Integrated machine for treating two-sheet lead-acid battery polar plate

A lead-acid battery and electrode plate treatment technology, applied in the direction of lead-acid battery electrodes, etc., can solve the problems of frequent lead dust, easy deposition of lead dust, complex structure, etc., reduce lead dust and waste pollution, improve equipment stability, and simplify machinery structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

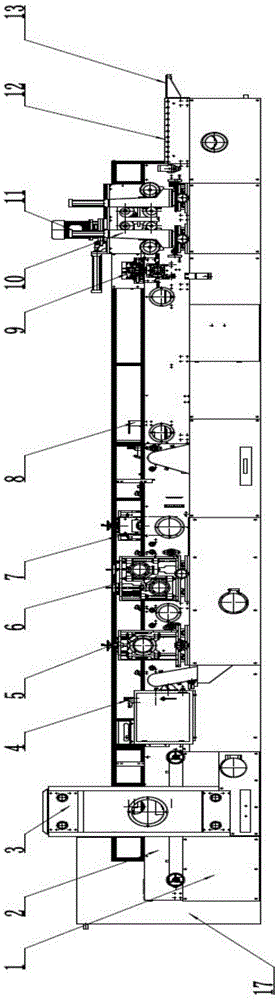

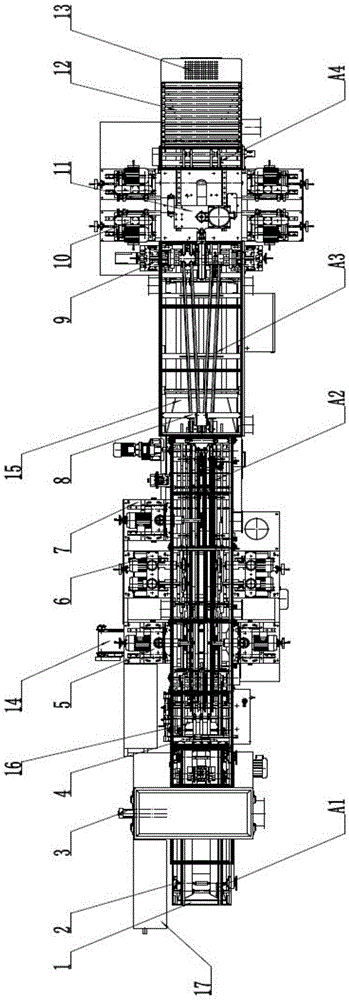

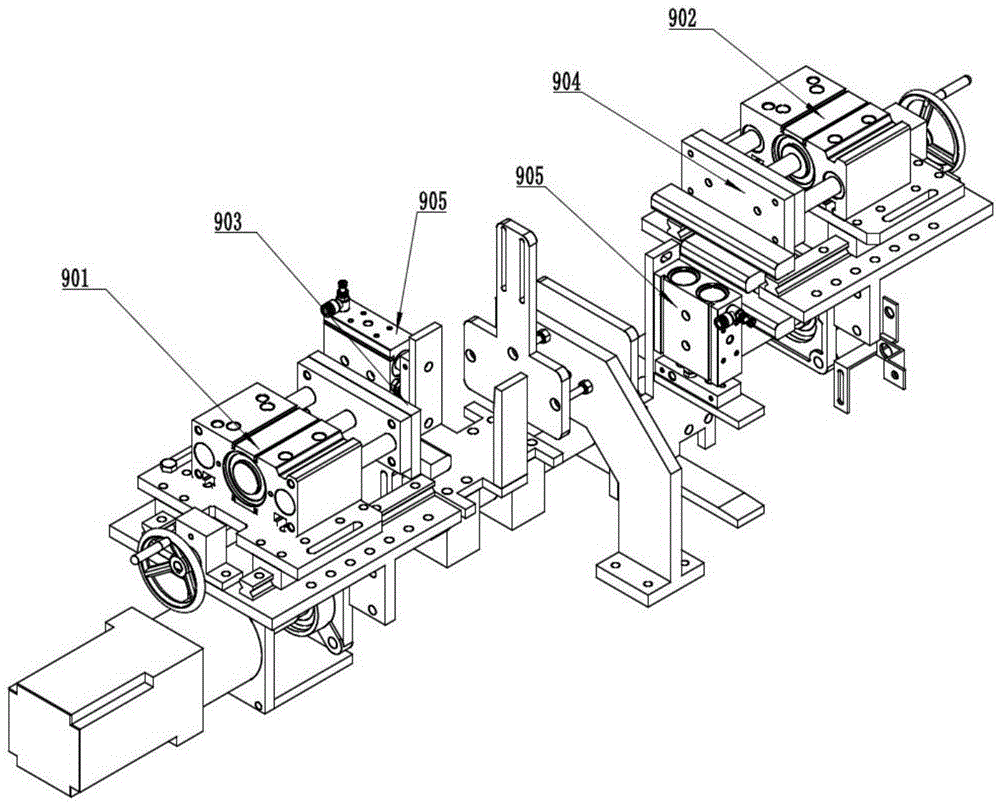

[0029] Such as figure 1 ,Such as figure 2 As shown, the present invention includes a frame 1, a sheet feeding mechanism 2, a brush upper and lower mechanism 3, a suction sheet loading mechanism 4, an ear cutting mechanism 5, an ear brush mechanism 6, a plate separating mechanism 7, a lamination mechanism 8, and a finishing mechanism 9 , the brush pole ear side mechanism 10, the brush pole ear opposite side mechanism 11 and the plate conveying device are connected in sequence, and are fixedly installed on the frame 1 respectively, and the electric control system 17 is respectively connected to the sheet feeding mechanism 2 and the brush upper and lower side mechanism 3 , suction sheet loading mechanism 4, ear cutting mechanism 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com