Outlet structure of solid particle container and solid particle container

A technology of outlet structure and solid particles, applied in bottle/container caps, capping containers tightly with caps, liquid handling, etc., can solve problems such as easy leakage, residual adhesion, and difficulty in controlling the amount of pouring, so as to achieve the goal of not easy to spill Leakage, good sealing, and accurate control of pouring volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

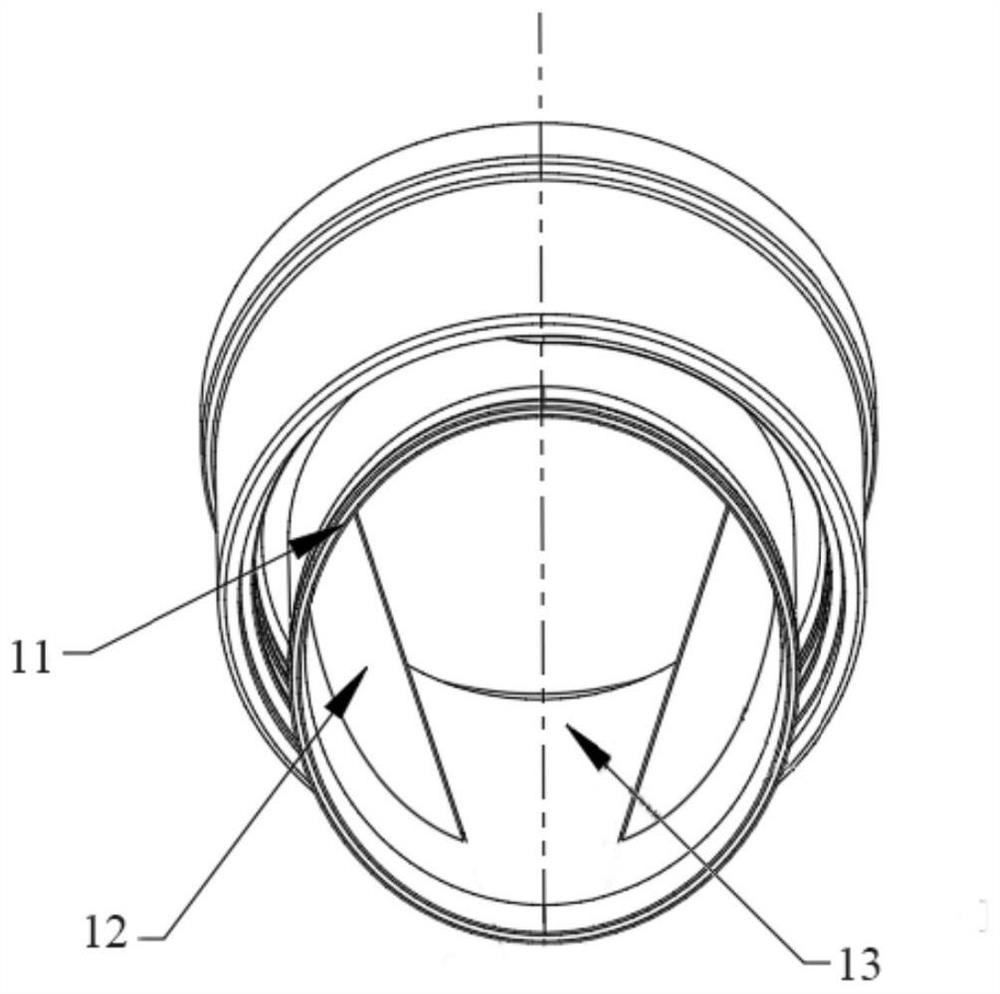

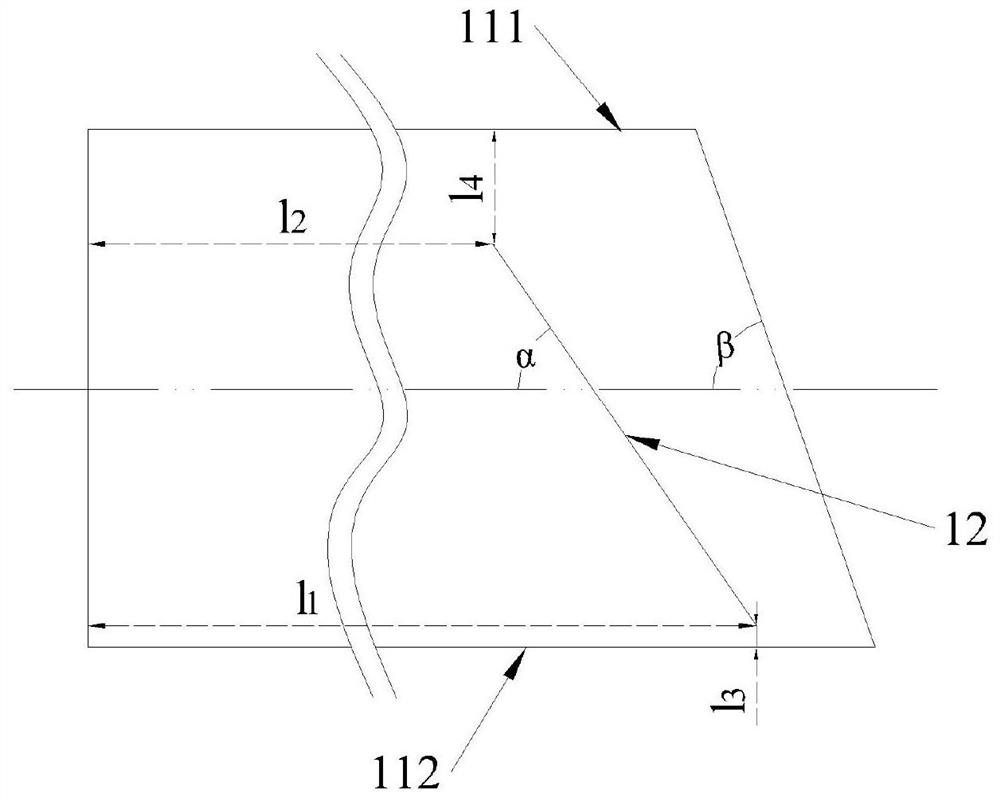

[0038] Such as Figure 1~4 As shown, the present embodiment provides an outlet structure of a solid particle container, including a discharge channel 11 and two guide baffles 12; the discharge channel 11 is cylindrical; two guide baffles 12 are located in the discharge channel 11, near the outlet end of the discharge channel 11, the diameter of the discharge channel 11 is symmetrically distributed on the axis of symmetry, and the discharge port 13 of the discharge channel 11 is formed between the two guide baffles 12; the guide baffle 12 is inclined from the outlet end to the inlet end, forming an included angle α with the main axis of the discharge channel 11; there is a distance l 1 , there is a distance l from the channel lower edge 112 of the discharge channel 11 3 There is a distance l between the far end of the diversion baffle plate 12 and the end face of the inlet end of the discharge channel 11 away from the outlet end 2 , there is a distance l from the upper edge 1...

Embodiment 2

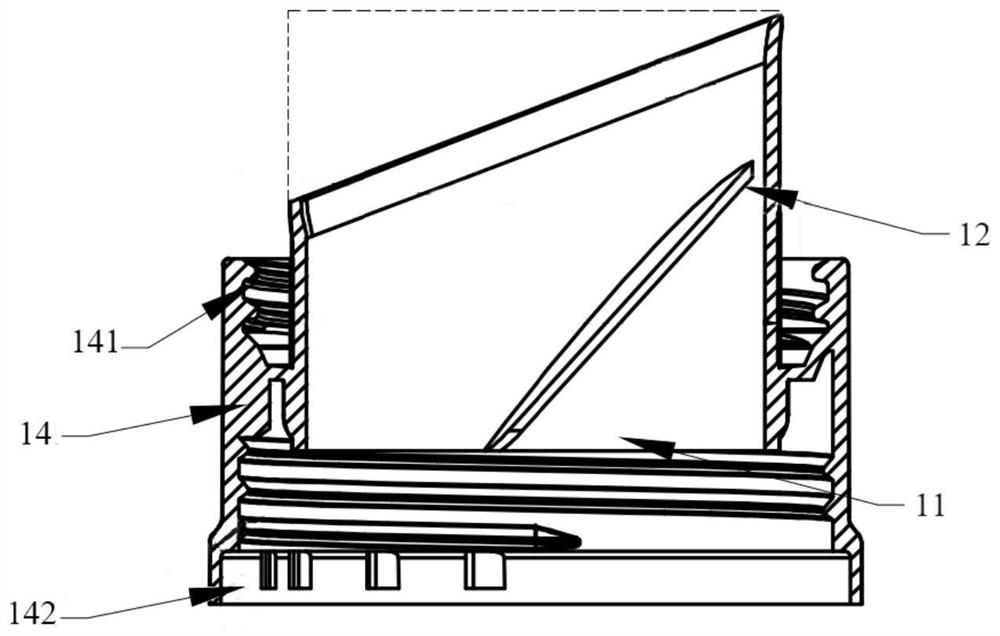

[0051] Such as Figure 5-7 As shown, the present embodiment provides a container for solid particles and a method for using the same. The container includes a chamber 20, a seal 30 and an outlet structure as described in Embodiment 1; the outlet structure 10 is connected to the chamber 20, so that The solid particles stored in the cavity 20 are poured out through the container outlet structure 10; the sealing member 30 is used to seal the outlet structure 10; the lower edge of the discharge port 13 is on the same side as the pouring direction of the container.

[0052] Specifically, the connection between the cavity 20 and the outlet structure 10 is provided with an outer seat 14; the outer seat 14 surrounds the outer wall of the discharge channel 11, and a first matching position 141 is provided between the outer seat 14 and the outer wall; the first matching The position 141 is used to install or disassemble the seal 30 ; the bottom of the outer seat 14 is provided with a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com