Integrated machine for treating pole plate of lead-acid storage battery

A lead-acid battery and electrode plate treatment technology, which is applied in the field of all-in-one machines, can solve the problems of frequent equipment failures and high plate scrapping rates, and achieve the effects of reducing cylinder drive, reducing the probability of scrapping, and reducing lead dust and waste pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following is a further detailed description of the present invention in conjunction with the accompanying drawings:

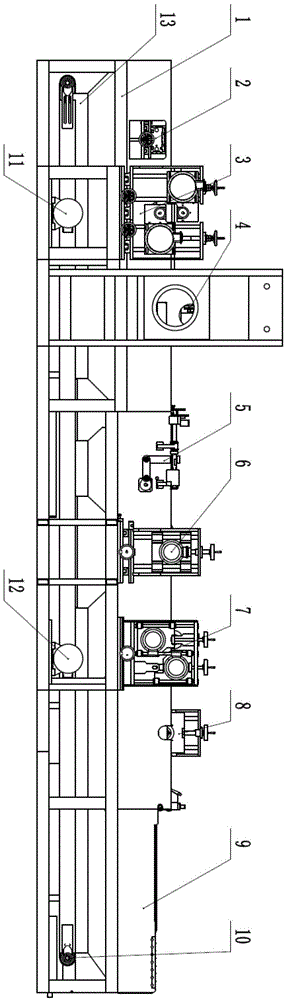

[0030] Such as figure 1 The integrated machine for processing large and dense plates is composed of a finishing mechanism 2, a brush side mechanism 3, a brush upper and lower mechanism 4, a suction sheet loading mechanism 5, an ear cutting mechanism 6, an ear brush mechanism 7, and a brush unilateral mechanism 8. The film receiving mechanism 9 is sequentially connected, fixedly connected in series on the frame 1, and the electrical control system is respectively connected with the finishing mechanism, the brush frame mechanism, the film suction mechanism, the ear cutting mechanism, the ear brush mechanism, the brush unilateral mechanism, and the pole plate delivery device.

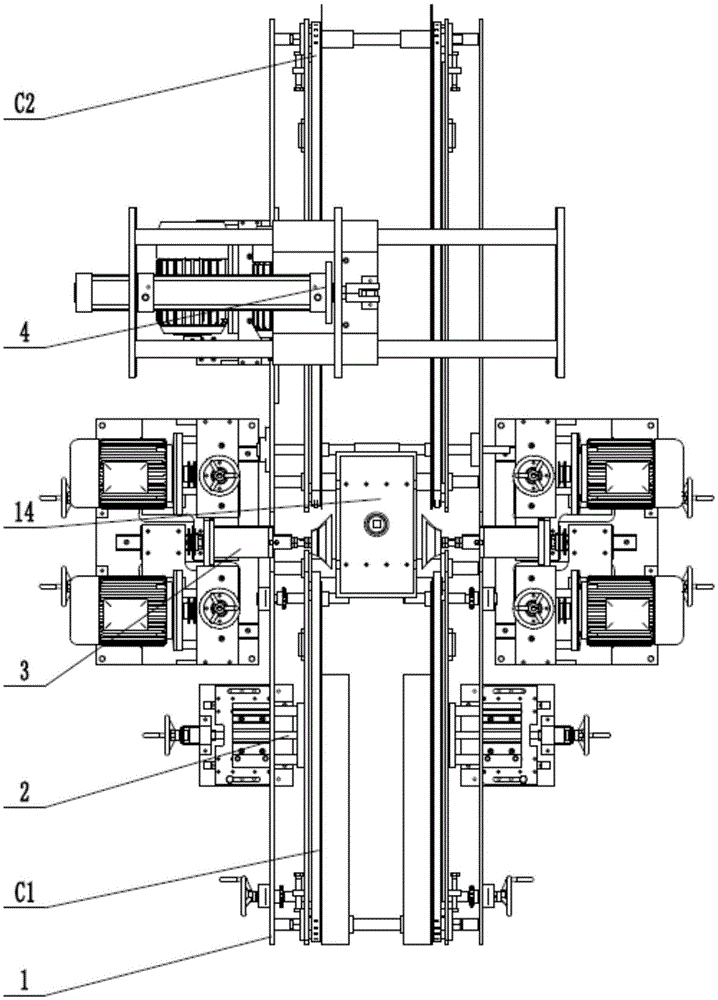

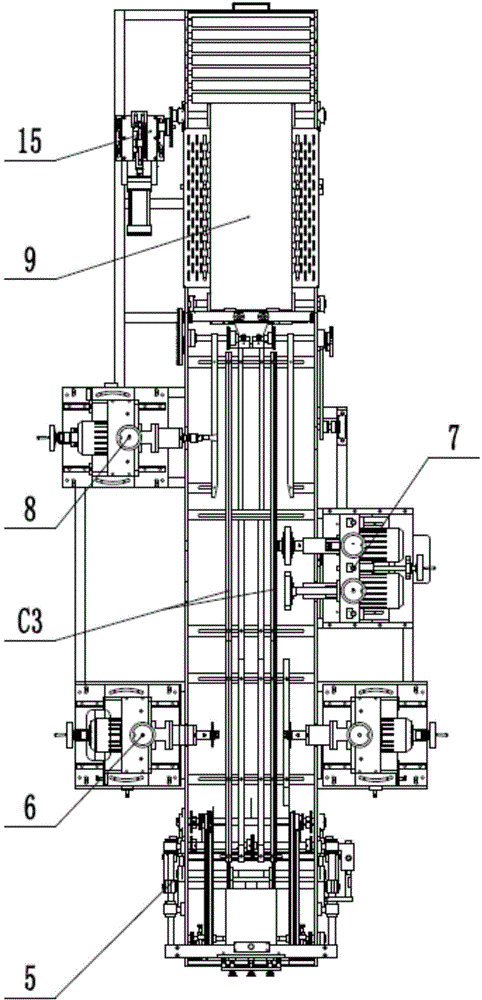

[0031] combine figure 1 , figure 2 , image 3 As shown, the plate conveying device includes four sections of plate conveying chains. The first conveyor chain section C1 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com