Patents

Literature

96results about How to "Reduce the chance of scrapping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

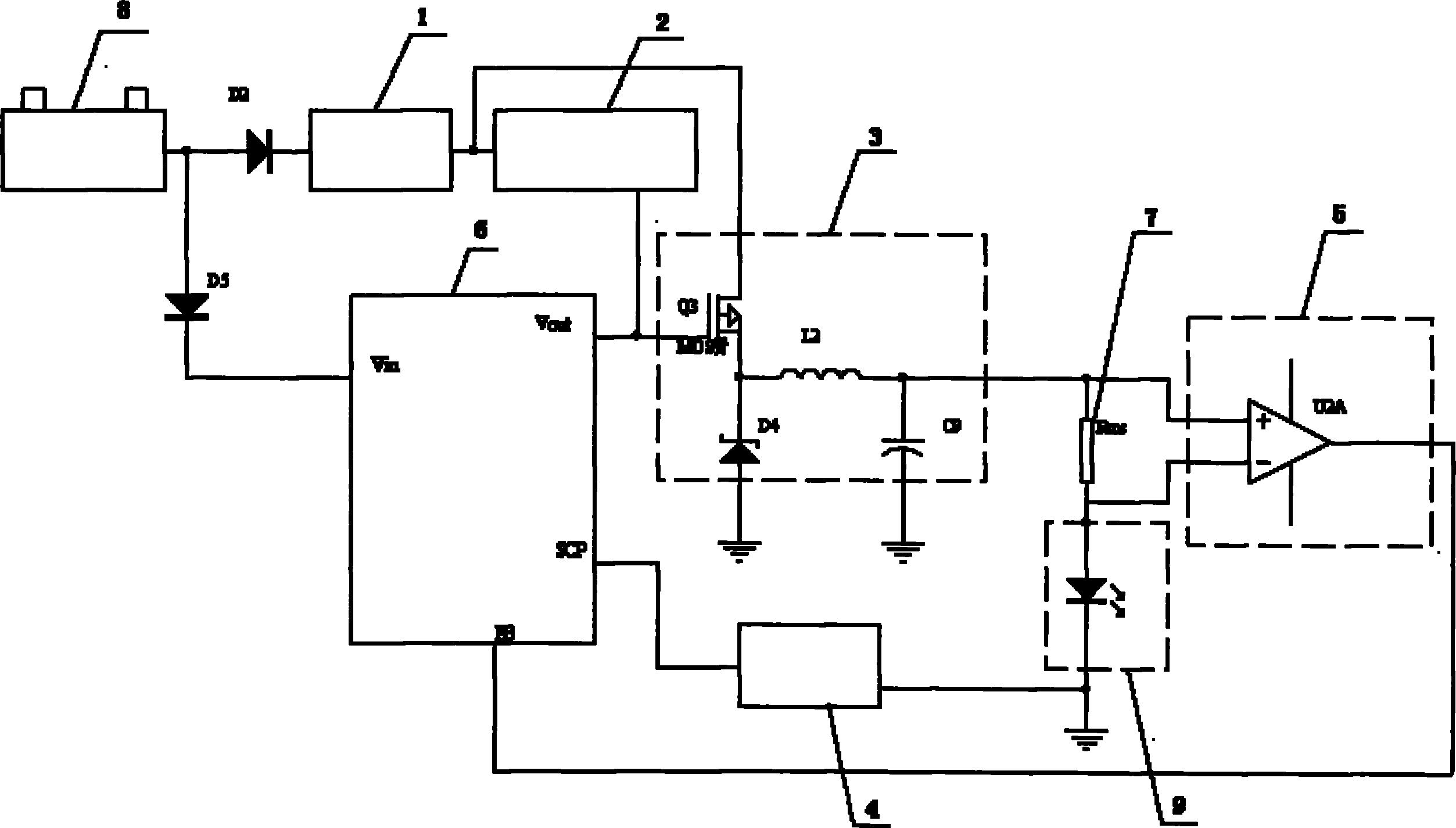

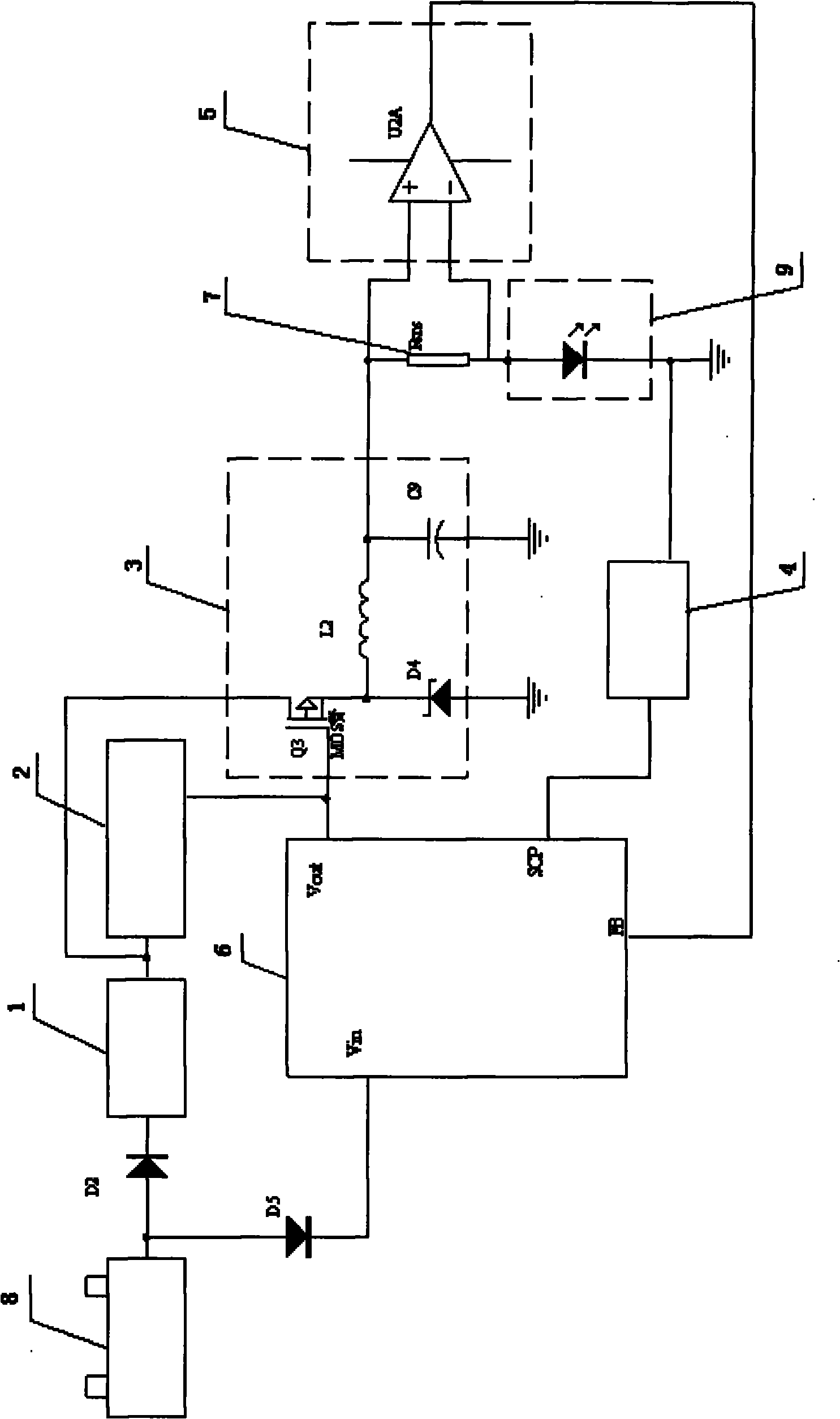

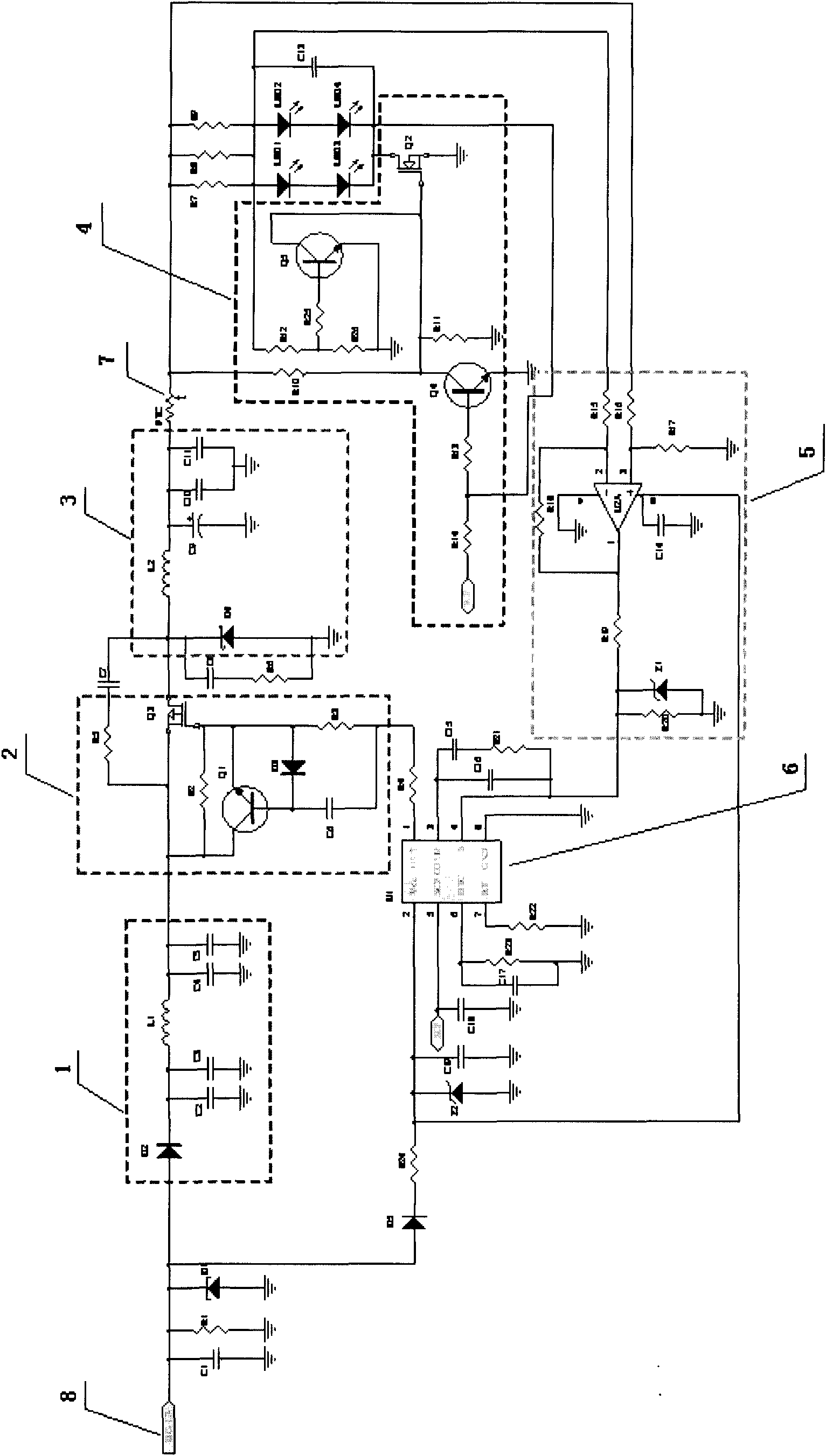

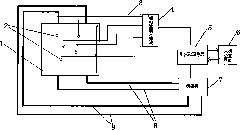

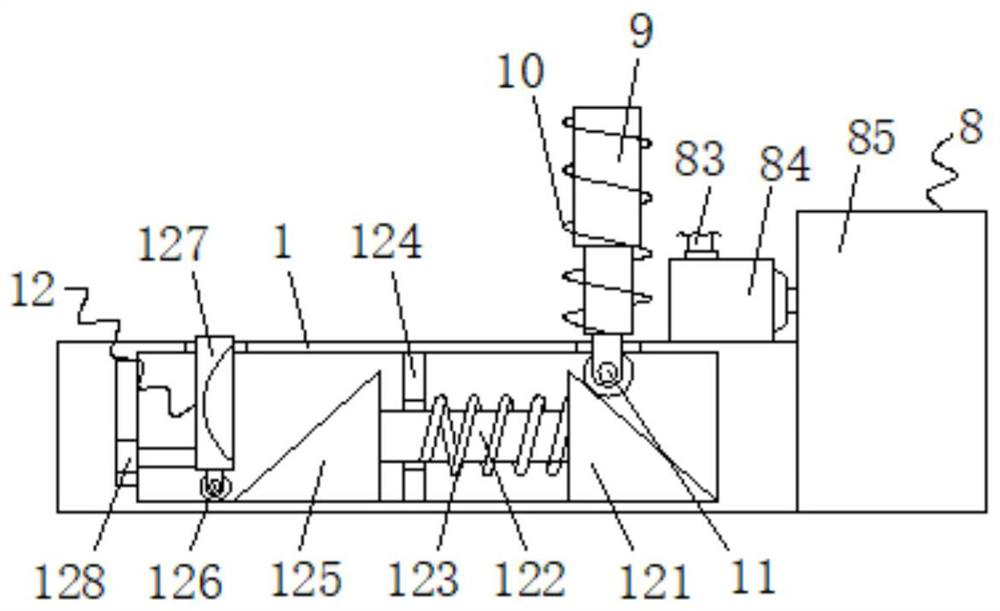

Step-down constant current LED drive circuit for automobile lighting

InactiveCN101815382ALow costImprove driving abilityElectric light circuit arrangementElectricityHigh rate

The invention relates to a step-down constant current LED drive circuit for automobile lighting. The circuit comprises an isolating circuit module (1), wherein the input end of the isolating circuit module (1) is electrically connected with a power supply (8), and the output end of the isolating circuit module (1) is electrically connected with an MOS transistor drive circuit module (2) and a converting circuit module (3); a Vin terminal of a PWM control chip (6) is electrically connected with the power supply (8), and a Vout terminal of the PWM control chip (6) is electrically connected with the MOS transistor drive circuit module (2) and the converting circuit module (3); the output end of the converting circuit module (3) is connected with an LED lamp set (9); one end of a feedback circuit module (5) is connected with the output of the converting circuit module (3) and the LED lamp set (9), and the other end of the feedback circuit module (5) is connected with an FB terminal of the PWM control chip; and a protection circuit module (4) is arranged between an earth terminal of the LED lamp set (9) and an SCP terminal of the PWM control chip. The drive circuit of the invention not only make the LED emit light constantly, but also has a short-circuit protection function, high rate of qualified products and low cost.

Owner:HASCO VISION TECHNOLOGY CO LTD

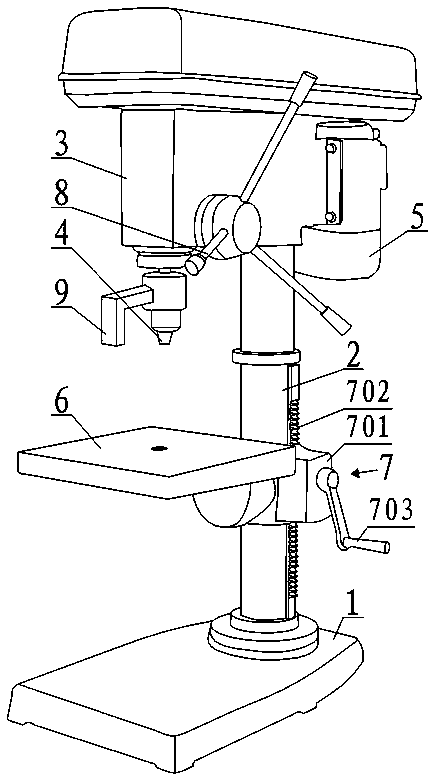

Drilling machine facilitating scrap collection

InactiveCN106514421AEasy to collectReduce precisionMaintainance and safety accessoriesBoring/drilling machinesFixed frameWorkload

The invention discloses a drilling machine facilitating scrap collection. The drilling machine comprises a support and a base. A linear motor is arranged on a top plate of the support. The bottom end of the linear motor is provided with a moving plate. The bottom end of the moving plate is provided with a telescopic rod. The bottom end of the telescopic rod is provided with a fixed frame. The middle portion of the bottom end of the fixed frame is connected with a pneumatic drilling machine in a sleeving mode. According to drilling machine facilitating scrap collection, wind generated by a draught fan is distributed through a flow distribution pipe to blow machined metal products; a suction fan operates to suck wind on a collection frame; wind flows to blow scraps generated after machining into the collection frame, and the scraps fall into a collection cavity; the electric telescopic rod operates to drive a cleaning plate to clean the scraps out of the collection cavity. Accordingly, scrap collection is facilitated, and the workload of workers is reduced. Heat generated during metal product machining is reduced. The cleanliness of the machine is guaranteed. The service life of the machine is prolonged. The machining precision of metal products is guaranteed.

Owner:WUXI CAIYUN MACHINERY & EQUIP

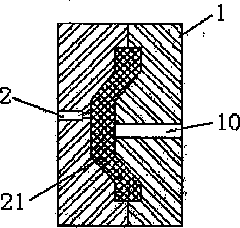

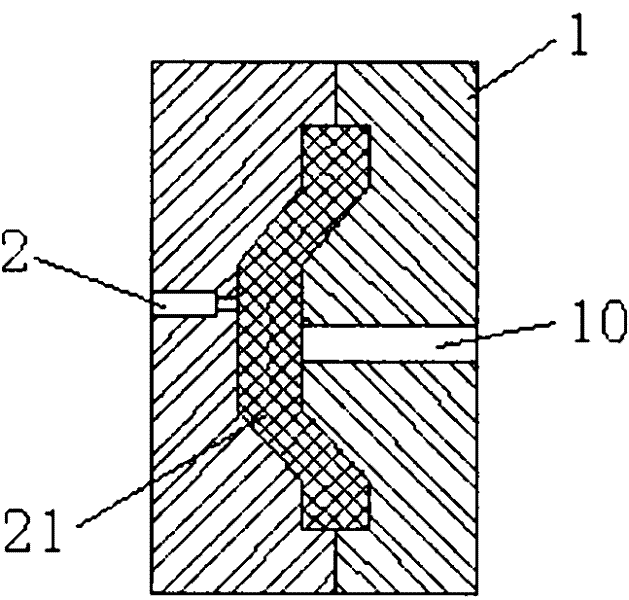

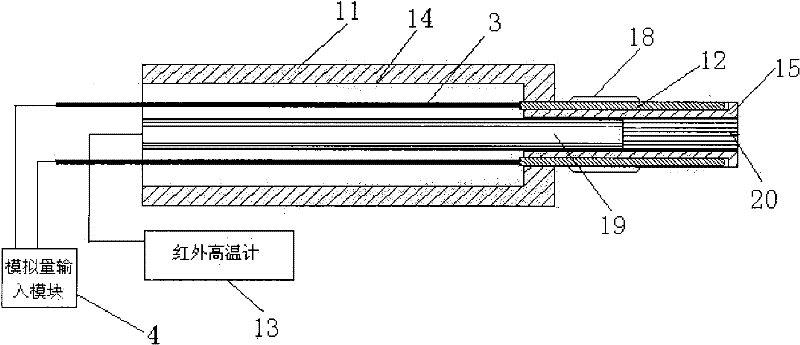

Die-casting mold multi-point precise temperature control system and method

The invention relates to a die-casting mold multi-point precise temperature control system and a method. The invention is characterized in that the system comprises a plurality of temperature detectors which are embedded in a mold, each temperature detector is repetitively connected with an analog quantity input module through a compensating lead wire, the analog quantity input modules are connected with a central processing unit, the central processing unit is respectively connected with a human-machine interaction interface and a mold temperature controller, a plurality of oil inlet pipes and a plurality of oil outlet pipes are arranged on the mold temperature controller, and the oil inlet pipes and the oil outlet pipes are respectively communicated with a plurality of flow passages arranged on the mold for forming a cyclic circulation pipeline. The invention has ingenious structural design, can improve the repeatability of the mold temperature control in the die-casting process, can improve the production efficiency, and can be widely used in the temperature control process of the die casting production.

Owner:TSINGHUA UNIV

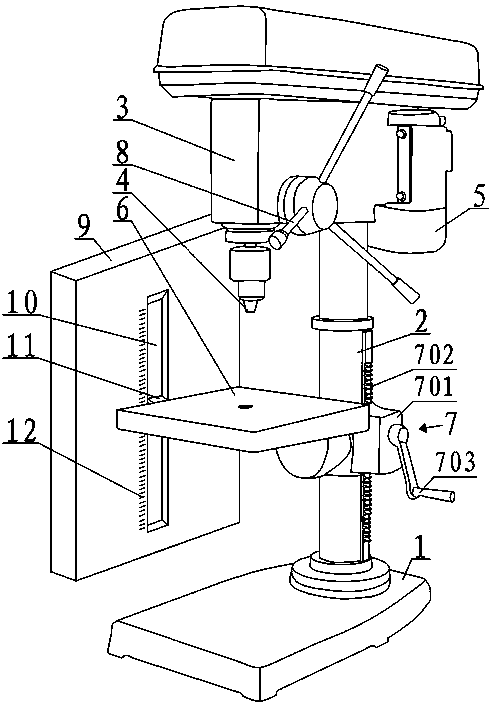

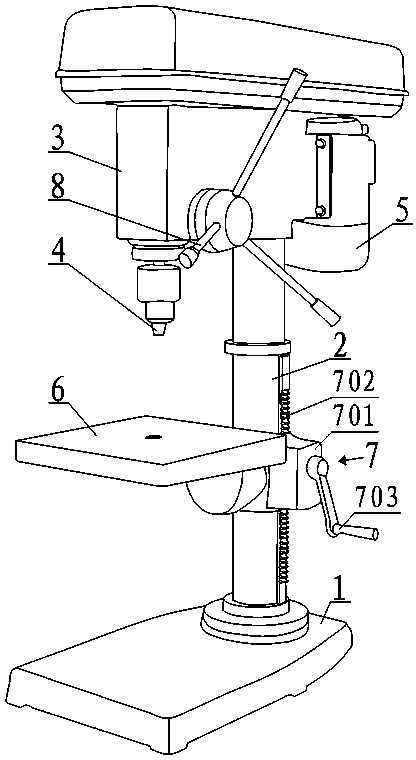

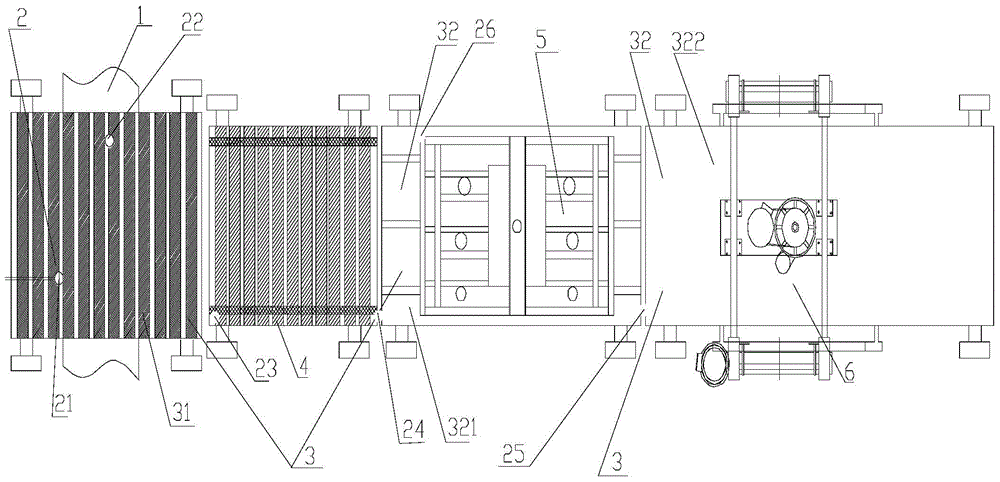

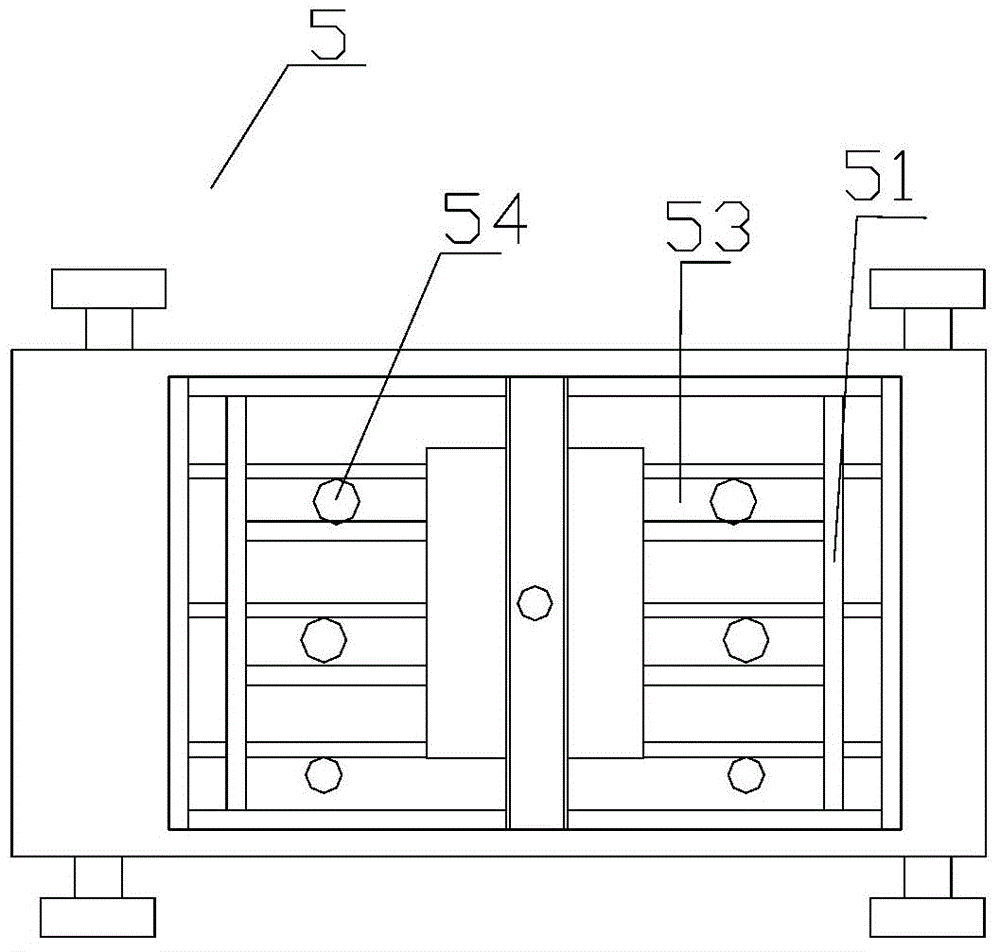

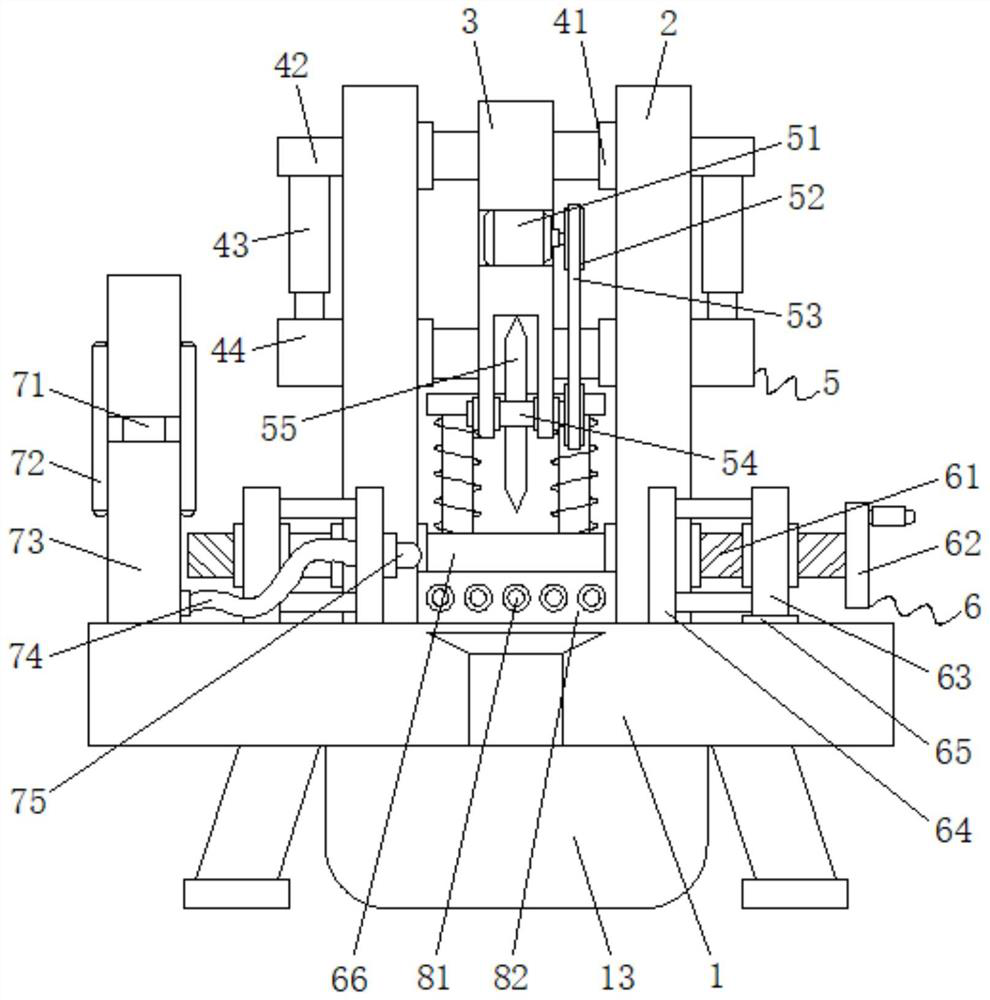

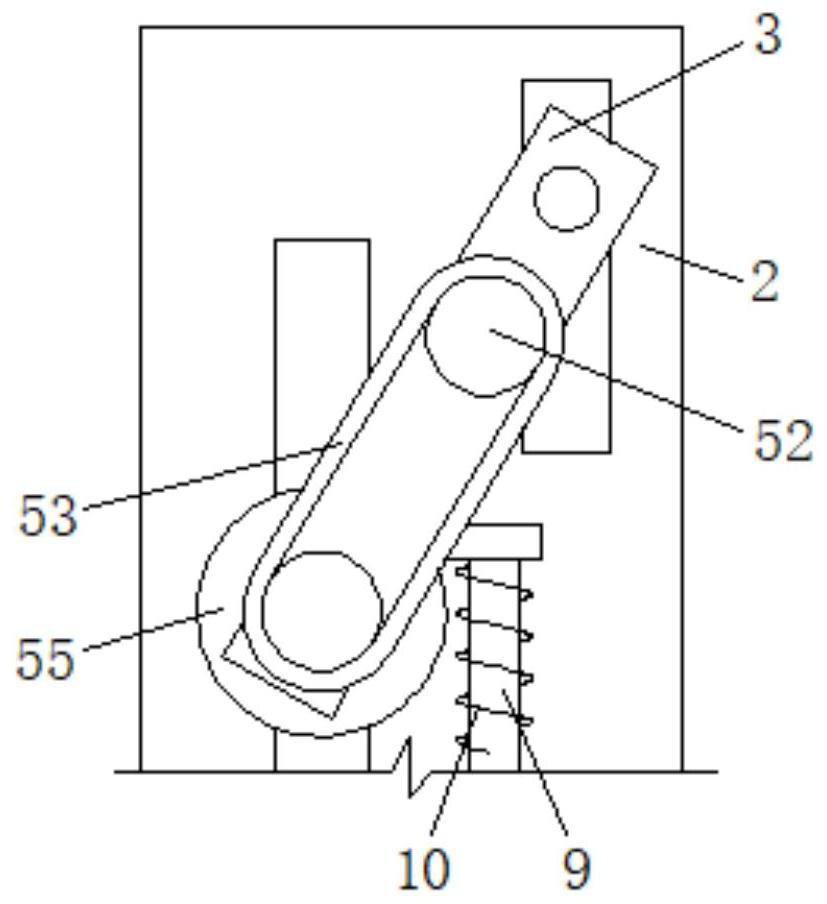

Synchronous-pulley drilling machine capable of improving drilling accuracy

InactiveCN103433525ASimple structureEasy to implementMeasurement/indication equipmentsLarge fixed membersDrive motorEngineering

The invention discloses a synchronous-pulley drilling machine capable of improving drilling accuracy. The synchronous-pulley drilling machine comprises a base, a stand column, a positioning base, a drill, a workbench, a guide rail, a shift rod, a scale strip, a workbench lifting mechanism and a driving motor, wherein the stand column is arranged on the base, both the positioning base and the workbench are connected to the stand column, the drill lifting mechanism is arranged on the positioning base, the upper end of the drill is connected to a drill lifting mechanism, and a synchronous-pulley positioning hole is formed in the position, right facing the drill, of the workbench. The guide rail is arranged on one side of the base and in parallel with the base, a guide groove is longitudinally formed in the guide rail in a concave mode, the scale strip is connected to the guide rail, one end of the shift rod is connected to the workbench, and the other end of the shift rod is embedded in the guide groove. When the synchronous-pulley drilling machine is applied, holes are drilled after a synchronous pulley is positioned so that the finished-product rate of synchronous-pulley drilling can be increased, and cost can be saved. According to the synchronous-pulley drilling machine, lifting displacement of the workbench is consistent with displacement of the shift rod in the guide groove, the displacement can be displayed through the scale strip and controlled accurately and conveniently, and the synchronous-pulley drilling machine can be applicable to being operated by novices.

Owner:CHENGDU SILVERTECH TIMING PULLEYS MFG

Synchronous pulley drilling machine used for manufacturing synchronous pulleys

InactiveCN103433524ASimple structureEasy to implementLarge fixed membersDriving apparatusControl engineeringElectric machinery

The invention discloses a synchronous pulley drilling machine used for manufacturing synchronous pulleys. The synchronous pulley drilling machine comprises a base, a stand column, a locating base, a drill bit, a workbench, a limiting mechanism and a driving motor driving the drill bit to rotate. The stand column is arranged on the base, both the locating base and the workbench are connected to the stand column, the workbench is located below the locating base, a drill bit lifting mechanism for controlling the drill bit to lift or descend is arranged on the locating base, a connecting base connected with the drill bit lifting mechanism is arranged at the upper end of the drill bit, the drill bit is located between the locating base and the workbench, and a synchronous pulley locating hole is formed in the portion, right facing toward the drill bit, of the workbench. The limiting mechanism comprises a transverse connecting plate and a longitudinal limiting plate, the longitudinal limiting plate is arranged above the workbench and parallel with the drill bit, and the two ends of the transverse connecting plate are connected with the longitudinal limiting plate and the connecting base respectively. When the synchronous pulley drilling machine is used, the synchronous pulleys can be drilled after being located, the rate of finished products of the synchronous pulleys can be promoted, and cost is saved. The drilling depth can be limited through the limiting mechanism, and thus the synchronous pulleys can be prevented from being damaged.

Owner:CHENGDU SILVERTECH TIMING PULLEYS MFG

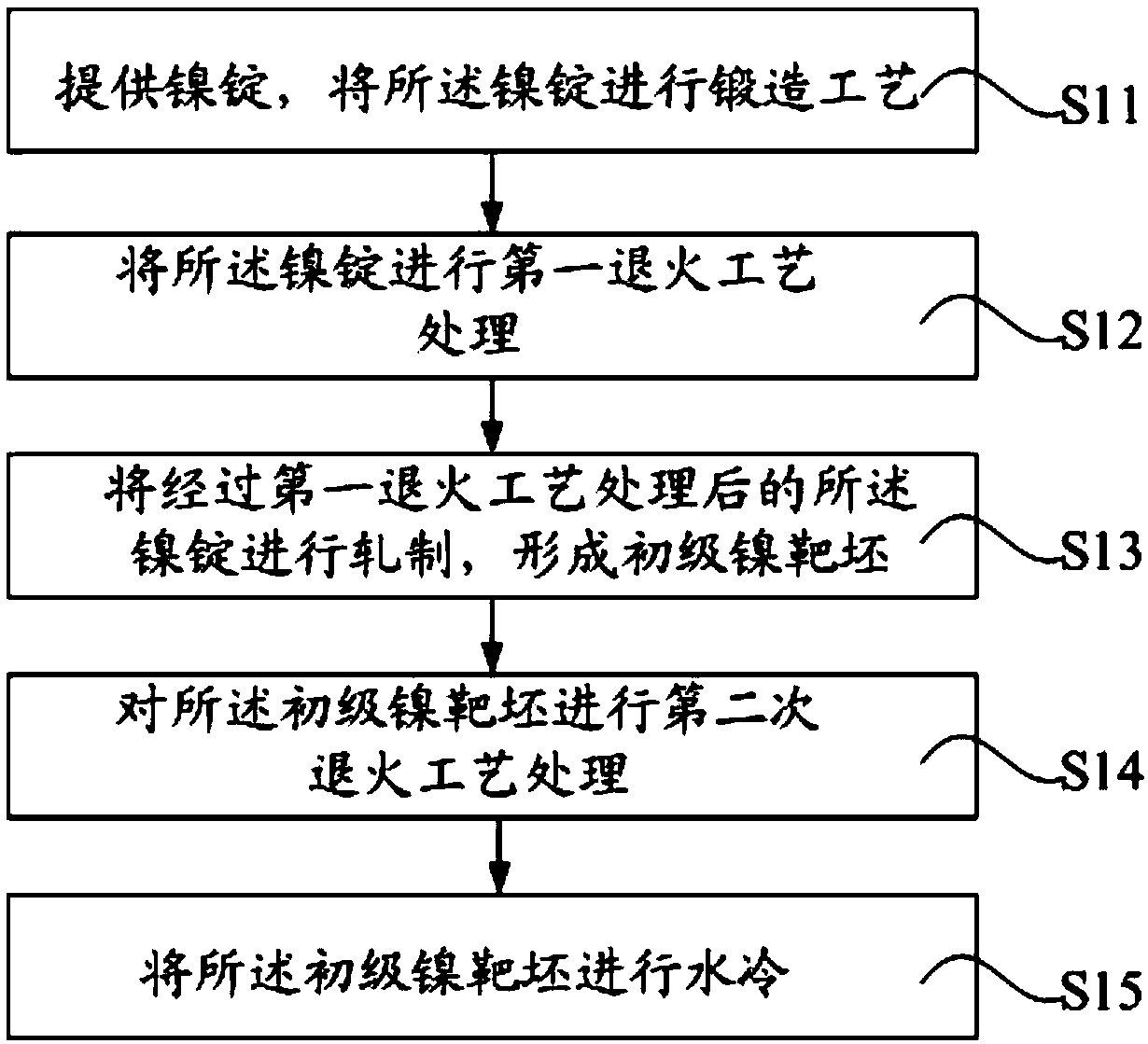

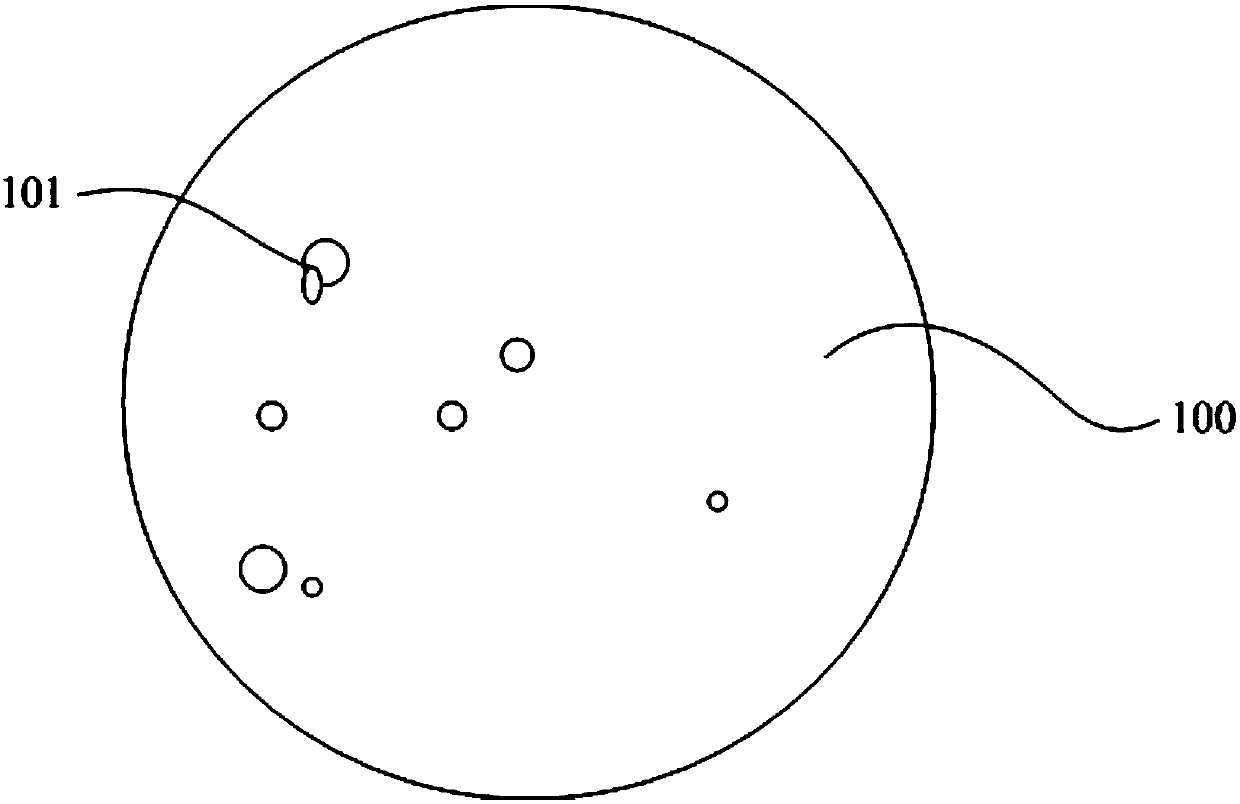

Nickel target blank and manufacturing method of target material

InactiveCN111088481AReduce hardnessReduce distortionVacuum evaporation coatingSputtering coatingIngotRoll forming

The invention discloses a nickel target blank and a manufacturing method of a target material. The manufacturing method of the nickel target blank comprises the following steps that a nickel ingot isprovided; the nickel ingot is subjected to first annealing process treatment, wherein the temperature of the first annealing process is 900-950 DEG C; and the nickel ingot treated by the first annealing process is rolled to form a primary nickel target blank. Before the nickel ingot is subjected to roll forming, the nickel ingot is subjected to primary annealing process treatment, so that the hardness of the nickel ingot material is reduced, so that the later cutting process is easier, residual stress in the nickel ingot is released, the deformation and cracking tendency of the material is reduced, and the effect of refining grains is achieved. The temperature of the first annealing process is controlled to be 900-950 DEG C, so that the interior of the rolled nickel target blank is free ofdefects, the nickel target material obtained after the nickel target blank is welded to a back plate is also free of defects, and the situation that the target material is scrapped due to the fact that the nickel target blank does not meet the requirement is reduced.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

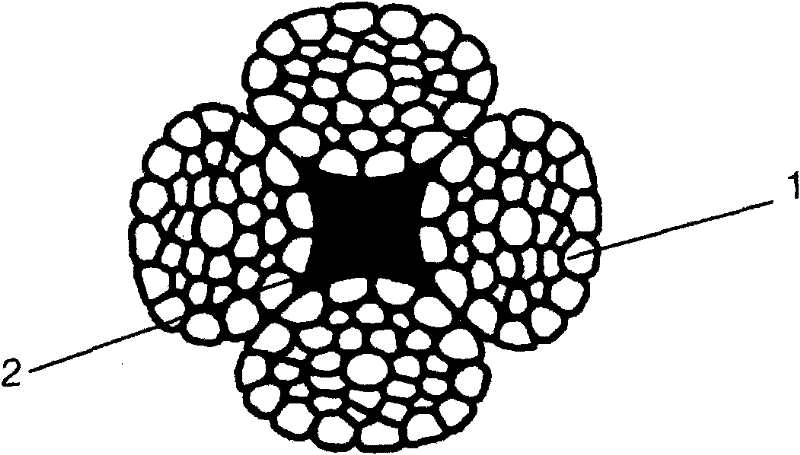

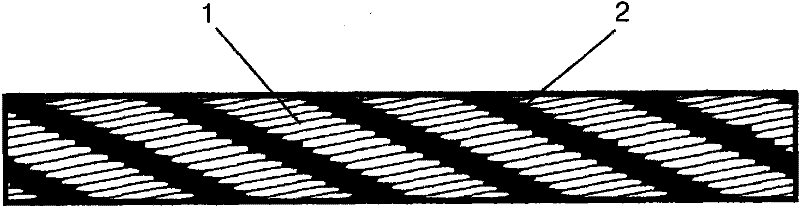

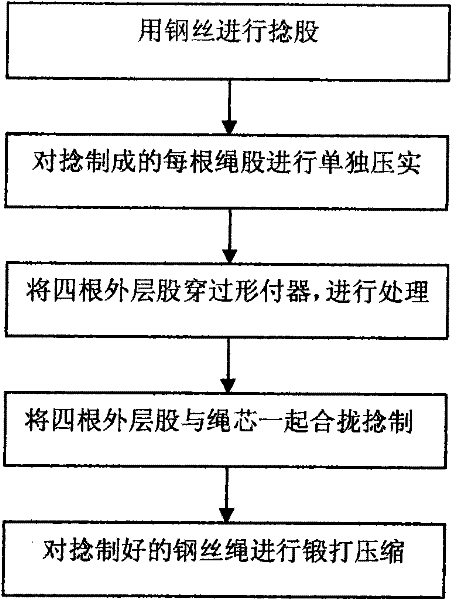

Single-layer four-strand non-rotating steel wire rope and manufacturing process thereof

InactiveCN102373631AReduce the chance of scrappingGuaranteed service lifeTextile cablesLubricationEngineering

The invention relates to a steel wire rope manufacturing process, in particular to single-layer four-strand non-rotating steel wire rope and a manufacturing process thereof. The steel wire rope is manufactured by spinning and hammering four outer layer strands which are independently compacted and a rope core containing an oil-containing polymer high molecular material, wherein the lay length of each outer layer strand is 6.6-7.0 times the diameter of the strand; and the lay length of the entire steel wire rope is 8.6-9.0 times the diameter of the rope. The steel wire rope provided by the invention has a flat and smooth outer surface, so that the contact areas of the steel wire rope with a pulley, a drum and a support wheel are increased, the stress concentration is reduced, and the service life of the steel wire rope is ensured; the rope core is made of the oil-containing polymer high molecular material, so that internal lubrication of steel wire rope is ensured; the manufacturing cost is relatively reduced; and a reasonable parameter design is adopted, so that the rotating resistance of the steel wire rope is equivalent to that of a 35W*7 surface contact steel wire rope.

Owner:贝尔卡特(青岛)钢丝产品有限公司

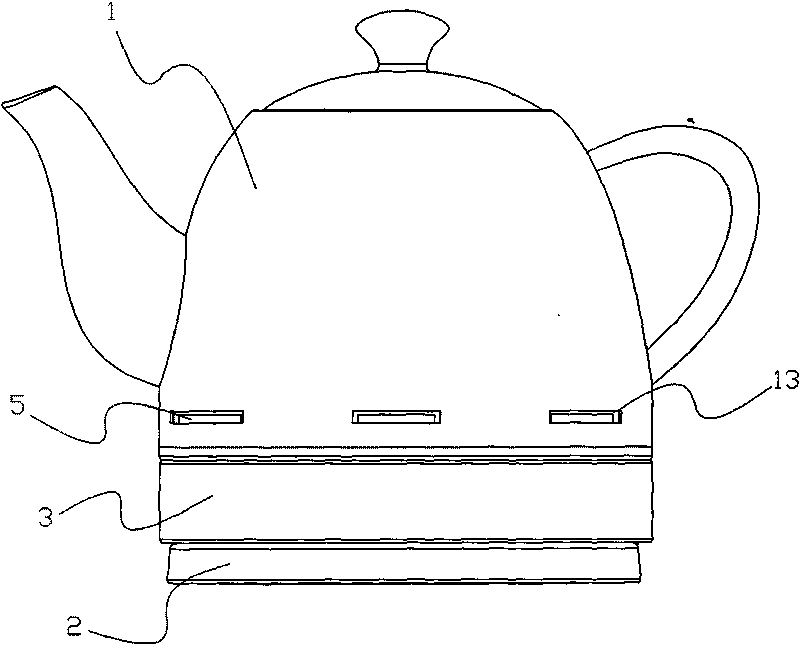

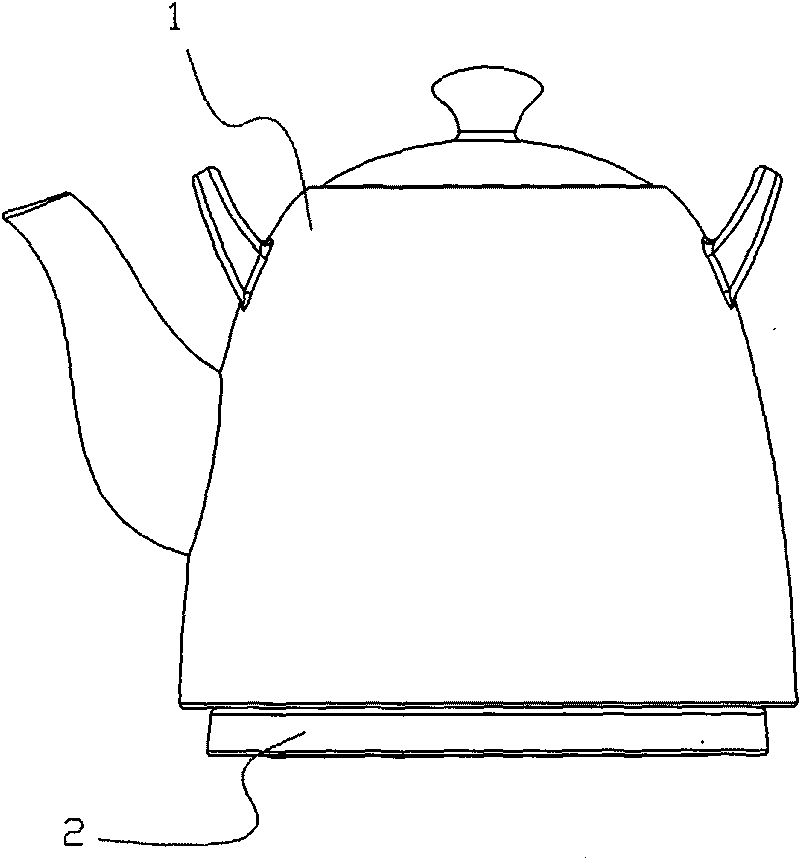

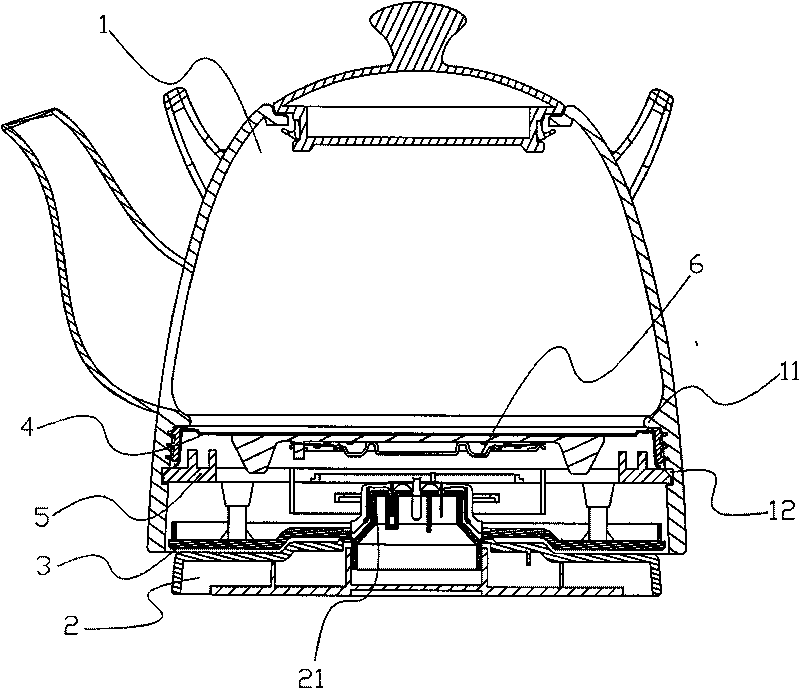

Ceramic electric kettle

InactiveCN101721129ANeat and beautiful appearanceNice appearanceWater-boiling vesselsChemical engineering

The invention relates to a ceramic electric kettle which comprises a kettle body and a power supply base, wherein the bottom of the kettle body is provided with a kettle bottom; a heating disk and a fixed clamping ring are arranged between the kettle bottom and the kettle body; a connector for connecting the kettle bottom is arranged on the power supply base; a convex clamping step is arranged on the inner wall of the lower part of the kettle body; an annular clamping groove is arranged on the inner wall of the kettle body which is positioned under the clamping step; the fixed clamping ring is clamped on the annular clamping groove; the heating disk is clamped between the clamping step and the fixed clamping ring; the fixed clamping ring is fixedly connected with the kettle bottom under the fixed clamping ring; and the kettle bottom is arranged in the side wall of the bottom of the kettle body. Compared with a through hole type bayonet structure of the original product, the outer wall of the kettle body can not be provided with holes; accordingly, the appearance of the kettle body is more neat and beautiful, a manufacturer can set the appearance and a decorative pattern of the ceramic kettle body easily, and the appearance diversity of the ceramic electric kettle is improved; the annular clamping groove does not need manual processing, the manufacture process difficulty and cost of the product are reduced, the waste probability is reduced, and the product is more beautiful.

Owner:丁国盛

Method for improving elongation rate and strain hardening index n value of cold-rolled deep-drawing steel

PendingCN110438312AImprove deformation abilityImprove forming stabilityProduction lineStrain stiffening

The invention discloses a method for improving elongation rate and strain hardening index n value of cold-rolled deep-drawing steel. The method comprises the steps of carrying out cold rolling by adopting a cold rolling reduction rate of 58%-77%, then carrying out cover annealing, and flattening to obtain the cold-rolled deep-drawing steel. The elongation rate of the cold-rolled deep-drawing steelis more than 40%, and the strain hardening index n value is 0.22-0.25. According to the method for improving the elongation rate and the strain hardening index n value of the cold-rolled deep-drawingsteel, through optimizing the production process method, the obtained cold-rolled deep-drawing steel has higher elongation rate and strain hardening index n value, the expansion and ductility performance of a steel plate material is improved, and the probability of fracture of the steel material in the expansion process is reduced; the production qualified rate is improved; and the method for improving the elongation rate and the strain hardening index n value of the cold-rolled deep-drawing steel is improved on the basis of an original steel production line, process parameter control is optimized, and industrial production improvement is facilitated.

Owner:BAOTOU IRON & STEEL GRP

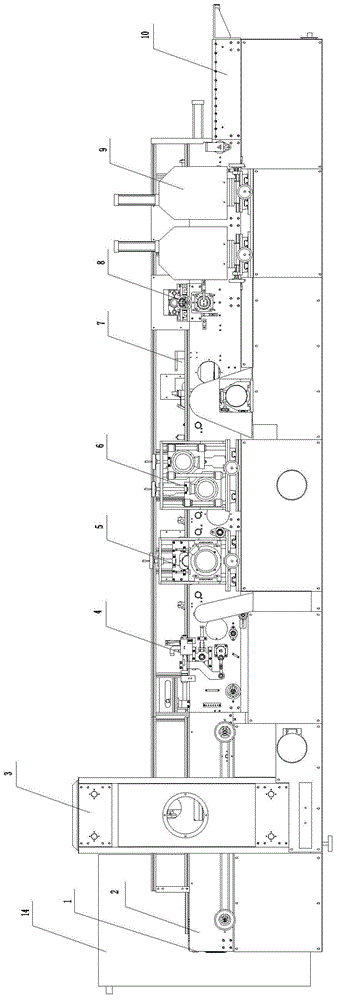

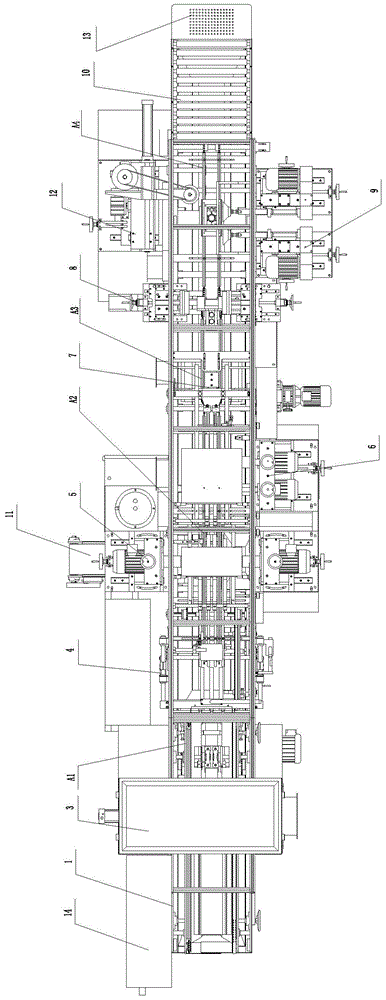

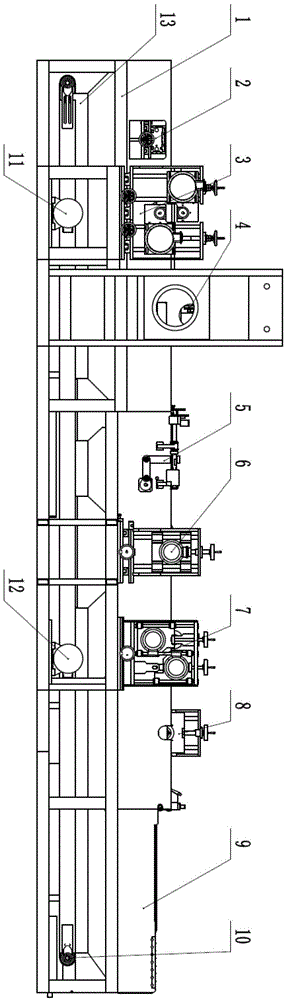

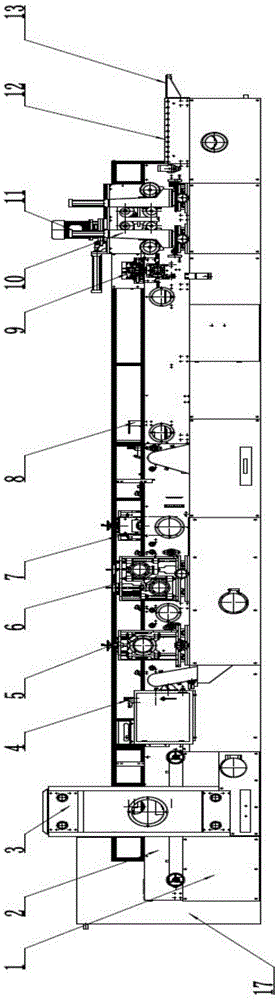

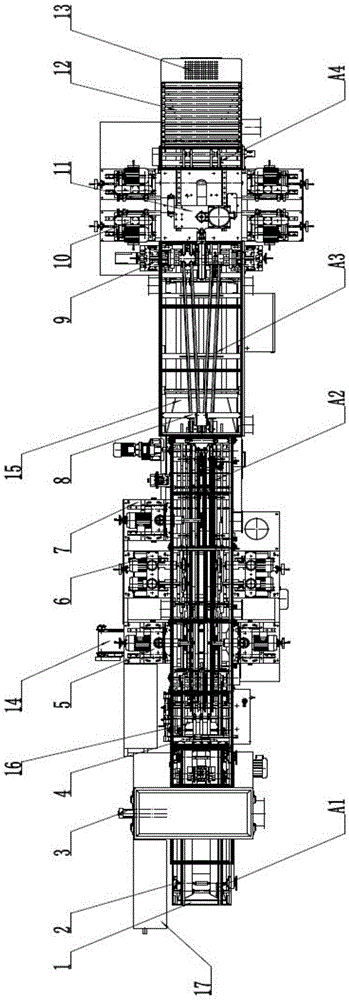

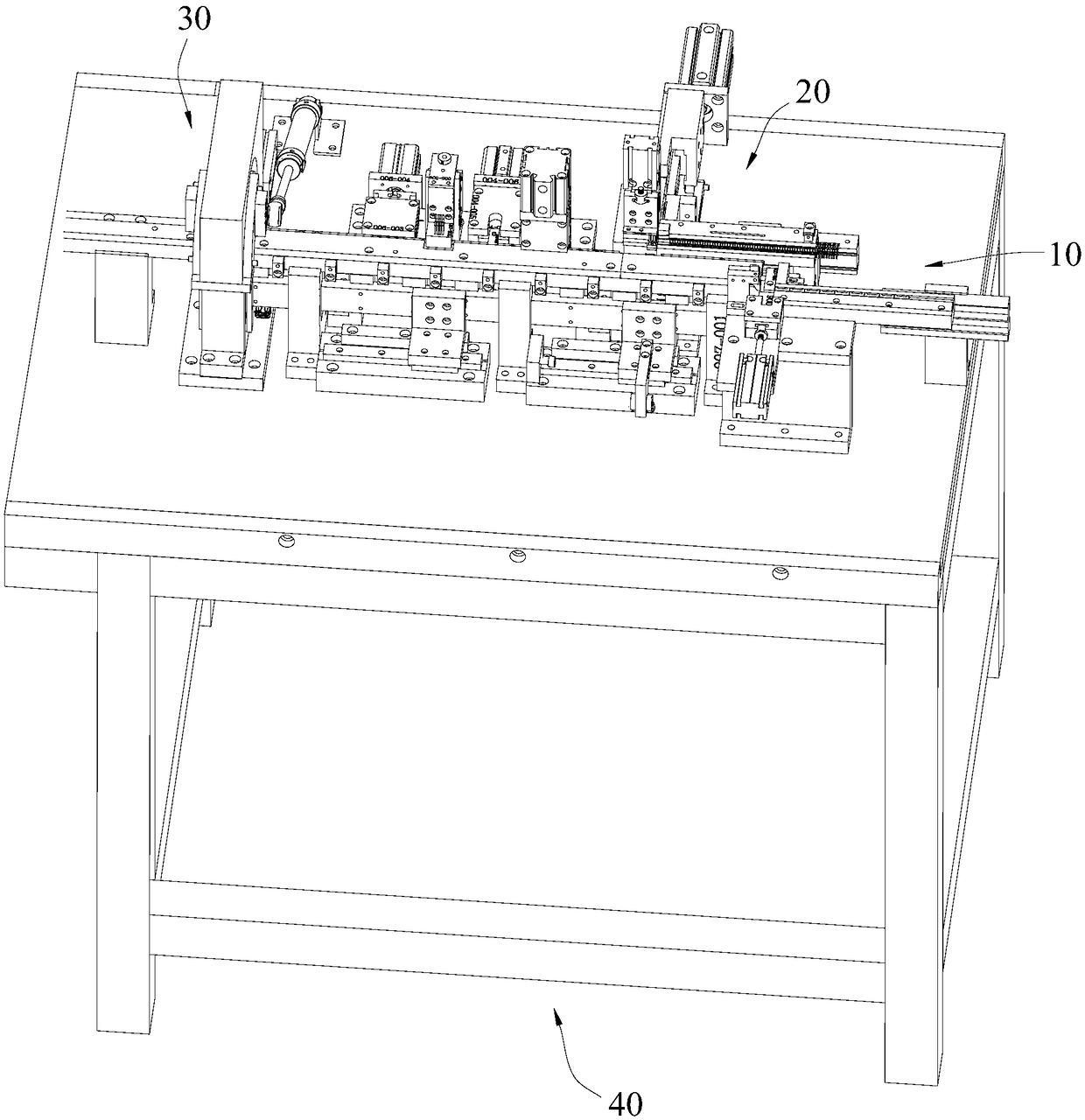

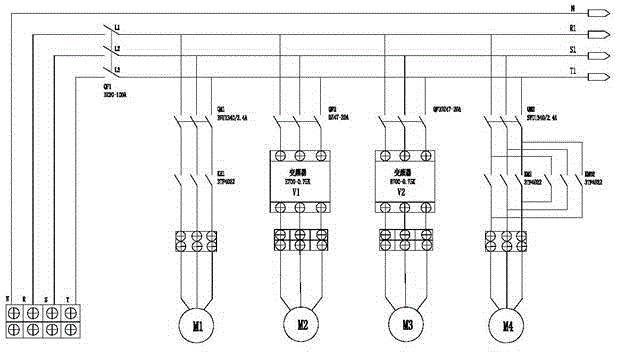

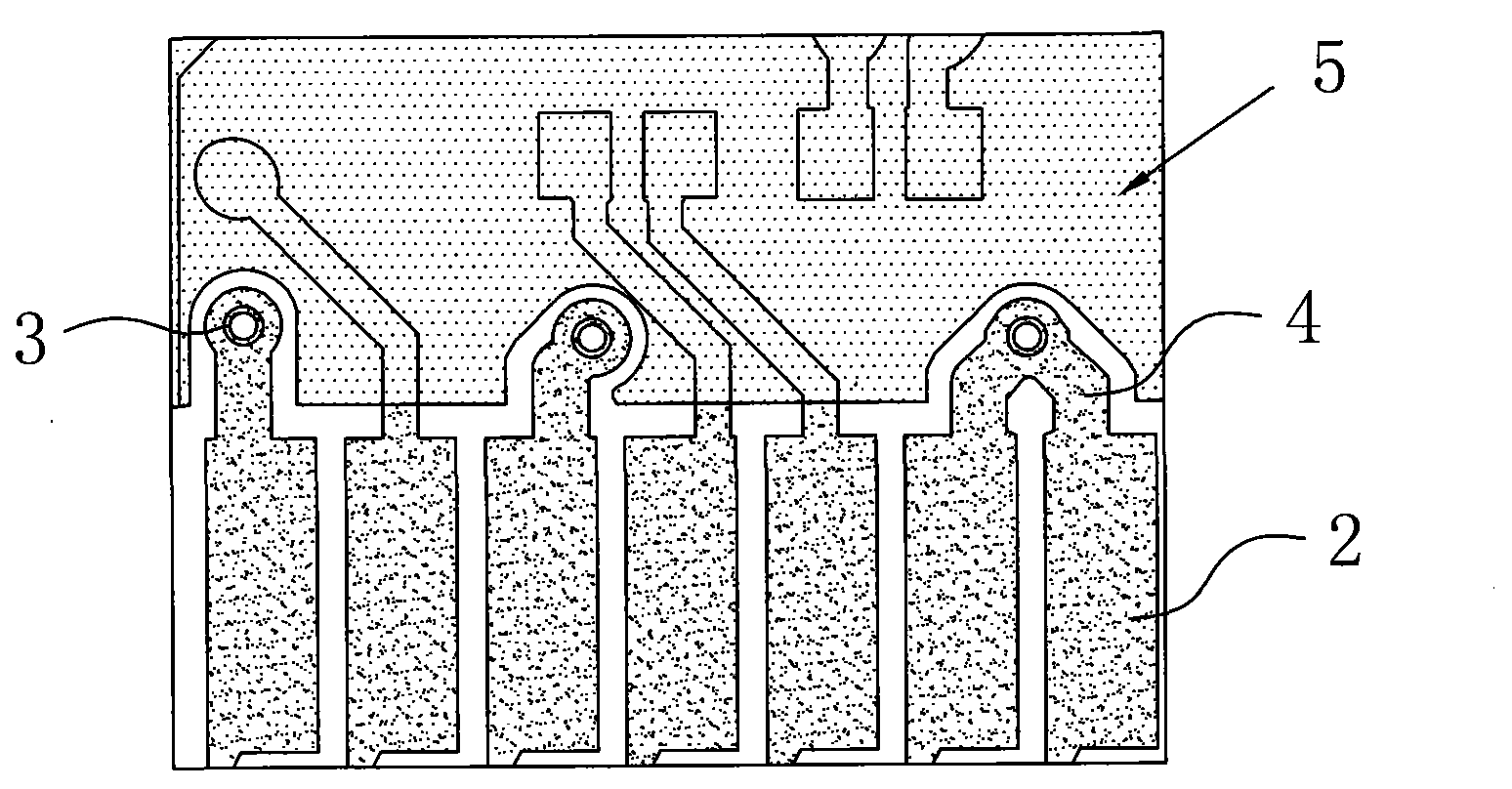

All-in-one machine for treating lead-acid battery plates

ActiveCN104916816AReduce the chance of scrappingSimple mechanical structureLead-acid accumulator electrodesElectrical controlLead–acid battery

The present invention relates to an all-in-one machine for treating lead-acid battery plates, and belongs to the technical field of the lead-acid battery manufacturing industry. The all-in-one machine for processing lead-acid battery plates comprises a rack, a sheet feeding mechanism, a mechanism for brushing upper and lower edges, a sheet sucking and feeding mechanism, a tab cutting mechanism, a tab brushing mechanism, a sheet stacking mechanism, a sorting mechanism, a mechanism for brushing tab side edges, a mechanism for brushing edges opposite to tabs, a plate conveying apparatus and an electrical control system, wherein the sheet feeding mechanism, the mechanism for brushing upper and lower edges, the sheet sucking and feeding mechanism, the tab cutting mechanism, the tab brushing mechanism, the sheet stacking mechanism, the sorting mechanism, the mechanism for brushing tab side edges and the mechanism for brushing edges opposite to tabs are joined in sequence and fixedly mounted on the rack. The all-in-one machine for processing lead-acid battery plates is simple and reasonable in structure, higher in productivity, better in stability, and superior in environmental protection. According to the present invention, a driving cylinder in the structure is saved, thereby improving machine stability; and meanwhile, the probability of discarding of the plates during delivery or treatment is greatly reduced.

Owner:江苏夕川科技有限公司

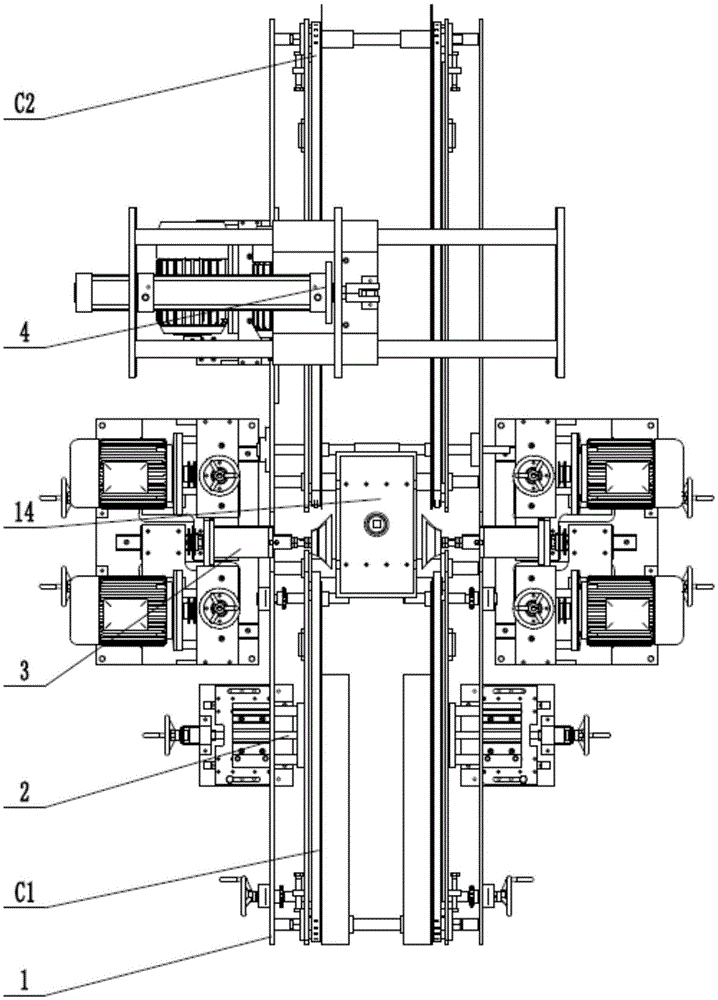

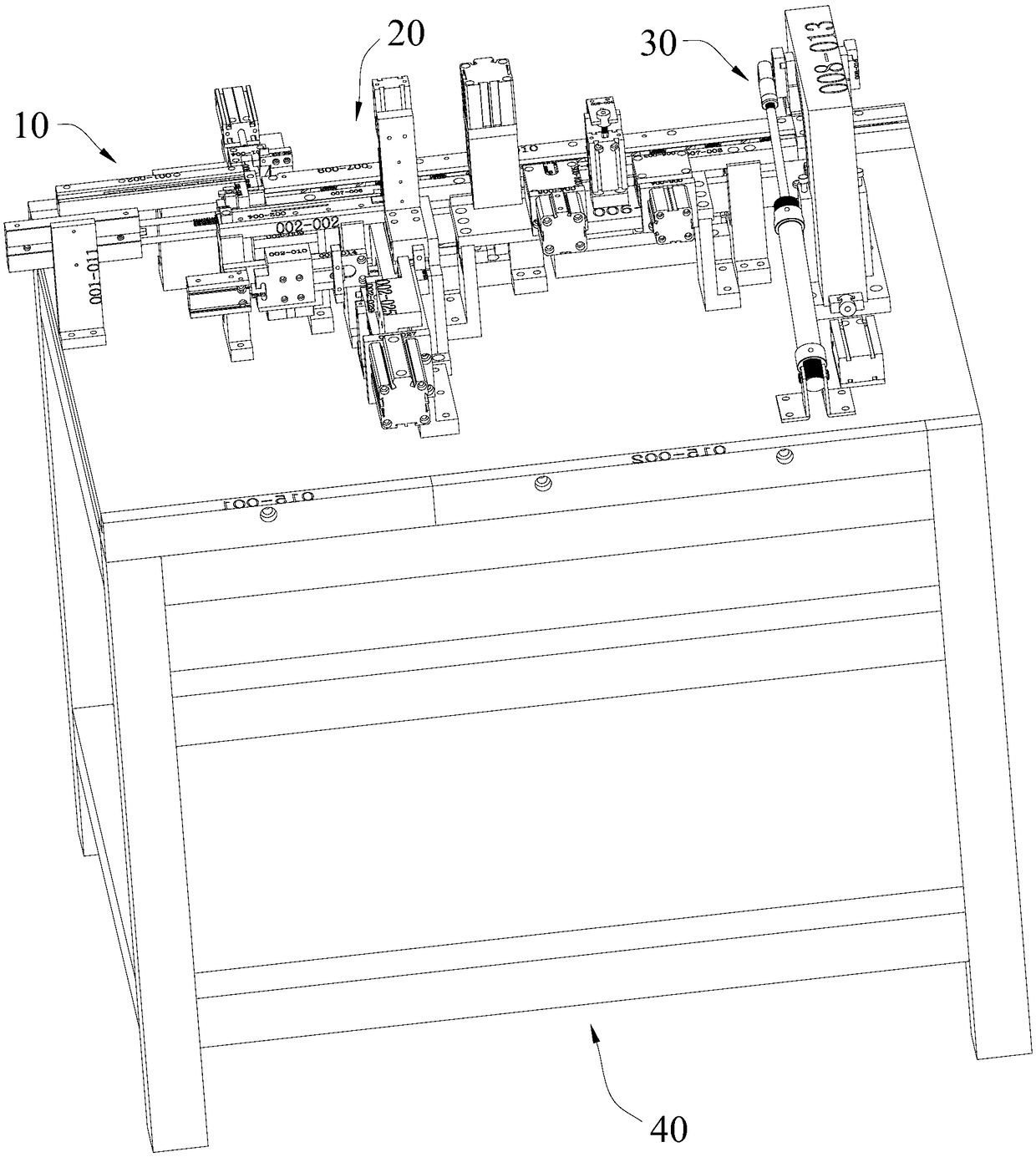

Integrated machine for treating pole plate of lead-acid storage battery

ActiveCN104362302AReduce the chance of scrappingSimple mechanical structureLead-acid accumulator electrodesElectrical controlRejection rate

The invention relates to an integrated machine for the treatment process of a pole plate of a lead-acid storage battery. The integrated machine comprises a stander, a finishing mechanism, a frame brushing mechanism, a plate sucking and assembling mechanism, a lug cutting mechanism, a lug brushing mechanism, a single-edge brushing mechanism, a pole plate conveying device and an electrical control system. According to the structure provided by the invention, the integrated machine has the following treatment mode: firstly surplus paste and burrs which are positioned on the stacked four-surface frame of the pole plate are integrally treated, and then lug cutting, lug brushing and single-edge brushing are carried out on the single pole plate. In such a way, the mechanical structure of the traditional pole plate treatment equipment is simplified, the air cylinder driving of the structure is reduced, the equipment stability is enhanced, and the rejection rate of the pole plate in conveying and treatment processes is greatly reduced. Besides, the integrated machine disclosed by the invention can be used for greatly reducing the lead dust and waste pollution of a production process by additionally arranging an integral sealing air-draft environmental-friendly device and a waste recovery device.

Owner:湖北海蓝装备科技有限公司

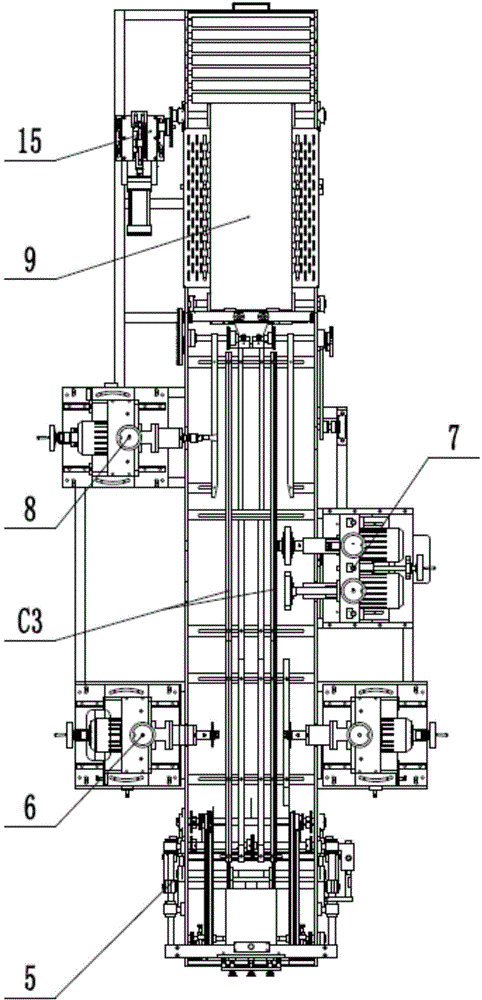

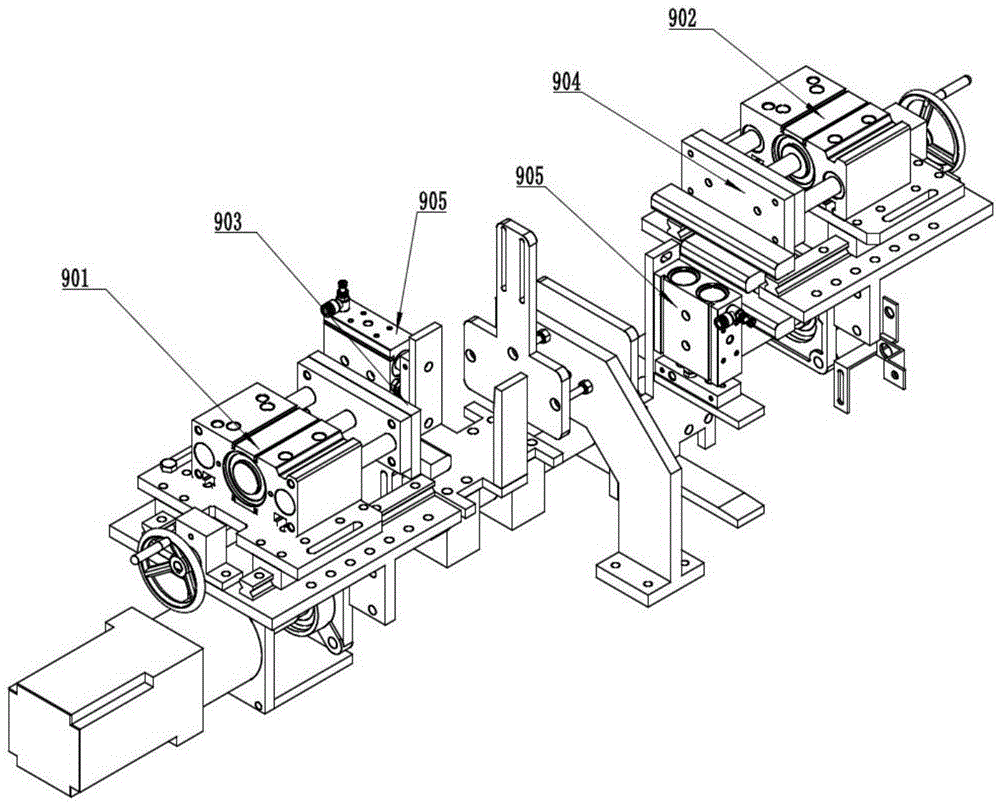

Integrated machine for treating two-sheet lead-acid battery polar plate

InactiveCN105428604AReduce the chance of scrappingSimple mechanical structureLead-acid accumulator electrodesControl systemElectrical control

The present invention relates to an integrated machine for treating a two-sheet lead-acid battery polar plate, and belongs to the technical field of the lead-acid battery manufacturing industry. The integrated machine comprises a machine rack, a sheet conveying mechanism, an upper-and-lower-edge brushing mechanism, a sheet sucking and feeding mechanism, a lug making mechanism, a lug brushing mechanism, a plate separating mechanism, a sheet stacking mechanism, a sorting mechanism, a tab side brushing mechanism, an opposite-to-tab-side brushing mechanism, a polar plate conveying apparatus, a tab recycling mechanism, a waste recycling mechanism I, a waste recycling mechanism II and an electrical control system. The opposite-to-tab-side brushing mechanism comprises a third horizontal guide mechanism and a third actuator mechanism. The third horizontal guide mechanism is fixedly connected to a top plate of the machine rack. The third horizontal guide mechanism is connected to the third actuator mechanism via a double-axis guide rail. The third actuator mechanism is a rolling brush controlled and driven by a cylinder. According to the integrated machine for processing a two-sheet lead-acid battery polar plate, driving performed by a cylinder in the structure is reduced, thereby improving device stability; and moreover, the probability of scrapping of the polar plate during conveying and treatment is greatly reduced.

Owner:武汉楚天鼎风科技有限公司

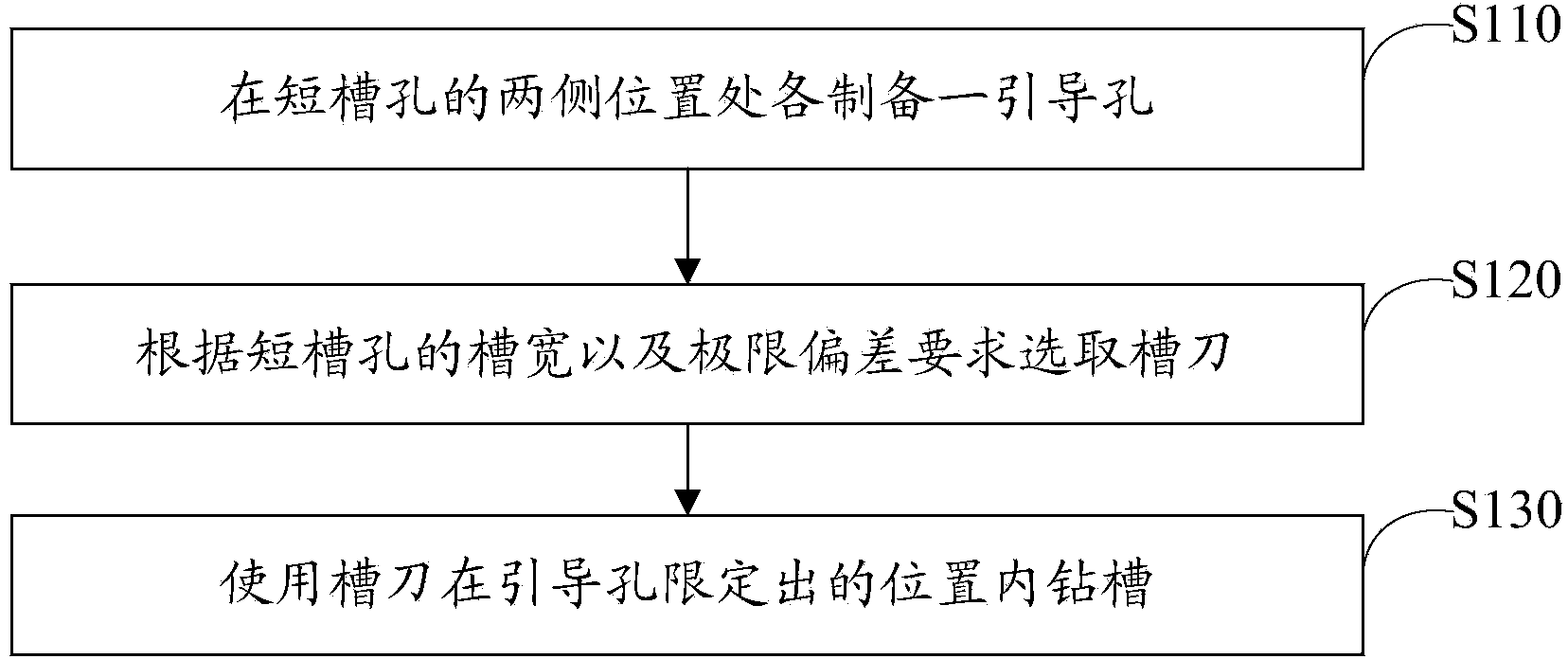

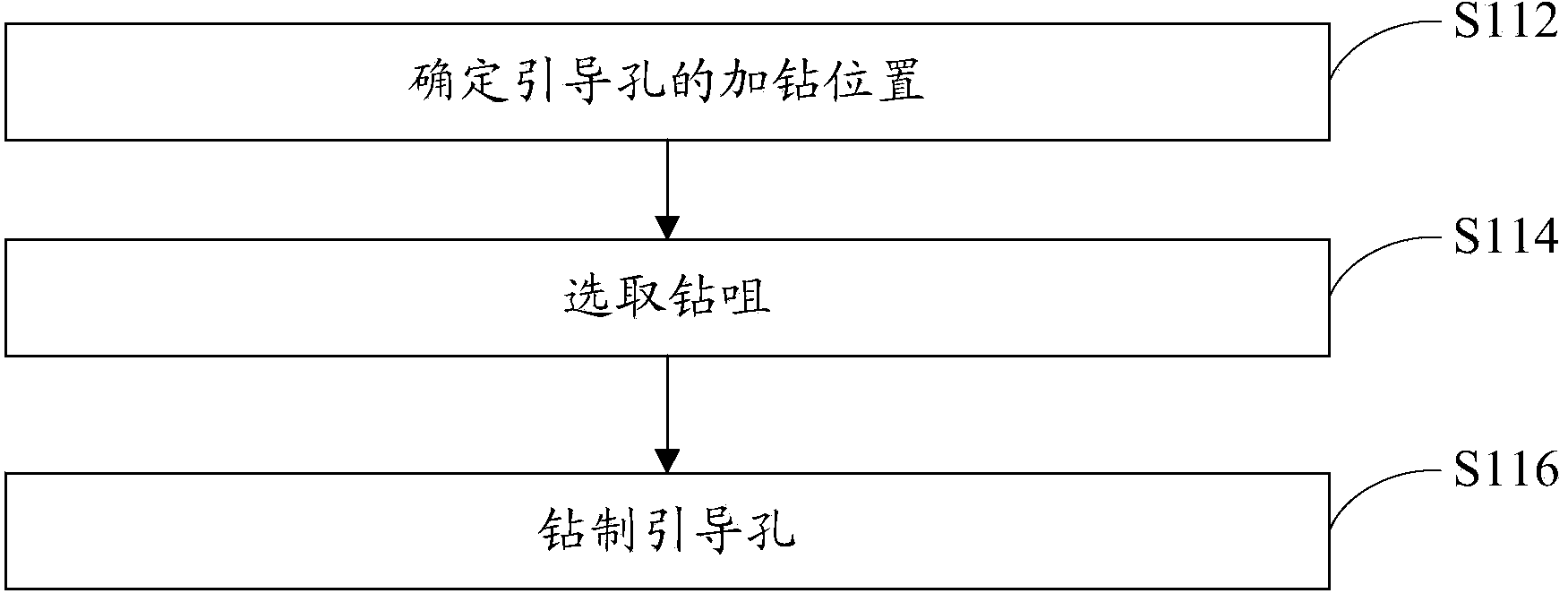

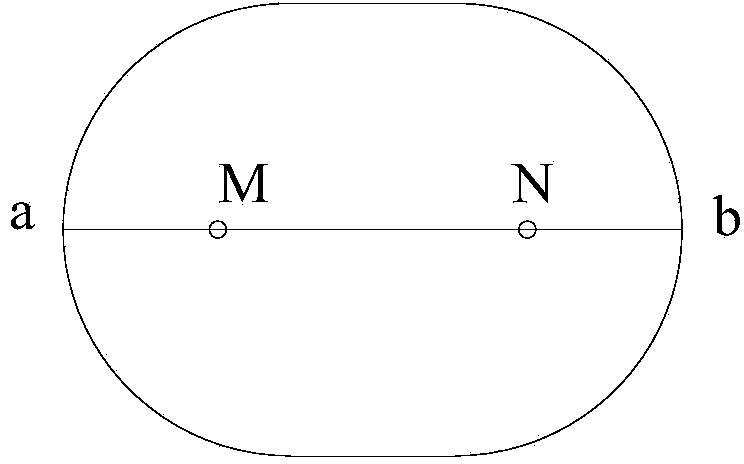

Method for preparing short slotted hole in printed circuit board

InactiveCN103862515AReduce the chance of scrappingEven by forceMetal working apparatusPrinted circuit board

The invention discloses a method for preparing a short slotted hole in a printed circuit board, which comprises the following steps of respectively preparing a guide hole in two sides of the short slotted hole, wherein the diameter of each guide hole is half of the slot length of the short slotted hole; according to the slot width of the short slotted hole and the limit deviation, selecting a slot mill; using the slot mill to drill a slot in the position defined by the guide holes, wherein the slot drilling feed speed is smaller than or equal to 0.6m per minute. According to the method for preparing the short slotted hole in the printed circuit board, the guide holes of which the diameters are equal to half of the slot length of the short slotted hole are firstly prepared; the guide holes exist, so that during slot drilling, the slot mill is stressed evenly, the problems of shorter slot length, slot edge gap, slot deviation and the like difficultly occur, the yield of the prepared short slotted hole is improved, the product stability is effectively improved, the product yield is further improved, and the probability that the printed circuit board is scrapped due to the slotted hole problem is reduced.

Owner:JIUJIANG HUAXIANG TECH +2

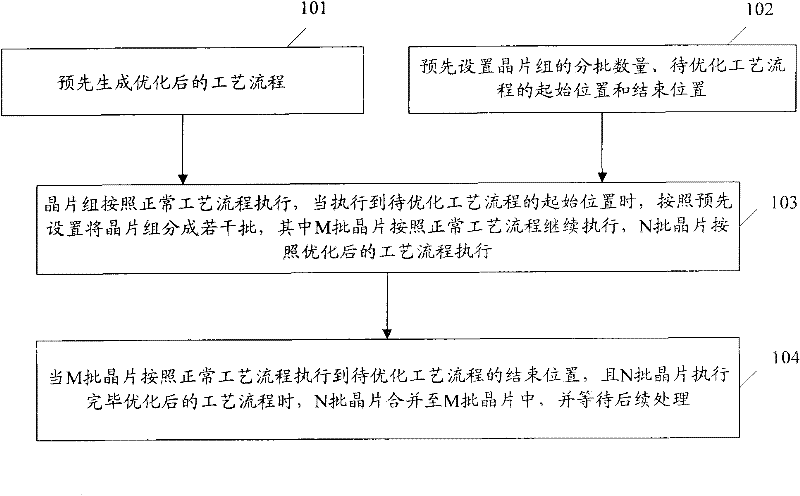

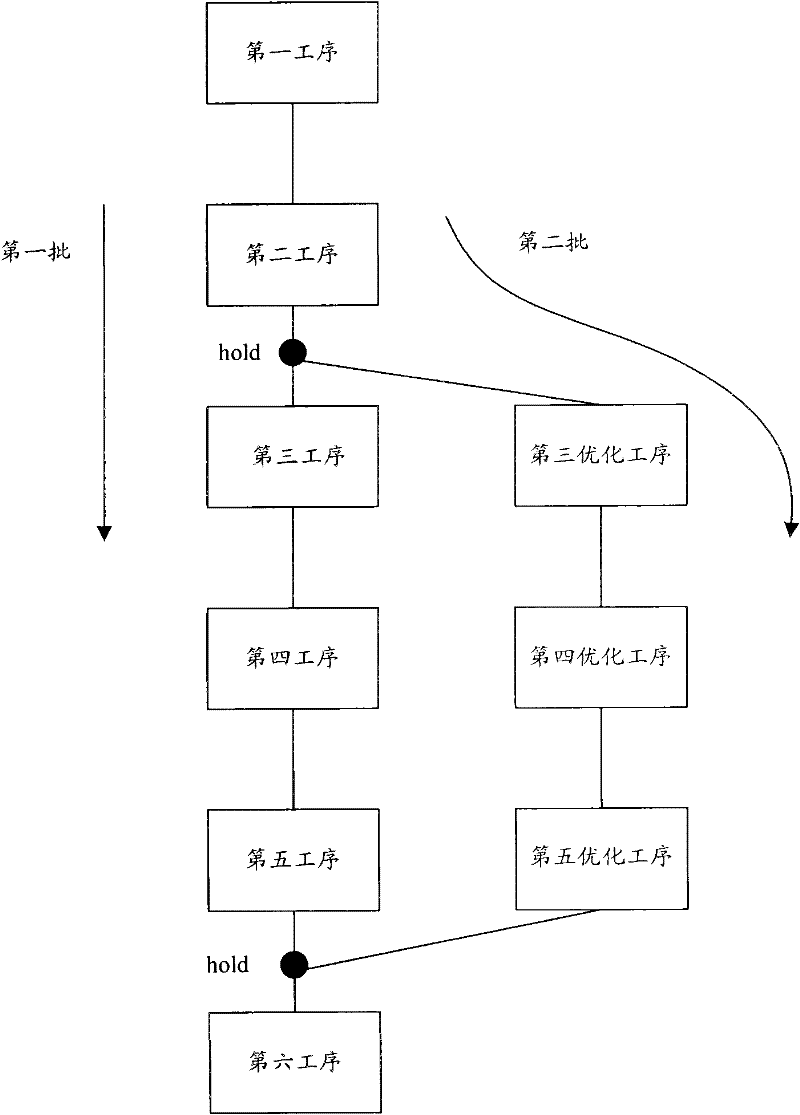

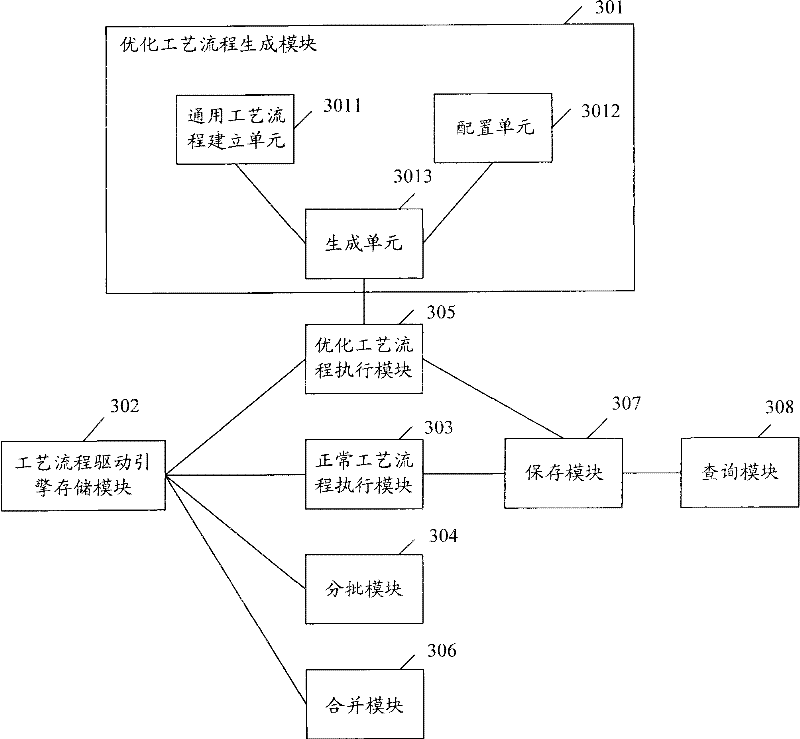

Method and device for optimizing technological process

ActiveCN102222599AReduce the chance of scrappingAccurate operationSemiconductor/solid-state device manufacturingAfter treatmentEngineering

The invention discloses a method for optimizing a technological process. An optimized technological process is produced in advance, and the number of batches of wafer sets and a starting position and an ending position of a technological process to be optimized are preset. The method comprises the following steps: the wafer sets are carried out according to a normal technological process, when the wafer sets are carried out to the starting position of the technological process to be optimized, the wafer sets are separated into a plurality of batches according to a preset valve, wherein M batches of wafer sets are continuously carried out according to the normal technological process, N batches of wafer sets are carried out according to the optimized technological process, and M and N are positive integers more than or equal to 1; when the M batches of wafer sets are carried out to the ending position of the technological process to be optimized according to the normal technological process, and the N batches of wafer sets are finished carrying out the optimized technological process, the N batches of wafer sets and the M batches of wafer sets are combined and wait for after-treatment. Meanwhile, the invention further discloses a device for optimizing the technological process; and with the adoption of the method and the device, the cost for optimizing can be lowered.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

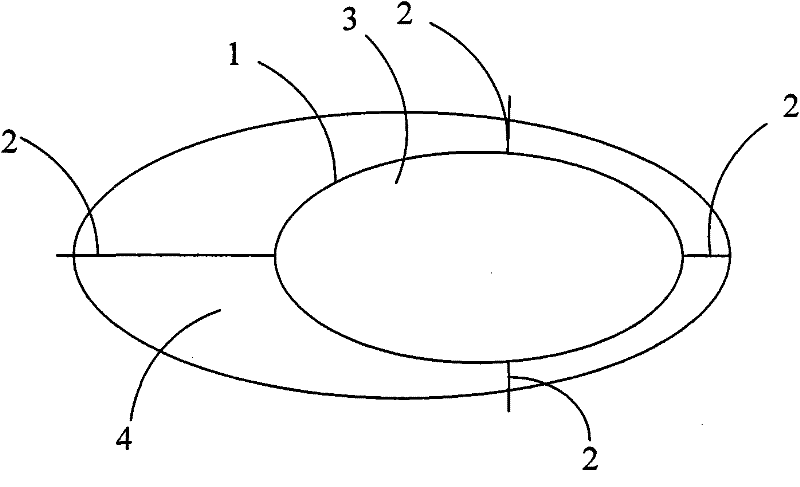

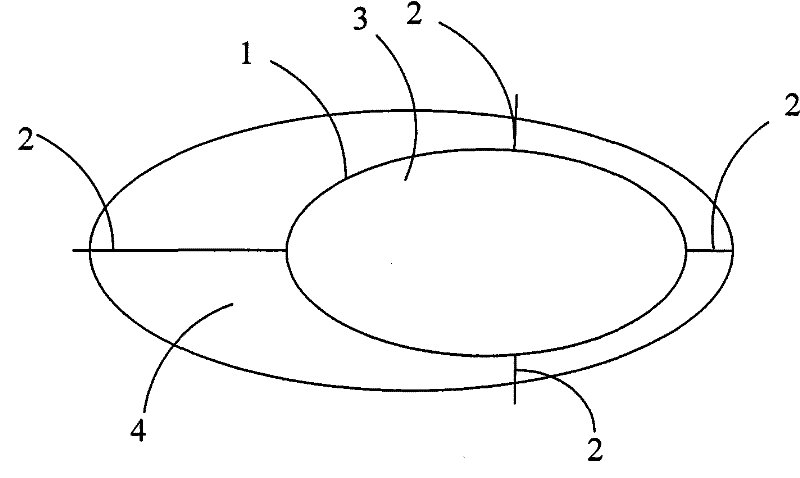

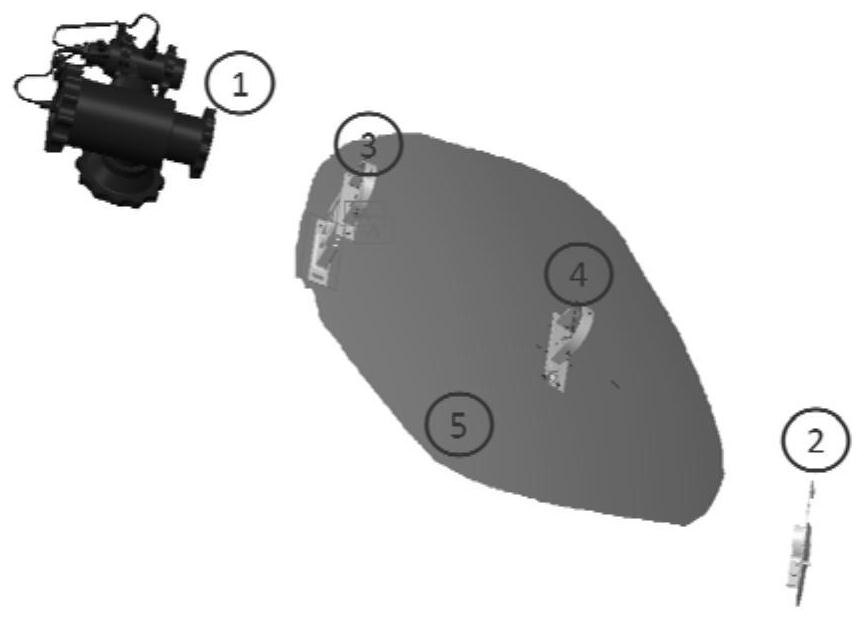

A kind of laser cutting method of lens

ActiveCN102294542AReduce the chance of scrappingTake away in timeLaser beam welding apparatusLaser lightScrap

The invention discloses a laser cutting method for a lens. In the method, the lens is cut on a lens blank along a predetermined track by using laser light; the predetermined track comprises an internal cutting line of the lens defined on the lens blank and at least one external cutting line for further distinguishing scraps positioned at the periphery of the lens; one end of the external cutting line is connected with the internal cutting line, and the other end of the external cutting line extends out of the edge of the scraps; the depth of the predetermined track on the lens track is smaller than the thickness of the lens; and after cutting along the predetermined track is performed, the lens blank is cooled immediately and the scraps are cleared along the predetermined track. According to the method, expansion of the lens caused by heat absorption is released in the cutting process by using the external cutting line; the scraps are not cut, so that heat absorbed by the lens is not too high; and heat absorbed by the lens can be taken away in time in the cooling step, and the scraps can be cleared easily along the predetermined track.

Owner:HANS LASER TECH IND GRP CO LTD

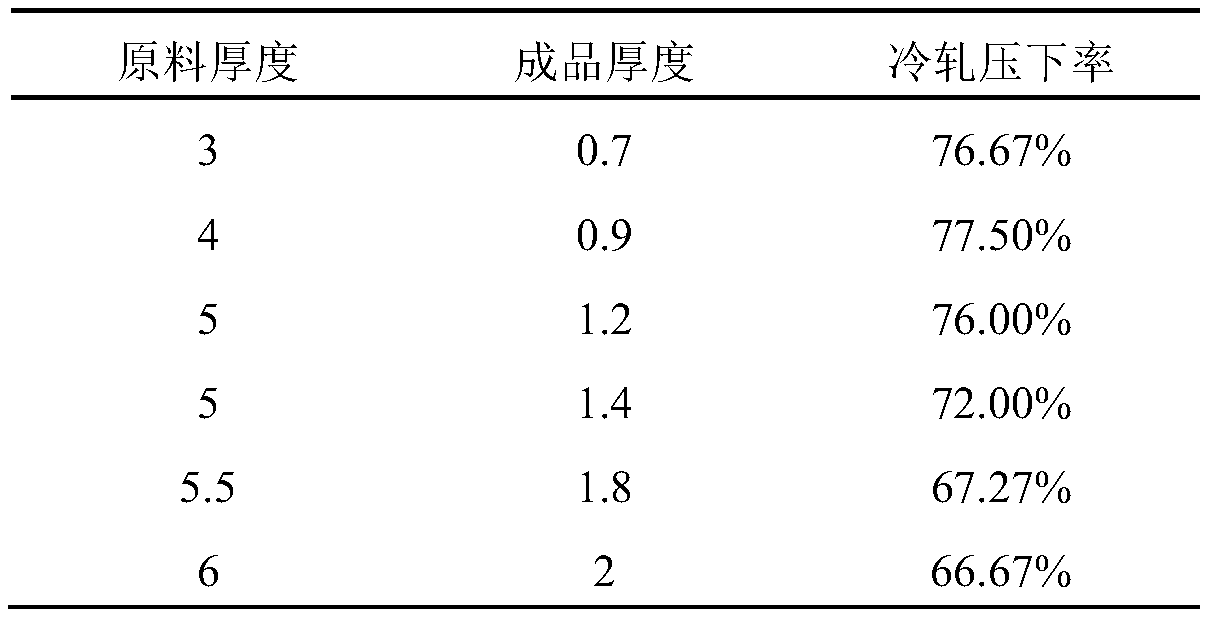

Method for improving the plastic strain ratio r value of cold-rolled deep-punching steel

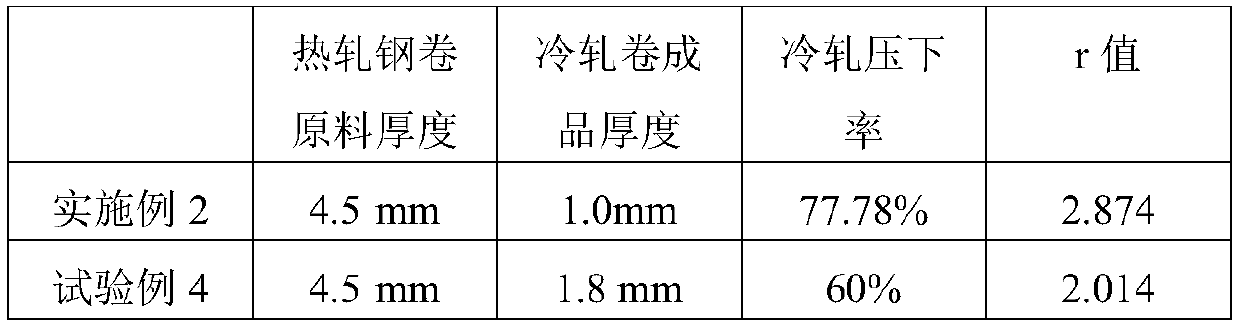

InactiveCN110499408AIncrease the plastic strain ratio r valueImprove stampingReduction rateProduction line

The invention discloses a method for improving the plastic strain ratio r value of cold-rolled deep-punching steel. The method comprises the following steps of carrying out cold rolling by adopting acold rolling reduction rate of 66.67% - 77.78%, and then carrying out batch annealing and leveling to obtain the cold-rolled deep-punching steel. According to the method for improving the plastic strain ratio r value of the cold-rolled deep-punching steel, the method of optimizing the production process is adopted, so that the obtained cold-rolled deep-punching steel has a good plastic strain ratio r value, the stamping and drawability performance of a steel plate material is improved, the probability of breakage of the steel material in the stamping and drawability processes is reduced, and the production qualified rate is improved; and according to the method for improving the plastic strain ratio r value of the cold-rolled deep-punching steel, improvement is carried out on the basis ofan original steel production line, technological parameter control is optimized, and industrial production improvement is facilitated.

Owner:BAOTOU IRON & STEEL GRP

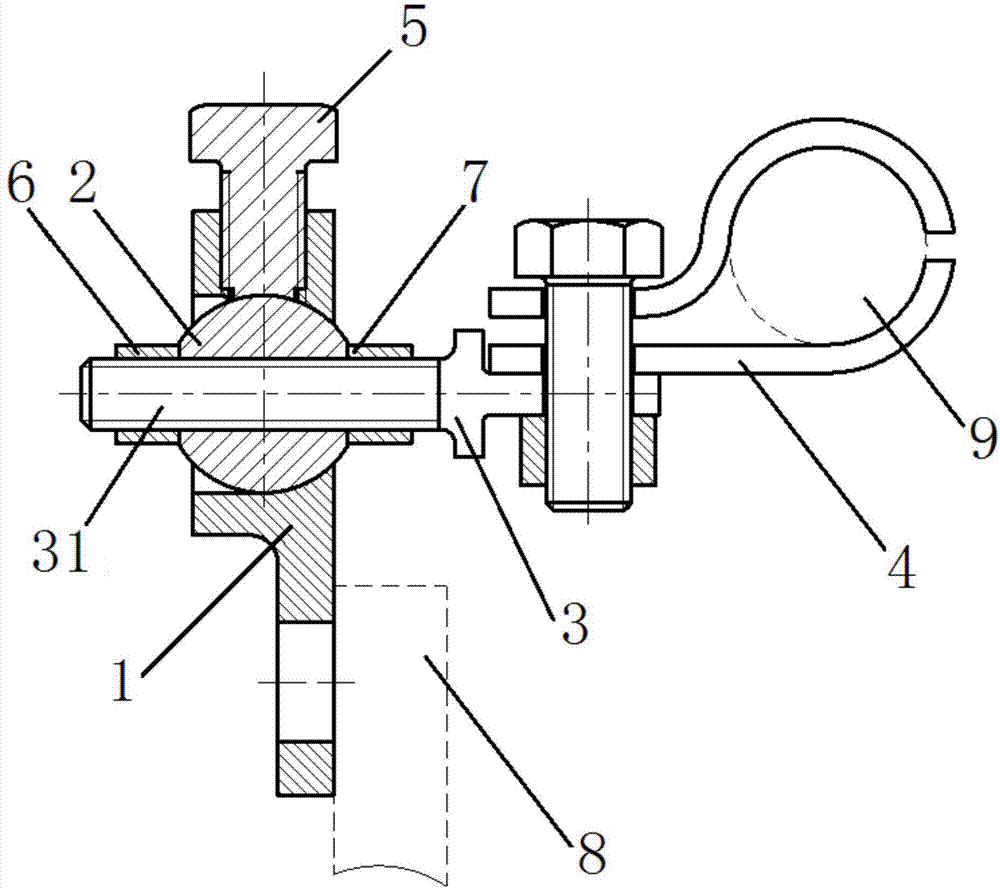

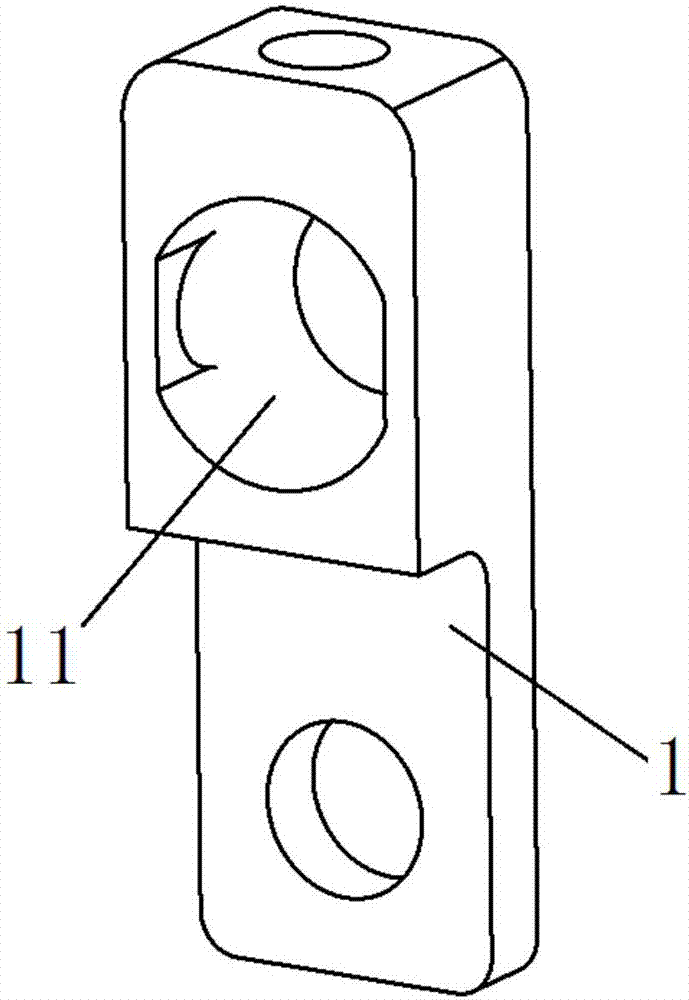

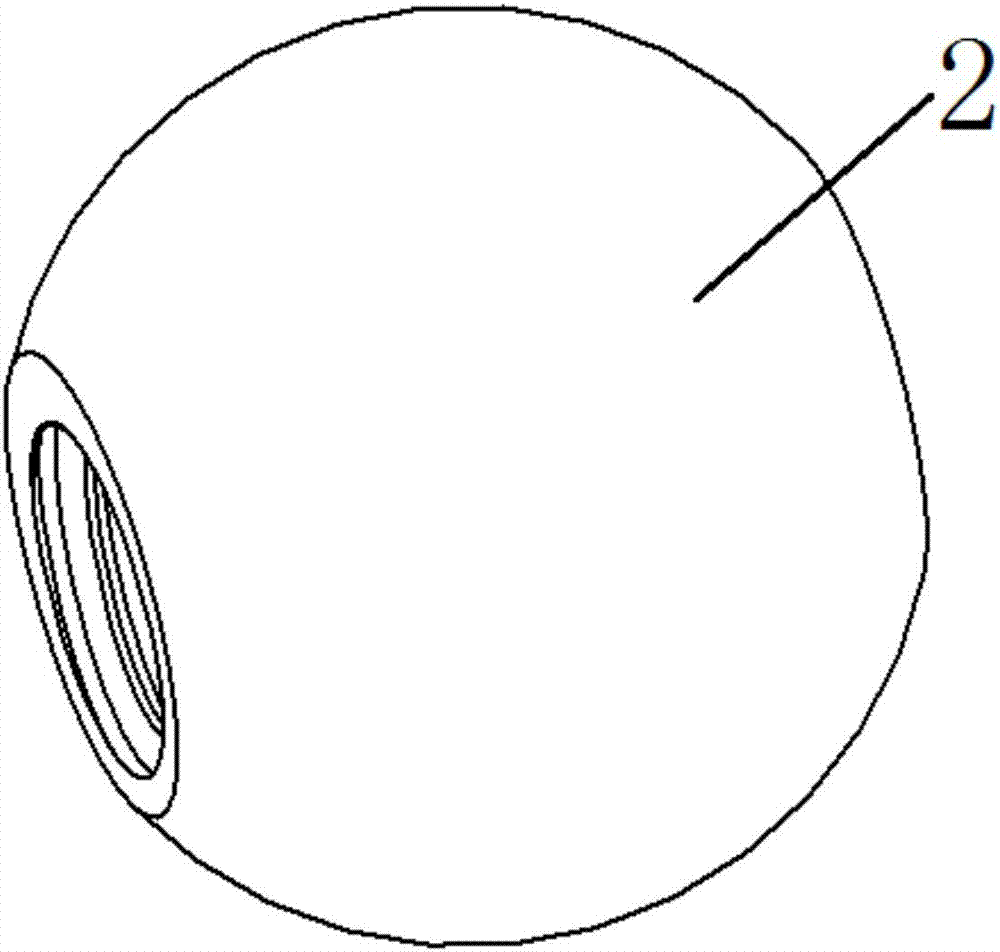

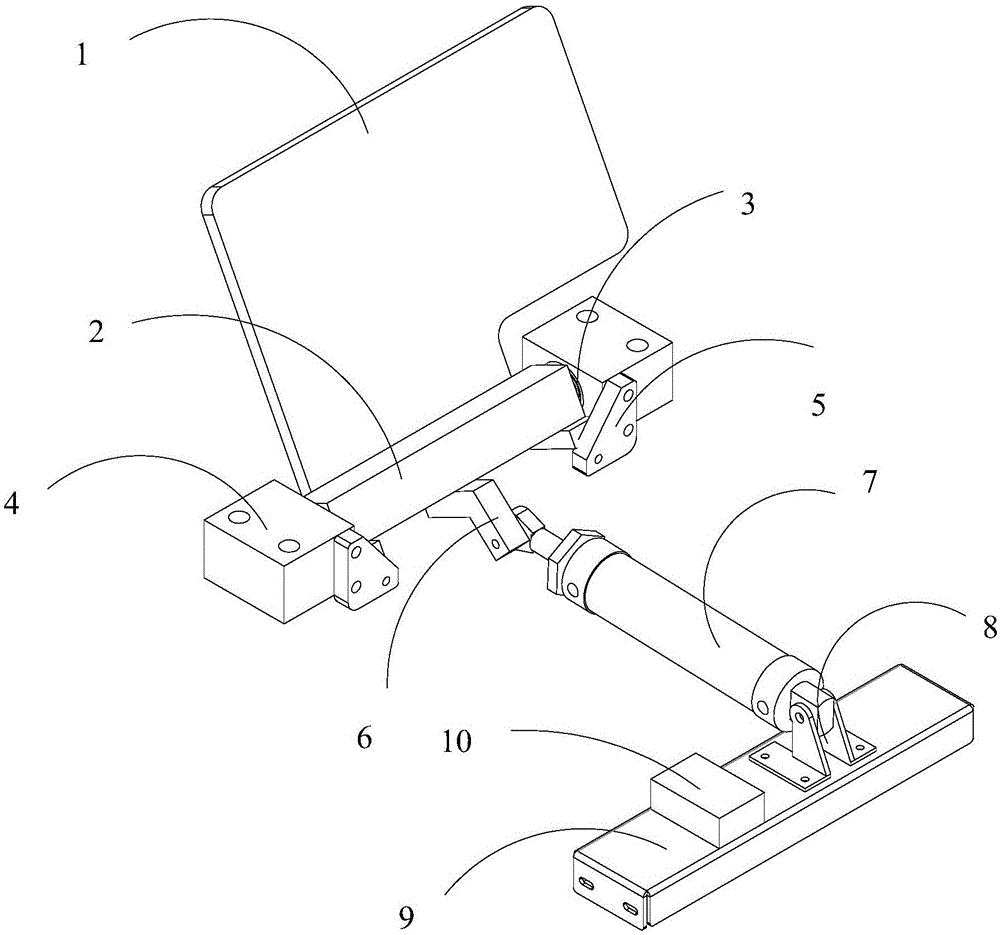

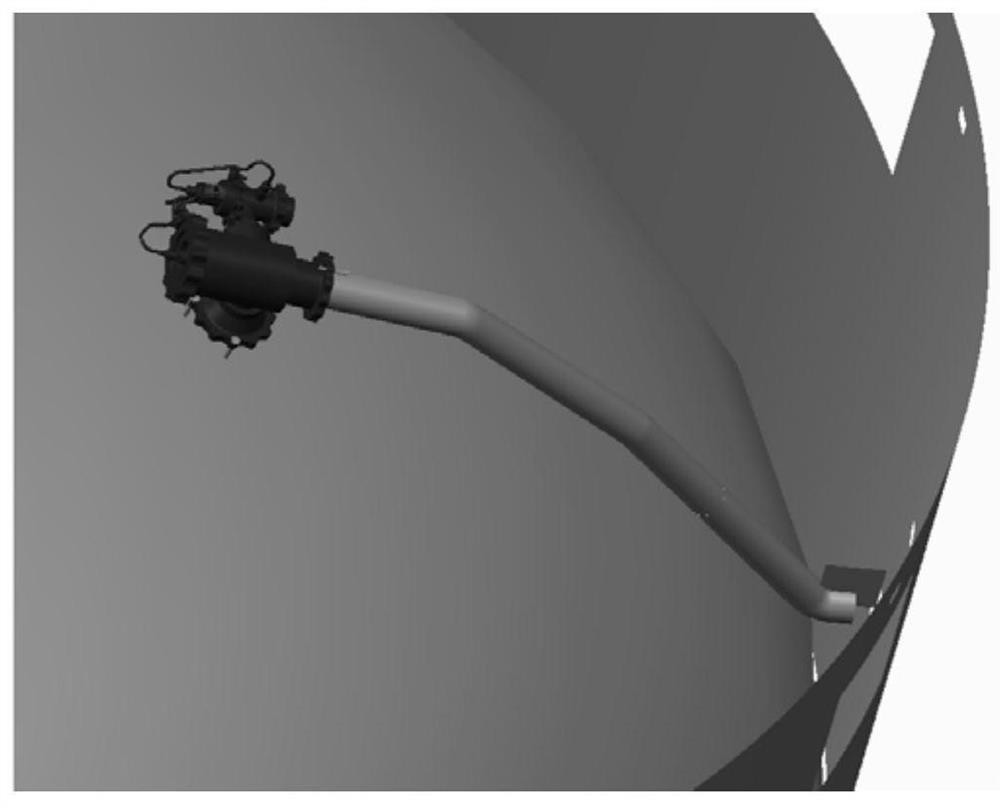

Fixing and adjusting device for engine pipeline

The invention relates to the technical field of pipeline fixation, in particular to a fixing and adjusting device for an engine pipeline. The fixing and adjusting device for engine pipeline comprises a bracket, a clamp, a sphere, a supporting rod and an adjusting and fixing component The bracket is fixed with a casing, and a spherical hole penetrating through the bracket is formed on the bracket; the sphere is spherical and mounted in the spherical hole; surface of the sphere is matched with the wall of the spherical hole; threaded holes penetrating through the sphere are formed on the sphere. Axis of each threaded hole passes through the centre of the sphere, one end of the supporting rod is a screw, the other end is the head of the supporting rod, the clamp is sleeved with the pipeline, and two joints of the clamp are fixed on the head of the supporting rob by a fastener. The screw penetrates through the sphere and is fixed with the sphere through the threaded holes, a first nut and a second nut are mounted on the screw, wherein the first nut and the second nut are correspondingly arranged at both sides of the sphere to press the sphere. The adjusting and fixing components are detachably arranged on the bracket, and the adjusting and fixing components fix the sphere in the bracket and prevent the sphere from rotating.

Owner:AECC SHENYANG ENGINE RES INST

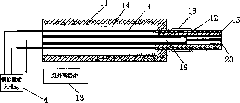

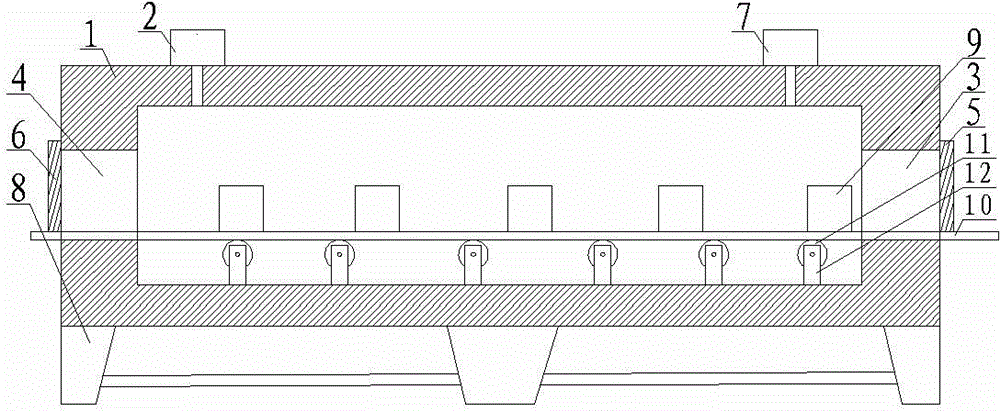

Device for conveniently heating aluminum alloy blank materials

InactiveCN104131153AReduce environmental differencesReduce crackingCharge supportsFurnace typesEngineeringAir blower

The invention discloses a device for conveniently heating aluminum alloy blank materials. The device comprises a furnace body, an air blower, an exhaust fan, a supporting plate and a weight-bearing mechanism; the left side and the right side of the furnace body are respectively provided with openings forming a discharging port and a feeding port; the air blower and the exhaust fan are both communicated with the interior of the furnace body; communication channels of the air blower and the exhaust fan with the furnace body are respectively positioned at the top of the left end and the right end of the furnace body. The supporting plate passes through the furnace body, and the left end and the right end of the supporting plate are respectively arranged at the feeding port and the discharging port of the furnace body; the weight-bearing mechanism comprises a plurality of supporting rollers arranged side by side in the furnace body and used for supporting the supporting plate. The device has the advantages of simple integral structure, convenient implementation and low cost; when in application, the air blower is adopted to add hot air into the furnace body for heating the interior of the furnace body, and the exhaust fan is adopted for exhausting air, so that the hot air in the furnace body is convenient to circulate, the heating difference of the aluminum alloy blank materials heated by the furnace body is reduced, and thus the cracking and scrapping probability of the blank materials can be reduced.

Owner:成都派莱克科技有限公司

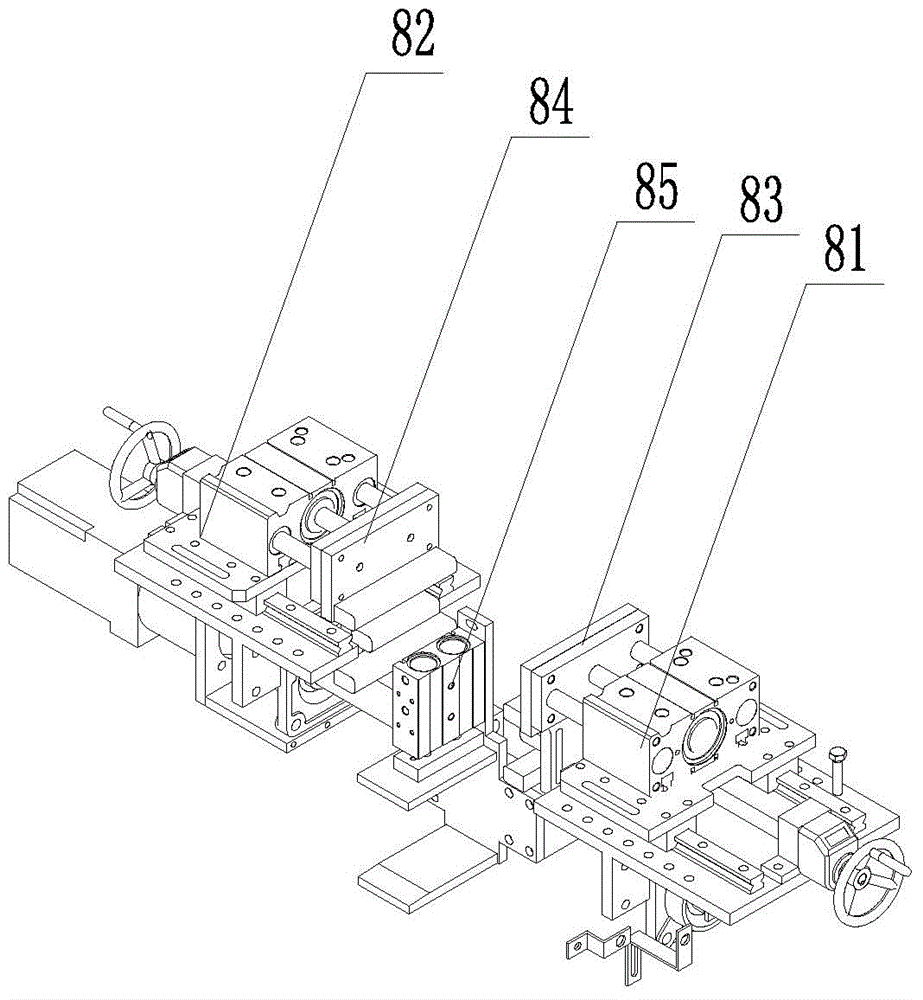

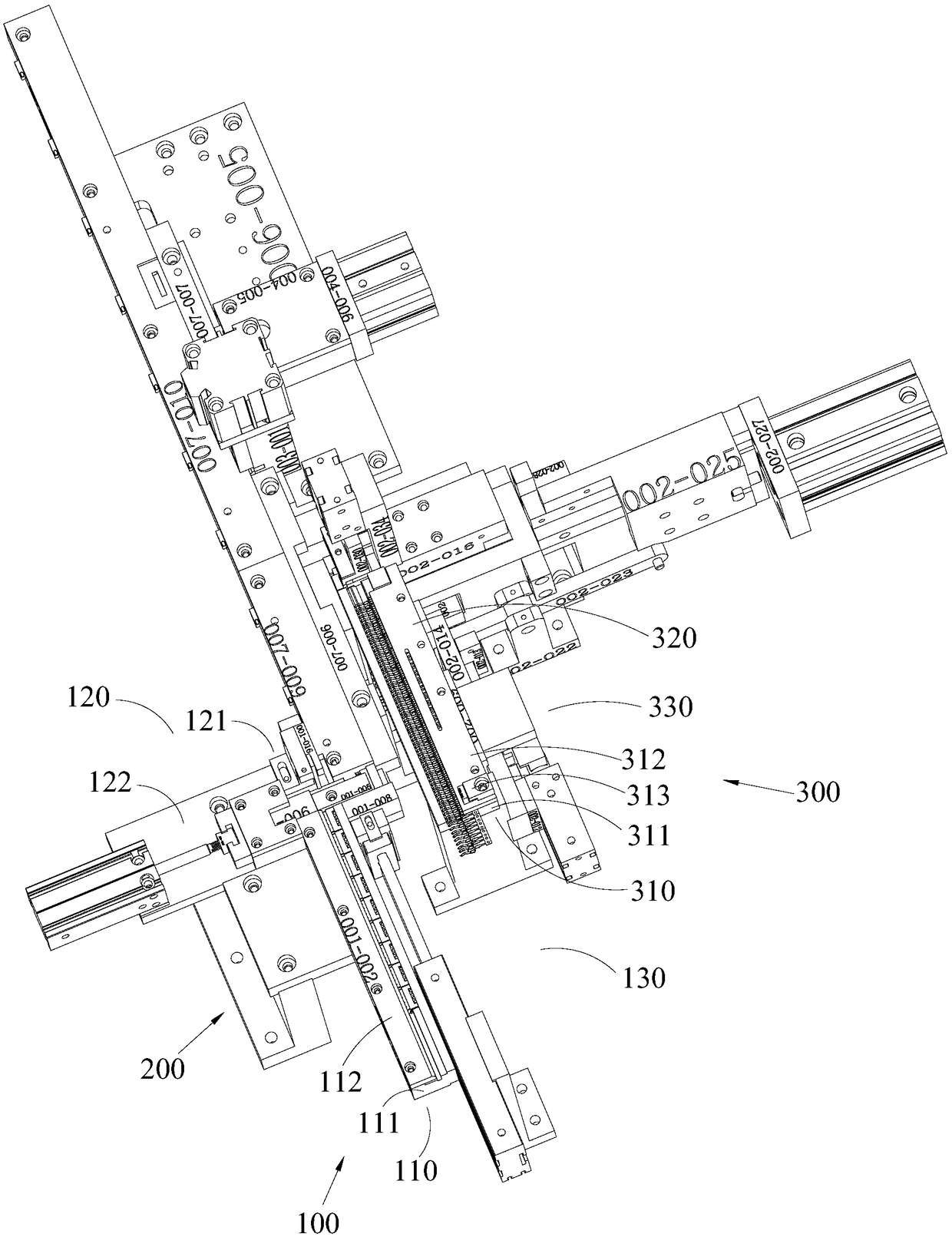

USB connector metal piece assembling mechanism and assembling device

InactiveCN109103728AQuality improvementReduce the chance of scrappingContact member assembly/disassemblyMetal sheetUSB

The invention discloses a USB connector metal sheet assembling mechanism and an assembling device, the mechanism comprising a mounting bracket, a lifting device and a plug-in assembling device, wherein the lifting device and the plug-in assembling device are respectively arranged on the mounting bracket; the plug-in assembling device comprises a horizontal drive assembly, an assembling assembly and a vertical drive assembly. The lifting device comprises a lifting assembly, a lever assembly and a lifting support block, and the lever assembly comprises a first lifting block, a second lifting block and a lever. The invention can accurately position the metal sheet and the protective shell, can ensure that the metal sheet is aligned with the plug-in interface of the shell, can also ensure thatthe metal sheet is inserted into the position, avoids the problem of loose data cable, improves the quality of the USB connector, and reduces the probability of the USB connector being scrapped; theinvention can avoid the problem of poor connection of the USB data cable, and improves the stability and reliability of the USB data cable connection.

Owner:HUIZHOU DEHONG TECH CO LTD

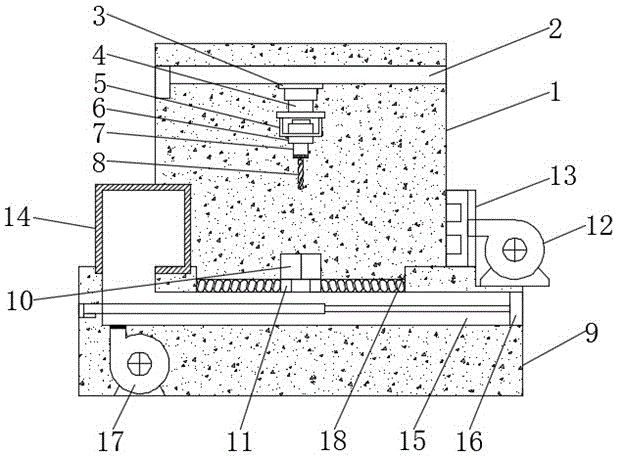

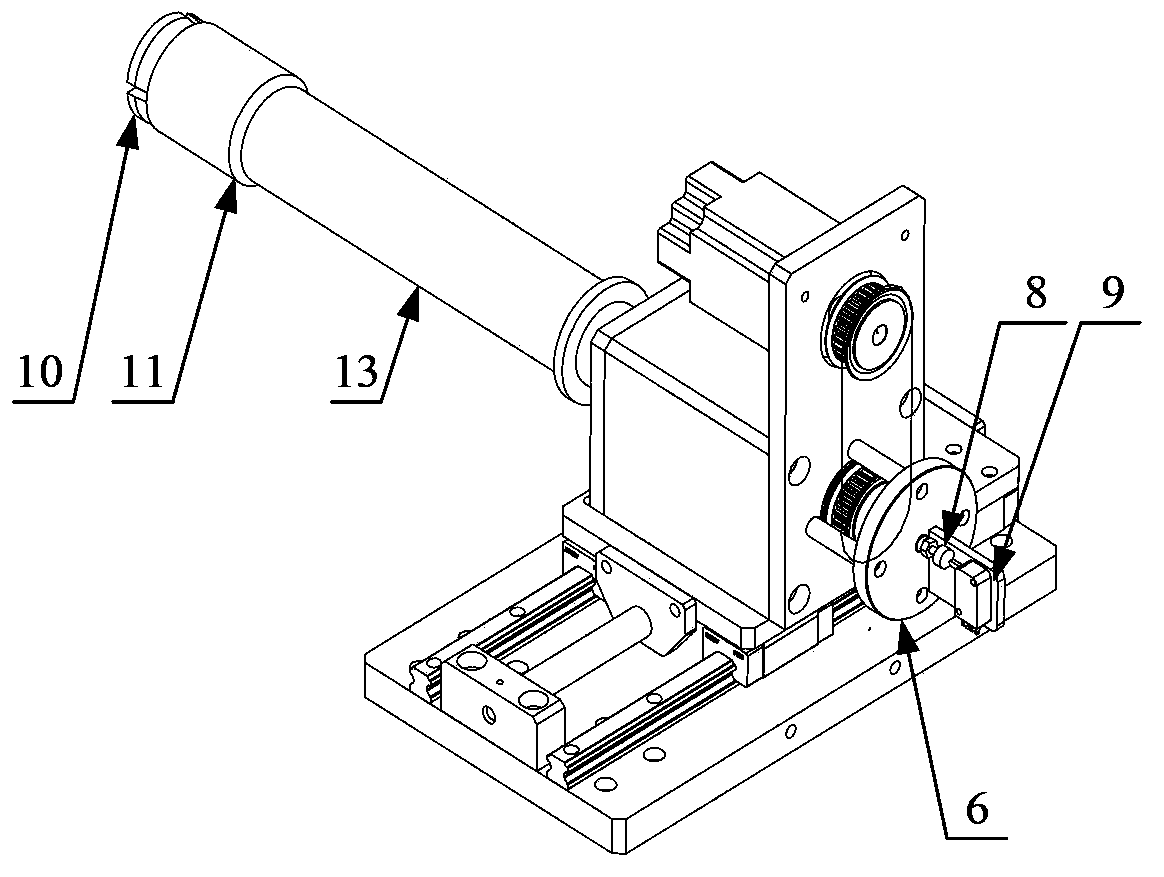

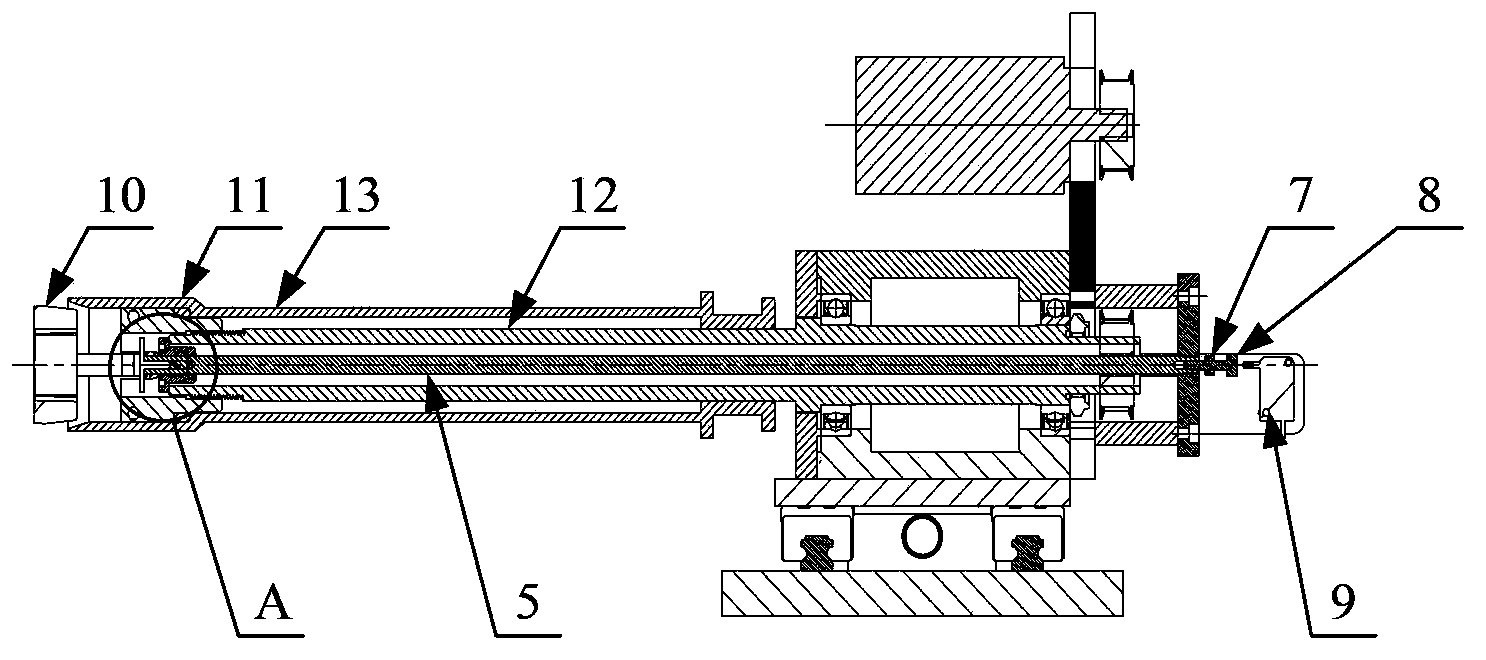

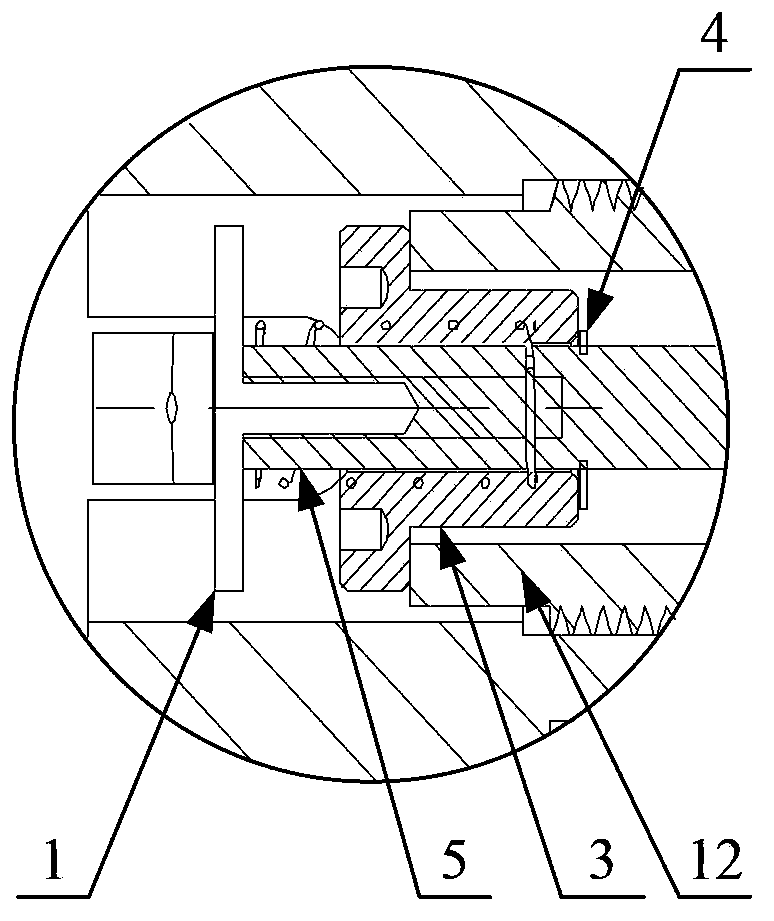

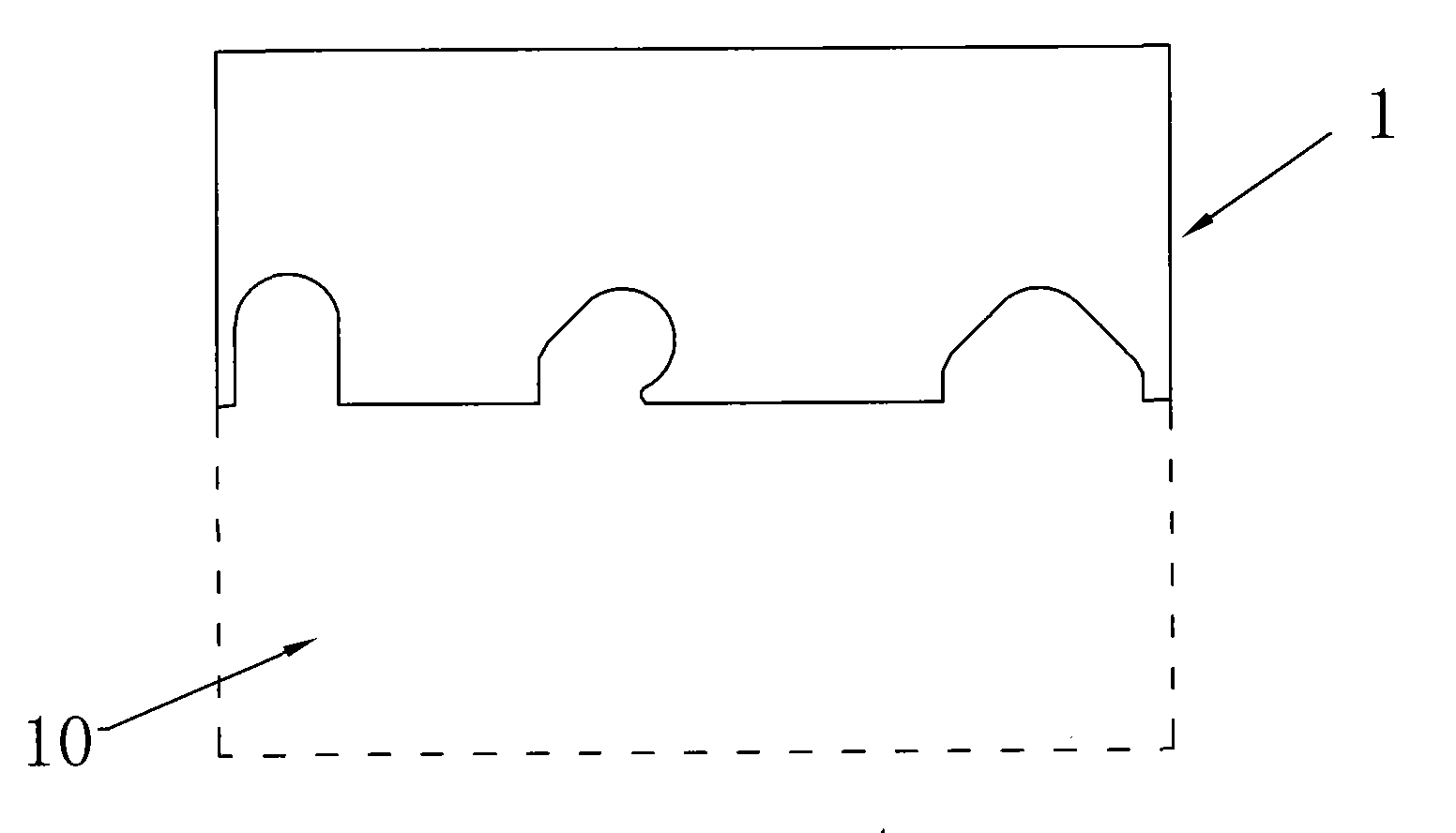

Equipment for drilling synchronous pulleys

InactiveCN103433523ASimple structureEasy to implementLarge fixed membersPositioning apparatusControl engineeringElectric machinery

The invention discloses a set of equipment for drilling synchronous pulleys. The equipment for drilling synchronous pulleys comprises a base (1), a stand column (2), a locating base (3), a drill bit (4), a workbench (6) and a driving motor (5) for driving the drill bit (4) to rotate. The stand column (2) is arranged on the base (1), both the locating base (3) and the workbench (6) are connected to the stand column (2), and the workbench (6) is located below the locating base (3). A drill bit lifting mechanism for controlling the drill bit (4) to lift or descend is arranged on the locating base (3), the upper end of the drill bit (4) is connected with the drill bit lifting mechanism, the drill bit (4) is located between the locating base (3) and the workbench (6), and a synchronous pulley locating hole is formed in the portion, right facing toward the drill bit (4), of the workbench (6). Due to the structure, the equipment for drilling synchronous pulleys is simple in overall structure, convenient to obtain and low in cost. When the equipment for drilling synchronous pulleys is used, the synchronous pulleys can be drilled after being located, thus, the rate of finished products of the synchronous pulleys can be improved, and cost is saved.

Owner:CHENGDU SILVERTECH TIMING PULLEYS MFG

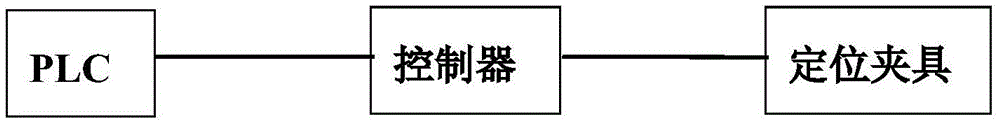

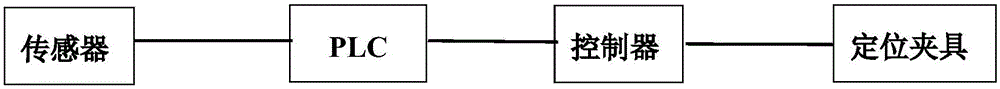

Positioning fixture and operation process of alarming system of positioning fixture

InactiveCN105127783AEasy to operateReduce the chance of workpiece scrappingWork clamping meansPositioning apparatusEngineeringBuilding construction

The invention provides a positioning fixture and an operation process of an alarming system of the positioning fixture. The positioning fixture comprises a positioning plate, a cylinder and a cylinder fixing plate. The cylinder fixing plate is connected with the cylinder which drives the positioning plate to rotate. A sensor is mounted on the positioning fixture and electrically connected with a controller. Components in the positioning fixture are controlled by the controller which receives orders output by a PLC. The positioning fixture further comprises the alarming system. The alarming system starts alarming and stops system operation when control over the positioning plate fails. The positioning fixture is simple in structure, the process is precise, safety of construction is guaranteed, and implementation is convenient.

Owner:广州德力数控设备有限公司

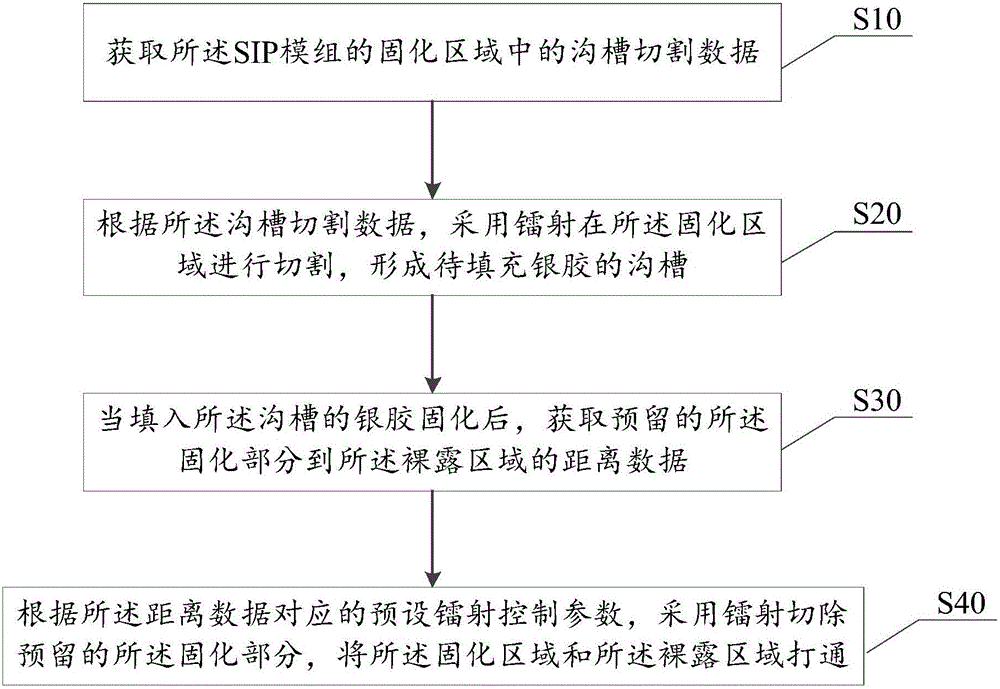

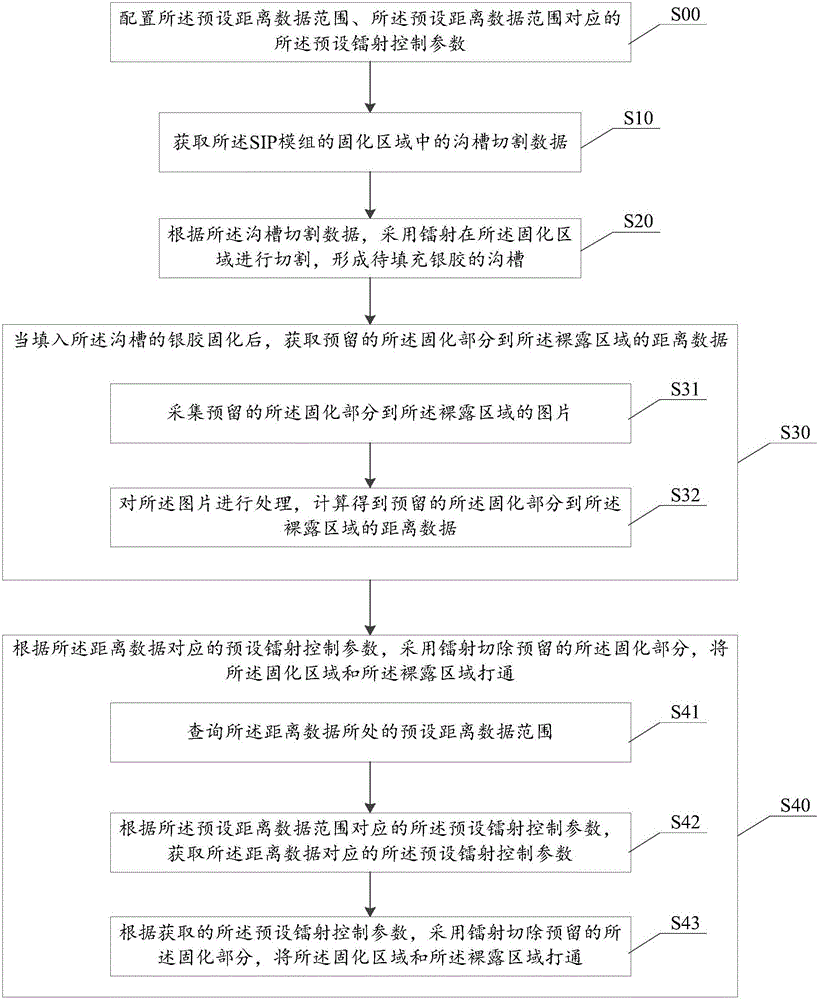

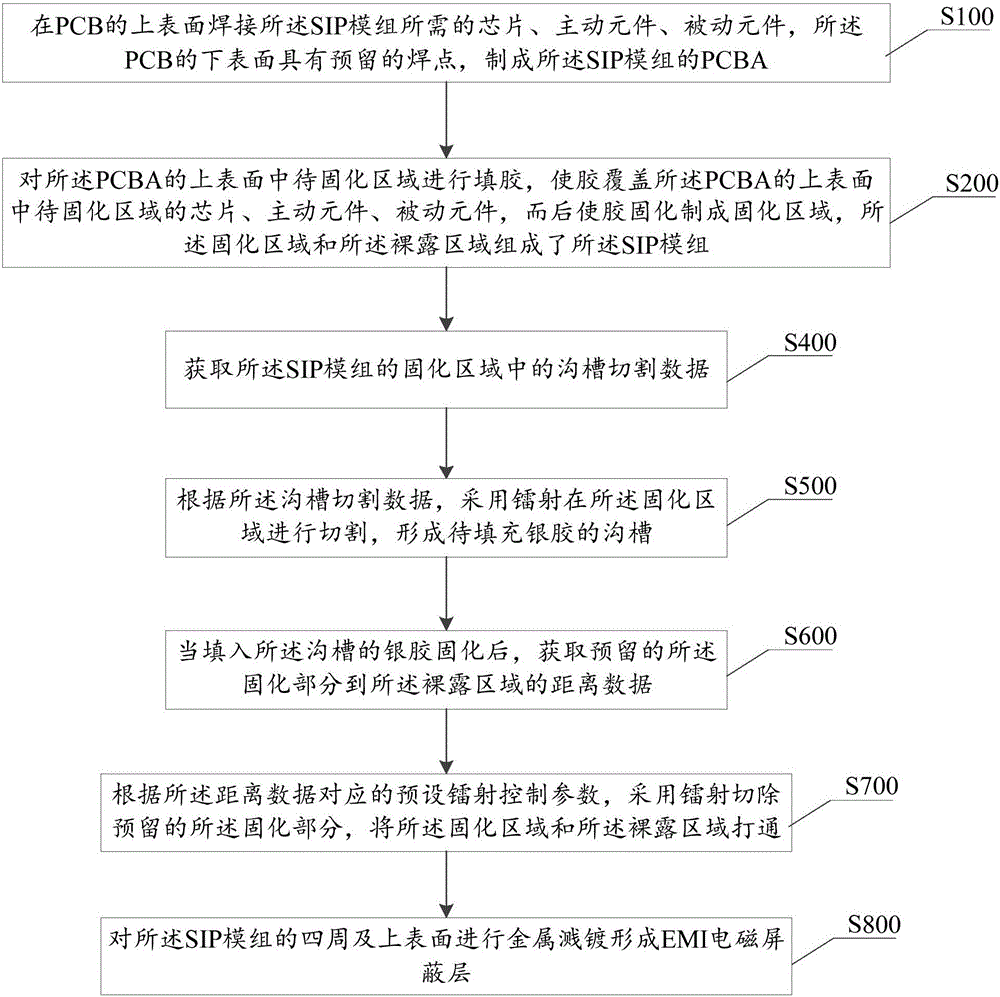

SIP module manufacturing method and elargol groove cutting method and system

The invention discloses an SIP module manufacturing method and an elargol groove cutting method and system and relates to the field of semiconductors. The elargol groove cutting method comprises the step that S10, groove cutting data in a curing region of an SIP module are obtained and comprise a groove cutting path and a groove cutting position; S20, cutting is conducted in the curing region through laser according to the groove cutting data, a groove for being filled with elargol is formed, and a preserved curing part exists in the position between the groove and the exposed region of the SIP module; S30, after the elargol charged into the groove is cured, data of the distance between the preserved curing part and the exposed region are obtained; and S40, according to preset laser control parameters corresponding to the distance data, the preserved curing part is cut through laser, and the curing region and the exposed region are broken through. After the elargol is cured, the corresponding preset laser control parameters are automatically obtained, the preserved curing part is cut, and the product scrapped probability is reduced.

Owner:HUANWEI ELECTRONICS SHANGHAI CO LTD

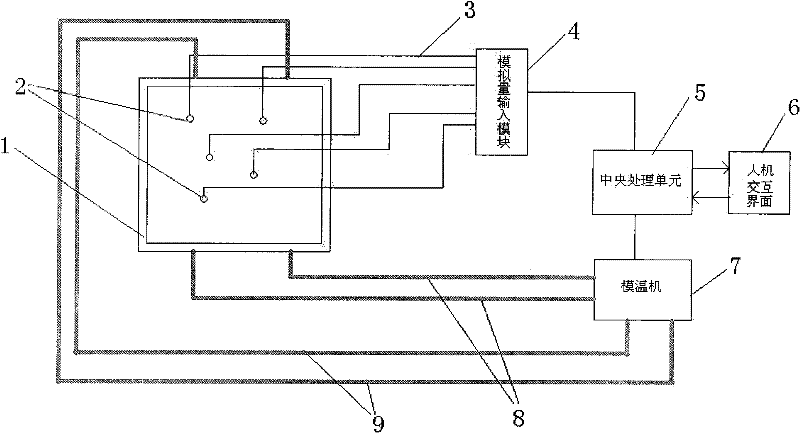

Die-casting mold multi-point precise temperature control system and method

The invention relates to a die-casting mold multi-point precise temperature control system and a method. The invention is characterized in that the system comprises a plurality of temperature detectors which are embedded in a mold, each temperature detector is repetitively connected with an analog quantity input module through a compensating lead wire, the analog quantity input modules are connected with a central processing unit, the central processing unit is respectively connected with a human-machine interaction interface and a mold temperature controller, a plurality of oil inlet pipes and a plurality of oil outlet pipes are arranged on the mold temperature controller, and the oil inlet pipes and the oil outlet pipes are respectively communicated with a plurality of flow passages arranged on the mold for forming a cyclic circulation pipeline. The invention has ingenious structural design, can improve the repeatability of the mold temperature control in the die-casting process, can improve the production efficiency, and can be widely used in the temperature control process of the die casting production.

Owner:TSINGHUA UNIV

Pipeline digital reconstruction method based on accurate measurement

PendingCN112395708AImprove pass rateLow experience requirementGeometric CADSpecial data processing applicationsProcess engineeringDigitization

The invention relates to a pipeline digital reconstruction method based on accurate measurement, in particular to a design method for achieving pipeline digital reconstruction based on accurate measurement of butt joints and boundaries. The method provided by the invention is suitable for pipeline products with different specifications, and has strong adaptability to complex and diverse pipeline production boundaries. Compared with a traditional manual aluminum wire sampling method, the pipeline digital reconstruction design method has the advantages that the product precision can be effectively improved, the product production period is shortened, and the requirement for experience of operators is relatively low. Meanwhile, the percent of pass of pipeline products produced through the pipeline digital reconstruction design method is high, the probability that the pipelines are scrapped due to too large sampling deviation is reduced, and the production cost can be reduced.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG

Automatic scratching control method for micropowder polished tile blank

ActiveCN104690813ATimely discovery of color abnormalitiesImprove detection efficiencyCeramic shaping apparatusProduction lineBrick

The invention relates to an automatic scratching control method for a micropowder polished tile blank. The method adopts a controller and segmented program control, and includes timed / manually-started automatic sending-out scratching control as follows: according to a tile feeding command, a glaze line lifting platform separates a tile blank from a production line and conveys the tile blank to a conveying platform; according to a conveying command, the conveying platform forwardly conveys the tile blank to an overturning mechanism; according to an overturning command, the overturning mechanism overturns the tile blank for the first time; according to a conveying command, the conveying platform forwardly conveys the tile blank to a scratching mechanism; according to a scratching command, the scratching mechanism drives an inner cutter head to scratch the tile blank back and forth in a rotating manner; according to a conveying command, the conveying platform sends the tile blank out of the scratching mechanism; according to an observing command, a drying mechanism lifts up an upper lampshade and turns on a lampshade for illuminating / drying; the automatic scratching control method further comprises manually-started sending-back control. According to the segmented program control method, through the segmented program control, manpower is reduced, operation mistakes and errors are avoided at the same time, and the inspecting efficiency and the inspecting result of blank spot inspection in ceramic tile production are greatly improved.

Owner:JIANGXI HEMEI CERAMICS

Pipe bending machine and chuck device thereof

ActiveCN104138947AAvoid bending position deviationImprove bending accuracyControl signalSignal processing

The invention discloses a chuck device. The chuck device comprises a chuck main body, and further comprises a transmission device sleeved in the chuck main body, wherein one end of the transmission device is a contact end contacted with a pipe to be bent extending in the chuck main body; and a signal processing mechanism is used for receiving a position signal of the other end of the transmission device and converting the position signal to a control signal for controlling the starting or shutting down of a pipe bending machine. The chuck device, provided by the invention, effectively prevents the condition of bent position deviation caused by placement of the pipe to be bent not in place corresponding to the chuck main body, so that the bent preciseness of the pipe to be bent is improved, the waste probability is reduced, and the production pass percent is increased. The invention further provides a pipe bending machine; the pipe bending machine comprises a chuck device; and the chuck device is any one of the chuck devices.

Owner:GREE ELECTRIC APPLIANCES INC

Windowing structure for pressing dry film before plating of goldfinger of module board

InactiveCN102438403AReduce the chance of scrappingConsistent appearancePrinted element electric connection formationResistElectrical and Electronics engineering

The invention discloses a windowing structure for pressing a dry film before the plating of a goldfinger of a module board, wherein a pad, a connecting circuit, through hole rings and a to-be-plated goldfinger are formed on the metal layer on the surface of the base board of the module board, the dry film is pressed and covered on the surface of the module board, the position of the dry film, which is positioned at the to-be-plated goldfinger, is windowed so as to expose the to-be-plated goldfinger, on the surface of the module board, except the through hole rings of a goldfinger, the connection circuit between the through holes of the goldfinger and the to-be-plated goldfinger and the position at the outer side of the surface the to-be-plated goldfinger, other rest positions are covered with solder resist ink, the windowing part of the dry film is extended to the through hole rings for exposing the goldfinger and the connection circuit between the through hole rings of the goldefinger and the to-be-plated goldfinger, so that the to-be-plated goldfinger, the through hole rings of the goldfinger as well as the connection circuit between the through hole rings of the goldfinger and the to-be-plated goldfinger are respectively plated with a golden layer, further, the appearance of the module board after the manufacture of the goldfinger is consistent, and the reject rate is greatly reduced.

Owner:竞陆电子(昆山)有限公司

Anti-deformation cutting device of plastic cosmetic bottle

ActiveCN112248058AEffectively fixedThere will be no deformationHollow article cleaningDirt cleaningBiomedical engineeringComposite material

The invention discloses an anti-deformation cutting device for a plastic cosmetic bottle, and belongs to the technical field of cosmetic bottles. The anti-deformation cutting device comprises a bottomplate and side plates, the side plates are fixedly connected to the left side and the right side of the upper surface of the bottom plate correspondingly, adjusting mechanisms are arranged on the opposite surfaces of the two side plates, a fixing plate is fixedly arranged between the two adjusting mechanisms, a cutting mechanism is arranged on the fixing plate, and a supporting plate is arrangedon the rear side of the cutting mechanism and fixedly connected to the back face of the fixing plate. According to the cutting device, a clamping mechanism is arranged, the cosmetic bottle can be clamped when two clamping plates get close to each other, the cosmetic bottle can be inflated when an inflation mechanism works so that the interior of the cosmetic bottle can be in an expanded state, andtherefore when the cosmetic bottle is cut by a cutting wheel to be extruded, the pressure cannot greatly influence the internally expanded cosmetic bottle, so that the cosmetic bottle does not deformwhen cut, the rejection rate of the cosmetic bottle is greatly reduced, and the processing efficiency of the cosmetic bottle is further improved.

Owner:徐州鸿源玻璃科技有限公司

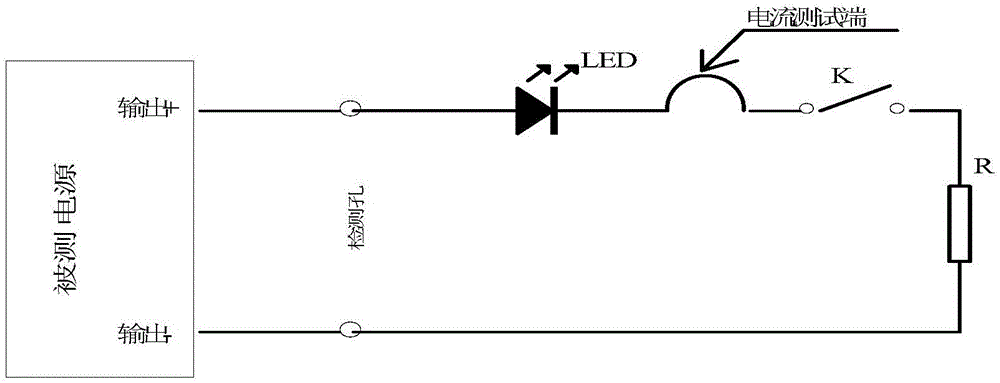

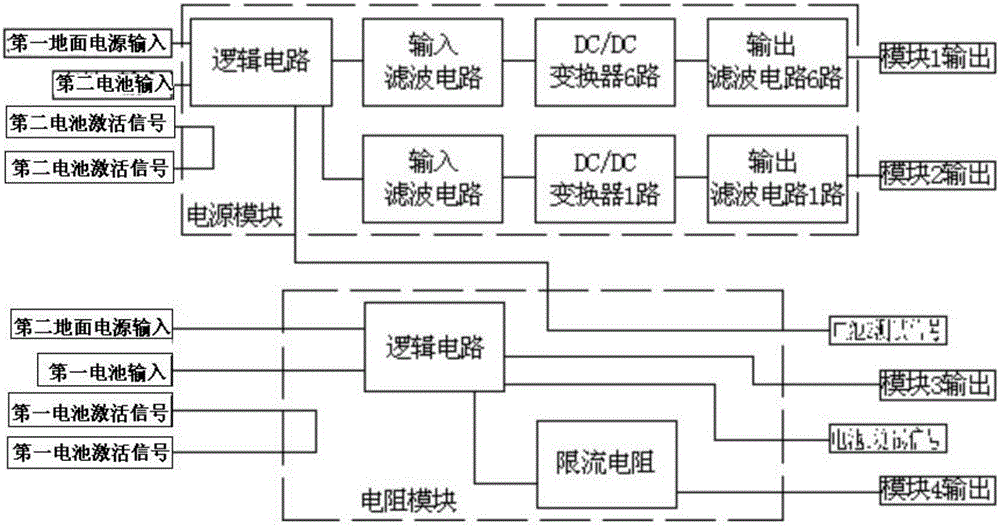

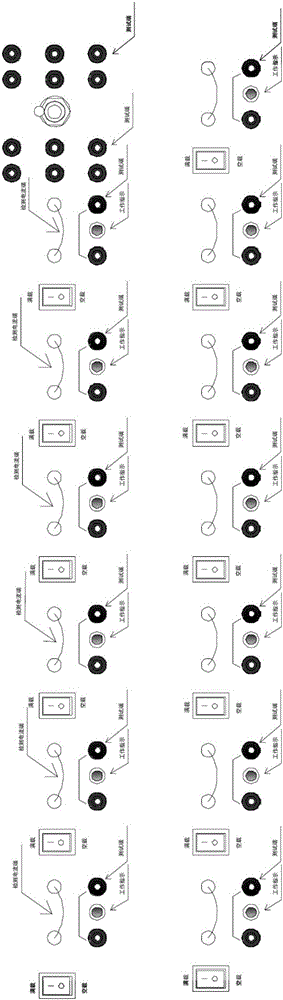

Precision test bench special for W-type secondary power supply converter

ActiveCN105717464AEasy to disassembleAccurate limitPower supply testingMeasurement instrument housingElectricityElectrical performance

The invention discloses a precision test bench special for a W-type secondary power supply converter. The test bench is manufactured based on parameter indexes required in design technical requirements. The electrical performance indexes of a secondary power supply tested by the test bench are in accord with the electrical parameter indexes mentioned in the secondary power supply design technical requirements.

Owner:AEROSPACE CHANGFENG CHAOYANG POWER SUPPLY

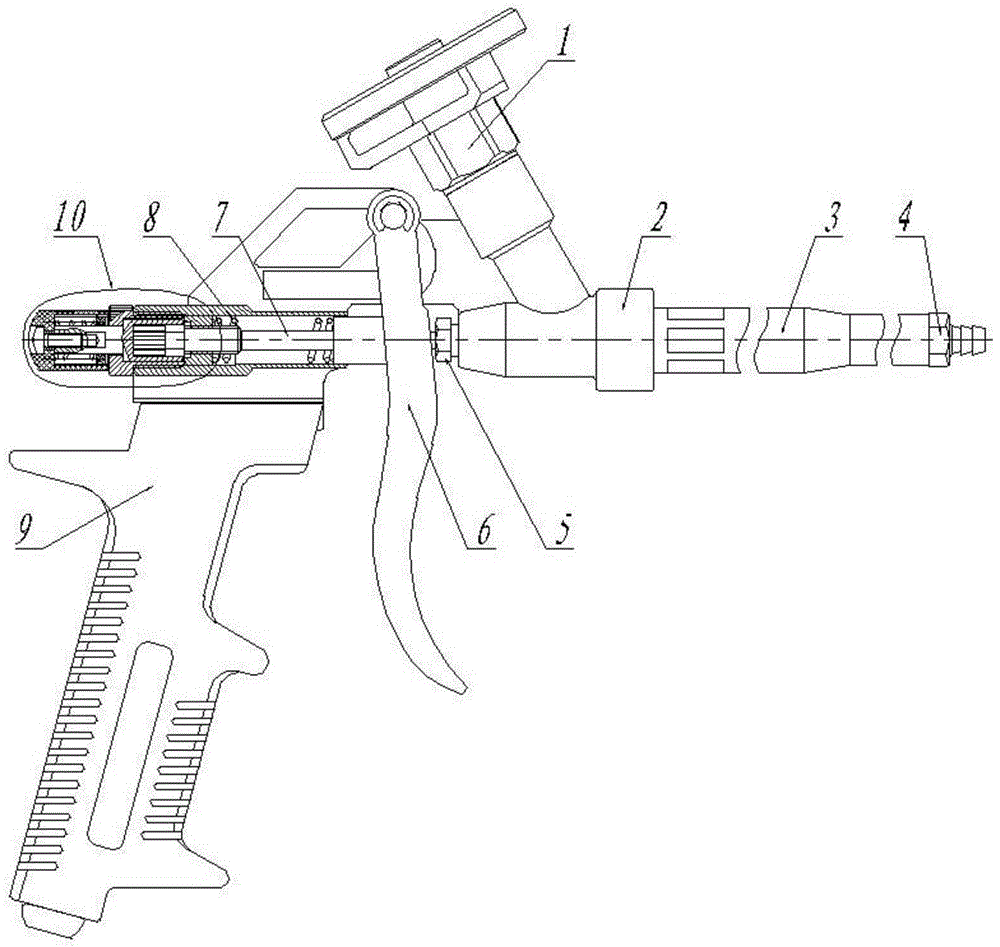

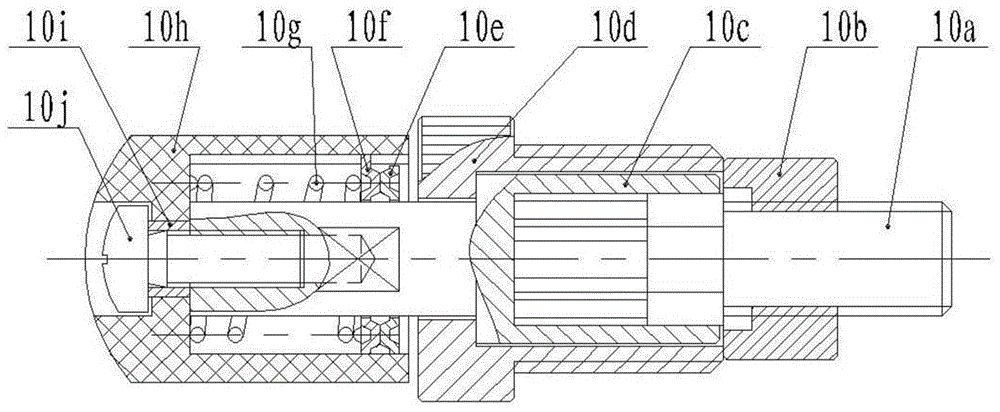

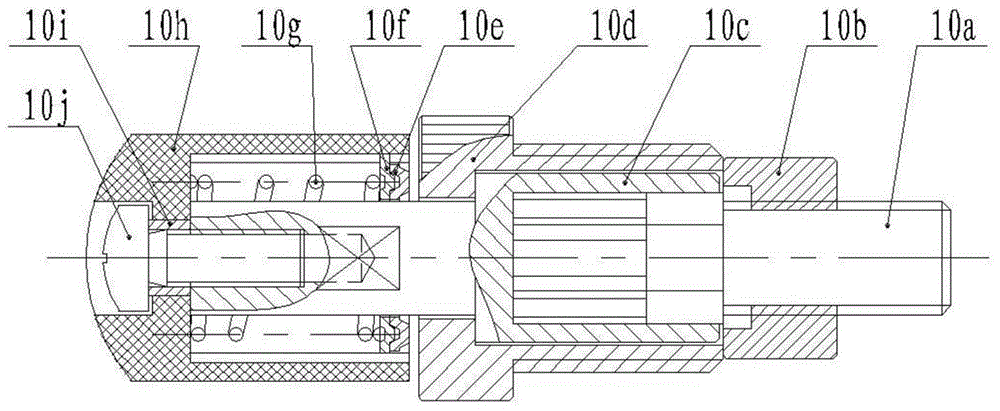

Foaming agent spray gun

ActiveCN103599863APrevent popupDoes not affect relative positionSingle-unit apparatusFoaming agentEngineering

The invention discloses a foaming agent spray gun which comprises a gun nozzle, a gun barrel, a gun body, an adapter and a handle. A trigger is arranged on the gun body; an aperture adjusting device is connected to the rear end of the gun barrel and comprises a connecting base, a movable screw rod, a nut, an adjusting rod and a compressed spring; the connecting base comprises an end cover and a hollow connecting part; the movable screw rod and the adjusting rod are arranged in the connecting base; the adjusting rod is composed of a front section and a rear section; a shaft shoulder is formed at the place where the front section and the rear section are connected; a through hole is formed in the end cover of the connecting base; the movable screw rod comprises a screw rod section and a sliding section; a containing cavity is arranged in the front section of the adjusting rod; a limiting mechanism is arranged between the front section and the sliding section of the movable screw rod; the compressed spring is located between a thimble slide block and the nut and tightly compresses the nut on the connecting base; the adjusting rod rotates to enable the movable screw rod to move forwards or backwards along the axial direction. The foaming agent spray gun has the advantages of good safety and labor-saving aperture adjustment.

Owner:ZHEJIANG VOLCANO MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com