Foaming agent spray gun

A technology of foam agent and spray gun, which is applied in the direction of spraying devices and single handheld devices, etc. It can solve the problems of adjusting the screw to fly, the spray gun is scrapped, and the elastic force is unstable, so as to maintain the tightness of the contact and reduce the probability of scrapping. Guarantee the effect of safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

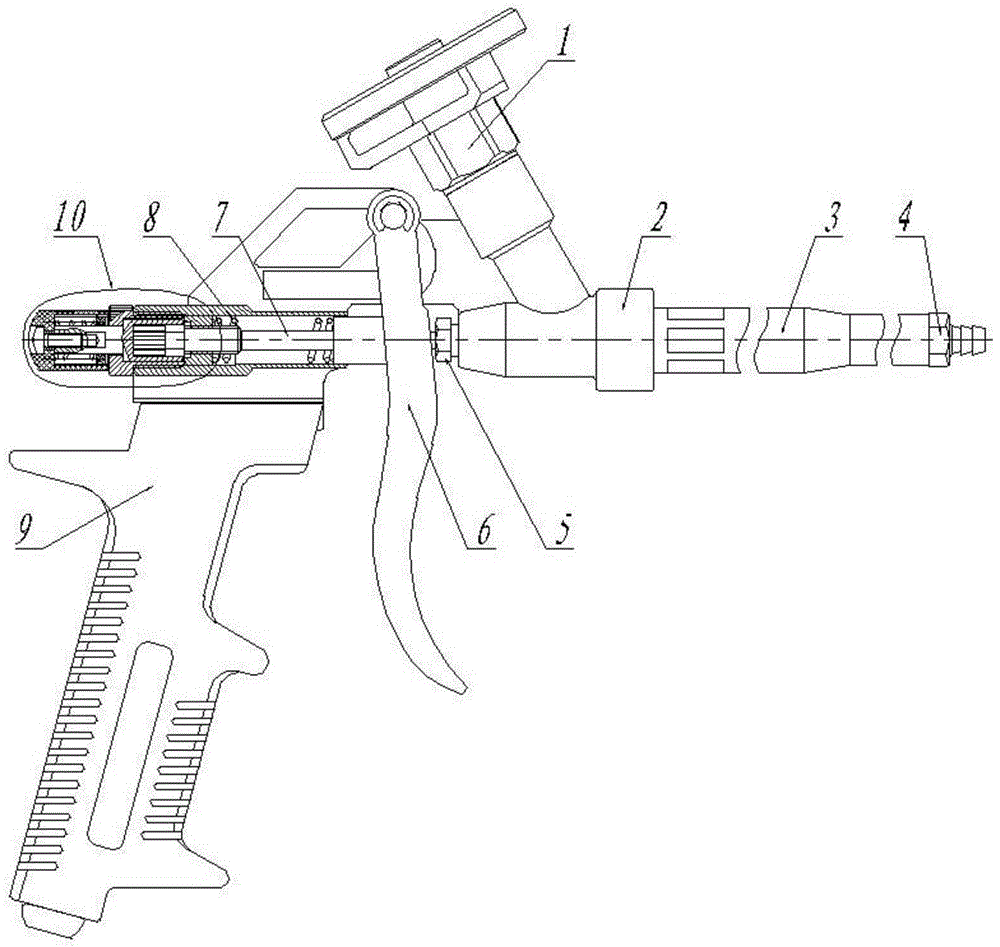

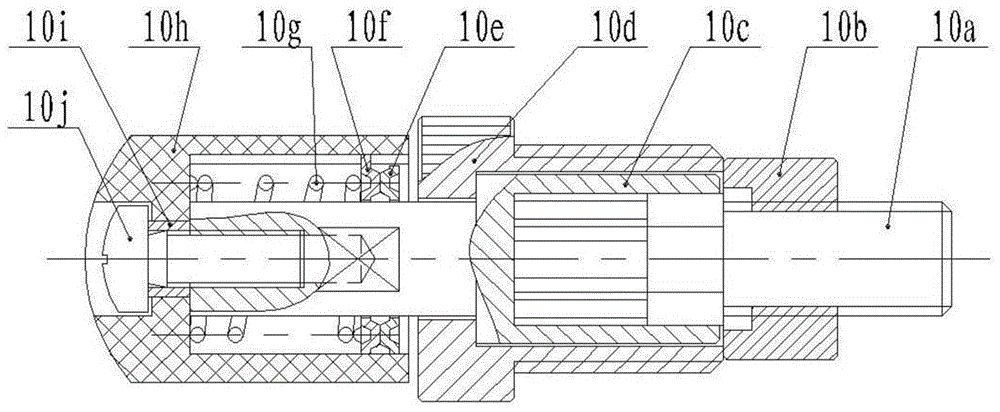

[0042] Such as figure 1Shown are two kinds of embodiments of the present invention, a kind of safety spray gun with adjustment reminding function, consists of gun nozzle 4, gun barrel 3, thimble 7, compression spring 8, gun body 2, opening adjustment device 10, trigger 6, Adapter 1 and handle 9 etc. are formed. The front of the gun body 2 is connected to the gun barrel 3, the front of the gun barrel 3 is connected to the gun nozzle 4, the rear and lower part of the gun body 2 is connected to the handle 9, the middle part of the gun body 2 is provided with a trigger 6, and a sealing device 5 is arranged between the gun body 2 and the trigger 6 , the front section of the thimble 7 is placed in the gun barrel 3, the trigger 6 is linked with the slider of the thimble 7; there is a hole at the front and upper part of the gun body 2, and the chemical agent with pressure enters the gun body 2 through the adapter 1 installed on the hole, The rear end of the gun body 2 is an opening a...

Embodiment 2

[0057] The difference between this embodiment and Embodiment 1 is that: the fixed part 10e and the rotating part 10f respectively include a circular base and protrusions evenly distributed on the ring, and dimples are formed between adjacent protrusions; the rotating part base and the adjustment The cap 10h is keyed, and the protrusion of the rotating part 10f is located in the recess of the fixed part, such as image 3 shown. The rest of the uniform structure is the same as Example 1.

[0058] When the adjustment rod 10c reaches the limit position, the adjustment rod 10c cannot rotate. If the external force continues to be applied at this time, the adjustment cap 10h will rotate relative to the adjustment rod 10c, and the protrusion of the rotation part 10f will break away from the current recess of the fixed part 10e. When the rotation part 10f When the protrusion enters the next recess of the fixing part 10e, the sounding component makes a sound, reminding the user that th...

Embodiment 3

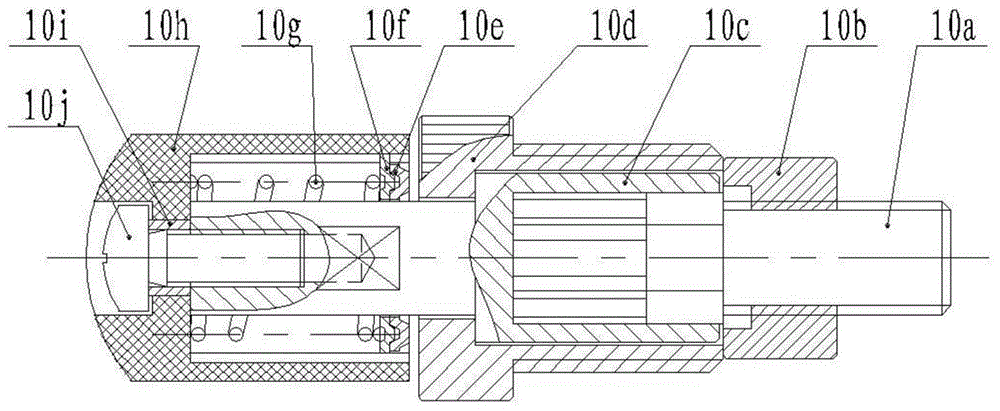

[0060] The difference between this embodiment and Embodiment 1 is that the fixed part 10e and the rotating part 10f respectively include a circular base body and pits evenly distributed on the ring, the rotating part base is connected with the adjustment cap, and the fixed part The pits and the pits of the rotating part are aligned to form a marble accommodation chamber, and each marble accommodation chamber is provided with a marble 10k, such as Figure 4 shown. All the other structures are the same as in Example 1.

[0061] When the adjustment rod 10c reaches the limit position, the adjustment rod 10c cannot rotate. If the external force continues to be applied at this time, the adjustment cap 10h will rotate relative to the adjustment rod 10c, and the pit of the rotation part 10f will leave the marble 10k until the next position of the rotation part 10f. The pit cooperates with the marble 10k, and the sounding component sounds when the marble 10k enters the pit, reminding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com