading/unloading, etc., can solve problems such as poor fluidity, volume error in barrels, unfavorable sales, etc., to reduce the error value, control the pouring volume accurately, and control Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

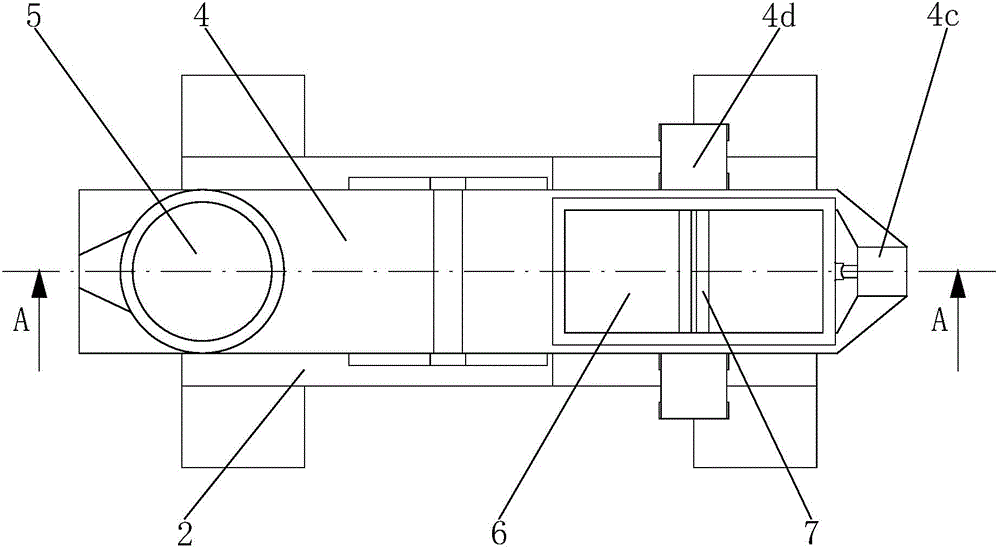

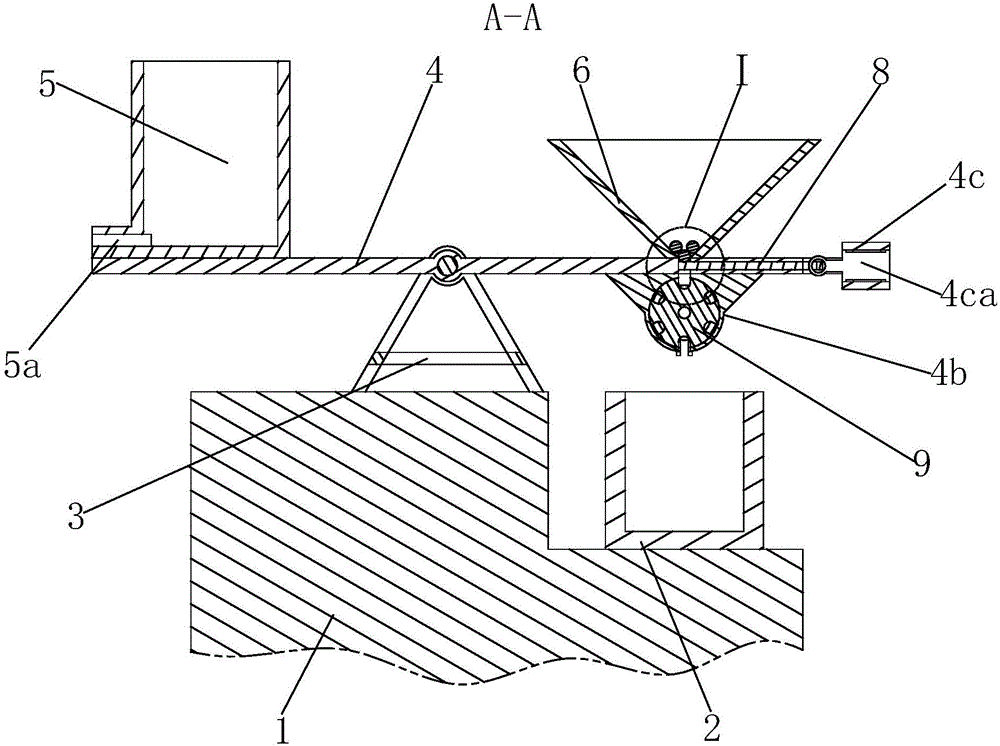

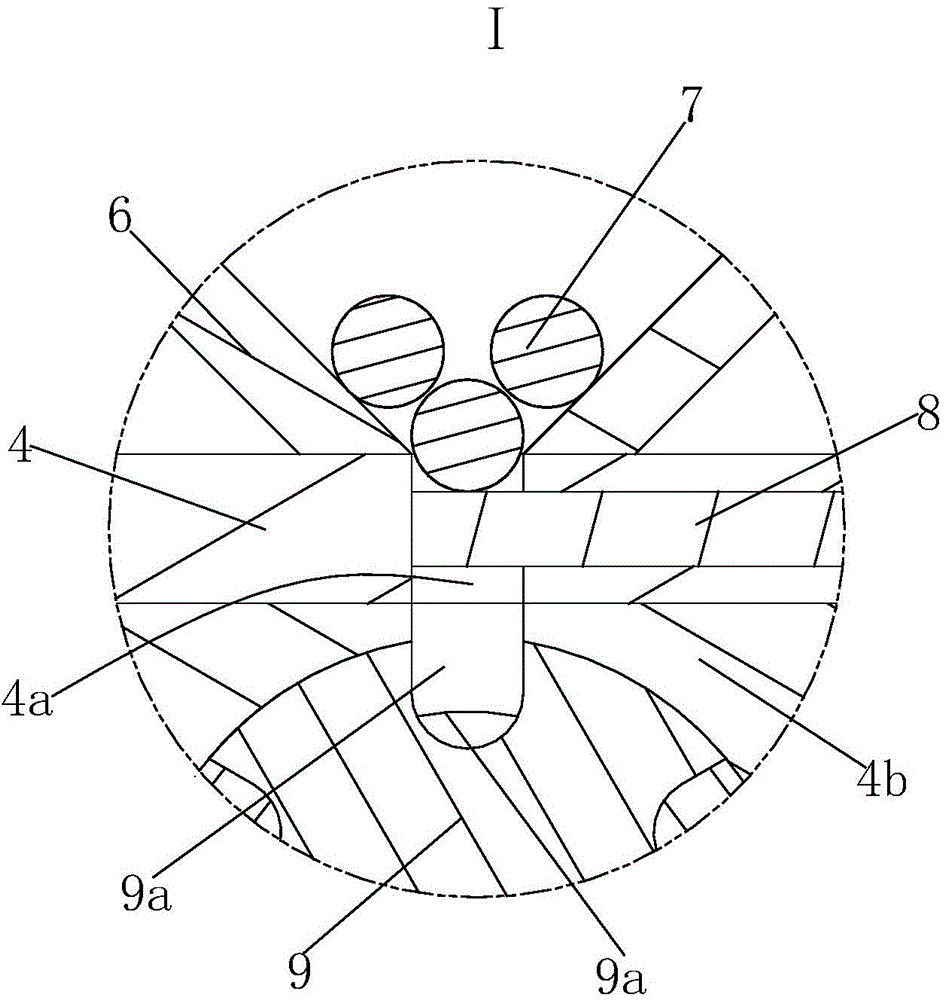

[0014] Such as Figure 1 to Figure 4 As shown, a quantitative dumping device for colloidal liquid dedicated to a paint barrel capping assembly line mainly includes a long seesaw 4, the middle end of which is hinged with a mounting frame 3, and the left part of the upper end of the long seesaw 4 is provided with a There is a paint bucket 5, the lower left part of the paint bucket 5 is provided with a tip nozzle 5a, and the upper right part of the long rocker 4 is equipped with an empty counterweight bin 6, and a counterweight round bar 7 is stacked inside the counterweight bin 6 , the long seesaw 4 is provided with a rectangular slot 4a corresponding to the shape of the counterweight round bar 7 directly below the counterweight bin 6, and the right end surface of the rectangular slot 4a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com