Fixing and adjusting device for engine pipeline

An engine and pipeline technology, applied in the field of engine pipeline fixed and adjustable devices, can solve problems such as damage and increase the probability of pipeline damage, and achieve the effects of improving assembly efficiency, reducing the probability of pipeline scrapping, and facilitating maintenance and loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

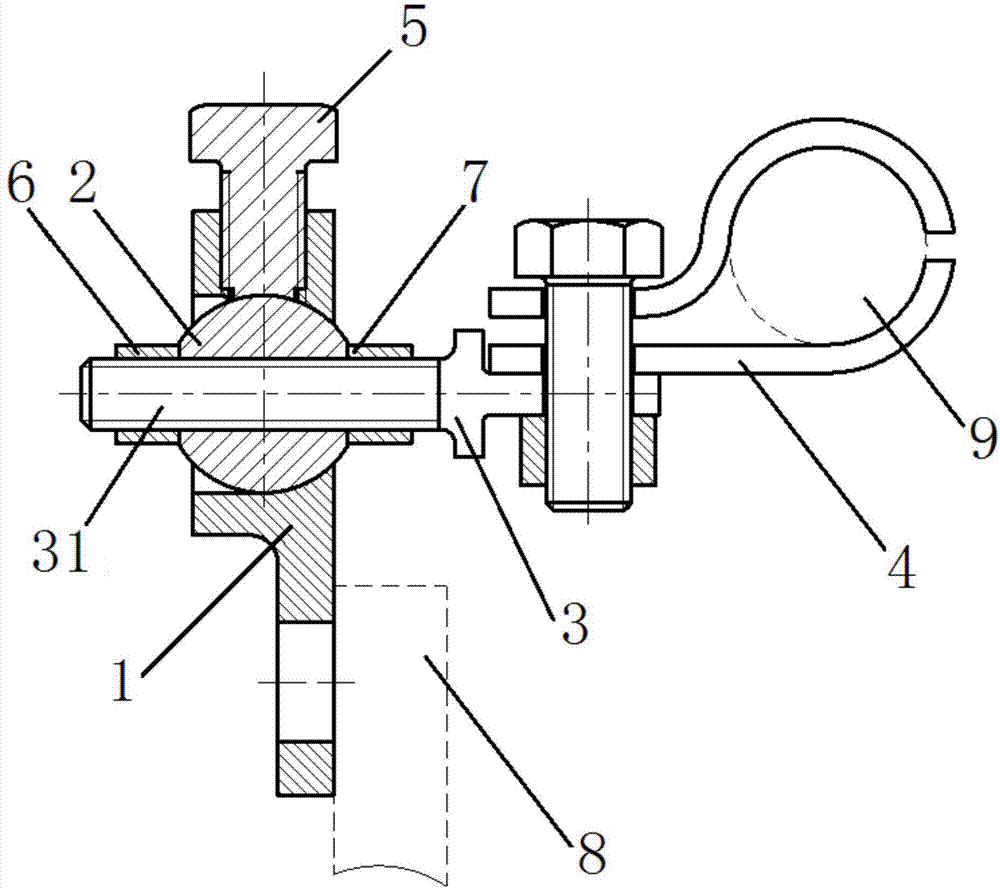

[0027] Such as figure 1 As shown, the present invention provides an engine pipeline fixing and adjustable device, including a bracket 1, a ball 2, a pole 3, a clip 4 and an adjustment and fixing assembly. In this embodiment, the adjustment and fixing assembly is a jacking screw 5 ;

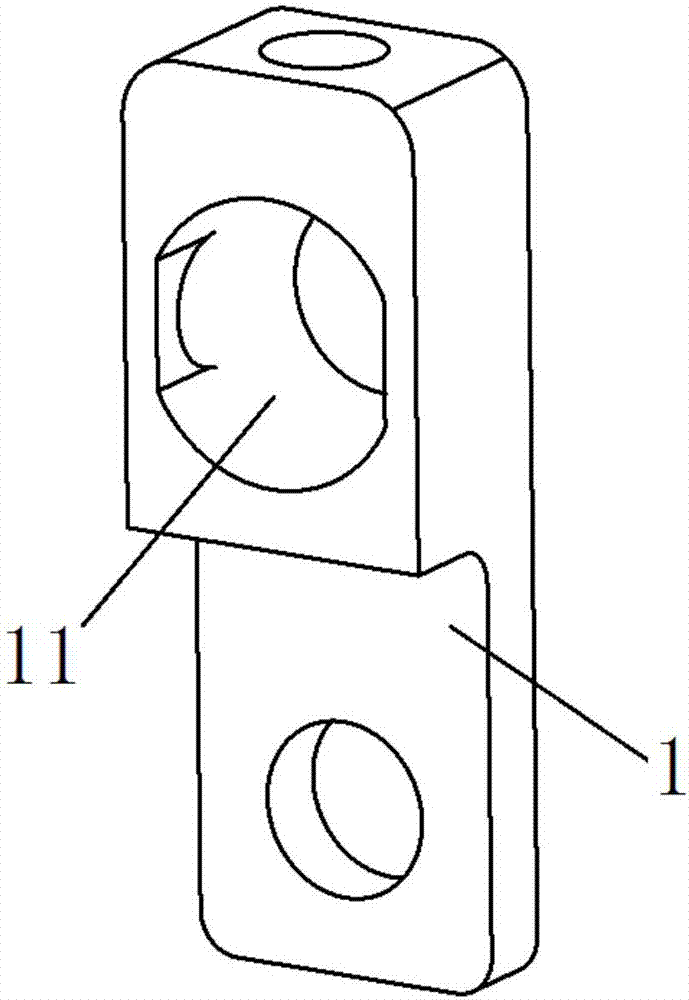

[0028] The three-dimensional schematic diagram of support 1 in this embodiment is as follows figure 2 As shown, the bracket 1 is provided with a spherical hole 11 that runs through the bracket 1, and a threaded hole for installing the jacking screw 5 is provided on the bracket 1. The threaded hole of the bracket 1 communicates with the spherical hole 11 and is located in the spherical hole. 11 directly above, the bracket 1 and the casing 8 are fixed, preferably, the casing 8 and the bracket 1 are fixed by bolts;

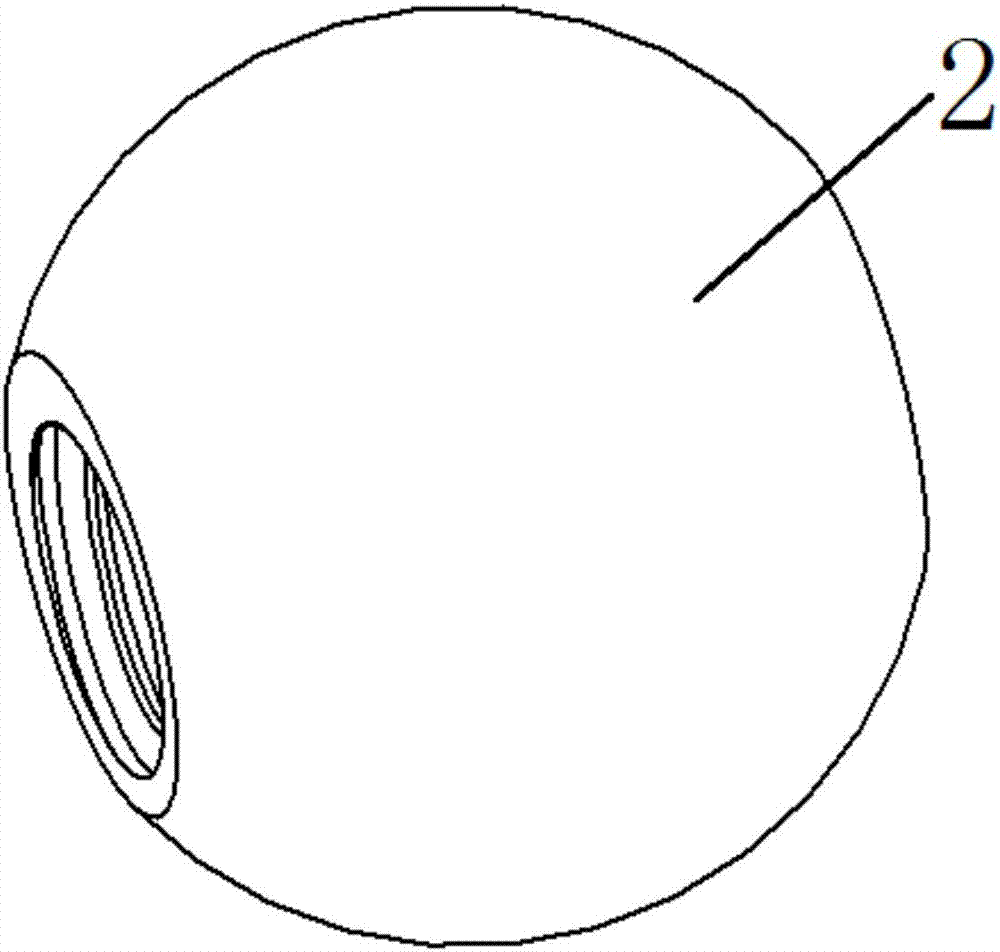

[0029] The three-dimensional schematic diagram of sphere 2 is shown in image 3 As shown, the sphere 2 is spherical and installed in the spherical hole 11, the spherical surface of t...

Embodiment 2

[0033] The three-dimensional schematic diagram of support 1 in this embodiment is as follows Figure 5 As shown, the bracket 1 is provided with two threaded holes for installing jacking screws 5, the threaded holes of the two brackets 1 are connected with the spherical hole 11, and the axes of the two jacking screws 5 pass through the sphere 2, the screw ends of the two jacking screws 5 are made of elastic rubber material, and the end faces of the screw ends are all concave spherical surfaces, and the concave spherical surface is in contact with the spherical surface of the sphere 2, that is, the sphericity of the concave spherical surface and the spherical surface of the sphere 2 The spherical degree of the contact part with the concave spherical surface is the same, and the sphere 2 is pressed from two directions by tightening the two jacking screws 5, so that the sphere 2 is fixed in the bracket 1 to prevent it from breaking away from the bracket 1, and simultaneously preven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com