Windowing structure for pressing dry film before plating of goldfinger of module board

A technology of gold fingers and fingers, which is applied in the window structure field of pressing dry film before gold finger plating, can solve the problems of inconsistent appearance, scrapping, non-sticking of gold and other problems of module boards, and achieve the effect of reducing the probability of scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

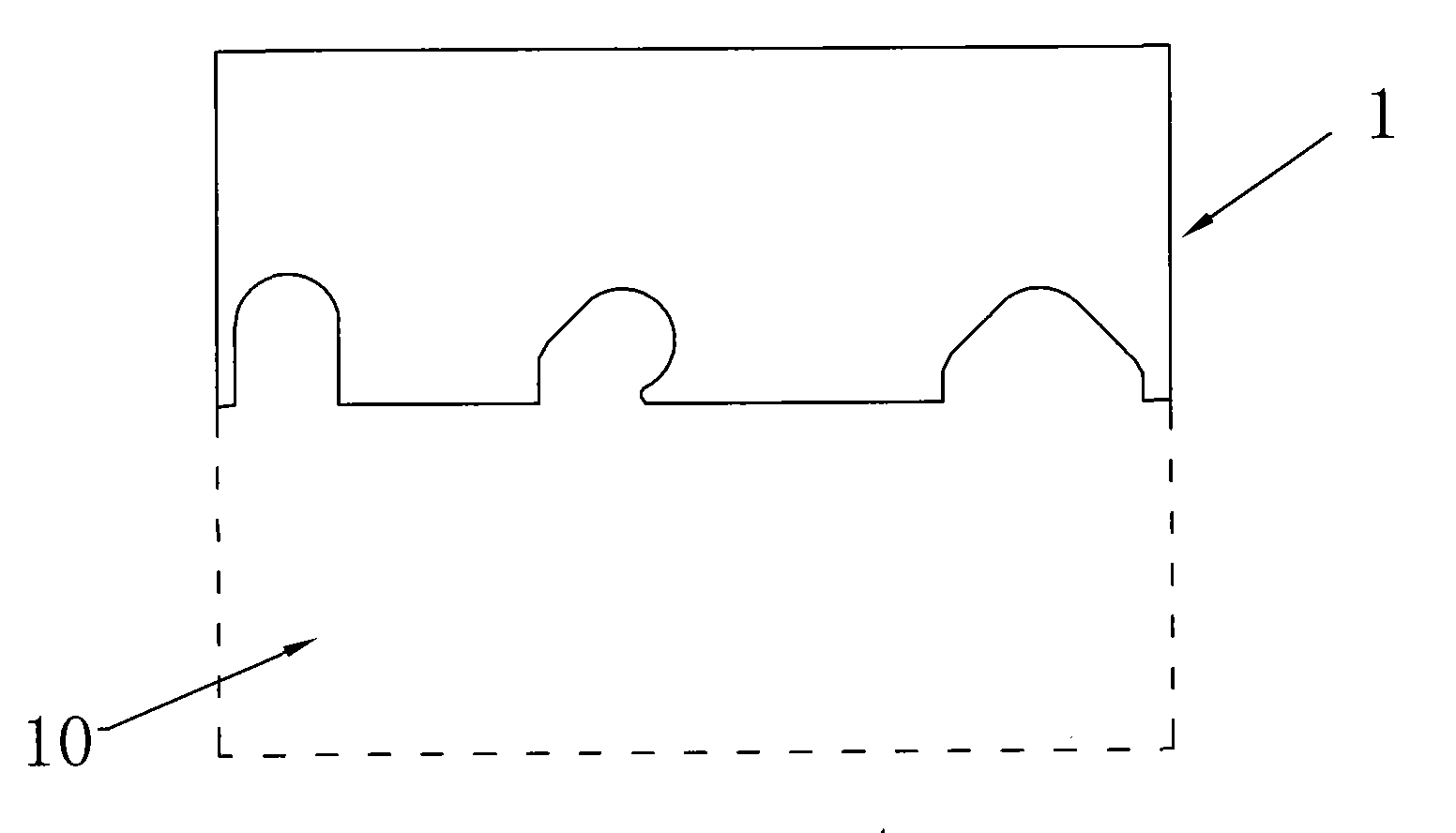

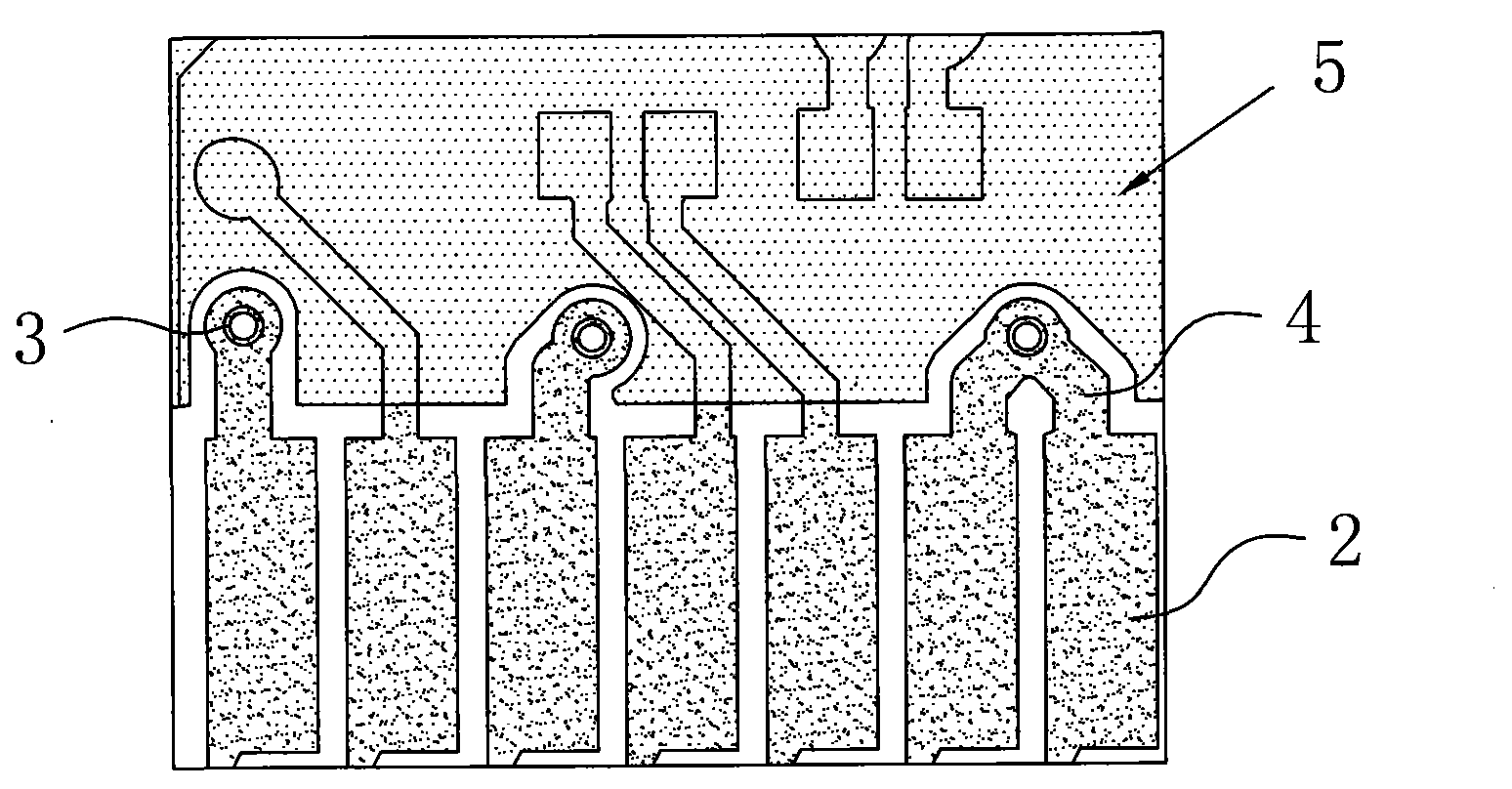

[0011] Embodiment: a window structure of a module board with a laminated dry film before gold finger plating, the metal layer on the substrate surface of the module board is formed with pads, connecting lines, via hole rings 3 and gold fingers 2 to be plated, the The dry film 1 is press-fitted and covered on the surface of the module board. The dry film opens a window at the position of the finger 2 to be gold-plated to expose the finger 2 to be gold-plated. The connection circuit 4 between the via hole ring 3 of the finger and the finger 2 to be gold-plated and the part outside the surface of the finger 2 to be gold-plated are all covered with solder resist ink 5; the part 10 of the dry film window is extended to expose the gold finger The via ring 3 of the gold finger and the connection line 4 between the via ring 3 of the gold finger and the finger 2 to be gold-plated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com